Here is my Fisher.

Posted by janpenguin

|

Re: Here is my Fisher. March 06, 2016 05:55PM |

Registered: 9 years ago Posts: 189 |

Metal Fisher.

I spent good hours to cleaning up and reaming all the holes of metal parts. Aluminum seemed not to have clean edge by laser cut and there were outstanding dimension inaccuracy around 0.1 mm to 0.2 mm. I spent several hours on the effector plates alone.

Things to do:

- Relocate the extruder to outside of panel

- Replace diagonal arms with rod end bearings and carbon or aluminum rods.

- Soldering the end stop switches?

Edited 1 time(s). Last edit at 03/06/2016 06:08PM by janpenguin.

I spent good hours to cleaning up and reaming all the holes of metal parts. Aluminum seemed not to have clean edge by laser cut and there were outstanding dimension inaccuracy around 0.1 mm to 0.2 mm. I spent several hours on the effector plates alone.

Things to do:

- Relocate the extruder to outside of panel

- Replace diagonal arms with rod end bearings and carbon or aluminum rods.

- Soldering the end stop switches?

Edited 1 time(s). Last edit at 03/06/2016 06:08PM by janpenguin.

|

Re: Here is my Fisher. March 07, 2016 07:37PM |

Registered: 9 years ago Posts: 189 |

|

Re: Here is my Fisher. March 10, 2016 10:10AM |

Registered: 8 years ago Posts: 26 |

Quote

janpenguin

Things to do:

- Relocate the extruder to outside of panel

- Replace diagonal arms with rod end bearings and carbon or aluminum rods.

- Soldering the end stop switches?

We seem to be doing similar things. Here are my panels with extruder access hole and modified end stop mounts for screws: [forums.reprap.org]

And here's an (untested) idea for traxxas rod end rods: [forums.reprap.org]

|

Re: Here is my Fisher. September 26, 2016 12:52PM |

Registered: 9 years ago Posts: 189 |

RepRapFirmware v1.11-ch, DWC v1.11

Please double, triple check M665 command before you upload it.

DWC doesn't report missing variable error of M665 and set the Cartesian mode not Delta implictly when it reboots.

When you run G28 (homing), the hell breaks loose!

M665 L160.00 R81.08 B75.00 H177.58

config.g

bed.g

Modifications:

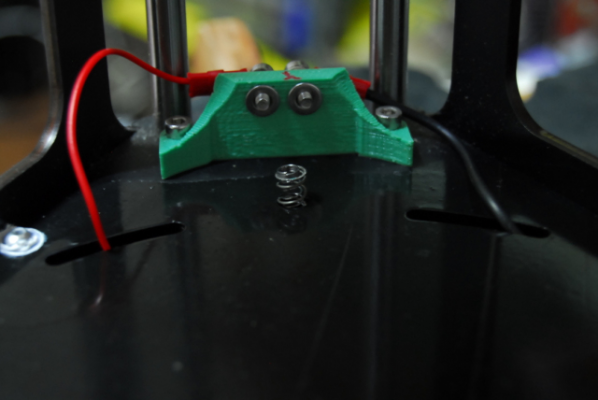

- double spring

I cut a ball point pen's spring half, inserted in the stock string. Spring reinforcement almost removed slack of print bed and

print bed works like a on/off switch.

- non-conductive print bed

- vibration damper

1 mm thickness of rubber reduces noise and vibration of the stepper motors.

I adjusted position of three pulleys 1 mm off.

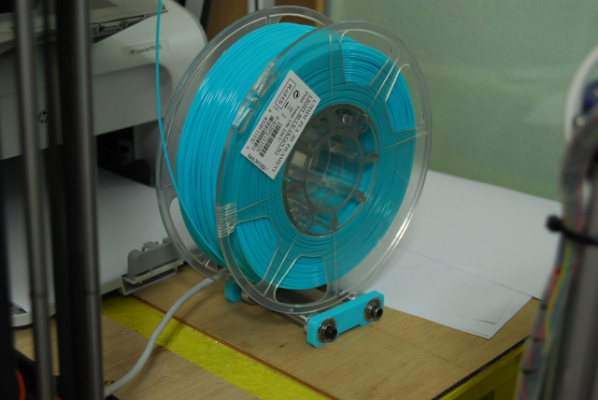

- temporary extruder drive

under powered, shallow throat breaks PLA filament as the filament gets steeper towards end of spool.

Continuous printing when the filament is broken is tricky. I'll replace it with Fisher 1's geared extruder.

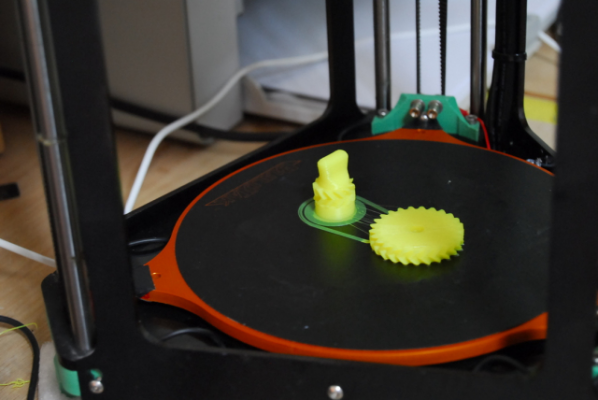

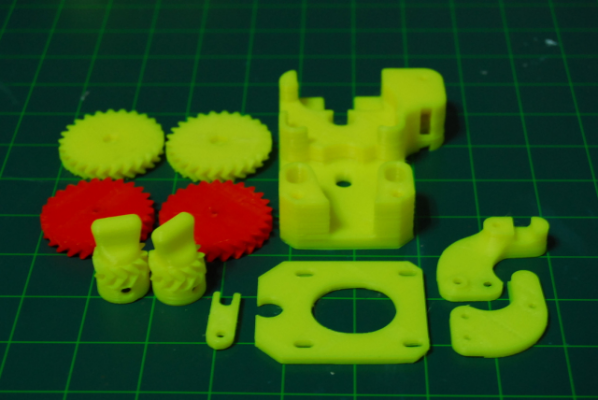

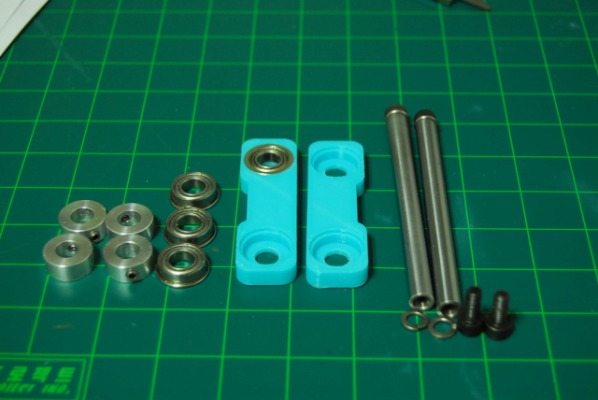

Parts for Fisher 1's geared extruder drive

It uses two MR93ZZ bearing (9 mm diameter) which I don't have in stock. Hopefully I'll get it today.

It has layer shift problem I really like to get rid of it.

To do:

- fine tuning

- two sets of polycarbonate diagonal arms.

- stock core parts for spare: thermistor, hotend set.

- Print models as much as I can so that I'll find which parts need to be replaced in regular base.

If it runs 300 hours without any mechanical failure, I definitely build two more big Fishers and use them as production machines. ^^

Edited 1 time(s). Last edit at 09/26/2016 12:59PM by janpenguin.

Please double, triple check M665 command before you upload it.

DWC doesn't report missing variable error of M665 and set the Cartesian mode not Delta implictly when it reboots.

When you run G28 (homing), the hell breaks loose!

M665 L160.00 R81.08 B75.00 H177.58

config.g

; Configuration file for emaker Fisher - delta 3D printer ; 2016/09/26 01:08 ; Communication and general M111 S0 ; Debug off M550 Preprapfisher ; Machine name (can be anything you like) M551 Preprap ; Machine password (used for FTP) M540 P0xBE:0xEF:0xDE:0xAD:0xFE:0x01 ; MAC Address (must be unique on your network) M552 P0.0.0.0 ; use DHCP ;M554 P192.168.1.1 ; Gateway M553 P255.255.255.0 ; Netmask M555 P2 ; Set output to look like Marlin G21 ; Work in millimetres G90 ; Send absolute coordinates... M83 ; ...but relative extruder moves ; Axis and motor configuration ; Homing crashed into the bed! M569 P0 S0 ; Drive 0 goes forwards M569 P1 S0 ; Drive 1 goes forwards M569 P2 S0 ; Drive 2 goes forwards M569 P3 S1 ; Drive 3 goes forwards M569 P4 S1 ; Drive 4 goes forwards M574 X2 Y2 Z2 S1 ; set endstop configuration (all endstops at high end, active high) ; 2016/09/25 M665 L160.00 R81.08 B75.00 H177.58 M666 X0.41 Y-2.38 Z1.97 ; G32 calibration deviation 0.014 2016/09/22 18:16 ; set delta radius, diagonal rod length, printable radius and homed height ; // M665 R80.13 L160.0 B75.00 H177.11 ; // M666 X0.14 Y-1.28 Z1.14 M92 X87.489 Y87.489 Z87.489 ; Set axis steps/mm M906 X800 Y800 Z800 E1000 ; Set motor currents (mA) M201 X4000 Y4000 Z4000 E4000 ; Accelerations (mm/s^2) M203 X15000 Y15000 Z15000 E9000 ; Maximum speeds (mm/min) M210 Z50 ; Homing feedrate M566 X1200 Y1200 Z1200 E1200 ; Maximum instant speed changes mm/minute ; Thermistors ;M305 P0 R4700 T100000 ; Uncomment for heatbed M305 P1 R4700 ; Tool definitions M140 H-1 ; Disable heatbed M563 P0 D0 H1 ; Define tool 0 G10 P0 S210 R-273 ; Set tool 0 operating and standby temperatures M301 H1 P12 I0.4 D80 W180 B300 ; Set tool 0 PID parameters ; //M92 E310 ; Set extruder steps per mm ; direct drive M92 E135.938 ;// Z probe and compensation definition M558 P4 X0 Y0 Z0 H4 ; Set Z probe type and dive height ; G31 X0 Y0 Z-0.3 P200 ; Set the zprobe height and threshold (put your own values here) G31 X0 Y0 Z-0.1 P1000 ; Set the zprobe height and threshold (put your own values here) ;*** If you are using axis compensation, put the figures in the following command ; // M556 S78 X0 Y0 Z0 ; Axis compensation here

bed.g

; emake Fisher ; 2016/09/25 01:20 ; Auto calibration routine for delta printers ; Before running this, you should have set up your zprobe X, Y and Z offsets to suit your build. ; This does a single iteration of auto calibration. Run this file multiple times until the values con verge. ; Then transfer the values to your config.g file. M561 ; clear any bed transform, otherwise homing may be at the wrong height ;G31 X0 Y0 ; don't want any probe offset for this ;G28 ; home the printer ;*** Remove the following line if your Z probe does not need to be deployed ;M98 Pdeployprobe.g ; deploy the mechanical Z probe M201 X500 Y500 Z500 ; The first time the probe is used after deployment, it gives slightly different results. ; So do an extra dummy probe here. The value stored gets overwritten later. ; G30 P0 X0 Y0 Z-99999 ; Probe the bed and do auto calibration ; R (bed radius) = 75.00 (default value was 79.00) ; x = R * cos(theta) ; y = R * sin(theta) ; Alpha (X) tower = 210 (theta) ; Beta (Y) tower = 330 ; Gamma (Z) tower = 90 ; // G1 X-67.95 Y-40.5 F12000 ; Move to X tower's position 4mm off the bed ; G1 X0.00 Y75.00 Z4 F2000 G1 X0.00 Y75.00 F2000 ; 9/22 20:36 ; bed.g file for RepRapFirmware, generated by Escher3D calculator ; 7 points, 6 factors, probing radius: 75, probe offset (0, 0) G30 P0 X0.00 Y75.00 Z-99999 ; Z tower G30 P1 X64.95 Y-37.50 Z-99999 ; Y tower G30 P2 X-64.95 Y-37.50 Z-99999 ; X tower ; G30 P3 X0.00 Y37.50 Z-99999 ; half way of Z tower ; G30 P4 X32.48 Y-18.75 Z-99999 ; half way of Y tower ; G30 P5 X-32.48 Y-18.75 Z-99999 ; half way of X tower G30 P3 X0 Y0 Z-99999 H-0.2 S0 ; center, and auto calibration G1 X0 Y0 F2000 ;*** Remove the following line if your Z probe does not need to be retracted ;M98 Pretractprobe.g ; deploy the mechanical Z probe M201 X4000 Y4000 Z4000 ;G91 ;G1 S1 X170 Y170 Z170 F15000 ; go part way up to speed up homing, endstops activated just in case ;G90 ;G28 ; Home the printer again so as to activate the new endstop adjustments

Modifications:

- double spring

I cut a ball point pen's spring half, inserted in the stock string. Spring reinforcement almost removed slack of print bed and

print bed works like a on/off switch.

- non-conductive print bed

- vibration damper

1 mm thickness of rubber reduces noise and vibration of the stepper motors.

I adjusted position of three pulleys 1 mm off.

- temporary extruder drive

under powered, shallow throat breaks PLA filament as the filament gets steeper towards end of spool.

Continuous printing when the filament is broken is tricky. I'll replace it with Fisher 1's geared extruder.

Parts for Fisher 1's geared extruder drive

It uses two MR93ZZ bearing (9 mm diameter) which I don't have in stock. Hopefully I'll get it today.

It has layer shift problem I really like to get rid of it.

To do:

- fine tuning

- two sets of polycarbonate diagonal arms.

- stock core parts for spare: thermistor, hotend set.

- Print models as much as I can so that I'll find which parts need to be replaced in regular base.

If it runs 300 hours without any mechanical failure, I definitely build two more big Fishers and use them as production machines. ^^

Edited 1 time(s). Last edit at 09/26/2016 12:59PM by janpenguin.

|

Re: Here is my Fisher. September 28, 2016 12:54AM |

Registered: 9 years ago Posts: 189 |

|

Re: Here is my Fisher. September 29, 2016 11:05AM |

Registered: 7 years ago Posts: 10 |

Check that the lower pulley is set vertically below the idler, about 1.5 - 2 mm away from the stepper motor.

I would suspect that that the life of the acrylic rods could be somewhat lengthened by not tightening the screws fully home, just sufficiently so to retain a decent grip on the ball bearings along with a drop of oil.

Rgds,

Neil.

I would suspect that that the life of the acrylic rods could be somewhat lengthened by not tightening the screws fully home, just sufficiently so to retain a decent grip on the ball bearings along with a drop of oil.

Rgds,

Neil.

|

Re: Here is my Fisher. September 29, 2016 10:12PM |

Registered: 9 years ago Posts: 189 |

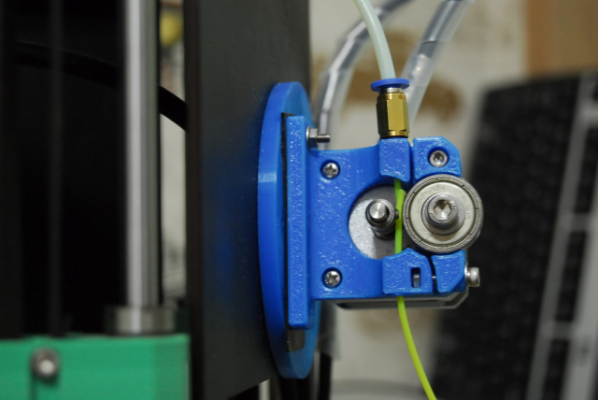

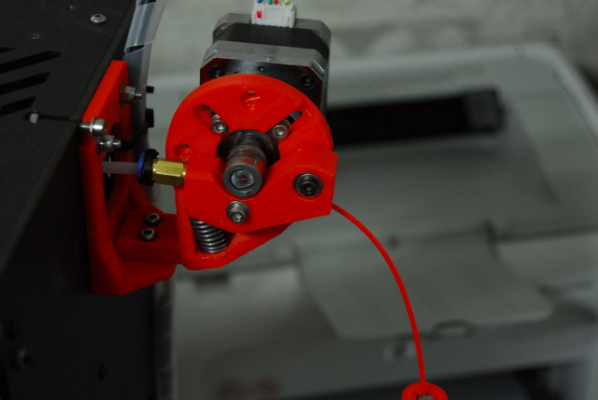

Installed B'struder

Kysan Nema 17 5.18:1 geared stepper motor

I had to change wire orders of the extruder for Kysan stepper motor.

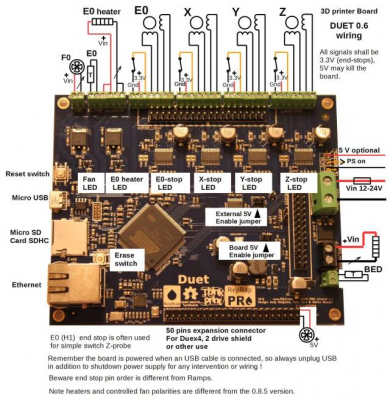

Wiring diagram I referenced.

Fisher mount I designed

[www.thingiverse.com]

B'struder extruder

[www.thingiverse.com]

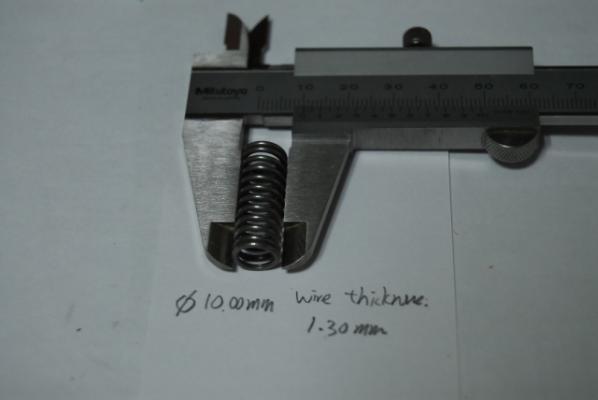

Tension spring that works good.

Specification:

Length: 30.00 mm

Outer diameter: 10.00 mm

Wire thickness: 1.30 mm

@Neil

Thans for the tip.

Edited 1 time(s). Last edit at 09/29/2016 10:36PM by janpenguin.

Kysan Nema 17 5.18:1 geared stepper motor

I had to change wire orders of the extruder for Kysan stepper motor.

Wiring diagram I referenced.

Fisher mount I designed

[www.thingiverse.com]

B'struder extruder

[www.thingiverse.com]

Tension spring that works good.

Specification:

Length: 30.00 mm

Outer diameter: 10.00 mm

Wire thickness: 1.30 mm

@Neil

Thans for the tip.

Edited 1 time(s). Last edit at 09/29/2016 10:36PM by janpenguin.

|

Re: Here is my Fisher. October 08, 2016 12:25AM |

Registered: 9 years ago Posts: 189 |

|

Re: Here is my Fisher. October 10, 2016 03:58AM |

Registered: 8 years ago Posts: 301 |

I'm tempted to build one of these B'Struders, but I cannot find the springs anywhere. Did you find a source for those springs?

DC42 Kossel 330mm x 2meters

My Thingiverse Creations

DC42 Kossel 330mm x 2meters

My Thingiverse Creations

|

Re: Here is my Fisher. October 10, 2016 05:19PM |

Registered: 9 years ago Posts: 189 |

|

Re: Here is my Fisher. October 19, 2016 09:05AM |

Registered: 9 years ago Posts: 189 |

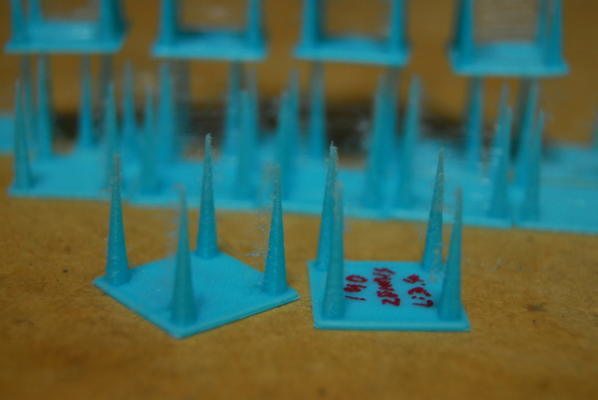

Extruder drive: B’struder

Kysan Nema 17 5.18:1 geared stepper motor, 2.4 V, 1.0 A

config.g

Retraction setting in Slic3r 1.2.9:

Length: 3.4 mm

Z Lift: 0.4 mm

Speed: 15 mm/s (10 mm/s and 20 mm/s give similar result.)

Retraction after layer change: on

Wipe on retraction: on

Calibration model: [www.thingiverse.com]

PLA filament temperature: 190 C

Layer height: 0.2 mm

All speeds of print moves: 30 mm/s (set the speed factor of DWC at 70%, which makes 21 mm/s.)

Travel speed: 250 mm/s

Kysan Nema 17 5.18:1 geared stepper motor, 2.4 V, 1.0 A

config.g

M201 X4000 Y4000 Z4000 E3000 ; Accelerations (mm/s^2) M203 X15000 Y15000 Z15000 E15000 ; Maximum speeds (mm/min) M906 X800 Y800 Z800 E800 ; Set motor currents (mA) M92 411.230

Retraction setting in Slic3r 1.2.9:

Length: 3.4 mm

Z Lift: 0.4 mm

Speed: 15 mm/s (10 mm/s and 20 mm/s give similar result.)

Retraction after layer change: on

Wipe on retraction: on

Calibration model: [www.thingiverse.com]

PLA filament temperature: 190 C

Layer height: 0.2 mm

All speeds of print moves: 30 mm/s (set the speed factor of DWC at 70%, which makes 21 mm/s.)

Travel speed: 250 mm/s

Sorry, only registered users may post in this forum.