Geared extruder designed for the Fisher

Posted by PRZ

|

Geared extruder designed for the Fisher August 12, 2015 11:19AM |

Registered: 8 years ago Posts: 475 |

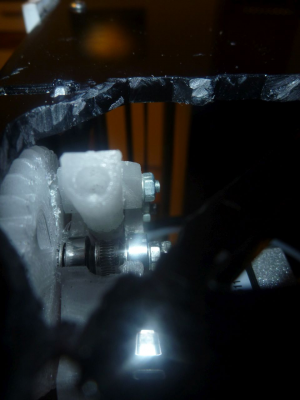

Hello, I have designed a geared extruder for the Fisher, to be installed like the existing one:

It does present the following advantages:

Easy access to the tensioner adjustment

Easy access to the hobbed insert for cleaning

More powerful extruder allowing thicker layers

Capable to unwind poorly wound spool (for me thats 2 spools on three tested !)

With spool on top, the path is the most direct possible

Bowden length reduced to 390mm, with more straight route.

Reduced current (from 1200 to 1000) will make less heat for stepper and board drivers

and in addition:

With a hole in the side panel, you can dye filament for extrusion calibration

as inconvenients :

Retract speed is reduced - I use 80mm/sec

You hear retraction due to play in gears (printing larger pinion ?)

potential wear on gears, but as it is printed in PETG, the risk is low

Bowden tongue more difficult to access, however you can see it from top

Assembly instructions, files and other details are here:

[rouzeau.net]

It does present the following advantages:

Easy access to the tensioner adjustment

Easy access to the hobbed insert for cleaning

More powerful extruder allowing thicker layers

Capable to unwind poorly wound spool (for me thats 2 spools on three tested !)

With spool on top, the path is the most direct possible

Bowden length reduced to 390mm, with more straight route.

Reduced current (from 1200 to 1000) will make less heat for stepper and board drivers

and in addition:

With a hole in the side panel, you can dye filament for extrusion calibration

as inconvenients :

Retract speed is reduced - I use 80mm/sec

You hear retraction due to play in gears (printing larger pinion ?)

potential wear on gears, but as it is printed in PETG, the risk is low

Bowden tongue more difficult to access, however you can see it from top

Assembly instructions, files and other details are here:

[rouzeau.net]

|

Re: Geared extruder designed for the Fisher August 12, 2015 12:04PM |

Registered: 8 years ago Posts: 475 |

Thats now on Github :

[github.com]

It shall be noted that as the first parts were not really well done due to unnoticed warping (more on that later, in principle PETG does not warp), the large gear and the base were re-printed with this extruder (the dyed parts).

So this extruder have printed its main parts with initial version of itself, RepRap style.

Also, for the spool on top, have a look on this topic : [forums.reprap.org]

Edited 1 time(s). Last edit at 08/12/2015 12:11PM by PRZ.

[github.com]

It shall be noted that as the first parts were not really well done due to unnoticed warping (more on that later, in principle PETG does not warp), the large gear and the base were re-printed with this extruder (the dyed parts).

So this extruder have printed its main parts with initial version of itself, RepRap style.

Also, for the spool on top, have a look on this topic : [forums.reprap.org]

Edited 1 time(s). Last edit at 08/12/2015 12:11PM by PRZ.

|

Re: Geared extruder designed for the Fisher August 12, 2015 03:02PM |

Registered: 8 years ago Posts: 38 |

|

Re: Geared extruder designed for the Fisher August 12, 2015 03:20PM |

Registered: 8 years ago Posts: 475 |

Hello,

I have no reason to rebuild my effector now, so I have not designed a new one. You will still need the wood plate for thermal insulation however.

I had a thorough look on the effector, however, but for other reasons. The Fisher fan is very noisy and I was in search of another cooling solution. At the end, I concluded that the only solution was to use the same form factor fan, but with the model 'M' with a lower speed, which is much more silent.

The problem is that will modify the hotend cooling. A printed effector can improve seriously the airflow and reduce the overall ensemble pressure drop.

What I don't know is if this reduction will be sufficient to maintain the same flowrate for the hotend with a lower power fan.

You need to make temperature measurements.

My fear is it may be not possible to reduce the fan power without slightly increasing the hotend fins.

Such modification go too far for what I can and what I want to do.

I think the noise problem shall be adressed by RRP as it implies too many modifications.

I have no reason to rebuild my effector now, so I have not designed a new one. You will still need the wood plate for thermal insulation however.

I had a thorough look on the effector, however, but for other reasons. The Fisher fan is very noisy and I was in search of another cooling solution. At the end, I concluded that the only solution was to use the same form factor fan, but with the model 'M' with a lower speed, which is much more silent.

The problem is that will modify the hotend cooling. A printed effector can improve seriously the airflow and reduce the overall ensemble pressure drop.

What I don't know is if this reduction will be sufficient to maintain the same flowrate for the hotend with a lower power fan.

You need to make temperature measurements.

My fear is it may be not possible to reduce the fan power without slightly increasing the hotend fins.

Such modification go too far for what I can and what I want to do.

I think the noise problem shall be adressed by RRP as it implies too many modifications.

|

Re: Geared extruder designed for the Fisher September 09, 2015 05:35AM |

Registered: 8 years ago Posts: 475 |

There was play in the gears, which created a boring clik-clak noise while retracting, so I designed two larger size pinions. I ended up using the larger one.

No more unpleasant clik-clack, while the retraction is still audible (you hear it more than for a direct extruder, because there is three time more rotations and motor acceleration is higher).

There is now three pinions size - 0, 1 and 2 -. 0 is the theoretical size, which was in the initial files, but it shall probably be too small.

It shall be noted that while printing isolated small parts as this pinion, the printing time is dictated by the cooling time between layers (25 sec for PETG), hence printing two pinions size don't take much more time than printing one, so don't hesitate to print size 1 and 2 in one go. This shall be precision stuff, so layer thickness is 0.2mm and speed lower than 50 mm/s.

Here are the revised STL files

Extruder_stl.zip

OpenScad program was updated on GitHub

[github.com]

And the instructions

Instructions.pdf

Edited 2 time(s). Last edit at 09/09/2015 06:28AM by PRZ.

No more unpleasant clik-clack, while the retraction is still audible (you hear it more than for a direct extruder, because there is three time more rotations and motor acceleration is higher).

There is now three pinions size - 0, 1 and 2 -. 0 is the theoretical size, which was in the initial files, but it shall probably be too small.

It shall be noted that while printing isolated small parts as this pinion, the printing time is dictated by the cooling time between layers (25 sec for PETG), hence printing two pinions size don't take much more time than printing one, so don't hesitate to print size 1 and 2 in one go. This shall be precision stuff, so layer thickness is 0.2mm and speed lower than 50 mm/s.

Here are the revised STL files

Extruder_stl.zip

OpenScad program was updated on GitHub

[github.com]

And the instructions

Instructions.pdf

Edited 2 time(s). Last edit at 09/09/2015 06:28AM by PRZ.

|

Re: Geared extruder designed for the Fisher September 09, 2015 05:54AM |

Registered: 8 years ago Posts: 475 |

A note for those who fear a more powerful extruder will risk to grind the filament.

In my setup, I reduced current to 1 A (to generate less heat on the board), so the power of this extruder is approximately 2.5 time the original, which does not make it a strong extruder, just average.

I recently got two thermal divergences where the temperature goes above 300°C, hence the hotend heater shut down. Impossible extrusion simply stopped the extruder motor, without grinding the filament. As the pressure was maintained constant by the stepper torque, the step loss were not audible and I did not noticed them immediately, so that lasted for one minute or two.

In my setup, I reduced current to 1 A (to generate less heat on the board), so the power of this extruder is approximately 2.5 time the original, which does not make it a strong extruder, just average.

I recently got two thermal divergences where the temperature goes above 300°C, hence the hotend heater shut down. Impossible extrusion simply stopped the extruder motor, without grinding the filament. As the pressure was maintained constant by the stepper torque, the step loss were not audible and I did not noticed them immediately, so that lasted for one minute or two.

|

Re: Geared extruder designed for the Fisher September 09, 2015 11:41AM |

Registered: 9 years ago Posts: 58 |

|

Re: Geared extruder designed for the Fisher September 09, 2015 12:34PM |

Registered: 8 years ago Posts: 475 |

Yes, worked and reworked, mod after mod, it looks a bit bad. And you haven't seen the last version, as I have replaced the spool support with a vertical axis one, I added new holes

Also the new arms works well, but looks quite weird, a bit like replacement prothesis.

Thanks a lot for this proposal, but I think I will do other stuff with the Fisher components, however I shall finish my other printer first. I shall somewhat prioritize.

Thats an interesting idea for other Fisher owners to work on DXF. But this is a beta, so I don't know what will be the final version. RRP told that they don't intend to modify much of the mechanics, but I think they have some modifications to do. Too many problems with cable routing and rods attachments.

Edited 1 time(s). Last edit at 09/09/2015 12:57PM by PRZ.

Also the new arms works well, but looks quite weird, a bit like replacement prothesis.

Thanks a lot for this proposal, but I think I will do other stuff with the Fisher components, however I shall finish my other printer first. I shall somewhat prioritize.

Thats an interesting idea for other Fisher owners to work on DXF. But this is a beta, so I don't know what will be the final version. RRP told that they don't intend to modify much of the mechanics, but I think they have some modifications to do. Too many problems with cable routing and rods attachments.

Edited 1 time(s). Last edit at 09/09/2015 12:57PM by PRZ.

Sorry, only registered users may post in this forum.