Designing a New High Heat Carbon Fiber Effector Plate (Work in Progress)

Posted by zaccom

|

Designing a New High Heat Carbon Fiber Effector Plate (Work in Progress) August 15, 2015 03:56AM |

Registered: 8 years ago Posts: 38 |

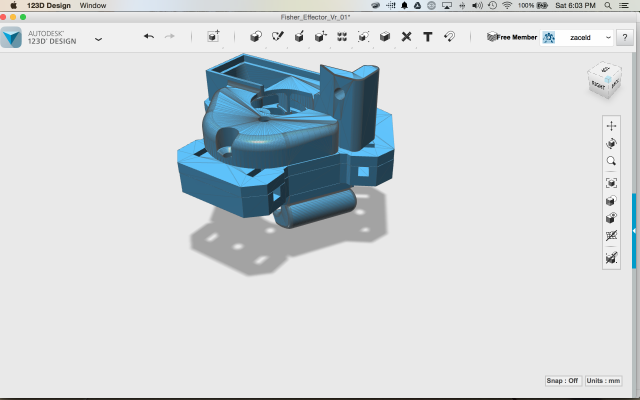

Ok so I have the dxf file for the lower effector plate that i will be working on incorporating a high heat carbon fiber so that the dc42 Mini Ir will fit close and mount to the nozzle as possible. I might have to fix the fan ducts to help hold the board but will not mess with the airflow. Also this will give other option with connector rods. Once done with my prototype and I get the board I send out the plans for you all or printout some effectors for a price but i have to test first. I might print out new rods with magnetic joints easier to take the effector plate for cleaning or maintenance. Shout out to parties interested. Also this could be used on other delta printers. Materials 3DXMax™ CFR Carbon Fiber Reinforced PLA Filament MPa 9100 rated. I cooked in a oven over 550 and barely even flex. Might later try Carbon Fiber PETG but this stuff is very strong. Use it on drones and lighter than regular filament. I forgot to add you be able to take the probes and springs off the bed so you be to just use Mini IR from dc42 and can change the bed out with a flatter and stronger materials than the warping acrylic.

Edited 2 time(s). Last edit at 08/15/2015 04:06AM by zaccom.

ZacCom Corporation Software and Engineering Design. www.zaccom.net

email: zeldridge@zaccom.net

UAV/FPV Drone Designer

Software game developer

AutoCAD and Blender Expert

3D printer hobbyist

Edited 2 time(s). Last edit at 08/15/2015 04:06AM by zaccom.

ZacCom Corporation Software and Engineering Design. www.zaccom.net

email: zeldridge@zaccom.net

UAV/FPV Drone Designer

Software game developer

AutoCAD and Blender Expert

3D printer hobbyist

|

Re: Designing a New High Heat Carbon Fiber Effector Plate (Work in Progress) August 15, 2015 08:04AM |

Registered: 8 years ago Posts: 83 |

|

Re: Designing a New High Heat Carbon Fiber Effector Plate (Work in Progress) August 15, 2015 11:16AM |

Registered: 8 years ago Posts: 38 |

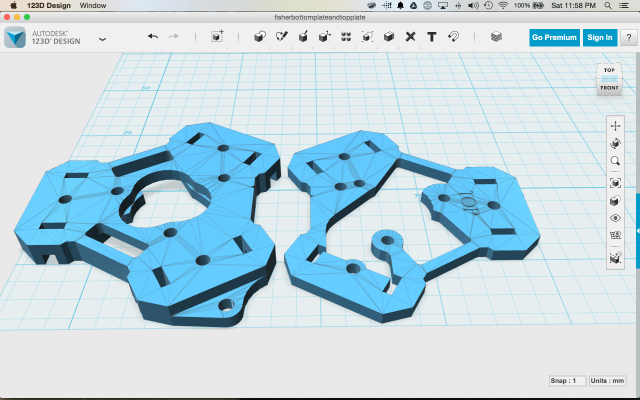

Ok here is a basic test fit on AutoCAD for basic effector. The two Bottom plates are one piece and top piece is the lid. Everything else fits and aligns up. I working on the Mini IR at this moment. But here is basic effector.

Edited 1 time(s). Last edit at 08/15/2015 11:28AM by zaccom.

ZacCom Corporation Software and Engineering Design. www.zaccom.net

email: zeldridge@zaccom.net

UAV/FPV Drone Designer

Software game developer

AutoCAD and Blender Expert

3D printer hobbyist

Edited 1 time(s). Last edit at 08/15/2015 11:28AM by zaccom.

ZacCom Corporation Software and Engineering Design. www.zaccom.net

email: zeldridge@zaccom.net

UAV/FPV Drone Designer

Software game developer

AutoCAD and Blender Expert

3D printer hobbyist

|

Re: Designing a New High Heat Carbon Fiber Effector Plate (Work in Progress) August 15, 2015 04:41PM |

Registered: 8 years ago Posts: 38 |

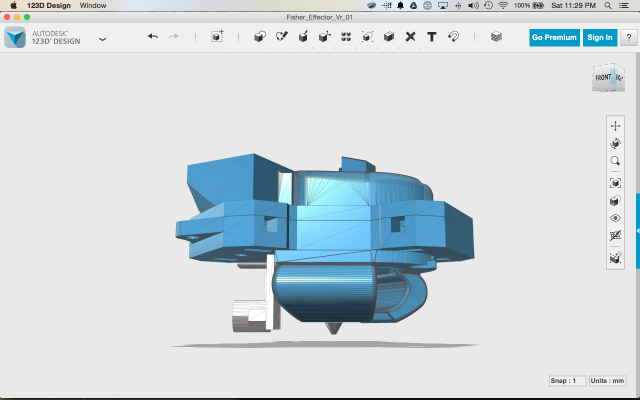

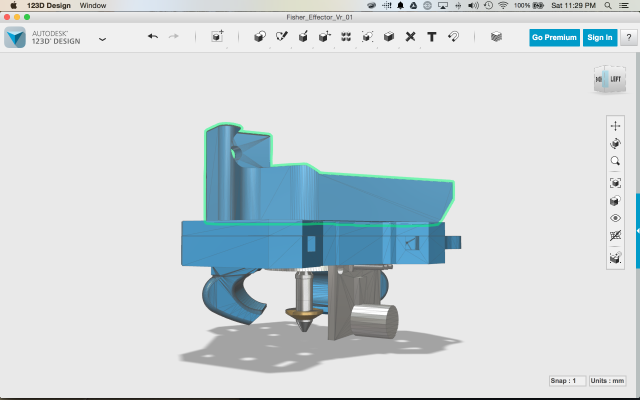

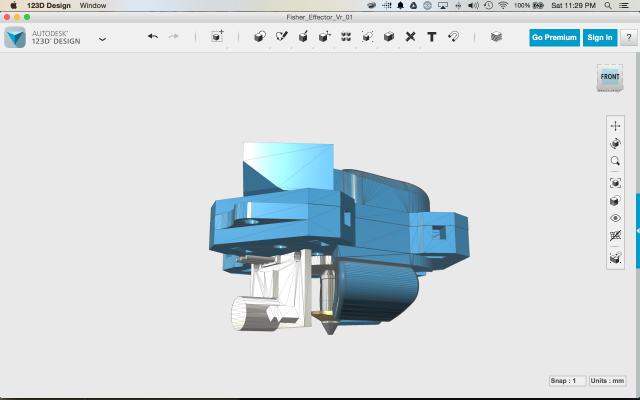

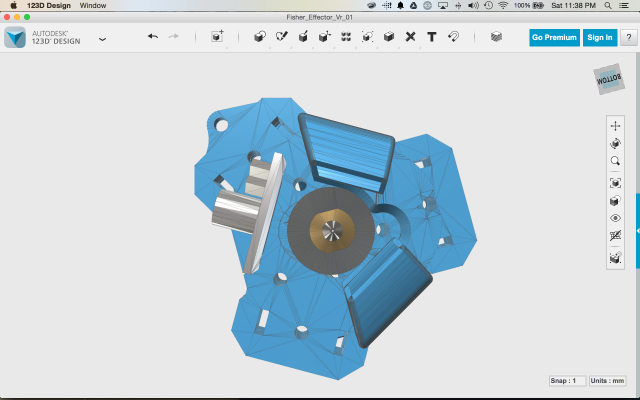

Ok I have a mockup possible spot for the mini IR, but not done. However, I make the effector button plate that has both bottom plate fused and top plate is by itself. dc42 will this work with your board? I will finish it with screws and stuff once I know this going to work.

Replacement effector or spareparts. Do not make in pla unless it high heat rated like carbon fiber will take heat. Any takers?

Edited 1 time(s). Last edit at 08/15/2015 05:03PM by zaccom.

ZacCom Corporation Software and Engineering Design. www.zaccom.net

email: zeldridge@zaccom.net

UAV/FPV Drone Designer

Software game developer

AutoCAD and Blender Expert

3D printer hobbyist

Replacement effector or spareparts. Do not make in pla unless it high heat rated like carbon fiber will take heat. Any takers?

Edited 1 time(s). Last edit at 08/15/2015 05:03PM by zaccom.

ZacCom Corporation Software and Engineering Design. www.zaccom.net

email: zeldridge@zaccom.net

UAV/FPV Drone Designer

Software game developer

AutoCAD and Blender Expert

3D printer hobbyist

|

Re: Designing a New High Heat Carbon Fiber Effector Plate (Work in Progress) August 15, 2015 05:22PM |

Registered: 8 years ago Posts: 38 |

|

Re: Designing a New High Heat Carbon Fiber Effector Plate (Work in Progress) August 15, 2015 06:57PM |

Registered: 15 years ago Posts: 11 |

Looking good!

My only concern is that you are potentially blocking the cable routing from the heater block to the cable tie point on the effector. The positioning of the heater block itself is important per the fisher instructions to avoid overheating the air vent nozzles and the proposed position of the IR board. I was looking at a possible mounting on the outside of the effector on the opposite side but it is a long way from the hot-end nozzle.

My Fisher has 17.2mm of clearance at the paper grabbing point and David's v1.1 IR board is 17.8mm high. Therefore the bottom of the board needs to project a maximum of 16.2mm below the effector to meet David's suggested minimum clearance and at least 14.8mm to ensure the board triggers before the nozzle hits the bed. There is likely to be a bit of variation between Fishers so some allowance for tolerances is needed.

Very interested to see what you end up with

My only concern is that you are potentially blocking the cable routing from the heater block to the cable tie point on the effector. The positioning of the heater block itself is important per the fisher instructions to avoid overheating the air vent nozzles and the proposed position of the IR board. I was looking at a possible mounting on the outside of the effector on the opposite side but it is a long way from the hot-end nozzle.

My Fisher has 17.2mm of clearance at the paper grabbing point and David's v1.1 IR board is 17.8mm high. Therefore the bottom of the board needs to project a maximum of 16.2mm below the effector to meet David's suggested minimum clearance and at least 14.8mm to ensure the board triggers before the nozzle hits the bed. There is likely to be a bit of variation between Fishers so some allowance for tolerances is needed.

Very interested to see what you end up with

|

Re: Designing a New High Heat Carbon Fiber Effector Plate (Work in Progress) August 16, 2015 04:15AM |

Registered: 8 years ago Posts: 38 |

So far it is just a make up on places the board is going to be set in grove where ever the board goes up so there still 1mm or .5 at the above the nozzle. Still have to look at what external parts that could get in the way. I finish a complete build with arms and screws in place with all the fastness and see what I can. Whisk I could but the board I little angled but I think the ir deflect and not read itself. But ir calibration is little new to me but the electronic parts and design I understand.

|

Re: Designing a New High Heat Carbon Fiber Effector Plate (Work in Progress) August 16, 2015 04:18AM |

Registered: 8 years ago Posts: 38 |

Quote

pjr

Looking good!

My only concern is that you are potentially blocking the cable routing from the heater block to the cable tie point on the effector. The positioning of the heater block itself is important per the fisher instructions to avoid overheating the air vent nozzles and the proposed position of the IR board. I was looking at a possible mounting on the outside of the effector on the opposite side but it is a long way from the hot-end nozzle.

My Fisher has 17.2mm of clearance at the paper grabbing point and David's v1.1 IR board is 17.8mm high. Therefore the bottom of the board needs to project a maximum of 16.2mm below the effector to meet David's suggested minimum clearance and at least 14.8mm to ensure the board triggers before the nozzle hits the bed. There is likely to be a bit of variation between Fishers so some allowance for tolerances is needed.

Very interested to see what you end up with

The board will fit in grove or slot in effecter to take care of that so mounting just needs to be worked out. If I could put a angle of the board I can't make mount incorporated with the fan nozzles.

|

Re: Designing a New High Heat Carbon Fiber Effector Plate (Work in Progress) August 16, 2015 02:22PM |

Registered: 8 years ago Posts: 38 |

Ok so I sometime today to work on the magnetic effector plate that will make it even easier to mount the IR Board or just something to just basic printing. Still working progress have to put all plats together on this one and make 30 to 45 degree mounting place for countersunk magnets and then work on the railing system. Trying make it so you don't have recreate the wheel but will be easer to take the effecter off and not have to worry about binding or breaking arms again. I might be able to stock arms with this setup.

Sorry, only registered users may post in this forum.