Carbon Arms

Posted by bgkdavis

|

Carbon Arms September 04, 2015 02:34AM |

Registered: 8 years ago Posts: 443 |

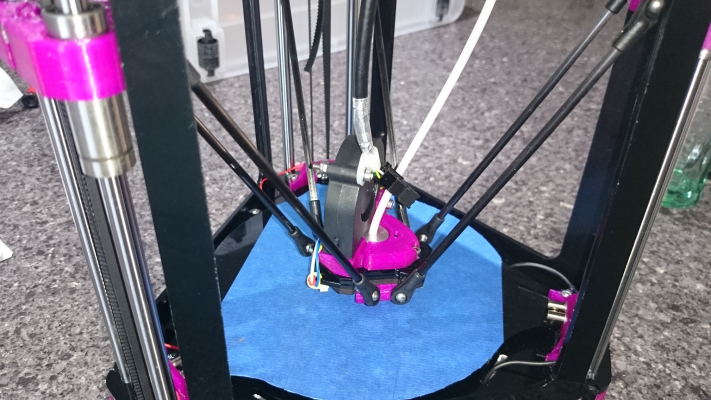

My parts finally arrived for my carbon arms and I've rebuilt my mortally sticken Fisher

The arms are made from 12 Mugen Seiki ball links available from RC Model shops

Also needed is 1m of 4mm carbon rod, model shops and kite shops often stock this

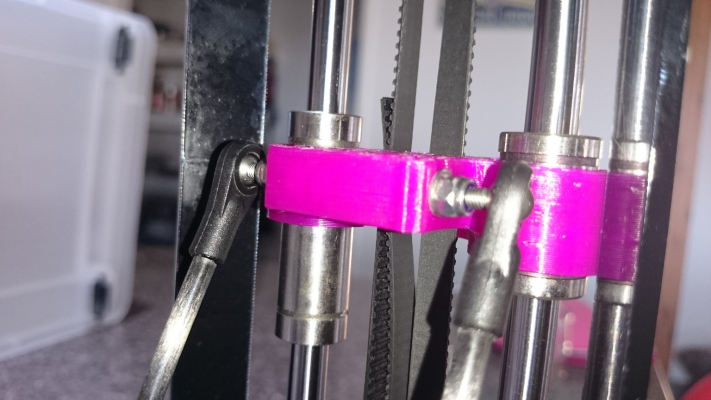

simply drill out (carefully) the ball ends to 4mm and cut the rod to length, best cut it oversized at first then trim it down with a dremmel so the assembled lengths are exactly 160mm centres.

the ball ends just clip in place witha little force

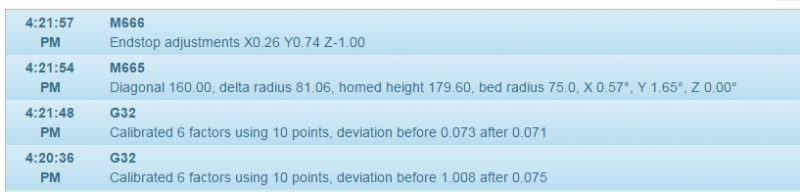

and the moment of truth first calibration data.....

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

The arms are made from 12 Mugen Seiki ball links available from RC Model shops

Also needed is 1m of 4mm carbon rod, model shops and kite shops often stock this

simply drill out (carefully) the ball ends to 4mm and cut the rod to length, best cut it oversized at first then trim it down with a dremmel so the assembled lengths are exactly 160mm centres.

the ball ends just clip in place witha little force

and the moment of truth first calibration data.....

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

|

Re: Carbon Arms September 04, 2015 03:49AM |

Registered: 8 years ago Posts: 83 |

|

Re: Carbon Arms September 04, 2015 03:57AM |

Registered: 8 years ago Posts: 443 |

before the Armageddon I was down to 0.042

[forums.reprap.org]

This was just the first calibration after the repair, now I've got the printer back working Ill try and get the calibration better.

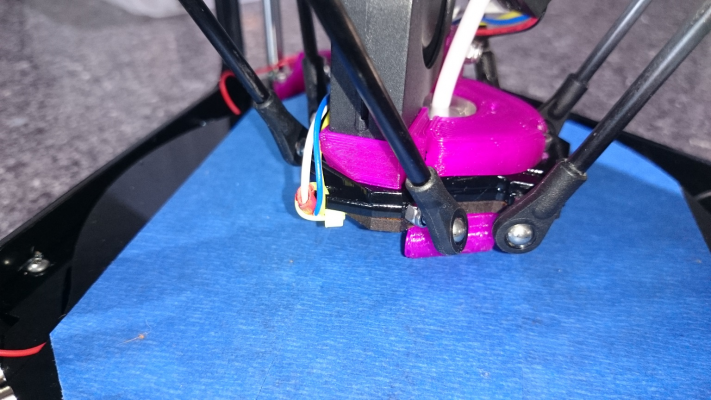

There is absolutely no backlash or slop in the ball-arm contacts and the whole kinematic assembly is a lot more rigid than before

The only problem I see with these arms is getting them to size is tricky and requires time and patience, but the end result looks great.

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

[forums.reprap.org]

This was just the first calibration after the repair, now I've got the printer back working Ill try and get the calibration better.

There is absolutely no backlash or slop in the ball-arm contacts and the whole kinematic assembly is a lot more rigid than before

The only problem I see with these arms is getting them to size is tricky and requires time and patience, but the end result looks great.

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

|

Re: Carbon Arms September 04, 2015 04:23AM |

Registered: 8 years ago Posts: 83 |

|

Re: Carbon Arms September 04, 2015 04:43PM |

Registered: 8 years ago Posts: 38 |

|

Re: Carbon Arms September 05, 2015 03:51PM |

Registered: 8 years ago Posts: 39 |

Just made myself som carbon arms too! Used traxxas links for 5.8 mm balls, so it's a little tight but I figured with some lubrication it won't be a problem I hope!  did you glue yours or did you just jam it in there? Not quite sure if it's tight enough to hold still... Just tested with some glued shrinktube, hope it holds up, don't want to superglue/locktite them, so much harder to get the exact length that way!

did you glue yours or did you just jam it in there? Not quite sure if it's tight enough to hold still... Just tested with some glued shrinktube, hope it holds up, don't want to superglue/locktite them, so much harder to get the exact length that way!

did you glue yours or did you just jam it in there? Not quite sure if it's tight enough to hold still... Just tested with some glued shrinktube, hope it holds up, don't want to superglue/locktite them, so much harder to get the exact length that way!

did you glue yours or did you just jam it in there? Not quite sure if it's tight enough to hold still... Just tested with some glued shrinktube, hope it holds up, don't want to superglue/locktite them, so much harder to get the exact length that way!

|

Re: Carbon Arms September 05, 2015 06:42PM |

Registered: 8 years ago Posts: 443 |

|

Re: Carbon Arms September 06, 2015 06:18AM |

Registered: 8 years ago Posts: 39 |

|

Re: Carbon Arms September 16, 2015 06:17PM |

Registered: 8 years ago Posts: 38 |

|

Re: Carbon Arms September 16, 2015 07:49PM |

Registered: 8 years ago Posts: 443 |

Remember my calibration figures are based on the 6/10 calibration which typically give much higher figures that the 6/7, and three of my cal points are in the areas of greater inacuracy, when comparing figures between machines its important to also compare the calibration routines, and im deliberately using a routine that provides the worst numerical results.

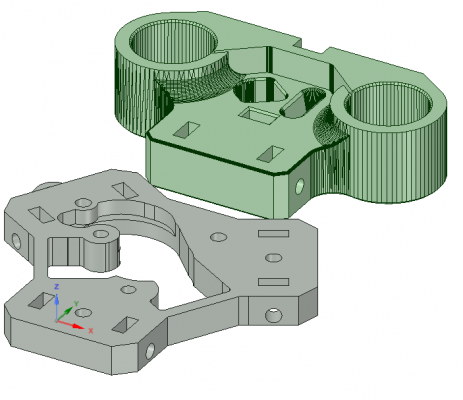

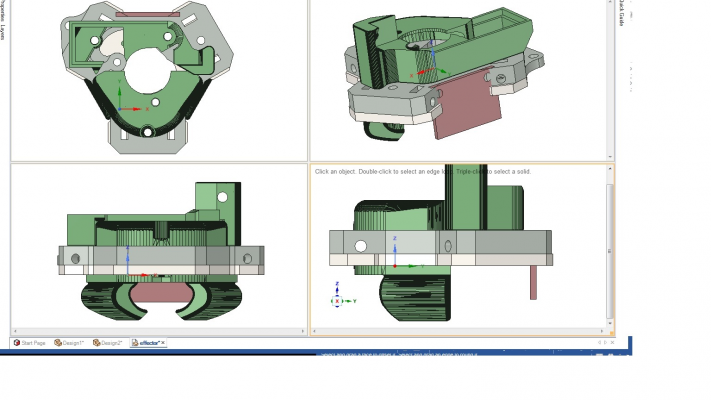

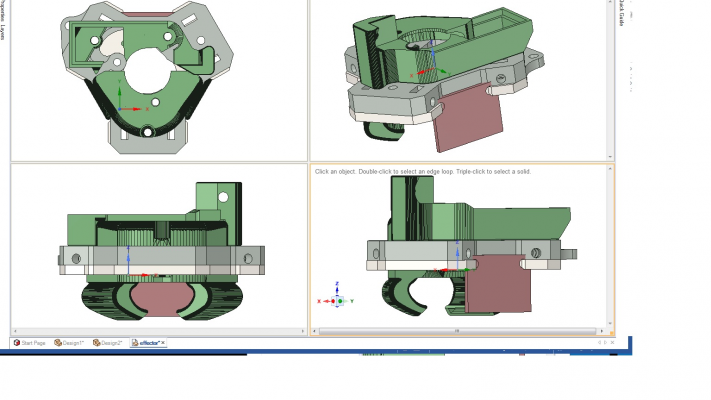

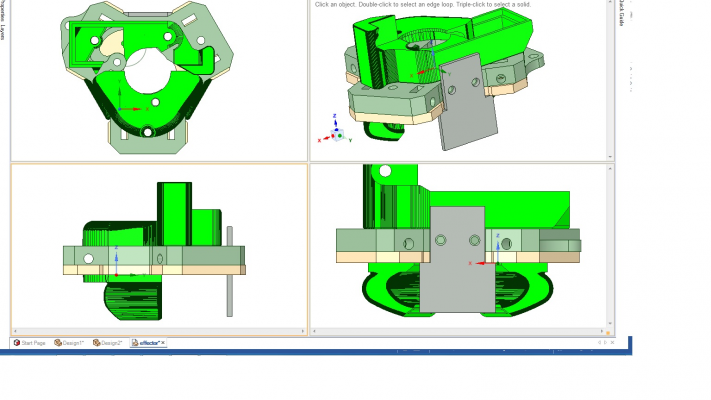

I am currently down at 0.05, but I've been working on a new design mod for the effector and carriages that will hopefully fix a lot of problems with the geometry, when I look at the effector its easy to see that its not perfectly horizontal and I attribute this to the balls not being on a constant plane, but regardless of the theory and calibration numbers, the bottom line is I'm getting great prints with very good accuracy, excellent surface finish and excellent consistency, which is a lot more important than some arbitrary numbers.

My new parts replace the 12 screws that hold the balls in place with 12 studs made from M3 threaded rod, so it will make it a lot easier to adjust the ball positions, the two acrylic plates in the effector are replaced by a single printed part, but I'm keeping the MDF bottom plate for heat protection.

I may actually put off upgrading with the new parts for a while, as it will mean completely dismantling the machine and disassembling the parts that I spent a long time assembling in the first place, if I notice the quality start to drop off or find I need even more quality then I may consider doing the rework, but for now I'm pretty happy with the carbon arms

Edited 1 time(s). Last edit at 09/16/2015 07:50PM by bgkdavis.

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

I am currently down at 0.05, but I've been working on a new design mod for the effector and carriages that will hopefully fix a lot of problems with the geometry, when I look at the effector its easy to see that its not perfectly horizontal and I attribute this to the balls not being on a constant plane, but regardless of the theory and calibration numbers, the bottom line is I'm getting great prints with very good accuracy, excellent surface finish and excellent consistency, which is a lot more important than some arbitrary numbers.

My new parts replace the 12 screws that hold the balls in place with 12 studs made from M3 threaded rod, so it will make it a lot easier to adjust the ball positions, the two acrylic plates in the effector are replaced by a single printed part, but I'm keeping the MDF bottom plate for heat protection.

I may actually put off upgrading with the new parts for a while, as it will mean completely dismantling the machine and disassembling the parts that I spent a long time assembling in the first place, if I notice the quality start to drop off or find I need even more quality then I may consider doing the rework, but for now I'm pretty happy with the carbon arms

Edited 1 time(s). Last edit at 09/16/2015 07:50PM by bgkdavis.

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

|

Re: Carbon Arms September 17, 2015 06:10AM |

Registered: 8 years ago Posts: 38 |

Quote

bgkdavis

before the Armageddon I was down to 0.042

[forums.reprap.org]

This was just the first calibration after the repair, now I've got the printer back working Ill try and get the calibration better.

There is absolutely no backlash or slop in the ball-arm contacts and the whole kinematic assembly is a lot more rigid than before

The only problem I see with these arms is getting them to size is tricky and requires time and patience, but the end result looks great.

I recommend if you going to make these arms and want to safe time. Get a piece of wood and 2mm or 4mm wood screws. Make you first arm with best measurements you can. After that arm is completed lay the arm on the board and get the two screws and screw them in the eye holes. Now you have template to make all the arms the same sizes every time. Oh I forgot screws tight or withe button of the eye whole or top for same measurements and all your arms will be precise.

|

Re: Carbon Arms September 17, 2015 07:16AM |

Registered: 8 years ago Posts: 443 |

heres a pic of my new design effector and carriage, I've printed them but not actually tested these yet, I would put the STL file up but its a little large, and I don't want to put them on Thingiverse until I've tested them

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

|

Re: Carbon Arms September 17, 2015 02:46PM |

Registered: 8 years ago Posts: 38 |

|

Re: Carbon Arms September 17, 2015 05:35PM |

Registered: 8 years ago Posts: 443 |

That is just a direct copy of the originals all that has been done is the bottom and middle plates are merged together, it doesnt solve the problems I have with the original design and gets rid of the mdf plate which I actually want to keep.

This version merges the top and middle plates and redesigns the ball mounts, this way I keep the mdf plate and solve the adjustability problem with the balls, and hopefully improve the alignment issues that the original design and the printed copy have.

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

This version merges the top and middle plates and redesigns the ball mounts, this way I keep the mdf plate and solve the adjustability problem with the balls, and hopefully improve the alignment issues that the original design and the printed copy have.

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

|

Re: Carbon Arms September 18, 2015 07:08PM |

Registered: 8 years ago Posts: 38 |

Quote

bgkdavis

That is just a direct copy of the originals all that has been done is the bottom and middle plates are merged together, it doesnt solve the problems I have with the original design and gets rid of the mdf plate which I actually want to keep.

This version merges the top and middle plates and redesigns the ball mounts, this way I keep the mdf plate and solve the adjustability problem with the balls, and hopefully improve the alignment issues that the original design and the printed copy have.

Bottom and Middle plate are merged and top plate is alone kinda like cap. Autocad I merged them and they been tested. Justing saying.

|

Re: Carbon Arms September 18, 2015 07:44PM |

Registered: 8 years ago Posts: 443 |

Yup, I can see that, and thats why the hot end Ive done is different.

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

|

Re: Carbon Arms September 21, 2015 02:51AM |

Registered: 8 years ago Posts: 7 |

I am interested in the effector redesign and think I will given time swap over to a modified effector plate and maybe the arms as you all have described. Wondering whether zaccom has used the DC42 IR sensor yet on the effector and if it is working Ok on his effector plate modification? I am interested since I have a board already.

|

Re: Carbon Arms September 21, 2015 03:37AM |

Registered: 8 years ago Posts: 443 |

Ive been thinking about dc42s sensor board, but I think it will require a signifigant redesign of both the board and effector to work, I was wondering if it was practical to remove the ir comonents from the board and mount them directly on the effector for example.

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

|

Re: Carbon Arms September 21, 2015 10:56AM |

Registered: 8 years ago Posts: 38 |

Quote

bgkdavis

Ive been thinking about dc42s sensor board, but I think it will require a signifigant redesign of both the board and effector to work, I was wondering if it was practical to remove the ir comonents from the board and mount them directly on the effector for example.

Yeah I got the board from him but need a slot in the effector to make it fit still work in progress if you find a good spot give me heads up I been trying the front, side, in the effector, pitch angel but depends on print bed I guess. I use zebra print bed with alu headbed setup.

|

Re: Carbon Arms September 21, 2015 11:01AM |

Registered: 8 years ago Posts: 38 |

Quote

ph610

I am interested in the effector redesign and think I will given time swap over to a modified effector plate and maybe the arms as you all have described. Wondering whether zaccom has used the DC42 IR sensor yet on the effector and if it is working Ok on his effector plate modification? I am interested since I have a board already.

Work in progress [forums.reprap.org]

Edited 1 time(s). Last edit at 09/21/2015 11:02AM by zaccom.

|

Re: Carbon Arms September 21, 2015 11:04AM |

Registered: 10 years ago Posts: 14,672 |

Quote

zaccom

Quote

bgkdavis

Ive been thinking about dc42s sensor board, but I think it will require a signifigant redesign of both the board and effector to work, I was wondering if it was practical to remove the ir comonents from the board and mount them directly on the effector for example.

Yeah I got the board from him but need a slot in the effector to make it fit still work in progress if you find a good spot give me heads up I been trying the front, side, in the effector, pitch angel but depends on print bed I guess. I use zebra print bed with alu headbed setup.

Depending on how much you would need to shorten the board, maybe it would be possible to shorten the board with a file sufficiently to fit it below the effector? You might need to use a piece of wire to replace the trace connecting the top of R5 to the Out pin.

Alternatively, is there any possibility of using a spacer to drop the hot end slightly?

Edited 1 time(s). Last edit at 09/21/2015 11:05AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Carbon Arms September 22, 2015 04:01AM |

Registered: 8 years ago Posts: 443 |

Quote

zaccom

Quote

ph610

I am interested in the effector redesign and think I will given time swap over to a modified effector plate and maybe the arms as you all have described. Wondering whether zaccom has used the DC42 IR sensor yet on the effector and if it is working Ok on his effector plate modification? I am interested since I have a board already.

Work in progress [forums.reprap.org]

If you just want a printed effector then this design may be ok, last I looked it is a functional copy of the original effector, so should be ok.

The design Im working on is an attempt at making it easier to adjust and to be a lot more ridgid than the original, Ive actually had something of an epiphany today that should make mine LOT easier to build, just need to get some set screws later this week, and will maybe tear down my fisher at the weekend to do a rebuild and test.

Ive just had a second epiphany on the ir sensor.... hey dc.... I need dimensions of your board, I think I can design a pcb that will fit if I make another design mod to my effector, I'm guessing the critical dims are the placement of the ir parts....what is the typical sensing distance of it?

Edited 1 time(s). Last edit at 09/22/2015 05:24AM by bgkdavis.

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

|

Re: Carbon Arms September 22, 2015 04:50AM |

Registered: 10 years ago Posts: 14,672 |

You will find the board dimensions at the end of [miscsolutions.wordpress.com]. The trigger height of the board is between 2.5 and 3.5mm measured from the bottom edge of the board.

How much height is there under the effector when the nozzle is touching the bed? If there is sufficient demand, I could make an even shorter board.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

How much height is there under the effector when the nozzle is touching the bed? If there is sufficient demand, I could make an even shorter board.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Carbon Arms September 22, 2015 05:09AM |

Registered: 8 years ago Posts: 443 |

this is DC42s standard probe fitted to a fisher effector

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

|

Re: Carbon Arms September 22, 2015 05:17AM |

Registered: 8 years ago Posts: 443 |

take 2 this version shows ithe board mounted 3mm from nozzle height, I'm a little concerned about the proximity to the hot end... this sketch doesnt show it

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

|

Re: Carbon Arms September 22, 2015 05:26AM |

Registered: 10 years ago Posts: 14,672 |

It looks to me that you have the board far enough from the hot end. My standard mount for use with the E3Dv6 hot end places the back of the board only about 5mm from the heater block. See the 5th picture at [www.thingiverse.com]. The temperature of the board should not be allowed to exceed 80C, so if you can keep your finger on it then it's not too hot.

Edited 1 time(s). Last edit at 09/22/2015 05:27AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Edited 1 time(s). Last edit at 09/22/2015 05:27AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Carbon Arms September 22, 2015 05:29AM |

Registered: 8 years ago Posts: 443 |

OK, here's my Idea

Edited 1 time(s). Last edit at 09/22/2015 05:29AM by bgkdavis.

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

- Modify the board shape so its an inverted T shape and a little taller

- Put the large capacitor on the underside of the board

- Move the mounting holes closer together

- Move the connection points to the top of the board

Edited 1 time(s). Last edit at 09/22/2015 05:29AM by bgkdavis.

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

|

Re: Carbon Arms September 22, 2015 05:42AM |

Registered: 10 years ago Posts: 14,672 |

Won't work, the primary function of the large capacitor is to block the direct light path between the LEDs and the phototransistor.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Carbon Arms September 22, 2015 05:47AM |

Registered: 8 years ago Posts: 443 |

OK, well plan B is to have all the components facing outwards...there will be a considerable offset from the nozzle though but you can only get so close to the nozzle anyway.

The other issue is this mod may only work with my carbon arm design, the acrylic arms are just too bulky and those holes in the lobes are where the balls get mounted , the whole assembly is going to be very tight.

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

The other issue is this mod may only work with my carbon arm design, the acrylic arms are just too bulky and those holes in the lobes are where the balls get mounted , the whole assembly is going to be very tight.

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

|

Re: Carbon Arms September 22, 2015 06:09AM |

Registered: 8 years ago Posts: 443 |

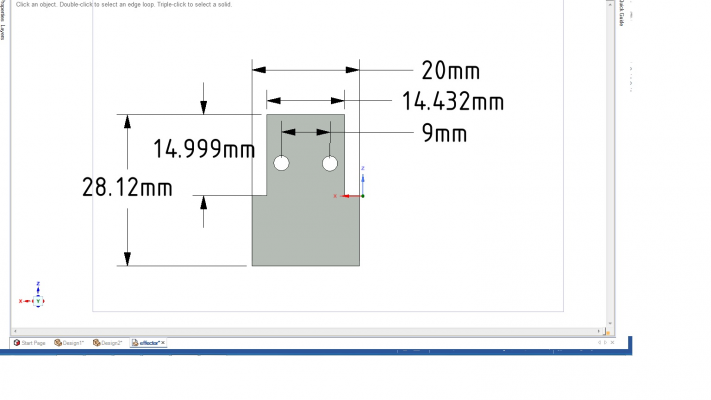

here is how I see the modified board looking, would need to prototype the fit to check for obstructions, and the board mounting may have to use countersunk screws to minimise obstruction potential

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

Sorry, only registered users may post in this forum.