new effector and carraige

Posted by bgkdavis

|

new effector and carraige September 25, 2015 05:49AM |

Registered: 8 years ago Posts: 443 |

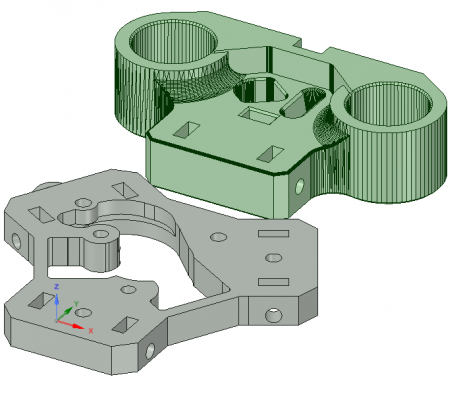

I've added my new effector and carriage to my Fisher and fairly pleased with the results, first calibrations were fairly consistent at 0.05 with a 6/10 calibration, and I'm currently running a print to bed the arms and everything in, then Ill run another set of calibrations and publish the figures

This mod replaces the two acrylic plates on the effector and the three carriages.

With the effector mod you will lose 1.5mm from your max print height.... but I just realised (belatedly) I could get that back by making more mods to the carriages.... maybe next strip down!

I've published my files on Thingiverse below

[www.thingiverse.com]

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

This mod replaces the two acrylic plates on the effector and the three carriages.

With the effector mod you will lose 1.5mm from your max print height.... but I just realised (belatedly) I could get that back by making more mods to the carriages.... maybe next strip down!

I've published my files on Thingiverse below

[www.thingiverse.com]

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

|

Re: new effector and carraige September 25, 2015 07:53AM |

Registered: 8 years ago Posts: 83 |

|

Re: new effector and carraige September 25, 2015 08:07AM |

Registered: 8 years ago Posts: 443 |

If you look closely at the models you will see slots for the nuts where there was originally features to accommodate screw heads, because I've replaced these features with simple slots and holes the location of the screws is a lot more positive.

The plain nuts and grub screws effectively replace the screws on the RRP original design, you will also need 12 M3 nylock nuts (which the original build will already have), plus 12 M3 washers to sit between the Nylocks and plastic..

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

The plain nuts and grub screws effectively replace the screws on the RRP original design, you will also need 12 M3 nylock nuts (which the original build will already have), plus 12 M3 washers to sit between the Nylocks and plastic..

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

|

Re: new effector and carraige September 25, 2015 08:21AM |

Registered: 8 years ago Posts: 443 |

btw if you want to know what the two extra hole are for, I was playing with a mod for mounting a modified version of DC42s differential IR board, and forgot to delete the holes afterwards

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

|

Re: new effector and carraige September 26, 2015 07:36AM |

Registered: 8 years ago Posts: 443 |

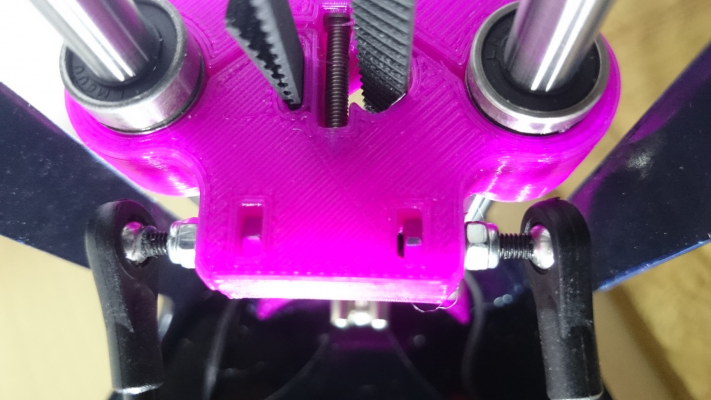

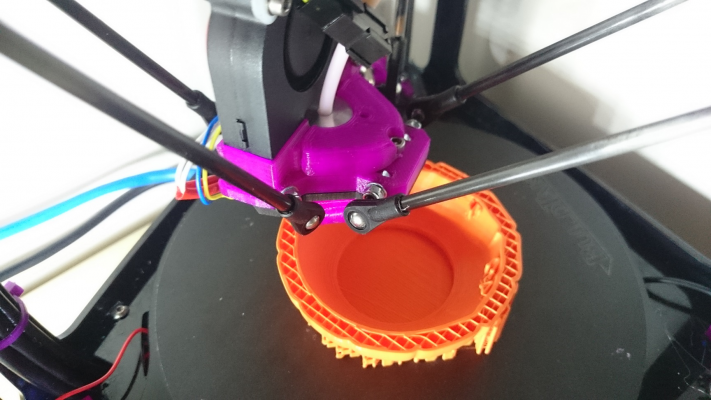

Took time to take a few pictures of the new parts, so far they are proving to be pretty successful. the 6/10 calibration returns 0.05 pretty reliably and I've been getting some great prints.

I've also added a power switch to my Fisher, got fed up with having to pull the plug to turn it off.

These pics show the assembly pretty clearly, the M3 nuts can be seen in the slots and the washers can just be made out between the nylocks and plastic

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

I've also added a power switch to my Fisher, got fed up with having to pull the plug to turn it off.

These pics show the assembly pretty clearly, the M3 nuts can be seen in the slots and the washers can just be made out between the nylocks and plastic

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

|

Re: new effector and carraige December 31, 2015 12:25PM |

Registered: 8 years ago Posts: 42 |

This is a great design, was thinking of something like this when building my Fisher the other day, I'm a newbie but have been following RepRap for a long time. I was thinking that captive nuts would be better than trying to get an Allen key into the cap screw heads. I was also thinking more simply that an M3 threaded bar would be better than the screw as this can be adjusted on the threads much easier than a bolt. When I get chance I will sketch this out. A specifically designed part for the balls would be better but probably more expensive to make, just a ball with the threaded bar attached to it would avoid using locktite on the assembly.

Edited 1 time(s). Last edit at 12/31/2015 12:25PM by geeksarebeta.

Edited 1 time(s). Last edit at 12/31/2015 12:25PM by geeksarebeta.

|

Re: new effector and carraige January 07, 2016 09:28AM |

Registered: 8 years ago Posts: 42 |

Instead of two separate screws to achieve this could these be used:

http://www.ebay.co.uk/itm/M3-A2-Stainless-Threaded-Bar-Rod-Studding-Allthread-3mm-/291641277129?var=&hash=item8986f0440d

But the bar would have to be both left and right hand threaded to work - no I dont think it would, might just buy a set and try it.

The carriage and effector head would then just have a 3mm clearance hole through it, the threaded bar would be passed throught the hole, a washer slipped over each end, followed by a nyloc nut, the balls can then be locked onto the end with threadloc. The threaded bars are 50mm in length, the balls being 6mm in diameter I would estimate that they're threaded ~3mm in depth so the ball-ball distance would then be 56mm, the nyloc nuts can then be adjusted each side to centralise the balls (i.e. each is the same distance from the centre of the carriage/effector). This would also make the carriage/effector more rigid as there's just a hole in it instead of a deep slot with relatively thin walls.

Any thoughts?

Edited 2 time(s). Last edit at 01/07/2016 10:03AM by geeksarebeta.

http://www.ebay.co.uk/itm/M3-A2-Stainless-Threaded-Bar-Rod-Studding-Allthread-3mm-/291641277129?var=&hash=item8986f0440d

But the bar would have to be both left and right hand threaded to work - no I dont think it would, might just buy a set and try it.

The carriage and effector head would then just have a 3mm clearance hole through it, the threaded bar would be passed throught the hole, a washer slipped over each end, followed by a nyloc nut, the balls can then be locked onto the end with threadloc. The threaded bars are 50mm in length, the balls being 6mm in diameter I would estimate that they're threaded ~3mm in depth so the ball-ball distance would then be 56mm, the nyloc nuts can then be adjusted each side to centralise the balls (i.e. each is the same distance from the centre of the carriage/effector). This would also make the carriage/effector more rigid as there's just a hole in it instead of a deep slot with relatively thin walls.

Any thoughts?

Edited 2 time(s). Last edit at 01/07/2016 10:03AM by geeksarebeta.

|

Re: new effector and carraige January 07, 2016 09:41AM |

Registered: 8 years ago Posts: 301 |

Wouldn't bolting something like this directly to the effector be better, then the width can be in the printed part and a self tapping bolt to hold these on.

[www.ebay.co.uk]

It would also be nice to see a version of this that an e3d hot end would fit, as it looks like quickset nozzle replacements could be an issue.

[www.ebay.co.uk]

It would also be nice to see a version of this that an e3d hot end would fit, as it looks like quickset nozzle replacements could be an issue.

|

Re: new effector and carraige January 07, 2016 10:18AM |

Registered: 8 years ago Posts: 42 |

Quote

DADIY

Wouldn't bolting something like this directly to the effector be better, then the width can be in the printed part and a self tapping bolt to hold these on.

[www.ebay.co.uk]

It would also be nice to see a version of this that an e3d hot end would fit, as it looks like quickset nozzle replacements could be an issue.

That is a good solution, but I would be concerned over the level or articulation availablein the rod-ends, but this can be quickly found out from playing with them. I assume that a carbon rod would be glued in between these to make the arms. The design of the effector and MDF plate would need to be reviewed though due to the bolts that attach it all together, they would interfere with the threaded bar.

I'm not a fan of self tapping into the PLA, especially with threads as small as M3, I'm not confident of them staying in the plastic if they're connected with a moving part that has the potential for heat cycling. If I were to use these balls I'd look to having the threaded bar still with a locknut either side of the bearing ball, then length could still be defined by the plastic part, but it's not actually holding the bearings on.

Edited 1 time(s). Last edit at 01/07/2016 10:23AM by geeksarebeta.

|

Re: new effector and carraige January 07, 2016 10:43AM |

Registered: 8 years ago Posts: 17 |

I had thought about using Neo Magnets insead of the balls and someone has done something like it - part of this "thing" is an E3D adaptor for his effector - I wonder if it's worth looking into modifying this with the Fisher in mind?

Effector using magnets

Edited 1 time(s). Last edit at 01/07/2016 10:43AM by Caribou.

Effector using magnets

Edited 1 time(s). Last edit at 01/07/2016 10:43AM by Caribou.

|

Re: new effector and carraige January 07, 2016 10:54AM |

Registered: 8 years ago Posts: 301 |

|

Re: new effector and carraige January 07, 2016 11:00AM |

Registered: 8 years ago Posts: 301 |

Quote

Caribou

I had thought about using Neo Magnets insead of the balls and someone has done something like it - part of this "thing" is an E3D adaptor for his effector - I wonder if it's worth looking into modifying this with the Fisher in mind?

Effector using magnets

For printing PLA we would need cooling for the heat sink and the plastic being put down, I would assume all we would need to do is make the current effector big enough to slide the E3D hot end into and use the same type of cooling. I don't the diameter of the e3d so cant compare it.

|

Re: new effector and carraige January 07, 2016 12:53PM |

Registered: 8 years ago Posts: 42 |

Quote

DADIY

Quote

Caribou

I had thought about using Neo Magnets insead of the balls and someone has done something like it - part of this "thing" is an E3D adaptor for his effector - I wonder if it's worth looking into modifying this with the Fisher in mind?

Effector using magnets

For printing PLA we would need cooling for the heat sink and the plastic being put down, I would assume all we would need to do is make the current effector big enough to slide the E3D hot end into and use the same type of cooling. I don't the diameter of the e3d so cant compare it.

There are links from the e3d website to documentation, from here you can get to all the drawings for the parts on the hot ends, I was looking earlier at the v6Lite as its the closest to the RRP one, unclear as to whether the cooling fan would be needed on the e3d heatsink if only printing in PLA. Does the current fan on the Fisher also blow over the heatsink?

I will have a look at a design of effector with the e3d hot end when I have time. I've got a model of the whole Fisher on CAD now so will be able to see if it all fits.

Edited 1 time(s). Last edit at 01/07/2016 12:54PM by geeksarebeta.

|

Re: new effector and carraige January 07, 2016 01:01PM |

Registered: 8 years ago Posts: 301 |

|

Re: new effector and carraige January 08, 2016 04:04AM |

Registered: 8 years ago Posts: 301 |

Quote

geeksarebeta

Quote

DADIY

Quote

Caribou

I had thought about using Neo Magnets insead of the balls and someone has done something like it - part of this "thing" is an E3D adaptor for his effector - I wonder if it's worth looking into modifying this with the Fisher in mind?

Effector using magnets

For printing PLA we would need cooling for the heat sink and the plastic being put down, I would assume all we would need to do is make the current effector big enough to slide the E3D hot end into and use the same type of cooling. I don't the diameter of the e3d so cant compare it.

There are links from the e3d website to documentation, from here you can get to all the drawings for the parts on the hot ends, I was looking earlier at the v6Lite as its the closest to the RRP one, unclear as to whether the cooling fan would be needed on the e3d heatsink if only printing in PLA. Does the current fan on the Fisher also blow over the heatsink?

I will have a look at a design of effector with the e3d hot end when I have time. I've got a model of the whole Fisher on CAD now so will be able to see if it all fits.

Looks like the lite version only prints up to 50mm/s Fisher can print to 80mm/s.

|

Re: new effector and carraige January 08, 2016 06:58AM |

Registered: 8 years ago Posts: 42 |

|

Re: new effector and carraige January 08, 2016 09:24AM |

Registered: 8 years ago Posts: 42 |

Mock up of the threaded rod version of the carriage assembly. Makes the part that carries the load a bit stronger by having more material in it, FYI I do not believe the balls are threaded that deep.

I have ordered some threaded bar to see if it will work, will print a mock up carriage to give it a go.

Edited 1 time(s). Last edit at 01/08/2016 09:30AM by geeksarebeta.

I have ordered some threaded bar to see if it will work, will print a mock up carriage to give it a go.

Edited 1 time(s). Last edit at 01/08/2016 09:30AM by geeksarebeta.

|

Re: new effector and carraige January 08, 2016 01:57PM |

Registered: 8 years ago Posts: 40 |

If you are going to change the carriage assembly, then it might be worth considering changing the spacing of the arms so that it is the same as the mini kossel, then it would be easy to get effectors for various heads. e.g

Jhead - in metal or Dual extruder, for chimera etc or diamond hotend

The gap between the kossel arms is just slightly smaller.

Jhead - in metal or Dual extruder, for chimera etc or diamond hotend

The gap between the kossel arms is just slightly smaller.

|

Re: new effector and carraige January 08, 2016 06:55PM |

Registered: 8 years ago Posts: 443 |

Quote

geeksarebeta

Mock up of the threaded rod version of the carriage assembly. Makes the part that carries the load a bit stronger by having more material in it, FYI I do not believe the balls are threaded that deep.

I have ordered some threaded bar to see if it will work, will print a mock up carriage to give it a go.

A single threaded bar is exactly what I wanted to avoid with this design, it doenst achieve the end goal of having an easy to adjust ball spacing, you will find that you will have to file the bars down individually to get the spacing's correct.....on the plus side it will give a more robust assembly, but ive been running with my original design for a few months now and its been no problem

Edited 1 time(s). Last edit at 01/08/2016 06:56PM by bgkdavis.

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

|

Re: new effector and carraige January 11, 2016 09:53AM |

Registered: 8 years ago Posts: 75 |

Im printing these right now, though i have enlarged the nut holes to fit nylon locking ones and bought 25mm slugs rather than 20. Sadly I had a mishap with my printer the other day resulting in a significant dismantle. After putting it back together i cant get a better deviation than 0.160... so Im going to do a full rebuild on it. @bgkdavis can you take a few more pictures so i know im assembling it properly.

|

Re: new effector and carraige January 11, 2016 09:55AM |

Registered: 8 years ago Posts: 42 |

Quote

bgkdavis

A single threaded bar is exactly what I wanted to avoid with this design, it doenst achieve the end goal of having an easy to adjust ball spacing, you will find that you will have to file the bars down individually to get the spacing's correct.....on the plus side it will give a more robust assembly, but ive been running with my original design for a few months now and its been no problem

I have had a play with designs of these, and I have to bow down to the better design that bgkdavis has already produced, I do believe that a single threaded bar gives the simplest and most straight forward build procedure and a lower overall parts count, but for the ability to adjust the distance between the balls without bgkdavis has the right solution.

I got some threaded bar but this is limited in length to 50mm / 100mm lengths, because of how deep the balls are threaded the 50mm bar only gives 54mm from ball-end to ball-end, at this distance the rods (RRP supplied) would clash with the nylock nuts. I cannot comment on whether the carbon-arms could cope with being this close together as I do not have any...yet.

I intend to upgrade my Fisher to bgkdavis' design, however I will need to make some accuracy improvements on my own device before printing any replacement parts as my prints are all coming out a little small at the minute.

|

Re: new effector and carraige January 11, 2016 10:12AM |

Registered: 8 years ago Posts: 75 |

Quote

geeksarebeta

Quote

bgkdavis

A single threaded bar is exactly what I wanted to avoid with this design, it doenst achieve the end goal of having an easy to adjust ball spacing, you will find that you will have to file the bars down individually to get the spacing's correct.....on the plus side it will give a more robust assembly, but ive been running with my original design for a few months now and its been no problem

I have had a play with designs of these, and I have to bow down to the better design that bgkdavis has already produced, I do believe that a single threaded bar gives the simplest and most straight forward build procedure and a lower overall parts count, but for the ability to adjust the distance between the balls without bgkdavis has the right solution.

I got some threaded bar but this is limited in length to 50mm / 100mm lengths, because of how deep the balls are threaded the 50mm bar only gives 54mm from ball-end to ball-end, at this distance the rods (RRP supplied) would clash with the nylock nuts. I cannot comment on whether the carbon-arms could cope with being this close together as I do not have any...yet.

I intend to upgrade my Fisher to bgkdavis' design, however I will need to make some accuracy improvements on my own device before printing any replacement parts as my prints are all coming out a little small at the minute.

Thats a good idea, im fortunate enough to have a ultimaker 2 as well that i use for work. its printing all these peices now using green to yellow thermochromic filament to be able to monitor how hot the pieces are getting while in use.

|

Re: new effector and carraige January 11, 2016 10:35AM |

Registered: 8 years ago Posts: 42 |

Quote

Sean.kennedy

Thats a good idea, im fortunate enough to have a ultimaker 2 as well that i use for work. its printing all these peices now using green to yellow thermochromic filament to be able to monitor how hot the pieces are getting while in use.

WOW, thats incredible. I've used a lot of thermal paint in the past but never a polymer. Would result in a fairly colourful printer I assume.

|

Re: new effector and carraige January 11, 2016 11:47AM |

Registered: 8 years ago Posts: 26 |

Would "balls" like these have the clearance required for the full range of movement? If they did, you wouldn't have to worry about the exact length of the rod used. [www.modelsport.co.uk]

They've been used here: [blog.think3dprint3d.com]

They've been used here: [blog.think3dprint3d.com]

|

Re: new effector and carraige January 11, 2016 11:53AM |

Registered: 8 years ago Posts: 301 |

|

Re: new effector and carraige January 11, 2016 07:26PM |

Registered: 8 years ago Posts: 443 |

Well its all about cost and simplicity, its far simpler to modify the basic fisher effector than to replace it with a Kossel effector, maybe you should just replace the fisher with a Kossel?

Personally I've never had any problem with the fisher hot end or extruder.

I would suggest that you look at the Fisher 1 effector and do a mashup of my original fisher beta based design and the fisher 1

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

Personally I've never had any problem with the fisher hot end or extruder.

I would suggest that you look at the Fisher 1 effector and do a mashup of my original fisher beta based design and the fisher 1

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

|

Re: new effector and carraige January 12, 2016 02:17AM |

Registered: 8 years ago Posts: 42 |

|

Re: new effector and carraige January 12, 2016 03:10AM |

Registered: 8 years ago Posts: 301 |

Quote

bgkdavis

Well its all about cost and simplicity, its far simpler to modify the basic fisher effector than to replace it with a Kossel effector, maybe you should just replace the fisher with a Kossel?

Personally I've never had any problem with the fisher hot end or extruder.

I would suggest that you look at the Fisher 1 effector and do a mashup of my original fisher beta based design and the fisher 1

My thinking was that at some point the hot end will need to be replaced due to the lack of spare parts now available since reprappro closed (quick-set nozzles seem impossible to source at the moment) so when we need to replace the hot end swapping to the Kossel effector and shortening the carriage bolts would be a simple fix.

Now if I had known reprap were going to close and leave us without spares/warranty etc and that the kossel had a version with Duet I would probably have gone that route in the first place. That said now that I've replaced the acrylic parts on the Fisher I am super happy with it.

|

Re: new effector and carraige January 12, 2016 03:25AM |

Registered: 9 years ago Posts: 1,159 |

Quote

DADIY

Quote

bgkdavis

Well its all about cost and simplicity, its far simpler to modify the basic fisher effector than to replace it with a Kossel effector, maybe you should just replace the fisher with a Kossel?

Personally I've never had any problem with the fisher hot end or extruder.

I would suggest that you look at the Fisher 1 effector and do a mashup of my original fisher beta based design and the fisher 1

My thinking was that at some point the hot end will need to be replaced due to the lack of spare parts now available since reprappro closed (quick-set nozzles seem impossible to source at the moment) so when we need to replace the hot end swapping to the Kossel effector and shortening the carriage bolts would be a simple fix.

Now if I had known reprap were going to close and leave us without spares/warranty etc and that the kossel had a version with Duet I would probably have gone that route in the first place. That said now that I've replaced the acrylic parts on the Fisher I am super happy with it.

Adding to that Robotdigg do a very nice Kossel Effector in Aluminium for $15 us and is made with a 16mm hole in the centre which is just the right size for a E3D type hotted (and the ball attachment points are threaded M3) Alloy Effector

Edited 1 time(s). Last edit at 01/12/2016 03:26AM by dougal1957.

|

Re: new effector and carraige January 12, 2016 04:36AM |

Registered: 8 years ago Posts: 75 |

Sorry, only registered users may post in this forum.