How do I solve this?

Posted by Jelle

|

How do I solve this? October 07, 2015 01:31PM |

Registered: 9 years ago Posts: 58 |

Hi there,

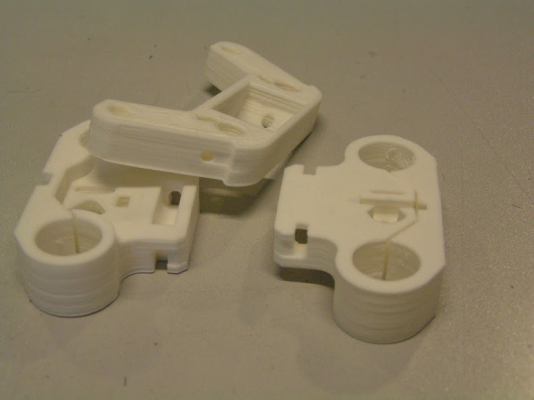

can anybody point me in the right direction to solve this artefact?

It looks like I have a lot of backlash, but when I grab the (cold!) nozzle it feels quite tight, I've seen much les ringing on UM's with a very wobbly hotend. I may also have a little overextrusion, the tops look overfilled on some points, could that cause the other artefact too?

can anybody point me in the right direction to solve this artefact?

It looks like I have a lot of backlash, but when I grab the (cold!) nozzle it feels quite tight, I've seen much les ringing on UM's with a very wobbly hotend. I may also have a little overextrusion, the tops look overfilled on some points, could that cause the other artefact too?

|

Re: How do I solve this? October 08, 2015 06:37AM |

Registered: 10 years ago Posts: 14,672 |

What artefact are you referring to? Do you mean the vertical sides are not a smooth as you would like, or something else?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: How do I solve this? October 08, 2015 06:49AM |

Registered: 8 years ago Posts: 443 |

Does look like hes got some cornering errors at the locations with 90 degree corners, looking at these pics I'm guessing his outer perimeters are anticlockwise, these can happen on CNCs when trying to move too fast or when there is a loss in stiffness. maybe need to slow down the outter perimeter pass

High speed cncs often have an 'exact position check' function for this exact reason whilst axes and encoder positions may think the tool has got to a position, it may actually be lagging a little due to elasticity factors so a momentary dwell is added to allow the laws of physics to catch up.

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

High speed cncs often have an 'exact position check' function for this exact reason whilst axes and encoder positions may think the tool has got to a position, it may actually be lagging a little due to elasticity factors so a momentary dwell is added to allow the laws of physics to catch up.

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

|

Re: How do I solve this? October 08, 2015 07:05AM |

Registered: 9 years ago Posts: 58 |

Yes the sides are not as smooth, but the artefact I was referring to the side that should be smooth are seemingly disturbed by holes or other features in the model. These appear to echo on the path the hotend takes, or the previous path of the effector seems to influence the current position. With cartesian bots I'd look for ringing or backlash, but with delta's I don't have the experience what to tweak to solve this.

|

Re: How do I solve this? October 08, 2015 08:21AM |

Registered: 13 years ago Posts: 1,611 |

I'd think it was backlash in one of the axes, causing the effector to wobble, possibly a loose nut on the effector or carriage. Check that all the screws in the effector and carriages are not loose, that the joints on the arms, carriages and effector have no play in them, the belts are tight enough, and the belt pulleys are tight on the motor shafts. You can usually test this by gently wobbling the effector by hand, and feeling for any looseness or movement. Also, when the printer probes the bed, make sure that there are no blobs of filament on the tip of the nozzle, or it will get an incorrect reading. It could also be a loose hot end.

Ian

RepRapPro tech support

Ian

RepRapPro tech support

|

Re: How do I solve this? October 08, 2015 11:26AM |

Registered: 9 years ago Posts: 58 |

Ian, I have noticed that the bed is (predictably) slightly concave, so a 10 point 6 factor calibration always has some remaining error. But that does not explain the backlash-like artefact, does it?

I have printed a second set at 50% speed, but I see no difference in the amount of play. Just from trying to move the nozzle or the effector I can feel no play, but I'll run by it again. It might be that this started after I disassembled the effector/hotend.

I have printed a second set at 50% speed, but I see no difference in the amount of play. Just from trying to move the nozzle or the effector I can feel no play, but I'll run by it again. It might be that this started after I disassembled the effector/hotend.

|

Re: How do I solve this? October 08, 2015 11:58AM |

Registered: 10 years ago Posts: 14,672 |

I have seen that type of effect even when there is no apparent backlash. It occurs to me that the perimeter on one side of the hole may be short enough for slic3r to consider it a small perimeter, which may be printed at a slower speed depending on how you have configured slic3r. I have found previously that print speed affects extrusion width.

Also I found that turning 'external perimeters first' gives me better print quality. The downside is that small holes with a vertical axis come out even smaller than they do with external perimeters first.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Also I found that turning 'external perimeters first' gives me better print quality. The downside is that small holes with a vertical axis come out even smaller than they do with external perimeters first.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: How do I solve this? October 11, 2015 05:00AM |

Registered: 8 years ago Posts: 5 |

Sorry, only registered users may post in this forum.