Fisher 1

Posted by BAD455

Hi all,

My first post on the forum :--)

I received my Fisher 1 yesterday and started to assemble it. This is my 4th build and it's going very nicely with the easy to follow instructions.

There have been changes from the beta version as you all know - I discovered them when putting together the motor assembly and could not find the required size bolts (as per the beta build log).

I figured out what had been done before finding the Fisher 1 update on the website. It shows how the motors should be going together with the modified plastics.

My next hurdle will be the extruder assembly. So far, I can't find a decent picture of how it should go together. Everything else is quite clear to me.

So, pretty please (With sugar on), can anyone post a picture of the geared extruder assembly?

Thanks!

Happy building

Ian

My first post on the forum :--)

I received my Fisher 1 yesterday and started to assemble it. This is my 4th build and it's going very nicely with the easy to follow instructions.

There have been changes from the beta version as you all know - I discovered them when putting together the motor assembly and could not find the required size bolts (as per the beta build log).

I figured out what had been done before finding the Fisher 1 update on the website. It shows how the motors should be going together with the modified plastics.

My next hurdle will be the extruder assembly. So far, I can't find a decent picture of how it should go together. Everything else is quite clear to me.

So, pretty please (With sugar on), can anyone post a picture of the geared extruder assembly?

Thanks!

Happy building

Ian

|

Re: Fisher 1 October 14, 2015 11:30AM |

Registered: 12 years ago Posts: 1,611 |

Hi Ian

I'm in the process of writing the instructions, and they should be finished by the end of the week; unfortunately taking picture, writing descriptions and checking all the details is taking longer than ideal. As you're an experienced builder, it shouldn't cause you too many problems - many parts are very similar to the Fisher beta. The extruder drive is quite different, and it's going to take a little longer until the instructions are ready. However, all the image files have already been uploaded, so you can go through them. All the (current) Fisher 1 images are named RRP-FISH1-[XXX].jpg where XXX is a number between 001 and 112.

The effector pictures (which are the other ones I've been asked about) are 063 to 084. So this is the first picture in the sequence:

The extruder drive pictures are 085 to 112. So this is the first picture in the sequence:

To see the build sequence, just change the number in the link. I hope that helps.

Ian

RepRapPro tech support

I'm in the process of writing the instructions, and they should be finished by the end of the week; unfortunately taking picture, writing descriptions and checking all the details is taking longer than ideal. As you're an experienced builder, it shouldn't cause you too many problems - many parts are very similar to the Fisher beta. The extruder drive is quite different, and it's going to take a little longer until the instructions are ready. However, all the image files have already been uploaded, so you can go through them. All the (current) Fisher 1 images are named RRP-FISH1-[XXX].jpg where XXX is a number between 001 and 112.

The effector pictures (which are the other ones I've been asked about) are 063 to 084. So this is the first picture in the sequence:

The extruder drive pictures are 085 to 112. So this is the first picture in the sequence:

To see the build sequence, just change the number in the link. I hope that helps.

Ian

RepRapPro tech support

|

Re: Fisher 1 October 14, 2015 01:05PM |

Registered: 12 years ago Posts: 1,611 |

|

Re: Fisher 1 October 14, 2015 07:59PM |

Registered: 10 years ago Posts: 12 |

Thanks for that Droftarts.

That's just what I was looking for :-)

I did notice that you have been updating the documentation today - I was almost folowing along with you. As I refreshed the pages, you were adding files.

Unfortunately, I have overtightened the effector rods and 4 have snapped at the ball mount. I mistakenly imagined that you tightened the pins up until the rods held up in the air. They were fine for a while, but snapped after 15 mins or so. I have emailed support with a question along these lines, but have also found a model on thingiverse, which will have to do until I can get the proper spares.

It's coming together though and I can't wait to get it printing - they were awesome at the TCT show.

Another topic I have questions about is simplify3d software settings. I have recently bought the software and was wondering if anyone has done a config file for it?

If not, I will post my findings when it is working.

Thanks for your help, Looking forward to having another go tomorrow.

Ian

That's just what I was looking for :-)

I did notice that you have been updating the documentation today - I was almost folowing along with you. As I refreshed the pages, you were adding files.

Unfortunately, I have overtightened the effector rods and 4 have snapped at the ball mount. I mistakenly imagined that you tightened the pins up until the rods held up in the air. They were fine for a while, but snapped after 15 mins or so. I have emailed support with a question along these lines, but have also found a model on thingiverse, which will have to do until I can get the proper spares.

It's coming together though and I can't wait to get it printing - they were awesome at the TCT show.

Another topic I have questions about is simplify3d software settings. I have recently bought the software and was wondering if anyone has done a config file for it?

If not, I will post my findings when it is working.

Thanks for your help, Looking forward to having another go tomorrow.

Ian

|

Re: Fisher 1 October 15, 2015 03:34AM |

Registered: 8 years ago Posts: 155 |

|

Re: Fisher 1 October 15, 2015 04:28AM |

Registered: 8 years ago Posts: 443 |

Most of us have broken arms, upgrading to some carbon or printed arms is highly reccomended.

Definately will give the new extruder a go, just got to figure what parts ill need for a conversion.

The new effector looks pretty sweet, but im happy with mine atm, may give it a go should I strip mine down again

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

Definately will give the new extruder a go, just got to figure what parts ill need for a conversion.

The new effector looks pretty sweet, but im happy with mine atm, may give it a go should I strip mine down again

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

|

Re: Fisher 1 October 15, 2015 06:22AM |

Registered: 10 years ago Posts: 12 |

Hi bgkdavis,

I think that it's your model I downloaded from thingiverse last night - thanks for that :-)

How are you guys going about upgrading to carbon? Using rc car rod ends and gluing into carbon rod?

If so, could you pass on the dimensions please? I might have a trip to the model shop!

Thanks for the help lads - much appreciated:-)

Ian

I think that it's your model I downloaded from thingiverse last night - thanks for that :-)

How are you guys going about upgrading to carbon? Using rc car rod ends and gluing into carbon rod?

If so, could you pass on the dimensions please? I might have a trip to the model shop!

Thanks for the help lads - much appreciated:-)

Ian

|

Re: Fisher 1 October 15, 2015 06:51AM |

Registered: 8 years ago Posts: 443 |

If the model is for arm parts then its not mine.

Everything you need know about carbon arms is here [forums.reprap.org] basically you need 12 6mm ball ends and 1m of 4mm carbon rod, your going to have to build and trim to get the dimensions right (160mm between centers).

The important thing about the arms is they need to be exactly the same length and no shorter than the 160mm of the stock arms, increasing the arm length will improve the overall stability of the printer, but you will loose maximum printing height.

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

Everything you need know about carbon arms is here [forums.reprap.org] basically you need 12 6mm ball ends and 1m of 4mm carbon rod, your going to have to build and trim to get the dimensions right (160mm between centers).

The important thing about the arms is they need to be exactly the same length and no shorter than the 160mm of the stock arms, increasing the arm length will improve the overall stability of the printer, but you will loose maximum printing height.

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

|

Re: Fisher 1 October 15, 2015 09:30AM |

Registered: 12 years ago Posts: 1,611 |

I have answered Ian separately by email:

We would really like to understand how they have broken. We haven't had any breakages in 6 weeks of testing! Please could you consider, and give me some feedback, on the following:

1. Please send me a picture showing how they have broken. Send any other pictures that may also be appropriate.

2. I understand that they have broken around the ball mount - which end? Carriage or effector? Or is it consistently one end (ie close to the hex, or round hole)?

3. Rod assembly: Where the rods assembled correctly, with the laser cutter kerf angled outwards? This causes the hole through the rod to be a different size on each side of the rod. The rods should have the 'small hole' side in contact with the steel ball. Using the 'large hole' side may cause the rod to interfere with with the screw that the steel balls mount on. I don't particularly think, if it is broken at the ball mount, it's to do with overtightening the screw into the arm; more likely it is catching on something.

4. Was the effector moving at the time (either moved by hand or under power)? Could they have hit anything (eg cable tie holding wiring) or binding on the carriage or effector? Did you check the spacing between the outsides of the balls on carriage and effector (56mm)? Did you put extra washers in, when you assembled the carriage and effector parts, that would cause the arms to interfere with the carriages or effector?

6. Environment: Is the place you're building your printer particularly cold, possibly causing the acrylic to be more brittle than normal? Have the rods been dropped on a hard surface, that may have cracked them?

Any information you can give us will help!

bgkdavis - I think "Most of us have broken arms" is a bit of an overstatement. We would have been sending out hundreds of replacements, and we're not. Changing to other rods brings it's own problems (exotic materials, expense, multiple parts, getting the length and fit correct, etc) whereas if we can finally get to the bottom of how to produce them without breakage, there would be no need to go to these extremes. Our design aims to be accurate, easy to produce, simple to assemble, reliable and cheap!

Ian

RepRapPro tech support

We would really like to understand how they have broken. We haven't had any breakages in 6 weeks of testing! Please could you consider, and give me some feedback, on the following:

1. Please send me a picture showing how they have broken. Send any other pictures that may also be appropriate.

2. I understand that they have broken around the ball mount - which end? Carriage or effector? Or is it consistently one end (ie close to the hex, or round hole)?

3. Rod assembly: Where the rods assembled correctly, with the laser cutter kerf angled outwards? This causes the hole through the rod to be a different size on each side of the rod. The rods should have the 'small hole' side in contact with the steel ball. Using the 'large hole' side may cause the rod to interfere with with the screw that the steel balls mount on. I don't particularly think, if it is broken at the ball mount, it's to do with overtightening the screw into the arm; more likely it is catching on something.

4. Was the effector moving at the time (either moved by hand or under power)? Could they have hit anything (eg cable tie holding wiring) or binding on the carriage or effector? Did you check the spacing between the outsides of the balls on carriage and effector (56mm)? Did you put extra washers in, when you assembled the carriage and effector parts, that would cause the arms to interfere with the carriages or effector?

6. Environment: Is the place you're building your printer particularly cold, possibly causing the acrylic to be more brittle than normal? Have the rods been dropped on a hard surface, that may have cracked them?

Any information you can give us will help!

bgkdavis - I think "Most of us have broken arms" is a bit of an overstatement. We would have been sending out hundreds of replacements, and we're not. Changing to other rods brings it's own problems (exotic materials, expense, multiple parts, getting the length and fit correct, etc) whereas if we can finally get to the bottom of how to produce them without breakage, there would be no need to go to these extremes. Our design aims to be accurate, easy to produce, simple to assemble, reliable and cheap!

Ian

RepRapPro tech support

|

Re: Fisher 1 October 15, 2015 10:31AM |

Registered: 8 years ago Posts: 155 |

|

Re: Fisher 1 October 15, 2015 11:54AM |

Registered: 9 years ago Posts: 14 |

|

Re: Fisher 1 October 15, 2015 01:41PM |

Registered: 12 years ago Posts: 1,611 |

Extruder drive instructions are now published. Unfortunately, I've had to deal with other things today, so haven't finished the wiring instructions.

The wiring is assembled with the last side panel, but the wiring is very similar to the Fisher Beta instructions, so you can probably carry on with this. There are two slots to put the wiring looms through, rather than one, now.

The top plate pushes on the top of the rods. When you fit this, slacken off the motor bolts, and push them through the motor mounts, so the top plate sits flush with the top of the side panels. Then tighten the motor mounts, the side panel tops into the idler, and the top panel, which screws into the idler too. This will stop the idler being pulled down, bowing out the side panels, when you fit and tension the carriage belts. THEN fit the motor pulleys and the belt, in much the same way as the Fisher beta.

The bed probe wiring is the same as Fisher beta. The bed plate is slightly different: it uses 3 x M3x8mm button head screws, through a 3mm acrylic spacer (found on the extruder drive acrylic sheet), and self-taps into the bed. The tops of the button head screws sit on the horizontal contacts.

Commissioning is much the same as Fisher beta, though we will be releasing a new SD image. The homing from Fisher beta MAY cause the hot end to come very close to, or hit, the bed, as we've gained a little height, but also lost it. We're also going to reverse the motor wiring order for the X, Y and Z (just flip the motor connector on the pins), to bring the wire colour order in line with our other printers, so they can all share the same wiring looms.

Hopefully that will help you move on, and hopefully I'll have time tomorrow to edit the pictures, upload them, and write all the descriptions. I could rush this, but perfection takes a little longer...

Please email me, or post on the Fisher forum, any suggestions for improvements to the instructions.

Ian

RepRapPro tech support

The wiring is assembled with the last side panel, but the wiring is very similar to the Fisher Beta instructions, so you can probably carry on with this. There are two slots to put the wiring looms through, rather than one, now.

The top plate pushes on the top of the rods. When you fit this, slacken off the motor bolts, and push them through the motor mounts, so the top plate sits flush with the top of the side panels. Then tighten the motor mounts, the side panel tops into the idler, and the top panel, which screws into the idler too. This will stop the idler being pulled down, bowing out the side panels, when you fit and tension the carriage belts. THEN fit the motor pulleys and the belt, in much the same way as the Fisher beta.

The bed probe wiring is the same as Fisher beta. The bed plate is slightly different: it uses 3 x M3x8mm button head screws, through a 3mm acrylic spacer (found on the extruder drive acrylic sheet), and self-taps into the bed. The tops of the button head screws sit on the horizontal contacts.

Commissioning is much the same as Fisher beta, though we will be releasing a new SD image. The homing from Fisher beta MAY cause the hot end to come very close to, or hit, the bed, as we've gained a little height, but also lost it. We're also going to reverse the motor wiring order for the X, Y and Z (just flip the motor connector on the pins), to bring the wire colour order in line with our other printers, so they can all share the same wiring looms.

Hopefully that will help you move on, and hopefully I'll have time tomorrow to edit the pictures, upload them, and write all the descriptions. I could rush this, but perfection takes a little longer...

Please email me, or post on the Fisher forum, any suggestions for improvements to the instructions.

Ian

RepRapPro tech support

|

Re: Fisher 1 October 15, 2015 02:17PM |

Registered: 10 years ago Posts: 12 |

Hi again Droftarts,

I'm a bit busy at the minute, but I thought I would just post to let you know that I have read your post.

I will post pictures of the ones that I broke along with some pictures of the ones I have printed from thingiverse - by Ortwin.

The printed ones have some flex in them even though I printed with 100% infill.

I was thinking of doing a re-work of them with a 2mm channel - so that we can glue 2mm diameter solid carbon fibre rod in as a stiffener.

If I can get some new batteries for my calipers, I'll model them on the new design with the hex bulge.

I have also bought some carbon and traxxas rod ends to make up some carbon fibre ones as a make do thing.

Looking at the acrylic design, it seems to allow for a greater movement when compared to the traxxas rod ends.

Anyway, I'll be back later with some photos and explanations for you.

Ohh, BTW, Should I continue this on here or through email? Just a thought... on the one hand it might be useful for others to see, but a bit long winded for others..

Ian

I'm a bit busy at the minute, but I thought I would just post to let you know that I have read your post.

I will post pictures of the ones that I broke along with some pictures of the ones I have printed from thingiverse - by Ortwin.

The printed ones have some flex in them even though I printed with 100% infill.

I was thinking of doing a re-work of them with a 2mm channel - so that we can glue 2mm diameter solid carbon fibre rod in as a stiffener.

If I can get some new batteries for my calipers, I'll model them on the new design with the hex bulge.

I have also bought some carbon and traxxas rod ends to make up some carbon fibre ones as a make do thing.

Looking at the acrylic design, it seems to allow for a greater movement when compared to the traxxas rod ends.

Anyway, I'll be back later with some photos and explanations for you.

Ohh, BTW, Should I continue this on here or through email? Just a thought... on the one hand it might be useful for others to see, but a bit long winded for others..

Ian

|

Re: Fisher 1 October 15, 2015 07:46PM |

Registered: 10 years ago Posts: 12 |

Quote

droftarts

I have answered Ian separately by email:

We would really like to understand how they have broken. We haven't had any breakages in 6 weeks of testing! Please could you consider, and give me some feedback, on the following:

1. Please send me a picture showing how they have broken. Send any other pictures that may also be appropriate.

Pictures to follow in daylight.

2. I understand that they have broken around the ball mount - which end? Carriage or effector? Or is it consistently one end (ie close to the hex, or round hole)?

I had only got as far as assembling the carriages. I put the screw through until it just came to the outer edge, then carefully popped them over the ball and tightened by a turn or two on each rod. I then carried on building the effector, but heard a 'pinging' sound after about 10 - 15 mins - that was the arms breaking. the second set went within minutes of the first, then a final set went as I was looking on the forum.

3. Rod assembly: Where the rods assembled correctly, with the laser cutter kerf angled outwards? This causes the hole through the rod to be a different size on each side of the rod. The rods should have the 'small hole' side in contact with the steel ball. Using the 'large hole' side may cause the rod to interfere with with the screw that the steel balls mount on. I don't particularly think, if it is broken at the ball mount, it's to do with overtightening the screw into the arm; more likely it is catching on something.

I followed the instructions on the site ' sharp edges should go together'. I don't trust my eyes completely, so I was feeling for a sharp edge.

4. Was the effector moving at the time (either moved by hand or under power)? Could they have hit anything (eg cable tie holding wiring) or binding on the carriage or effector? Did you check the spacing between the outsides of the balls on carriage and effector (56mm)? Did you put extra washers in, when you assembled the carriage and effector parts, that would cause the arms to interfere with the carriages or effector?

The effector was not attached - I haven't got that far yet. It was just sitting on the bench waiting for the next parts to be fitted.

6. Environment: Is the place you're building your printer particularly cold, possibly causing the acrylic to be more brittle than normal? Have the rods been dropped on a hard surface, that may have cracked them?

Building in the living room - normal 18 - 22 centigrade. I don't recall dropping the arms at all. Just popped them out of the laser cut sheet and pulled the plastic sheet off, then stuck them together.

Any information you can give us will help!

bgkdavis - I think "Most of us have broken arms" is a bit of an overstatement. We would have been sending out hundreds of replacements, and we're not. Changing to other rods brings it's own problems (exotic materials, expense, multiple parts, getting the length and fit correct, etc) whereas if we can finally get to the bottom of how to produce them without breakage, there would be no need to go to these extremes. Our design aims to be accurate, easy to produce, simple to assemble, reliable and cheap!

With regards to this final quote, I can see that your arm design allows for a large degree of movement around the ball because the points of contact are top and bottom. There might be constraints in the range of movement with the traxxas style mount.

I use the traxxas style arms on both a 3DR and a mini Kossel without issue, but I think there is something to be gained from having the rods pivot about the top and bottom as opposed to the left and right sides.

Ian G

|

Re: Fisher 1 October 15, 2015 07:56PM |

Registered: 8 years ago Posts: 443 |

Maybe I misspoke by saying 'most of us', I wasn't implying most of RRP customers, just saying that broken arms (and acrylic parts in general) are common, and 'many' of us have moved on from the acrylic arms.

I fully appreciate why RRP use the acrylic, and it does show a certain ingenuity, as they are a simple and accurate method that efficiently uses waste material..........BUT, they are going to break......and that may not be a bad thing either, when mine broke I got a failed print tangled in the Effector and the machine tried to beat itself to death, which ended up breaking all the arms..... on the one hand the sacrificial breakage of the arms, may have saved me from a lot of other damage, on the other hand I suspect the initial print failure started with a broken arm and the rest was cascade failure.

BAD455

The freedom of movement issues concerned me too, and I looked at a lot of alternatives before settling on the Traxxas ball ends, it turns out they may have less freedom that the acrylic, but they do have plenty of freedom for the Fisher, building them is not for the impatient, but if you take time to build them accurately then you probably will never change them again

Your idea to make the arms using stiffened printed arms is interesting, it may solve a lot of the build accuracy issues, but rather than copy the acrylic arms design Id look at a one piece printed shaft stiffened with carbon, with maybe a screwed clamp at both ends to hold the balls have a look at these [forums.reprap.org] you may want to add a few places along the shaft to put cable ties that will help clamp the carbon and plastic together.

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

I fully appreciate why RRP use the acrylic, and it does show a certain ingenuity, as they are a simple and accurate method that efficiently uses waste material..........BUT, they are going to break......and that may not be a bad thing either, when mine broke I got a failed print tangled in the Effector and the machine tried to beat itself to death, which ended up breaking all the arms..... on the one hand the sacrificial breakage of the arms, may have saved me from a lot of other damage, on the other hand I suspect the initial print failure started with a broken arm and the rest was cascade failure.

BAD455

The freedom of movement issues concerned me too, and I looked at a lot of alternatives before settling on the Traxxas ball ends, it turns out they may have less freedom that the acrylic, but they do have plenty of freedom for the Fisher, building them is not for the impatient, but if you take time to build them accurately then you probably will never change them again

Your idea to make the arms using stiffened printed arms is interesting, it may solve a lot of the build accuracy issues, but rather than copy the acrylic arms design Id look at a one piece printed shaft stiffened with carbon, with maybe a screwed clamp at both ends to hold the balls have a look at these [forums.reprap.org] you may want to add a few places along the shaft to put cable ties that will help clamp the carbon and plastic together.

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

|

Re: Fisher 1 October 16, 2015 03:06AM |

Registered: 8 years ago Posts: 155 |

They must have been too tight. Mine have been fine, the ends of the bolts are just under flush with the top of the locknuts. This has worked fine on my machine for a couple of months now.

If you are going to upgrade to carbon rods then I would do it in the same style as the acrylic ones, cut them out of sheet. However they will need to be most of the thickness of the acrylic to be stiff enough.

If you are going to upgrade to carbon rods then I would do it in the same style as the acrylic ones, cut them out of sheet. However they will need to be most of the thickness of the acrylic to be stiff enough.

|

Re: Fisher 1 October 16, 2015 05:24AM |

Registered: 8 years ago Posts: 34 |

Quote

droftarts

I have answered Ian separately by email:

We would really like to understand how they have broken. We haven't had any breakages in 6 weeks of testing! Please could you consider, and give me some feedback, on the following:

1. Please send me a picture showing how they have broken. Send any other pictures that may also be appropriate.

2. I understand that they have broken around the ball mount - which end? Carriage or effector? Or is it consistently one end (ie close to the hex, or round hole)?

3. Rod assembly: Where the rods assembled correctly, with the laser cutter kerf angled outwards? This causes the hole through the rod to be a different size on each side of the rod. The rods should have the 'small hole' side in contact with the steel ball. Using the 'large hole' side may cause the rod to interfere with with the screw that the steel balls mount on. I don't particularly think, if it is broken at the ball mount, it's to do with overtightening the screw into the arm; more likely it is catching on something.

4. Was the effector moving at the time (either moved by hand or under power)? Could they have hit anything (eg cable tie holding wiring) or binding on the carriage or effector? Did you check the spacing between the outsides of the balls on carriage and effector (56mm)? Did you put extra washers in, when you assembled the carriage and effector parts, that would cause the arms to interfere with the carriages or effector?

6. Environment: Is the place you're building your printer particularly cold, possibly causing the acrylic to be more brittle than normal? Have the rods been dropped on a hard surface, that may have cracked them?

Any information you can give us will help!

bgkdavis - I think "Most of us have broken arms" is a bit of an overstatement. We would have been sending out hundreds of replacements, and we're not. Changing to other rods brings it's own problems (exotic materials, expense, multiple parts, getting the length and fit correct, etc) whereas if we can finally get to the bottom of how to produce them without breakage, there would be no need to go to these extremes. Our design aims to be accurate, easy to produce, simple to assemble, reliable and cheap!

Ian

RepRapPro tech support

We have the Beta kit and have broken several arms. You sent two by return under warranty (thank you) but since then another has snapped. Most broke around the ball-end but one has snapped across the hole for the bolt :-(

I am now in the process of making the carbon arms as per bgkdavis' suggestion. Pictures to follow in new thread :-)

|

Re: Fisher 1 October 16, 2015 01:13PM |

Registered: 8 years ago Posts: 82 |

|

Re: Fisher 1 October 16, 2015 03:10PM |

Registered: 8 years ago Posts: 155 |

|

Re: Fisher 1 October 16, 2015 05:37PM |

Registered: 8 years ago Posts: 443 |

Quote

Martoh

Droftarts, why did you put cap head screws for the effector balls ? The new effector is printed for hex head and then you don't need allen key.

I would guess that it came down to length consistency, if you have read my build of the fisher where I set the ball positions accurately, you may have noted my comment on the poor size consistency of the effector hex head screws compared to the carriges caphead screws.

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

|

Re: Fisher 1 October 16, 2015 09:42PM |

Registered: 10 years ago Posts: 12 |

Hi all,

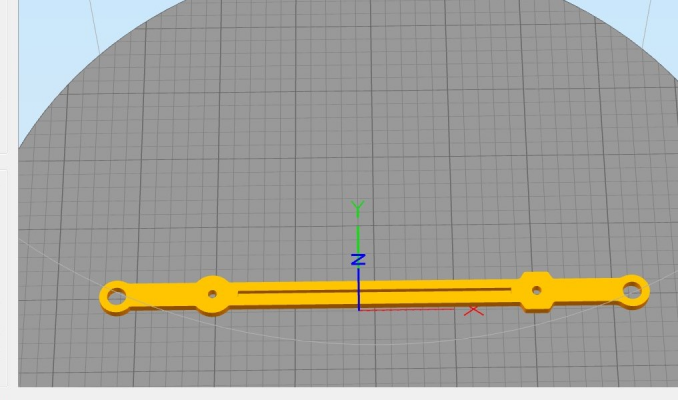

This is a quick picture of my proposed strengthening design for an emergency printed replacement arm for the fisher.

There is a 2mm wide, 2mm deep slot in the middle ready to accept a length of 2mm diameter carbon rod - super glued in place.

I have used the idea before when reinforcing model aeroplane wings made of polystyrene and it has given good results.

How it will perform on the printer remains to be seen.... I suspect it will be better than just PLA, but probably not as good as the original acrylic. If I get time, I will try to run some simulations with different materials to see how they compare.

Ideas / suggestions appreciated. It's easy enough to change things round.

Ian

Edited 2 time(s). Last edit at 10/16/2015 09:45PM by BAD455.

|

Re: Fisher 1 October 17, 2015 09:08AM |

Registered: 8 years ago Posts: 443 |

Hey BAD455

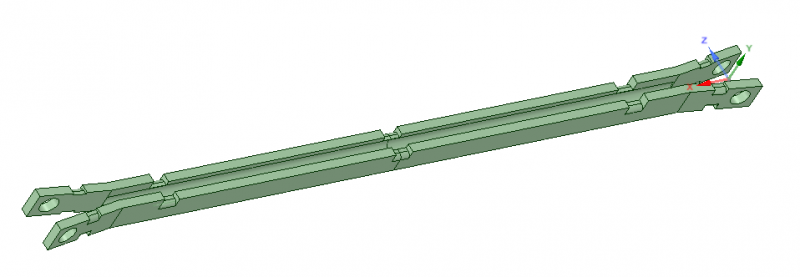

this is kinda what I had in mind for a printed carbon reinforced arm,this design is little more than a sketch, and I've no plans to test it, but I think it may make a good combination of a printed arm with carbon stiffness element

btw, the notches are for cable ties these should be able to hold the carbon element in place and also provide the clamping to hold the balls

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

this is kinda what I had in mind for a printed carbon reinforced arm,this design is little more than a sketch, and I've no plans to test it, but I think it may make a good combination of a printed arm with carbon stiffness element

btw, the notches are for cable ties these should be able to hold the carbon element in place and also provide the clamping to hold the balls

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

|

Re: Fisher 1 October 17, 2015 12:50PM |

Registered: 10 years ago Posts: 12 |

Hi BgkDavis,

Ooh, I like that!

If that's an I-beam section, It should be pretty strong anyway, even without the carbon reinforcement.

I'm not sure from the drawing, it could be 2 separate pieces with a carbon rod sandwich.

I'm electrical rather than mechanically biased - we think differently :-)

My inspiration is simply that at the moment, I am short of arms to get the printer working - even if only for testing / setup.

I don't want to make the carbons just yet because I have only got Traxxas ball joints which seem to be too small for the standard fisher balls. It would be a right pain to swap all of them over to get it working properly. I would like to keep it standard if I can.

Thanks for sharing, I will have a look if I can get some time on Solidworks and see if I can knock something up. I have got a length of 2mm carbon, so it might be the solution I'm looking for.

Have a great weekend - I'm working nights :-(

Ian

Ooh, I like that!

If that's an I-beam section, It should be pretty strong anyway, even without the carbon reinforcement.

I'm not sure from the drawing, it could be 2 separate pieces with a carbon rod sandwich.

I'm electrical rather than mechanically biased - we think differently :-)

My inspiration is simply that at the moment, I am short of arms to get the printer working - even if only for testing / setup.

I don't want to make the carbons just yet because I have only got Traxxas ball joints which seem to be too small for the standard fisher balls. It would be a right pain to swap all of them over to get it working properly. I would like to keep it standard if I can.

Thanks for sharing, I will have a look if I can get some time on Solidworks and see if I can knock something up. I have got a length of 2mm carbon, so it might be the solution I'm looking for.

Have a great weekend - I'm working nights :-(

Ian

|

Re: Fisher 1 October 17, 2015 05:14PM |

Registered: 8 years ago Posts: 443 |

I actually drew it as a U channel, but it would work as an I section

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

|

Re: Fisher 1 October 18, 2015 12:43AM |

Registered: 8 years ago Posts: 443 |

Ive put the files up here,[www.thingiverse.com] if you want to edit the source file then use DesignSpark from RS (its free)

Edited 1 time(s). Last edit at 10/18/2015 12:44AM by bgkdavis.

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

Edited 1 time(s). Last edit at 10/18/2015 12:44AM by bgkdavis.

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

|

Re: Fisher 1 October 18, 2015 03:34AM |

Registered: 9 years ago Posts: 1,159 |

How about having it with a square hole down the middle for the Carbon Fibre tube (Sq Section stuff would be good for this) then put a pause in the print at the point where to tube part is to be closed to allow for the Carbon tube to be inserted into the print you could even have the ends closed so that the CF then becomes captive as part of the arm.

Just an idea it would also mean no Cable ties or other fixings.

Doug

Just an idea it would also mean no Cable ties or other fixings.

Doug

|

Re: Fisher 1 October 18, 2015 03:51AM |

Registered: 8 years ago Posts: 443 |

Round section has the best omnidirectional strength, and I've got no problem with using cable ties, but feel free to make any changes you want, I actually prefer my original carbon arm design

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

|

Re: Fisher 1 October 19, 2015 03:33AM |

Registered: 9 years ago Posts: 14 |

Well, finish assembly of my Fisher 1, all went well, but has anyome worked out how the filament is supposed to route into the extruder drive, there is a small length of Bowden tubing supplied, but for the life on me i can't see an exit point in the frame, other that the slots in the lid.

Also the mains lead supplied with my Power unit was NBG, luckly I had a spare clover left mains cable I could use.

Just need the New SD image to be released to get it running, as i tried the beta SD image, but the new extruder drive is the other way round, so filament going the wrong way...

Also the mains lead supplied with my Power unit was NBG, luckly I had a spare clover left mains cable I could use.

Just need the New SD image to be released to get it running, as i tried the beta SD image, but the new extruder drive is the other way round, so filament going the wrong way...

|

Re: Fisher 1 October 19, 2015 03:47AM |

Registered: 10 years ago Posts: 14,672 |

Quote

wmacm00

Just need the New SD image to be released to get it running, as i tried the beta SD image, but the new extruder drive is the other way round, so filament going the wrong way...

See [forums.reprap.org].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Fisher 1 October 19, 2015 03:49AM |

Registered: 9 years ago Posts: 14 |

Sorry, only registered users may post in this forum.