S3D fail

Posted by Theolodian

|

S3D fail October 24, 2015 09:23AM |

Registered: 8 years ago Posts: 155 |

S3D has been great, except apparently it doesn't tell you the print won't fit on the bed and will crash your printer....it looks like it fits in S3D, stl window and gcode preview, no warnings, and then no warnings/errors in the Duet either so it crashes the printer. At least the only damage is the Buildtak as the belts just pop out.

|

Re: S3D fail October 24, 2015 11:26AM |

Registered: 10 years ago Posts: 14,672 |

By default, the firmware will not allow the head to go outside the bed radius, unless you override that with M564. What do you have the bed radius set to? It is the B parameter in the M665 command in config.g.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: S3D fail October 24, 2015 12:04PM |

Registered: 8 years ago Posts: 155 |

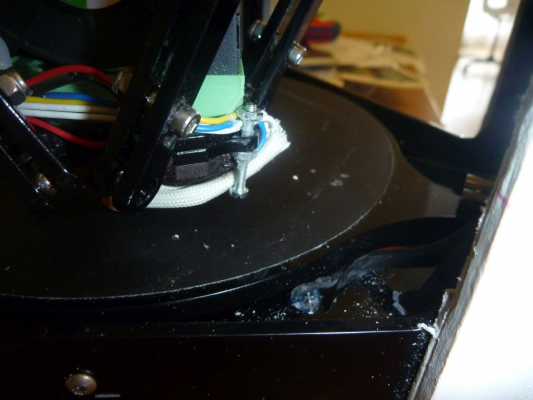

B75. It wasn't way out. Maybe I should drop that to B70 and try again. When you carefully measure the gcode preview in S3D it does look like it was trying to go outside 150mm.

However, where the nozzle crashed into the bed is exactly 10mm inside the Buildtak, which is 165mm diameter. So it really crashed at 145mm diameter. This is the tower where I had to route the cables all over the place so maybe I lost that 2.5mm of diameter there.

However, where the nozzle crashed into the bed is exactly 10mm inside the Buildtak, which is 165mm diameter. So it really crashed at 145mm diameter. This is the tower where I had to route the cables all over the place so maybe I lost that 2.5mm of diameter there.

|

Re: S3D fail October 24, 2015 03:07PM |

Registered: 8 years ago Posts: 155 |

|

Re: S3D fail October 24, 2015 03:46PM |

Registered: 8 years ago Posts: 155 |

Well, that was a challenging print. At 114mm long it curled up off the bed by 1mm at one end. It would have been right on 150mm diameter with the earlier skirt settings. I reduced those and it did print without crashing. However, even with on the eSun PLA that came with the Fisher the bed curvature and the PLA shrinkage both made an object of that dimension a marginal print. I should have run a larger H value to set Z0 higher due to the larger print.

Maybe unless you have your cable very tidy on the effector AND the tower then you can't really go to 150mm anyway. This print was 130mm including the skirt and it was close enough that I would worry a lot about 140mm. However, the part was 114mm and curled so the Fisher can still go larger than the PLA would seem to be happy about. Still twice as long as I ever got out of ABS on the Cupcake catastrophe so I'm not complaining just giving warning.

Maybe unless you have your cable very tidy on the effector AND the tower then you can't really go to 150mm anyway. This print was 130mm including the skirt and it was close enough that I would worry a lot about 140mm. However, the part was 114mm and curled so the Fisher can still go larger than the PLA would seem to be happy about. Still twice as long as I ever got out of ABS on the Cupcake catastrophe so I'm not complaining just giving warning.

|

Re: S3D fail October 24, 2015 03:57PM |

Registered: 8 years ago Posts: 155 |

To clarify on S3D, the virtual bed in the STL viewer and the gcode preview suggested there was PLENTY of extra room when I was actually at 150mm on the print so I didn't think that I would be that close to the limits of the Fisher. So I have an issue with S3D, I seem to have an issue with cables interfering at under 150mm (would vary by how the Fisher is built), and the Duet did not warn at 150mm - however I was not clearly over 150mm so may not have triggered that.

|

Re: S3D fail October 24, 2015 05:17PM |

Registered: 8 years ago Posts: 475 |

What I have done to limit the problem with the effector cable is to remove the zip-tie and use a bolt M2.5 as a locker. You shall take care not to have the head too low, on my first test, it was impacting bed supports.

For the cables, I think the best is to route them outside the printer.

For the Fisher 1.0, they have separated the route of the cables, but this was already the case on my Fisher Beta (following a building mistake), and anyway I experienced problems. Also: Zip tie 'knots' shall be outside the printer.

For the cables, I think the best is to route them outside the printer.

For the Fisher 1.0, they have separated the route of the cables, but this was already the case on my Fisher Beta (following a building mistake), and anyway I experienced problems. Also: Zip tie 'knots' shall be outside the printer.

|

Re: S3D fail October 25, 2015 04:24AM |

Registered: 8 years ago Posts: 155 |

|

Re: S3D fail October 26, 2015 04:22PM |

Registered: 8 years ago Posts: 155 |

The other problem that I forgot with S3D is that it doesn't put the skirt AROUND the supports. So if you have say a pumpkin shaped object, it puts the supports on top of the skirt which then causes the nozzle to crash into the part every layer because there is essentially an extra layer there. Thankfully on the Fisher this just means that the bed clacks around a lot but the print doesn't fail.

|

Re: S3D fail October 28, 2015 02:48PM |

Registered: 8 years ago Posts: 155 |

|

Re: S3D fail December 04, 2015 04:19AM |

Registered: 8 years ago Posts: 301 |

Just discovered too that S3D shows a larger print bed than the machine has, although after some googling I discovered that I had set the print bed size in S3D to 150x150 when in reality the software expects you to put in the largest square you can print inside the circle, so in my case 106mm.

more details from the S3D forum is anyone is interested - [forum.simplify3d.com]

Update -

It turns out that S3D only calculates the build volume as a square, so if you have your bed size correctly shown you wont be able to place objects to print outside the 106mm square or use auto arrange correctly - more details here - [forum.simplify3d.com]

For now I have created a short 150mm cylinder that i can drop into the project to see the parts are laid out OK, and I'll have to guess at whether the skirt/brim will fit too.

Edited 1 time(s). Last edit at 12/04/2015 05:32AM by DADIY.

more details from the S3D forum is anyone is interested - [forum.simplify3d.com]

Update -

It turns out that S3D only calculates the build volume as a square, so if you have your bed size correctly shown you wont be able to place objects to print outside the 106mm square or use auto arrange correctly - more details here - [forum.simplify3d.com]

For now I have created a short 150mm cylinder that i can drop into the project to see the parts are laid out OK, and I'll have to guess at whether the skirt/brim will fit too.

Edited 1 time(s). Last edit at 12/04/2015 05:32AM by DADIY.

Sorry, only registered users may post in this forum.