In time for Christmas?

Posted by Gmanx

|

In time for Christmas? November 22, 2015 09:05AM |

Registered: 8 years ago Posts: 26 |

I'm a little disappointed that the Fisher Delta 1.0 kit I ordered on Nov 5th has been delayed indefinitely due to RepRapPro being 'extremely busy'.

I fully understand how this can happen, especially if a product suddenly gains favour and the supplier has trouble fulfilling existing orders in good time.

However, RepRapPro are currently advertising pre-made units for delivery 'in time for Christmas'.

One would hope that looking after their current customers was more important than speculating on impulse purchases.

I fully understand how this can happen, especially if a product suddenly gains favour and the supplier has trouble fulfilling existing orders in good time.

However, RepRapPro are currently advertising pre-made units for delivery 'in time for Christmas'.

One would hope that looking after their current customers was more important than speculating on impulse purchases.

|

Re: In time for Christmas? November 26, 2015 04:48AM |

Registered: 8 years ago Posts: 26 |

I got a follow-up message from Sally at RepRapPro yesterday to say that my kit will be in the next batch shipped, hopefully early next week.

Good news!

I've used Denford 'Up', Cubex Trio, Da Vinci 1.0 and Nobel 1.0 printers professionally so I'm looking forward to seeing what I can achieve with a low-cost home-brew kit in my workshop.

Good news!

I've used Denford 'Up', Cubex Trio, Da Vinci 1.0 and Nobel 1.0 printers professionally so I'm looking forward to seeing what I can achieve with a low-cost home-brew kit in my workshop.

|

Re: In time for Christmas? December 03, 2015 02:17PM |

Registered: 8 years ago Posts: 26 |

Well, my printer arrived last night and seems to be all present and correct, hurrah!

I was hoping to have it build, calibrated and printing by now but I think I'll put off the build until I have more time at the Christmas break.

I was hoping to have it build, calibrated and printing by now but I think I'll put off the build until I have more time at the Christmas break.

|

Re: In time for Christmas? December 05, 2015 03:49PM |

Registered: 8 years ago Posts: 26 |

I just checked through my kit again (carefully) to make sure everything was as it should be and one of the bags has the wrong size screws in. D'oh!

The M3x16mm pack is full of 25mm screws. The length of these is crucial for the build - they are what hold the steel balls on the carriages and the effector. I'm not about to try sawing 9mm off all of these.

I contacted support, so hopefully they'll be able to get the correct ones out to me soon.

I think I'm going to build the kit now as opposed to doing it during the holidays - that way I'm prepared in case I run into any more build issues and I can hopefully just enjoy printing at Christmas.

Edited 2 time(s). Last edit at 12/05/2015 03:59PM by Gmanx.

The M3x16mm pack is full of 25mm screws. The length of these is crucial for the build - they are what hold the steel balls on the carriages and the effector. I'm not about to try sawing 9mm off all of these.

I contacted support, so hopefully they'll be able to get the correct ones out to me soon.

I think I'm going to build the kit now as opposed to doing it during the holidays - that way I'm prepared in case I run into any more build issues and I can hopefully just enjoy printing at Christmas.

Edited 2 time(s). Last edit at 12/05/2015 03:59PM by Gmanx.

|

Re: In time for Christmas? December 07, 2015 06:08AM |

Registered: 8 years ago Posts: 301 |

|

Re: In time for Christmas? December 07, 2015 11:52AM |

Registered: 8 years ago Posts: 26 |

Thanks DADIY - good advice. I bought a vernier caliper today to check those tolerances and I'll be sure to lock those sphere nuts tight!

I have to say, Sally and the RepRapPro support team have been very helpful today and have already sent me an email explaining what went wrong, and posted out a new pack of screws.

That's what I call support. Outstanding.

Edited 1 time(s). Last edit at 12/07/2015 12:21PM by Gmanx.

I have to say, Sally and the RepRapPro support team have been very helpful today and have already sent me an email explaining what went wrong, and posted out a new pack of screws.

That's what I call support. Outstanding.

Edited 1 time(s). Last edit at 12/07/2015 12:21PM by Gmanx.

|

Re: In time for Christmas? December 08, 2015 10:21AM |

Registered: 8 years ago Posts: 301 |

If you plan to build over Christmas I would recommend you order the carbon fiber rod and ends to replace the acrylic ones in the kit, they didn't last me 5 minutes and several other people on here recommend the upgrade. I also found it made the machine a little quieter too. If you get the mugen track rod ends they came in packs of 10 - sadly.

The buildtak is fairly fragile stuff so I'd recommend you get some painters tape and use that for a bit before you apply the buildtak. I tried lots of different tape and found that the 3m 2060 Hard-to-Stick Surfaces tape to be the best - its the green one.

The buildtak is fairly fragile stuff so I'd recommend you get some painters tape and use that for a bit before you apply the buildtak. I tried lots of different tape and found that the 3m 2060 Hard-to-Stick Surfaces tape to be the best - its the green one.

|

Re: In time for Christmas? December 15, 2015 05:10PM |

Registered: 8 years ago Posts: 26 |

Thanks again DADIY - I'll certainly be getting the carbon rod upgrade. I can understand though, why the lasercut pieces make commercial sense for RepRapPro.

In the meantime, the printer is built, commissioned and has printed it's first file - the Makerbot Robo included in the firmware.

[youtu.be]

The build went really smoothly. The instructions were very clear and the component quality is wonderful. Three snags I did come across:

1/ I took out the filament feed tube that goes into the feed mechanism - it was sending filament into the feed assembly at a funny angle stopping it from getting picked up by the hobbed bolt.

2/ One of the carriage arms kept popping off - I realised that it was hitting the ratchet on one of the cable ties, so I just spun that around out of the way.

3/ I forgot that the hot end (being hot) would melt into the bed (I'm using painter's tape - not the supplied Buildtak plate) so I have three very small dints in the bed plate. No biggie - I'll cover them with tape to keep the bed probing accurate.

All in all I'm very pleased with the kit. I love the fact that I can maintain it 100% having built it from the ground up.

In the meantime, the printer is built, commissioned and has printed it's first file - the Makerbot Robo included in the firmware.

[youtu.be]

The build went really smoothly. The instructions were very clear and the component quality is wonderful. Three snags I did come across:

1/ I took out the filament feed tube that goes into the feed mechanism - it was sending filament into the feed assembly at a funny angle stopping it from getting picked up by the hobbed bolt.

2/ One of the carriage arms kept popping off - I realised that it was hitting the ratchet on one of the cable ties, so I just spun that around out of the way.

3/ I forgot that the hot end (being hot) would melt into the bed (I'm using painter's tape - not the supplied Buildtak plate) so I have three very small dints in the bed plate. No biggie - I'll cover them with tape to keep the bed probing accurate.

All in all I'm very pleased with the kit. I love the fact that I can maintain it 100% having built it from the ground up.

|

Re: In time for Christmas? December 16, 2015 09:48AM |

Registered: 8 years ago Posts: 301 |

Pleased it went well.

I too have some spots on the bed from the hot end. Infact today I had a piece of glass cut to experiment with a flatter build service.

I found the arms starting cracking/breaking after 8 hours of use.

There's also an improved firmware from dc42 that might help improve reliability. Also Id recommend you look at the 6 point calibrations for bed.g.

One other tip, if you make the carbon ends with the mugen rod ends, You'll need to drill them out to fit then ends - I used 3mm carbon fibre rod and then make a little jig to hold them in place as a little air between rod/end epoxy will try to push them apart. I measured out 160mm in a scrap of wood and drilled two 5.5mm holes, and then inserted two 5.5mm drill bits upside down (smooth side inserted into wood) and then when they were glued I slid them over the drill and put a piece of grease proof paper between the rods to stop the glue sticking together.

Edited 1 time(s). Last edit at 12/16/2015 10:18AM by DADIY.

I too have some spots on the bed from the hot end. Infact today I had a piece of glass cut to experiment with a flatter build service.

I found the arms starting cracking/breaking after 8 hours of use.

There's also an improved firmware from dc42 that might help improve reliability. Also Id recommend you look at the 6 point calibrations for bed.g.

One other tip, if you make the carbon ends with the mugen rod ends, You'll need to drill them out to fit then ends - I used 3mm carbon fibre rod and then make a little jig to hold them in place as a little air between rod/end epoxy will try to push them apart. I measured out 160mm in a scrap of wood and drilled two 5.5mm holes, and then inserted two 5.5mm drill bits upside down (smooth side inserted into wood) and then when they were glued I slid them over the drill and put a piece of grease proof paper between the rods to stop the glue sticking together.

Edited 1 time(s). Last edit at 12/16/2015 10:18AM by DADIY.

|

Re: In time for Christmas? December 16, 2015 04:09PM |

Registered: 8 years ago Posts: 26 |

Great advice, DADIY - thanks!

I had an issue with the extruder sticking - turns out the brass collar on the end of the bowden tube was pinching too tightly, especially when I started to print and the tube was curling around as the hot end rises/falls.

I used a slightly bigger drill to ream out the end of the bowden tube, put back the brass collar and now it's good.

Also, the hobbed bolt tends to pop through the extruder drive housing too far (the bearing next to the lock-nut wants to pop fully through the printed housing). When this happens, the grooves in the hobbed bolt are mis-aligned with the filament feed apertures. I fond the only way to re-align the assembly is to take apart the bolt/bearings etc and start again.

I had an issue with the extruder sticking - turns out the brass collar on the end of the bowden tube was pinching too tightly, especially when I started to print and the tube was curling around as the hot end rises/falls.

I used a slightly bigger drill to ream out the end of the bowden tube, put back the brass collar and now it's good.

Also, the hobbed bolt tends to pop through the extruder drive housing too far (the bearing next to the lock-nut wants to pop fully through the printed housing). When this happens, the grooves in the hobbed bolt are mis-aligned with the filament feed apertures. I fond the only way to re-align the assembly is to take apart the bolt/bearings etc and start again.

|

Re: In time for Christmas? December 16, 2015 04:40PM |

Registered: 8 years ago Posts: 301 |

I found I need to print hotter than the filament guide. I suspect the thermistor isn't too accurate. I get the best results putting the first layer down at 220c and the rest between 205 and 210 depending on ambient temperature before I increased the temperature I had various extruder and nozzle issues.

I also found an eBay seller called 3form that have good pla at a great price. But they are 1kg rolls so needs a new spool holder.

I also found an eBay seller called 3form that have good pla at a great price. But they are 1kg rolls so needs a new spool holder.

|

Re: In time for Christmas? December 17, 2015 02:40AM |

Registered: 9 years ago Posts: 1,159 |

Quote

DADIY

I found I need to print hotter than the filament guide. I suspect the thermistor isn't too accurate. I get the best results putting the first layer down at 220c and the rest between 205 and 210 depending on ambient temperature before I increased the temperature I had various extruder and nozzle issues.

I also found an eBay seller called 3form that have good pla at a great price. But they are 1kg rolls so needs a new spool holder.

Try hobby king they do 0.5kG rolls of ESUN Pla same as you would have got with the printer for around £5 a roll (You may have to check the EU Warehouse tho as the UK one sells out very quickly) HobbyKing PLA

Doug

|

Re: In time for Christmas? December 24, 2015 01:17PM |

Registered: 8 years ago Posts: 26 |

Thanks for the recommendations!

I had a filament delivery issue - which I eventually worked out was a restriction in the hot end of the Bowden tube. I dis-assembled the hot end leaving just the radiator with Bowden tube screwed in and then drilled out the tube to 2mm. That did the job and I'm now happily printing away.

I had initially thought that the nozzle was jammed, perhaps with a chunk of PTFE swarf I'd missed. Given that, I ordered a replacement nozzle which Sally did as a special - and it arrived today! I really can't fault the service I've had from RepRapPro.

So, I now have a spare nozzle, just in case, which gives me peace of mind.

Edited 1 time(s). Last edit at 12/24/2015 01:17PM by Gmanx.

I had a filament delivery issue - which I eventually worked out was a restriction in the hot end of the Bowden tube. I dis-assembled the hot end leaving just the radiator with Bowden tube screwed in and then drilled out the tube to 2mm. That did the job and I'm now happily printing away.

I had initially thought that the nozzle was jammed, perhaps with a chunk of PTFE swarf I'd missed. Given that, I ordered a replacement nozzle which Sally did as a special - and it arrived today! I really can't fault the service I've had from RepRapPro.

So, I now have a spare nozzle, just in case, which gives me peace of mind.

Edited 1 time(s). Last edit at 12/24/2015 01:17PM by Gmanx.

|

Re: In time for Christmas? December 24, 2015 03:40PM |

Registered: 8 years ago Posts: 26 |

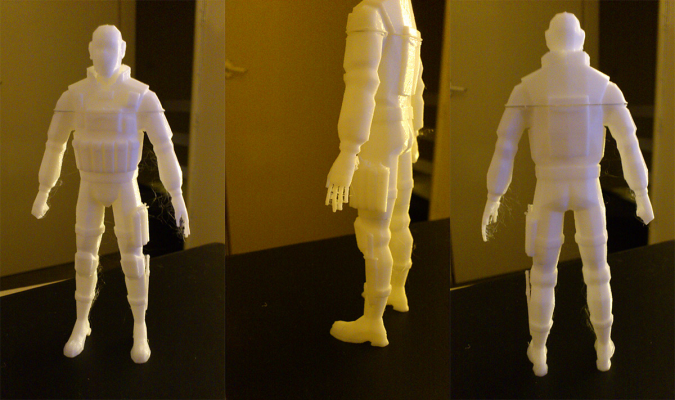

Just printed this little fella out. He's the first human character I modelled in Maya back in 2002 (I think) so I thought it only fitting that I make him real.

He's about 5.5 inches tall, printed in 3 parts with no support and held together (for now) with BluTack. I'm very happy with how he came out.

Edited 1 time(s). Last edit at 12/24/2015 03:53PM by Gmanx.

He's about 5.5 inches tall, printed in 3 parts with no support and held together (for now) with BluTack. I'm very happy with how he came out.

Edited 1 time(s). Last edit at 12/24/2015 03:53PM by Gmanx.

|

Re: In time for Christmas? December 26, 2015 08:24AM |

Registered: 8 years ago Posts: 26 |

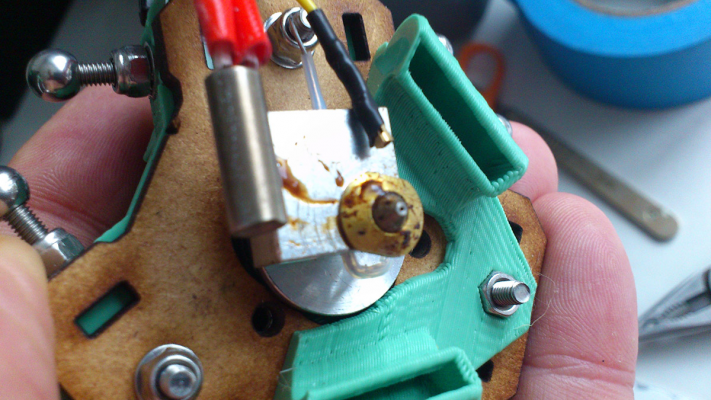

Anyone know what this brown deposit is on the hot end? Do I have the heat set too high (210) ? Is it anything to worry about? My prints have been turning out fine, so it's confusing.

|

Re: In time for Christmas? December 26, 2015 08:30AM |

Registered: 8 years ago Posts: 301 |

Mines the same as yours and is printing fine for about a month now. I guess it where the nozzle touches some filament like when the skirt curls a little in the first pass. I also print my first layers ar 220c - due to printing in a cold room, although it may just be the thermister being off a little.

|

Re: In time for Christmas? December 27, 2015 11:05AM |

Registered: 8 years ago Posts: 26 |

Thanks DADIY. I might have to get myself a probing thermometer to properly check my hot end temps and re-calibrate.

I've now managed to completely clog up two nozzles. That after a full day printing successfully. The prints were coming out beautifully too.

The hot end stopped feeding filament though the printer was still going through the process of moving the print head around. I tried with a new print and got about 10 minutes in, then the same happened again. After that, I couldn't get filament to flow whatever I tried.

I tried (stupidly, I now realise after some research) drilling out the blockage from the nozzle with small drills in my Dremel. I got most of the melted filament out and finished from the outside with a needle pushed into the .4mm hole. That worked, and I got filament flowing again - but only managed to extrude about 40mm before it clogged again.

When it clogs, I can hear the filament feeder clicking as it's trying to feed through. I've had blockages before and checked through right from the feeder, along the Bowden tube to the hot end and I now know that there's free passage all the way into the nozzle.

So, now I'm feeling a little frustrated. Can PLA set solid when over-heated? What I mean by that is that it sets and will not melt again. The residue inside the nozzle seemed VERY solid and difficult to drill out. Is there anything that I can soak the nozzle in to release the PLA? Will Acetone do it?

I'm going to step away from the printer for a couple of days and do some research. I can't afford to keep buying nozzles.

Edited 4 time(s). Last edit at 12/27/2015 11:14AM by Gmanx.

I've now managed to completely clog up two nozzles. That after a full day printing successfully. The prints were coming out beautifully too.

The hot end stopped feeding filament though the printer was still going through the process of moving the print head around. I tried with a new print and got about 10 minutes in, then the same happened again. After that, I couldn't get filament to flow whatever I tried.

I tried (stupidly, I now realise after some research) drilling out the blockage from the nozzle with small drills in my Dremel. I got most of the melted filament out and finished from the outside with a needle pushed into the .4mm hole. That worked, and I got filament flowing again - but only managed to extrude about 40mm before it clogged again.

When it clogs, I can hear the filament feeder clicking as it's trying to feed through. I've had blockages before and checked through right from the feeder, along the Bowden tube to the hot end and I now know that there's free passage all the way into the nozzle.

So, now I'm feeling a little frustrated. Can PLA set solid when over-heated? What I mean by that is that it sets and will not melt again. The residue inside the nozzle seemed VERY solid and difficult to drill out. Is there anything that I can soak the nozzle in to release the PLA? Will Acetone do it?

I'm going to step away from the printer for a couple of days and do some research. I can't afford to keep buying nozzles.

Edited 4 time(s). Last edit at 12/27/2015 11:14AM by Gmanx.

|

Re: In time for Christmas? December 27, 2015 02:31PM |

Registered: 8 years ago Posts: 10 |

|

Re: In time for Christmas? December 28, 2015 02:05PM |

Registered: 8 years ago Posts: 301 |

I had a couple of blockages before I cranked up the temp from the 190c stated. Usually I increase to about 250c whilst trying to push and retract. I've also used a pin to prick up the nozzle.

I tend to print the first layer at 220c and then drop to 205 when using pla. I got to these numbers through trial and error.

I tend to print the first layer at 220c and then drop to 205 when using pla. I got to these numbers through trial and error.

Sorry, only registered users may post in this forum.