Extruder motor struggles past nozzel

Posted by ByteSlinger

|

Extruder motor struggles past nozzel January 23, 2016 10:07AM |

Registered: 8 years ago Posts: 61 |

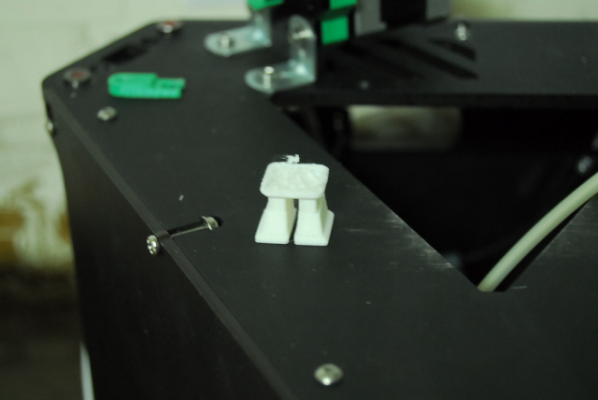

I finished my Fisher earlier this week and was VERY happy with the quality of the robot print I did as my first print.

However, today I plugged it in and went to print my second model. This time however, problems have struck!

The extruder motor is struggling, drastically!

With the motor powered off (and the hot end up to 190) I can extrude and retract by hand with absolutely no problems.

With the motor powered on and controlled by the GUI I can retract and extrude no problem.

However, as soon as the filament reaches the end of the nozzel, if I try and extrude any further, the motor just vibrates loudly, shaking the whole side of the printer.

Short of swapping out the filament I have literally changed nothing since printing my perfect robot.

What's going on and what on earth could have caused this?

However, today I plugged it in and went to print my second model. This time however, problems have struck!

The extruder motor is struggling, drastically!

With the motor powered off (and the hot end up to 190) I can extrude and retract by hand with absolutely no problems.

With the motor powered on and controlled by the GUI I can retract and extrude no problem.

However, as soon as the filament reaches the end of the nozzel, if I try and extrude any further, the motor just vibrates loudly, shaking the whole side of the printer.

Short of swapping out the filament I have literally changed nothing since printing my perfect robot.

What's going on and what on earth could have caused this?

|

Re: Extruder motor struggles past nozzel January 23, 2016 06:31PM |

Registered: 10 years ago Posts: 14,672 |

One possibility is that you have a partially failed driver chip such that one of the two motor phases can only be energised in one direction. One way to test this is to swap the extruder motor cable with one of the tower motor cabless (with the power off!) and use the M569 command to swap them in firmware too. See if that moves the problem to the tower that you switched the extruder motor with.

However, there is probably a simpler explanation, so let's see what suggestions other users come up with.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

However, there is probably a simpler explanation, so let's see what suggestions other users come up with.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Extruder motor struggles past nozzel January 24, 2016 04:39AM |

Registered: 9 years ago Posts: 1,159 |

Didn't the design of the extruder change from the Beta to the Released Version Check that you had the parts for the release version printed and not the Beta ones

Byteslinger AFAIK got the very last Fisher hardware kit and had to source the printed parts separately so this is a possibility

Doug

Edited 1 time(s). Last edit at 01/24/2016 04:40AM by dougal1957.

Byteslinger AFAIK got the very last Fisher hardware kit and had to source the printed parts separately so this is a possibility

Doug

Edited 1 time(s). Last edit at 01/24/2016 04:40AM by dougal1957.

|

Re: Extruder motor struggles past nozzel January 24, 2016 05:35AM |

Registered: 8 years ago Posts: 61 |

Quote

dc42

One possibility is that you have a partially failed driver chip such that one of the two motor phases can only be energised in one direction. One way to test this is to swap the extruder motor cable with one of the tower motor cabless (with the power off!) and use the M569 command to swap them in firmware too. See if that moves the problem to the tower that you switched the extruder motor with.

However, there is probably a simpler explanation, so let's see what suggestions other users come up with.

I really hope this isn't the case

I'll try and give this a try today. Apologies but how exactly do I use the M569 command to swap them in the firmware?

Quote

dougal1957

Didn't the design of the extruder change from the Beta to the Released Version Check that you had the parts for the release version printed and not the Beta ones

Byteslinger AFAIK got the very last Fisher hardware kit and had to source the printed parts separately so this is a possibility

Good thinking but yes I definitely have the latest design. It's the geared extruder motor block that this one is running.

|

Re: Extruder motor struggles past nozzel January 24, 2016 07:28AM |

Registered: 9 years ago Posts: 1,159 |

Quote

ByteSlinger

Quote

dc42

One possibility is that you have a partially failed driver chip such that one of the two motor phases can only be energised in one direction. One way to test this is to swap the extruder motor cable with one of the tower motor cabless (with the power off!) and use the M569 command to swap them in firmware too. See if that moves the problem to the tower that you switched the extruder motor with.

However, there is probably a simpler explanation, so let's see what suggestions other users come up with.

I really hope this isn't the case

I'll try and give this a try today. Apologies but how exactly do I use the M569 command to swap them in the firmware?

Quote

dougal1957

Didn't the design of the extruder change from the Beta to the Released Version Check that you had the parts for the release version printed and not the Beta ones

Byteslinger AFAIK got the very last Fisher hardware kit and had to source the printed parts separately so this is a possibility

Good thinking but yes I definitely have the latest design. It's the geared extruder motor block that this one is running.

Just realised that you have changed filament at the time this started Filaments are not all the same I would try with a hotter hotend than 190 (Esun which is what RRP supplied does work at around 190 some others may go as high as 220 or so.

|

Re: Extruder motor struggles past nozzel January 24, 2016 10:13AM |

Registered: 8 years ago Posts: 61 |

Quote

dougal1957

Quote

ByteSlinger

Quote

dc42

One possibility is that you have a partially failed driver chip such that one of the two motor phases can only be energised in one direction. One way to test this is to swap the extruder motor cable with one of the tower motor cabless (with the power off!) and use the M569 command to swap them in firmware too. See if that moves the problem to the tower that you switched the extruder motor with.

However, there is probably a simpler explanation, so let's see what suggestions other users come up with.

I really hope this isn't the case

I'll try and give this a try today. Apologies but how exactly do I use the M569 command to swap them in the firmware?

Quote

dougal1957

Didn't the design of the extruder change from the Beta to the Released Version Check that you had the parts for the release version printed and not the Beta ones

Byteslinger AFAIK got the very last Fisher hardware kit and had to source the printed parts separately so this is a possibility

Good thinking but yes I definitely have the latest design. It's the geared extruder motor block that this one is running.

Just realised that you have changed filament at the time this started Filaments are not all the same I would try with a hotter hotend than 190 (Esun which is what RRP supplied does work at around 190 some others may go as high as 220 or so.

Great shout! Will try this in the next hour and get right back to you!

|

Re: Extruder motor struggles past nozzel January 24, 2016 11:19AM |

Registered: 8 years ago Posts: 61 |

|

Re: Extruder motor struggles past nozzel January 25, 2016 05:15AM |

Registered: 8 years ago Posts: 301 |

Are you trying to extrude too much, you might need to set the extrude amount down to 1 or 5 if you're any higher then the motor can struggle. Also try increasing the temperature a little 190 may be a little low depending on the filament your using.

DC42 Kossel 330mm x 2meters

My Thingiverse Creations

DC42 Kossel 330mm x 2meters

My Thingiverse Creations

|

Re: Extruder motor struggles past nozzel January 25, 2016 02:06PM |

Registered: 8 years ago Posts: 475 |

Printing well the robot may be a false signal, because it is made to print well, even if its is a bit challenging for cooling.

What occurs frequently while starting a machine is that the filament doesn't slide well at the inlet or outlet of the bowden tube, because the cleaning with a bit was not sufficient of because the bowden is screwed with too much torque, which reduce its internal diameter, as PTFE is quite 'soft'.

So you may try:

- Sligthly unscrew the brass end on extruder side

- Sligthly unscrew on hotend side. I systematically unscrew by a half turn after screwing on the hotend

Also, the extruder tensioner shall not be abusively tightened. If the filament don't slip that ok. However, the motor shall skip steps while there is a blockage, but not grind the filament.

Edited 1 time(s). Last edit at 01/25/2016 02:06PM by PRZ.

What occurs frequently while starting a machine is that the filament doesn't slide well at the inlet or outlet of the bowden tube, because the cleaning with a bit was not sufficient of because the bowden is screwed with too much torque, which reduce its internal diameter, as PTFE is quite 'soft'.

So you may try:

- Sligthly unscrew the brass end on extruder side

- Sligthly unscrew on hotend side. I systematically unscrew by a half turn after screwing on the hotend

Also, the extruder tensioner shall not be abusively tightened. If the filament don't slip that ok. However, the motor shall skip steps while there is a blockage, but not grind the filament.

Edited 1 time(s). Last edit at 01/25/2016 02:06PM by PRZ.

|

Re: Extruder motor struggles past nozzel January 25, 2016 09:15PM |

Registered: 8 years ago Posts: 9 |

I'm having a very similar issue. As soon as I start to print or extrude anything my extruder starts slipping incredibly easily, yet it functions fine feeding it through the Bowden tube even at 60mm/s.

The problems occur when it reaches the hotend, and the extruder just slips and won't extrude much if at all.

The problems occur when it reaches the hotend, and the extruder just slips and won't extrude much if at all.

|

Re: Extruder motor struggles past nozzel January 28, 2016 08:15AM |

Registered: 8 years ago Posts: 61 |

Quote

DADIY

Are you trying to extrude too much, you might need to set the extrude amount down to 1 or 5 if you're any higher then the motor can struggle. Also try increasing the temperature a little 190 may be a little low depending on the filament your using.

Nope, definitely not trying to extrude too much. Tried every combination of speed and amount and makes no difference I'm afraid.

As for temperature, was originally printing at 190 but tried taking it all the way up to 220 and still no difference.

Quote

PRZ

Printing well the robot may be a false signal, because it is made to print well, even if its is a bit challenging for cooling.

What occurs frequently while starting a machine is that the filament doesn't slide well at the inlet or outlet of the bowden tube, because the cleaning with a bit was not sufficient of because the bowden is screwed with too much torque, which reduce its internal diameter, as PTFE is quite 'soft'.

So you may try:

- Sligthly unscrew the brass end on extruder side

- Sligthly unscrew on hotend side. I systematically unscrew by a half turn after screwing on the hotend

Also, the extruder tensioner shall not be abusively tightened. If the filament don't slip that ok. However, the motor shall skip steps while there is a blockage, but not grind the filament.

I know what you mean about the robot being designed to print well, but I don't think that should have an impact on this particular issue. If I was able to print right now, but badly, then perhaps it could be a factor, but the fact that I can't even just extrude right now even when not printing leads me to believe that it's a more serious issue than just the way the model was sliced and subsequent G-Code.

Equally with the impact of the bowden tube tightening down on the filament, I'm just not sure why this would suddenly start happening as it was fine before. However, with this new motor arriving this week, if that doesn't solve the problem, I may take apart my hotend to get to this and take a look.

Same with the hot end being too tight, this is a likely issue mine has so I will address this but I don't think it could be what's causing the actual issue as I haven't tightened it any more since my initial print.

With mine it's not so much that the extruder is slipping, but the motor actually struggles to push. If I watch the manual knob on the end of the extruder motor column, it turns fine and smoothly till it reaches the hot end, then it basically just sits static and shakes (occasionally with a little jump/jerk forward).Quote

FragrantParrot

I'm having a very similar issue. As soon as I start to print or extrude anything my extruder starts slipping incredibly easily, yet it functions fine feeding it through the Bowden tube even at 60mm/s.

The problems occur when it reaches the hotend, and the extruder just slips and won't extrude much if at all.

|

Re: Extruder motor struggles past nozzel January 30, 2016 06:13PM |

Registered: 8 years ago Posts: 61 |

|

Re: Extruder motor struggles past nozzel January 30, 2016 07:38PM |

Registered: 8 years ago Posts: 61 |

OK, after just one print the issue has returned.

I'm now thinking it could actually be something to do with the Idler Lever

Any ideas? Is it known to be a bad design on this printer? If so, are there any recommended fixes/solutions?

Edited 1 time(s). Last edit at 01/30/2016 08:02PM by ByteSlinger.

I'm now thinking it could actually be something to do with the Idler Lever

Any ideas? Is it known to be a bad design on this printer? If so, are there any recommended fixes/solutions?

Edited 1 time(s). Last edit at 01/30/2016 08:02PM by ByteSlinger.

|

Re: Extruder motor struggles past nozzel February 08, 2016 05:32AM |

Registered: 9 years ago Posts: 1,159 |

This is a video showing the issue (Op Posted this on another forum we both belong to) so any advise would be gratefully received.

It looks to me like there is an issue with the Hotend/Bowden somewhere but don't know where

Fisher extruder issue

TIA this issue is driving us nuts trying to get to the bottom of it (Op has tried increasing motor current and temps to no avail)

Doug

It looks to me like there is an issue with the Hotend/Bowden somewhere but don't know where

Fisher extruder issue

TIA this issue is driving us nuts trying to get to the bottom of it (Op has tried increasing motor current and temps to no avail)

Doug

|

Re: Extruder motor struggles past nozzel February 08, 2016 09:38AM |

Registered: 8 years ago Posts: 301 |

You seem to have a lot more plastic being extruded than I do on my fisher which makes me wonder if you are over extruding. If I use the extrude button too much then my motor will crunch when too much pressure of filament builds up, the side affect of over extrusion is that you can clog up the extruder.

Just as a thought, have you got your steps per mm set correctly in config.g - you should have this line by default that sets this.

M92 E310 ; Set to 137 for direct drive. Set extruder steps per mm

Also in your slicer are you using the defaults. 1.73mm filament and 95% extruder. Also in the web interface I assume you have extruder at 100%.

If all of those things check out I would be inclined to extract the filament and dismantle the hot end. You can probable cheat this by cutting the cable ties by the fan and removing the two screws from the bottom, the hot end should push through and then unscrew the heat sink so that you can visually see if everything is clear. Also whilst you have the bowden tube disconnected you can slide some filament through and feel for anything snagging.

DC42 Kossel 330mm x 2meters

My Thingiverse Creations

Just as a thought, have you got your steps per mm set correctly in config.g - you should have this line by default that sets this.

M92 E310 ; Set to 137 for direct drive. Set extruder steps per mm

Also in your slicer are you using the defaults. 1.73mm filament and 95% extruder. Also in the web interface I assume you have extruder at 100%.

If all of those things check out I would be inclined to extract the filament and dismantle the hot end. You can probable cheat this by cutting the cable ties by the fan and removing the two screws from the bottom, the hot end should push through and then unscrew the heat sink so that you can visually see if everything is clear. Also whilst you have the bowden tube disconnected you can slide some filament through and feel for anything snagging.

DC42 Kossel 330mm x 2meters

My Thingiverse Creations

|

Re: Extruder motor struggles past nozzel March 10, 2016 10:24AM |

Registered: 8 years ago Posts: 61 |

Quote

DADIY

You seem to have a lot more plastic being extruded than I do on my fisher which makes me wonder if you are over extruding. If I use the extrude button too much then my motor will crunch when too much pressure of filament builds up, the side affect of over extrusion is that you can clog up the extruder.

I've just checked and it's extruding perfectly to the mm (Just to check, the mm that you are extruding is the amount of filament it is pulling in, not the length it's pushing out correct?).

Quote

DADIY

Just as a thought, have you got your steps per mm set correctly in config.g - you should have this line by default that sets this.

M92 E310 ; Set to 137 for direct drive. Set extruder steps per mm

Also in your slicer are you using the defaults. 1.73mm filament and 95% extruder. Also in the web interface I assume you have extruder at 100%.

Yup, definitely got that line in my config, though I'm not using the 1.73mm filament default as it's more like 1.68mm in reality. Do you think that could be it?

Quote

DADIY

If all of those things check out I would be inclined to extract the filament and dismantle the hot end. You can probable cheat this by cutting the cable ties by the fan and removing the two screws from the bottom, the hot end should push through and then unscrew the heat sink so that you can visually see if everything is clear. Also whilst you have the bowden tube disconnected you can slide some filament through and feel for anything snagging.

I've not dismantled the hot end 3 times and completely replaced the nozzel twice.

I really am at a major loss here!

I have so many things waiting on me having this thing functioning and after three months of half finished prints, but I don't have the time to continue failing at getting this thing running or the money to replace it.

Any last suggestions would be very appreciated!

Symptoms:

- 9 times out of 10 struggles to extrude past the nozzel (Extrudes fine up to that point then the extruder starts to make struggling noises and wares down the filament)

- When it does extrude ok and a print is started, 15-25 minutes into an absolutely PERFECT print, it just stops extruding (the top layer looks a little fluffy)

- When retracting the filament right out after a failed print or it struggling to extrude, the end of the filament looks swollen

Solutions tried:

- Tried multiple filaments from different brands

- Tried increasing and decreasing motor currents

- Cleaning nozzel

- Replacing nozzel (twice)

- Dismantling the hotend and re-building (twice)

- Replacing extruder motor

- Varying hot end temperature all the way from 190 to 220

- Slowed print speed

- Checking extrusion speed (it's pulling the exact amount of filament in as it should)

DC42, a few people have suggested that I speak to you if no solutions come up here. Apparently you are not too far from me in Bristol? Do you think this is something you'd be willing to take a look at if all else fails and I were to bring it to you?

Edited 1 time(s). Last edit at 03/10/2016 10:25AM by ByteSlinger.

|

Re: Extruder motor struggles past nozzel March 10, 2016 09:05PM |

Registered: 9 years ago Posts: 189 |

I experienced jamming of filament in Fisher yesterday after relocating the extruder with longer Bowden tube.

Whenever the pushing force of extruder becomes weaker than resistance force inside the Bowden tube during printing, the hobbed gear start grinding the filament as you see below. No more advancement of filament.

The tip of filament inside heat sink is expanded due to the heat. It prevents retraction.

Failed printing.

Whenever the pushing force of extruder becomes weaker than resistance force inside the Bowden tube during printing, the hobbed gear start grinding the filament as you see below. No more advancement of filament.

The tip of filament inside heat sink is expanded due to the heat. It prevents retraction.

Failed printing.

|

Re: Extruder motor struggles past nozzel March 10, 2016 09:08PM |

Registered: 8 years ago Posts: 9 |

|

Re: Extruder motor struggles past nozzel March 11, 2016 04:41AM |

Registered: 8 years ago Posts: 61 |

|

Re: Extruder motor struggles past nozzel March 11, 2016 06:28AM |

Registered: 10 years ago Posts: 14,672 |

Quote

ByteSlinger

[[b]DC42[/b], a few people have suggested that I speak to you if no solutions come up here. Apparently you are not too far from me in Bristol? Do you think this is something you'd be willing to take a look at if all else fails and I were to bring it to you?

I'm near Langport, Somerset so that is a possibility.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Extruder motor struggles past nozzel March 16, 2016 07:30AM |

Registered: 8 years ago Posts: 20 |

|

Re: Extruder motor struggles past nozzel March 20, 2016 08:13AM |

Registered: 8 years ago Posts: 61 |

For anyone who hasn't seen in the other thread "Motor skipping Steps", I spent Saturday afternoon at DC42's as he very kindly spent his time looking over my Fisher and eventually getting it working.

Here's a breakdown of the steps he took (quoted from the other thread):

Thanks again Dave!

Edited 1 time(s). Last edit at 03/20/2016 08:13AM by ByteSlinger.

Here's a breakdown of the steps he took (quoted from the other thread):

Quote

dc42

I helped someone else with a similar problem this afternoon. These are the steps we took:

1. The original filament (supplied with the machine I am told) didn't extrude cleanly, but formed a glob attached to the nozzle. We switched to a roll of eSun PLA I had.

2. Dismantled the hot end, unscrewed the nozzle from the heatsink, then screwed it back in but with thermal transfer compound on the nozzle threads this time.

3. Reassembled the hot end without the Bowden tube. Checked that we could push filament through the hot end when it was hot.

4. With the Bowden tube connected, the extruder drive could mostly extrude into free air at 5mm/sec, but occasionally skipped steps. We increased the motor current to 1200mA and the temperature to 210C, then it skipped steps only very occasionally.

5. With power off, swapped the E0 and X motor cables over on the Duet, then tested the printer after sending M569 commands to account for the swap. This was to check that there wasn't a fault on the E0 driver chip.

6. After experiencing a period of time when the extruder motor just vibrated instead of moving, checked all the connections in the extruder motor cable and re-made some.

[EDIT] 6a. Did several cycles of heat to 200C, extrude, cool to 100C, retract filament completely and cut off the end, to remove any foreign matter from the nozzle.

7. Did a 35 minute test print, initially at 1200mA current and 210C. It went well (no skipped steps noticed), so part way through we dropped the temperature to 205C. It continued to print well.

My conclusion is that the Fisher 1.0 extruder is slightly under-powered. It would be better with a higher torque motor or increased gearing. It's OK at 50mm/sec print speed, but can't consistently manage the ~5mm/sec rate needed for 100mm/sec print speed.

Thanks again Dave!

Edited 1 time(s). Last edit at 03/20/2016 08:13AM by ByteSlinger.

Sorry, only registered users may post in this forum.