Effector for E3D v6

Posted by jmg123

|

Effector for E3D v6 January 31, 2016 08:19AM |

Registered: 8 years ago Posts: 40 |

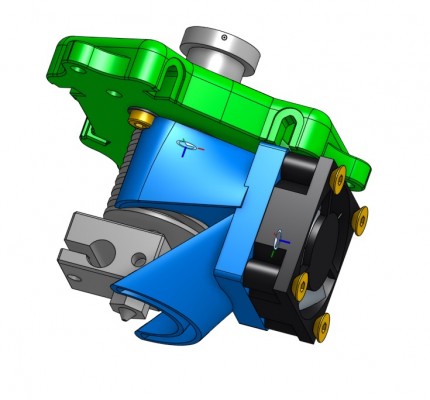

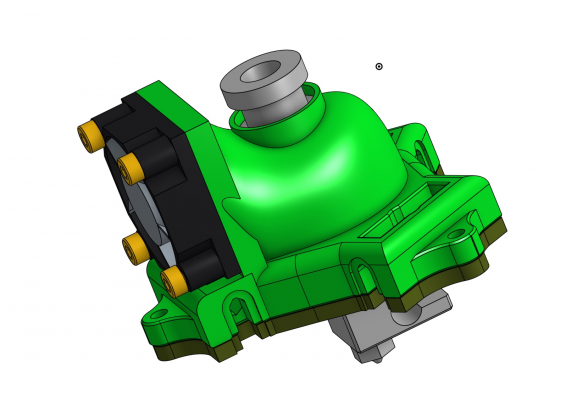

With the sad demise of RepRapPro, and the uncertainty of the long term future sources of Fisher nozzles, I decided to design a new effector fan assembly that would work with E3D v6 (not lite) in Onshape . The files are public so anyone can copy or remix them.

The E3D v6 has a longer, and wider heatsink than the original Fisher one, so none of the original effector parts can really be used (including the mdf). I therefore decided to go for a fully 3D printed effector and fan covering, The size of the heatsink also meant there wasn't really a way to include the original fan from the fisher, so instead I am using a 30mm 24v one.

The heatsink is held in place by three bolts with 6 washers, one each for top and bottom. they grip fine, but I reckon there is scope for moving them inwards by ~0.3mm .

My current prototype is printed in PETG with a glass transition of 70C, I've got a thermal imaging camera on order, to see if the heatsink around the area of the fan duct can get higher than this, hopefully it should be ok, otherwise it'll have to be printed in ABS.

I reckon that there is a chance than a couple of mm of build area horizontally and around 18mm vertically, will be lost, as the fan sticks out slightly more than the effector plate, currently my Fisher is halfway through an upgrade from Acrylic/PLA Fisher beta, to a Fisher 1.0 with Polycarbonate/ABS and support for triple extruders.

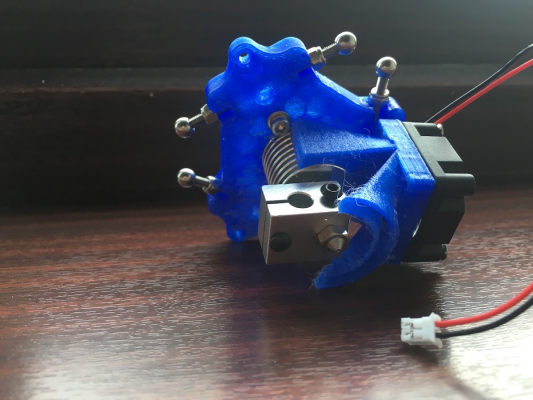

The pictures are of my prototype, with a cheap e3d v6 clone, as I didn't want to damage my real one whilst designing/measuring/prototyping.

Once this is working on my fisher I will start work on a multi extruder, can't currently decide between the e3d chimera , cyclops, or a diamond hot end. The diamond's three extruders seems like overkill, but would be easy to mount, and would possibly lose less space, Designing for the other two would be quicker, but more space would be lost. Maybe I'll just machine myself some fisher XT panels, and do both

The E3D v6 has a longer, and wider heatsink than the original Fisher one, so none of the original effector parts can really be used (including the mdf). I therefore decided to go for a fully 3D printed effector and fan covering, The size of the heatsink also meant there wasn't really a way to include the original fan from the fisher, so instead I am using a 30mm 24v one.

The heatsink is held in place by three bolts with 6 washers, one each for top and bottom. they grip fine, but I reckon there is scope for moving them inwards by ~0.3mm .

My current prototype is printed in PETG with a glass transition of 70C, I've got a thermal imaging camera on order, to see if the heatsink around the area of the fan duct can get higher than this, hopefully it should be ok, otherwise it'll have to be printed in ABS.

I reckon that there is a chance than a couple of mm of build area horizontally and around 18mm vertically, will be lost, as the fan sticks out slightly more than the effector plate, currently my Fisher is halfway through an upgrade from Acrylic/PLA Fisher beta, to a Fisher 1.0 with Polycarbonate/ABS and support for triple extruders.

The pictures are of my prototype, with a cheap e3d v6 clone, as I didn't want to damage my real one whilst designing/measuring/prototyping.

Once this is working on my fisher I will start work on a multi extruder, can't currently decide between the e3d chimera , cyclops, or a diamond hot end. The diamond's three extruders seems like overkill, but would be easy to mount, and would possibly lose less space, Designing for the other two would be quicker, but more space would be lost. Maybe I'll just machine myself some fisher XT panels, and do both

|

Re: Effector for E3D v6 January 31, 2016 09:32AM |

Registered: 10 years ago Posts: 14,672 |

On a delta, it's very hard to completely eliminate varying effector tilt as the head translates in the XY plane. As a result, multiple nozzle configurations can be problematic, because the two nozzles don't stay at exactly the same height. So I suggest the Cyclops or the Diamond.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Effector for E3D v6 January 31, 2016 10:39AM |

Registered: 8 years ago Posts: 40 |

Good point, hadn't thought about how much the effector would tilt. In that case I'll go for the diamond, as the only real benefit to the other was that the chimera/cyclops are hot swappable with the same heatsink. Price wise they are pretty similar £108 for the cyclops, and £103 for the diamond with e3dv6 lite heatsinks or £149 with e3dv6 heatsinks

|

Re: Effector for E3D v6 January 31, 2016 10:45AM |

Registered: 10 years ago Posts: 14,672 |

Quote

jmg123

Good point, hadn't thought about how much the effector would tilt. In that case I'll go for the diamond, as the only real benefit to the other was that the chimera/cyclops are hot swappable with the same heatsink. Price wise they are pretty similar £108 for the cyclops, and £103 for the diamond with e3dv6 lite heatsinks or £149 with e3dv6 heatsinks

The e3d lite heatsinks are stainless steel instead of aluminium, so much heavier than the e3dv6 ones and not really suitable for a delta.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Effector for E3D v6 January 31, 2016 05:44PM |

Registered: 8 years ago Posts: 40 |

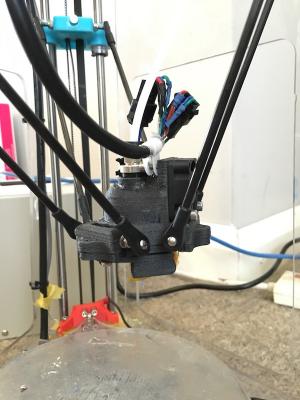

I mounted it on my old fisher beta, to check how much space is lost, the height needs 20mm taking of, and the radius needs 5mm taking off, so the config.g needs changing to this:

I reckon if I cut about 2mm off the bottom of the cooler, then no printable radius will need to be lost which is a bonus.

Just for curiosity sake after I measured the the clearances, I decided to see how good/bad the cheap E3Dv6 clone was and the answer is terrible! The thermistor that came with it was pretty similar to the stock fisher thermistor, readings were very close on both, but the clone thermistor cuts out at 175 Degrees, so not particularly useful for actually extruding anything! After a quick swap over to an original fisher thermistor I tried again, but the heat block took around 10 minutes to get up to temperature so who knows whether the heat cartridge is damaged, or not actually the 24V 40 W as advertised. To top it all off, the head of screw that holds the heat cartridge in disintegrated when I tried to untighten it after the test.

Luckily none of that bothers me, as my Fisher has an official E3D v6 to go in there when I have finished all my upgrades to 1.0 + a few other improvements.. You definitely get what you pay for with the cheap clones that include 24v cartridge , thermistor, fan, bowden tube + fittings, nozzle heat block heat sink and free shipping all for £5.98 - corners have to be cut somewhere, and it is better to support the original designers.

Edited 1 time(s). Last edit at 01/31/2016 05:47PM by jmg123.

M665 R75.0 L160.0 B75 H160.0 ; set delta radius, diagonal rod length, printable radius and homed height

I reckon if I cut about 2mm off the bottom of the cooler, then no printable radius will need to be lost which is a bonus.

Just for curiosity sake after I measured the the clearances, I decided to see how good/bad the cheap E3Dv6 clone was and the answer is terrible! The thermistor that came with it was pretty similar to the stock fisher thermistor, readings were very close on both, but the clone thermistor cuts out at 175 Degrees, so not particularly useful for actually extruding anything! After a quick swap over to an original fisher thermistor I tried again, but the heat block took around 10 minutes to get up to temperature so who knows whether the heat cartridge is damaged, or not actually the 24V 40 W as advertised. To top it all off, the head of screw that holds the heat cartridge in disintegrated when I tried to untighten it after the test.

Luckily none of that bothers me, as my Fisher has an official E3D v6 to go in there when I have finished all my upgrades to 1.0 + a few other improvements.. You definitely get what you pay for with the cheap clones that include 24v cartridge , thermistor, fan, bowden tube + fittings, nozzle heat block heat sink and free shipping all for £5.98 - corners have to be cut somewhere, and it is better to support the original designers.

Edited 1 time(s). Last edit at 01/31/2016 05:47PM by jmg123.

|

Re: Effector for E3D v6 February 01, 2016 03:06AM |

Registered: 8 years ago Posts: 301 |

Watching this thread with great interest. Also interesting to know that the clone e3d hot end suck so much.

I will publish the panel drawing I used to laser cut the new panels on thingiverse later as post a link (they are too big to upload here.)

Drawings for the Fisher XT panels can be found here - [www.thingiverse.com]

Edited 1 time(s). Last edit at 02/01/2016 03:57AM by DADIY.

DC42 Kossel 330mm x 2meters

My Thingiverse Creations

I will publish the panel drawing I used to laser cut the new panels on thingiverse later as post a link (they are too big to upload here.)

Drawings for the Fisher XT panels can be found here - [www.thingiverse.com]

Quote

jmg123

With the sad demise of RepRapPro, and the uncertainty of the long term future sources of Fisher nozzles, I decided to design a new effector fan assembly that would work with E3D v6 (not lite) in Onshape . The files are public so anyone can copy or remix them.

The E3D v6 has a longer, and wider heatsink than the original Fisher one, so none of the original effector parts can really be used (including the mdf). I therefore decided to go for a fully 3D printed effector and fan covering, The size of the heatsink also meant there wasn't really a way to include the original fan from the fisher, so instead I am using a 30mm 24v one.

The heatsink is held in place by three bolts with 6 washers, one each for top and bottom. they grip fine, but I reckon there is scope for moving them inwards by ~0.3mm .

My current prototype is printed in PETG with a glass transition of 70C, I've got a thermal imaging camera on order, to see if the heatsink around the area of the fan duct can get higher than this, hopefully it should be ok, otherwise it'll have to be printed in ABS.

I reckon that there is a chance than a couple of mm of build area horizontally and around 18mm vertically, will be lost, as the fan sticks out slightly more than the effector plate, currently my Fisher is halfway through an upgrade from Acrylic/PLA Fisher beta, to a Fisher 1.0 with Polycarbonate/ABS and support for triple extruders.

The pictures are of my prototype, with a cheap e3d v6 clone, as I didn't want to damage my real one whilst designing/measuring/prototyping.

Once this is working on my fisher I will start work on a multi extruder, can't currently decide between the e3d chimera , cyclops, or a diamond hot end. The diamond's three extruders seems like overkill, but would be easy to mount, and would possibly lose less space, Designing for the other two would be quicker, but more space would be lost. Maybe I'll just machine myself some fisher XT panels, and do both

[attachment 71325 Untitled.jpg]

[attachment 71322 IMG_0470.JPG][attachment 71323 IMG_0472.JPG][attachment 71324 IMG_0469.JPG]

Edited 1 time(s). Last edit at 02/01/2016 03:57AM by DADIY.

DC42 Kossel 330mm x 2meters

My Thingiverse Creations

|

Re: Effector for E3D v6 February 01, 2016 04:17AM |

Registered: 13 years ago Posts: 119 |

Hello jmg123,

It's great to see community developed modifications to a RepRap. The original Fisher hot end was designed to keep the nozzle tip close to the plane of the effector ball joints, the thinking being that the further away the nozzle is, the more error will be introduced to the position of the nozzle from tilting of the head as it moves.

eMAKER will continue to supply Fisher spares as long as there is a market for them, see here for nozzles for example.

[emaker.io]

[emaker.limited]

It's great to see community developed modifications to a RepRap. The original Fisher hot end was designed to keep the nozzle tip close to the plane of the effector ball joints, the thinking being that the further away the nozzle is, the more error will be introduced to the position of the nozzle from tilting of the head as it moves.

eMAKER will continue to supply Fisher spares as long as there is a market for them, see here for nozzles for example.

[emaker.io]

[emaker.limited]

|

Re: Effector for E3D v6 April 17, 2016 05:04PM |

Registered: 8 years ago Posts: 40 |

I've been meaning to update the thread, for a while. Based on the advice of jmgiacalone, I did a redesign to sit the ball joints closer to the nozzle tip

To do this the 30mm fan had to be above the effector plate, so I designed a covering to channel the airflow through the E3D heatisink, and out the bottom to the nozzle blower from the original fisher. Using carbon fibre rod arms means that no printable volume is lost and the head can still reach the extremities of the build plate. With the orignal fisher acylic arms, a bit is lost unfortunately.

I had thought I would need to cut the effector bottom (olive green in the cad model above) out of wood, but for the prototype the formfutura carbonfil printed version is working well. The advantage of having two parts is that I can drop out the nozzle and heatsink assembly (screwed to the olive coloured part) for maintenance or change overs without having to pop off the carbon arms.

So far I've been printing with it for a couple of weeks with no issues.

Latest onshape cad model is here

STL file on thingiverse

Edited 1 time(s). Last edit at 04/19/2016 02:22PM by jmg123.

To do this the 30mm fan had to be above the effector plate, so I designed a covering to channel the airflow through the E3D heatisink, and out the bottom to the nozzle blower from the original fisher. Using carbon fibre rod arms means that no printable volume is lost and the head can still reach the extremities of the build plate. With the orignal fisher acylic arms, a bit is lost unfortunately.

I had thought I would need to cut the effector bottom (olive green in the cad model above) out of wood, but for the prototype the formfutura carbonfil printed version is working well. The advantage of having two parts is that I can drop out the nozzle and heatsink assembly (screwed to the olive coloured part) for maintenance or change overs without having to pop off the carbon arms.

So far I've been printing with it for a couple of weeks with no issues.

Latest onshape cad model is here

STL file on thingiverse

Edited 1 time(s). Last edit at 04/19/2016 02:22PM by jmg123.

|

Re: Effector for E3D v6 April 18, 2016 04:42AM |

Registered: 8 years ago Posts: 301 |

Hi, Are you using an official E3D v6 hot end or a clone with your design, I understand that some of the clones are not the same dimensions as the official?

DC42 Kossel 330mm x 2meters

My Thingiverse Creations

DC42 Kossel 330mm x 2meters

My Thingiverse Creations

|

Re: Effector for E3D v6 April 19, 2016 01:59PM |

Registered: 8 years ago Posts: 40 |

The photo is of official everthing apart from the heatsink which is a clone. I've tried it with the official heatsink and it worked ok, i had to sand the top cutout a bit for both, but it does give a good fit.

The clone heatsink I had was the same dimensions as the official v6 but with a different bowden connector.

The design of the effector was based on the drawings on the e3d website.

The clone heatsink I had was the same dimensions as the official v6 but with a different bowden connector.

The design of the effector was based on the drawings on the e3d website.

|

Re: Effector for E3D v6 June 13, 2016 09:49AM |

Registered: 8 years ago Posts: 301 |

Hi JMG.

Just wondered how this was holding up. Is it still working OK? If it is could you recommend a clone hot end that like yours?

DC42 Kossel 330mm x 2meters

My Thingiverse Creations

Just wondered how this was holding up. Is it still working OK? If it is could you recommend a clone hot end that like yours?

DC42 Kossel 330mm x 2meters

My Thingiverse Creations

|

Re: Effector for E3D v6 June 13, 2016 01:57PM |

Registered: 8 years ago Posts: 40 |

Yes it is still working well , I have got through two rolls of filament since the upgrade. i have since upgraded it from carbon fibre to polycarbonate, as the higher heat deflection will allow it to print at high temperatures (<260C)) The clone hot ends range from absolute rubbish, to fine and it is a bit of a lottery when you buy them,, so i would recommend getting the official one if you can, as they will always work well, and the support is good from e3d.

Other mods inhave since done include carbon fibre arms, and an e3d titan extruder drive, which is awesome with awkward filament like laybrick

Other mods inhave since done include carbon fibre arms, and an e3d titan extruder drive, which is awesome with awkward filament like laybrick

|

Re: Effector for E3D v6 June 13, 2016 03:36PM |

Registered: 8 years ago Posts: 301 |

Thanks for the update. I don't suppose you recall the eBay seller you got the clone from?

DC42 Kossel 330mm x 2meters

My Thingiverse Creations

DC42 Kossel 330mm x 2meters

My Thingiverse Creations

Sorry, only registered users may post in this forum.