Flexible PLA from RigidInk

Posted by ntsewell

|

Flexible PLA from RigidInk April 14, 2016 08:48AM |

Registered: 8 years ago Posts: 8 |

Hi all,

Has anyone tried printing with the flexible PLA from RigidInk? I ordered a 1kg reel as I wanted to make some flexible grips for a project at work. I've printed loads of bits in PLA on my Delta and it's been great - so I'm guessing the problem I'm having here is related to temperature or speed, or both! I've tried builds at 190, 200, 210 and 220 degrees. I've tried not having the retraction turned on, I've tried different numbers of perimeters and different fill patterns, but the result is always more or less the same.

Attached are two 25mm cubes which I have tired to print. I gave up part of the way through because it clearly wasn't working.

Any thoughts would be much appreciated. I'm using Slic3r with the Standard settings having downloaded and installed the profile pack for the Fisher Delta.

Many thanks

Neil

Has anyone tried printing with the flexible PLA from RigidInk? I ordered a 1kg reel as I wanted to make some flexible grips for a project at work. I've printed loads of bits in PLA on my Delta and it's been great - so I'm guessing the problem I'm having here is related to temperature or speed, or both! I've tried builds at 190, 200, 210 and 220 degrees. I've tried not having the retraction turned on, I've tried different numbers of perimeters and different fill patterns, but the result is always more or less the same.

Attached are two 25mm cubes which I have tired to print. I gave up part of the way through because it clearly wasn't working.

Any thoughts would be much appreciated. I'm using Slic3r with the Standard settings having downloaded and installed the profile pack for the Fisher Delta.

Many thanks

Neil

|

Re: Flexible PLA from RigidInk April 15, 2016 10:16PM |

Registered: 8 years ago Posts: 443 |

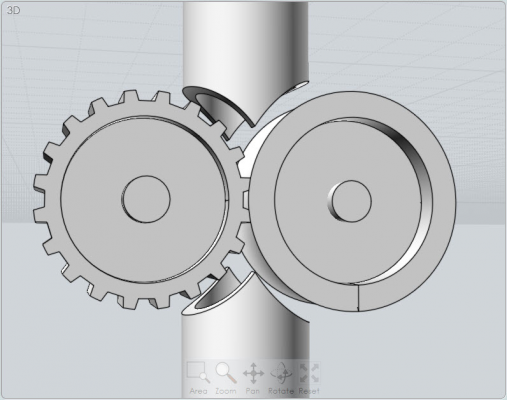

The trick to printing flexible filaments is your extruder.

A good flexible filament extruder doenst have any gaps between the drive cog and the bowden tube, and it has as shot as distance from the drive wheel to the hot end as possible

For normal PLA the filament has a certain degree of rigidity that means the extruder can work if the extruder has a gap of 10-15mm, but flexible PLA cant bridge such gaps.

do this test, take a length of normal PLA about 50mm long and old it 5 mm from the end, now press the end agains a firm surface, and you should find the filament stays rigid, now slowly increade teh distance from the end until you find the point where the filament buckles, I just did this test whilst writing and got to 40mm.

Now repeat the experiement with your flexible material..... did you get past 10mm? mine buckled between 5-10mm.

you should also have noticed whilst doing this test that the filament is compressible.... compressible filament is bad news for a bowden tube extruder

to use a material with such a low rigidity you need to do two things, first miimise teh distance from teh extruder to the hot end, and secondly make sure there are no unsupported gaps after the extruder drive cog

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

A good flexible filament extruder doenst have any gaps between the drive cog and the bowden tube, and it has as shot as distance from the drive wheel to the hot end as possible

For normal PLA the filament has a certain degree of rigidity that means the extruder can work if the extruder has a gap of 10-15mm, but flexible PLA cant bridge such gaps.

do this test, take a length of normal PLA about 50mm long and old it 5 mm from the end, now press the end agains a firm surface, and you should find the filament stays rigid, now slowly increade teh distance from the end until you find the point where the filament buckles, I just did this test whilst writing and got to 40mm.

Now repeat the experiement with your flexible material..... did you get past 10mm? mine buckled between 5-10mm.

you should also have noticed whilst doing this test that the filament is compressible.... compressible filament is bad news for a bowden tube extruder

to use a material with such a low rigidity you need to do two things, first miimise teh distance from teh extruder to the hot end, and secondly make sure there are no unsupported gaps after the extruder drive cog

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

|

Re: Flexible PLA from RigidInk April 19, 2016 05:59AM |

Registered: 8 years ago Posts: 8 |

Hi, and thanks for the reply!

I see what you mean regarding the force necessary to cause the filament to buckle. But how do I reduce the distance from my extruder to the hot end? The Fisher Delta has a length of bowden tube that I can't really shorted (well, I might be able to reduce it by 10%, but it's still 350mm long), and I haven't looked inside the extruder to see if I can in some way shorten the unsupported length from where the knurled wheel and bearing guide the filament into the opening at the end of the bowden tube, but I can't imagine it's something that can be changed, is it?

Is there a modification that I can do, or is it just the case that I now unfortunately have a 1kg spool of material that'll never work very well with my machine?!

Many thanks!

Neil

I see what you mean regarding the force necessary to cause the filament to buckle. But how do I reduce the distance from my extruder to the hot end? The Fisher Delta has a length of bowden tube that I can't really shorted (well, I might be able to reduce it by 10%, but it's still 350mm long), and I haven't looked inside the extruder to see if I can in some way shorten the unsupported length from where the knurled wheel and bearing guide the filament into the opening at the end of the bowden tube, but I can't imagine it's something that can be changed, is it?

Is there a modification that I can do, or is it just the case that I now unfortunately have a 1kg spool of material that'll never work very well with my machine?!

Many thanks!

Neil

|

Re: Flexible PLA from RigidInk April 19, 2016 07:16AM |

Registered: 8 years ago Posts: 443 |

You should not have to shorten the bowden, but it would help, im looking at getting one of these

[e3d-online.com]

If you look at the vid you can see how they have added a support tube to ad stiffness to flexible filament

Edited 1 time(s). Last edit at 04/19/2016 08:59PM by bgkdavis.

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

[e3d-online.com]

If you look at the vid you can see how they have added a support tube to ad stiffness to flexible filament

Edited 1 time(s). Last edit at 04/19/2016 08:59PM by bgkdavis.

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

|

Re: Flexible PLA from RigidInk April 19, 2016 11:06AM |

Registered: 8 years ago Posts: 61 |

|

Re: Flexible PLA from RigidInk April 19, 2016 08:17PM |

Registered: 9 years ago Posts: 189 |

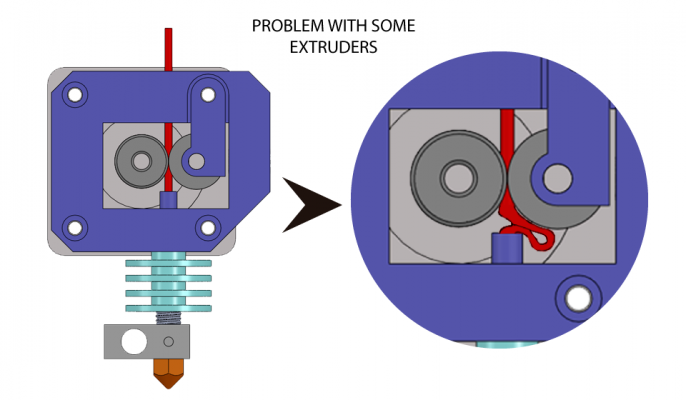

Here is what I found about the problem of normal extruder out of curiosity.

Solutions

Ninjaflex! Printing flexible filament with Gregs/Wades extruder!

[youtu.be]

Edited 1 time(s). Last edit at 04/19/2016 09:15PM by janpenguin.

Solutions

Ninjaflex! Printing flexible filament with Gregs/Wades extruder!

[youtu.be]

Edited 1 time(s). Last edit at 04/19/2016 09:15PM by janpenguin.

|

Re: Flexible PLA from RigidInk April 19, 2016 08:58PM |

Registered: 8 years ago Posts: 443 |

yeah, I'm expecting problems with the bowden tube as well, the problem is the bowden principle depends on the material having a good stiffness and low coefficient of friction.

Flexible PLA has a poor stiffness, when you put pressure on the end it will tend to expand, swell in the tube and increase the resistance from friction.

Even if you solve the friction problem, the next issue you have is the compressed filament will have a high spring effect, which may mean that you have to do a lot of retraction to try and control ooze

I've also bought a E3D hot end that can be configured with the extruder in either bowden or direct mode, but I wont be trying to fit a direct extruder configuration to a fisher

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

Flexible PLA has a poor stiffness, when you put pressure on the end it will tend to expand, swell in the tube and increase the resistance from friction.

Even if you solve the friction problem, the next issue you have is the compressed filament will have a high spring effect, which may mean that you have to do a lot of retraction to try and control ooze

I've also bought a E3D hot end that can be configured with the extruder in either bowden or direct mode, but I wont be trying to fit a direct extruder configuration to a fisher

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

|

Re: Flexible PLA from RigidInk April 28, 2016 04:59PM |

Registered: 8 years ago Posts: 8 |

Thanks for the comments and ideas everyone - but I don't know how I would be able to fix the E3D hot end into my Fisher Delta? I mean, is it supposed to replace the extruder and the rest of the hot end entirely? If so, presumably I should print something first that allows it to be mounted, then take out the existing hot end assembly and replace it? Is this what is being suggested if I want to work with flexible material?

Thanks for you help(s) again!

Neil

Thanks for you help(s) again!

Neil

|

Re: Flexible PLA from RigidInk April 28, 2016 06:11PM |

Registered: 8 years ago Posts: 443 |

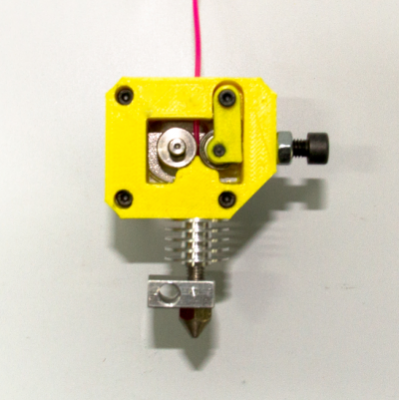

Its not the hot end you need to replace its the extruder.

I believe someone is working on a E3D effector for a fisher

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

I believe someone is working on a E3D effector for a fisher

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

|

Re: Flexible PLA from RigidInk April 29, 2016 07:46AM |

Registered: 8 years ago Posts: 40 |

Quote

ntsewell

Thanks for the comments and ideas everyone - but I don't know how I would be able to fix the E3D hot end into my Fisher Delta? I mean, is it supposed to replace the extruder and the rest of the hot end entirely? If so, presumably I should print something first that allows it to be mounted, then take out the existing hot end assembly and replace it? Is this what is being suggested if I want to work with flexible material?

Thanks for you help(s) again!

Neil

Quote

bgkdavis

Its not the hot end you need to replace its the extruder.

I believe someone is working on a E3D effector for a fisher

Hi

I've done a 3D printable effector for the E3D hotend it replaces the entire effector assembly on the fisher, but still uses a bowden tube, so in that respect it will probably be no better/worse than the stock fisher setup. Putting a direct drive extruder/hotend onto the effector would be a massive amount of weight to be moving around.

Sorry, only registered users may post in this forum.