Fisher heatbed

Posted by jmgiacalone

|

Fisher heatbed May 31, 2016 03:23PM |

Registered: 13 years ago Posts: 119 |

We have put together a heatbed kit for people to upgrade their Fishers, to allow printing in a broader range of materials, such as ABS, HIPS and PETG. You'll need a 120W PSU, which beta owners will already have, but otherwise the bed is a straight replacement for the standard (un-heated) one.

Files are on github for those who are interested [github.com]

More details on the blog [emaker.io]

Let me know if you have any questions.

[emaker.io]

[emaker.limited]

Files are on github for those who are interested [github.com]

More details on the blog [emaker.io]

Let me know if you have any questions.

[emaker.io]

[emaker.limited]

|

Re: Fisher heatbed June 01, 2016 12:43AM |

Registered: 8 years ago Posts: 443 |

Interesting, however, one of the things I liked about the Fisher bed was the way it was easy to remove the build plate for cleaning or replacing the print surface, so a quick connect/disconnect connector would be nice.

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

|

Re: Fisher heatbed June 01, 2016 05:04AM |

Registered: 13 years ago Posts: 119 |

Hello bgkdavis,

I did think about putting a connector above the base plate so the bed could be easily and completely removed from the machine, but decided against it for now as disconnecting it with the machine on will trigger a heater fault.

The wires are long enough to pop the bed out and away form the machine enough to clean, see a couple of photos here.

It would be simple enough to cut the wires and fit connectors on yourself if you wished to use it in this way. Something like the Molex Microfit range should be suitable.

Edited 1 time(s). Last edit at 06/01/2016 05:04AM by jmgiacalone.

[emaker.io]

[emaker.limited]

I did think about putting a connector above the base plate so the bed could be easily and completely removed from the machine, but decided against it for now as disconnecting it with the machine on will trigger a heater fault.

The wires are long enough to pop the bed out and away form the machine enough to clean, see a couple of photos here.

It would be simple enough to cut the wires and fit connectors on yourself if you wished to use it in this way. Something like the Molex Microfit range should be suitable.

Edited 1 time(s). Last edit at 06/01/2016 05:04AM by jmgiacalone.

[emaker.io]

[emaker.limited]

|

Re: Fisher heatbed June 01, 2016 11:53AM |

Registered: 8 years ago Posts: 40 |

|

Re: Fisher heatbed June 01, 2016 06:38PM |

Registered: 13 years ago Posts: 119 |

Hello jmg123,

I've been planning to test the Fisher with 24v, and in fact received a suitable power supply in the post today, so I'll let you know how it goes.

We do have bed springs. I'll get them listed on the site over the next couple of days.

[emaker.io]

[emaker.limited]

I've been planning to test the Fisher with 24v, and in fact received a suitable power supply in the post today, so I'll let you know how it goes.

We do have bed springs. I'll get them listed on the site over the next couple of days.

[emaker.io]

[emaker.limited]

|

Re: Fisher heatbed June 01, 2016 08:38PM |

Registered: 8 years ago Posts: 443 |

While your stocking upgrade kits you could do a lot worst than put up a Carbon arm kit to replace the RRP crappy acrylic arms, and speaking of broken acrylic I need to replace one of the side panels on mine

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

|

Re: Fisher heatbed June 02, 2016 05:15AM |

Registered: 8 years ago Posts: 40 |

Quote

jmgiacalone

Hello jmg123,

I've been planning to test the Fisher with 24v, and in fact received a suitable power supply in the post today, so I'll let you know how it goes.

We do have bed springs. I'll get them listed on the site over the next couple of days.

Great thanks, I've converted my fisher to 24V and be powered by one of these so I can also easily try it at 19V and 24V, just wanted to check, that the 24V was theoretically possible before I gave it a go.

|

Re: Fisher heatbed June 03, 2016 05:42AM |

Registered: 8 years ago Posts: 83 |

|

Re: Fisher heatbed June 03, 2016 06:18AM |

Registered: 13 years ago Posts: 119 |

@Greg_be

Thanks for your order! I'm just waiting for the packing boxes to arrive, so I'll try and get a batch of heatbed kits out today.

@jmg123

You may need a power supply which can provide more current than the one you linked to.

Cartridge heater resistance is 6 Ohms and the bed is 3 Ohms. So at 24v, the hot end will draw 4A and the bed 8A. Your power supply therefore needs to be able to supply at least 12A at 24v, or 288W power. These figures cater for powering all the heaters at full power, which is not necessary except to speed up the warmup time from cold. During printing, the heaters operate at a fraction of their maximum power.

You can adjust the M301 S parameter to reduce the power available for the heaters, but with only 5A available, I fear you may need to reduce the power so much that your heaters will not be of much use.

[emaker.io]

[emaker.limited]

Thanks for your order! I'm just waiting for the packing boxes to arrive, so I'll try and get a batch of heatbed kits out today.

@jmg123

You may need a power supply which can provide more current than the one you linked to.

Cartridge heater resistance is 6 Ohms and the bed is 3 Ohms. So at 24v, the hot end will draw 4A and the bed 8A. Your power supply therefore needs to be able to supply at least 12A at 24v, or 288W power. These figures cater for powering all the heaters at full power, which is not necessary except to speed up the warmup time from cold. During printing, the heaters operate at a fraction of their maximum power.

You can adjust the M301 S parameter to reduce the power available for the heaters, but with only 5A available, I fear you may need to reduce the power so much that your heaters will not be of much use.

[emaker.io]

[emaker.limited]

|

Re: Fisher heatbed June 03, 2016 11:41AM |

Registered: 8 years ago Posts: 40 |

Quote

jmgiacalone

@jmg123

You may need a power supply which can provide more current than the one you linked to.

Cartridge heater resistance is 6 Ohms and the bed is 3 Ohms. So at 24v, the hot end will draw 4A and the bed 8A. Your power supply therefore needs to be able to supply at least 12A at 24v, or 288W power. These figures cater for powering all the heaters at full power, which is not necessary except to speed up the warmup time from cold. During printing, the heaters operate at a fraction of their maximum power.

It think it should be ok, the e3dV6 30w Cartridge on my hotend is 24Volts/19.2Ohms = 1.25Amps . The PSU has a function where you can internally chain both channels together in series or parallel for 60v/5A or 30v/10A, so allowing for the overhead of the duet itself (~150mA) and the 4 steppers (500mA Each) means that it should be able to feed the bed around 6.6A = ~ 158W ~ 83% of the intended power whilst running everything flat out, or more if the motors aren't doing anything during initial bed warmup phase. I always run it with the over current and over voltage protection enabled, so if it cuts out, I can just back the bed power down a fraction until it is happy.

Edited 1 time(s). Last edit at 06/03/2016 11:41AM by jmg123.

|

Re: Fisher heatbed June 06, 2016 06:40AM |

Registered: 8 years ago Posts: 301 |

Its really good to see that the Fisher kit is being actively supported again, have you got any other upgrade kits in mind? Perhaps the multi colour extruder?

DC42 Kossel 330mm x 2meters

My Thingiverse Creations

DC42 Kossel 330mm x 2meters

My Thingiverse Creations

|

Re: Fisher heatbed June 10, 2016 01:24PM |

Registered: 8 years ago Posts: 83 |

|

Re: Fisher heatbed June 12, 2016 01:56PM |

Registered: 8 years ago Posts: 40 |

Just got round to installing my heated bed kit, works like a charm

, Polycarbonate printing with no warping

|

Re: Fisher heatbed June 12, 2016 03:17PM |

Registered: 13 years ago Posts: 119 |

Awesome! I have misplaced my spool of Polycarbonate, so I couldn't test that material, but I'm pleased to see it working for you.

What temperatures are you running?

[emaker.io]

[emaker.limited]

What temperatures are you running?

[emaker.io]

[emaker.limited]

|

Re: Fisher heatbed June 12, 2016 05:44PM |

Registered: 8 years ago Posts: 40 |

I printed with an extruder temp of 265 degrees and a bed temperature of 85 degrees. This was a slightly higher bed temperature than in the polymaker pc-plus data sheet, but i wanted to try and counteract some of the effect of the airflow coming from the nozzles. It stuck to the buildtak slightly too well, making it a little differcult to get the part off at the end, next time I think i'll print with a raft , as suggested in the polymaker datasheet.

|

Re: Fisher heatbed June 12, 2016 06:13PM |

Registered: 13 years ago Posts: 119 |

You may find it better to print onto Kapton then. When it cools, parts tend to come off more easily.

If you don't want the airflow across the top of your part from the nozzle ducts, you can easily remove them. There'll still be a downdraft over the part, but it won't be so aggressive. That's what I do when printing with ABS, as otherwise it tends to delaminate during printing.

[emaker.io]

[emaker.limited]

If you don't want the airflow across the top of your part from the nozzle ducts, you can easily remove them. There'll still be a downdraft over the part, but it won't be so aggressive. That's what I do when printing with ABS, as otherwise it tends to delaminate during printing.

[emaker.io]

[emaker.limited]

|

Re: Fisher heatbed June 25, 2016 04:15PM |

Registered: 8 years ago Posts: 15 |

Re easy heatbed removal on the Fisher, I have fitted a JST dual line connector pair, available from RC modelling suppliers and ebay, in-line with the heatbed black & red thermistor wires and the existing thermistor PCB connector. The polarised JST connector plug and socket are thin enough to slip through the curved wiring slot in the Fisher base and will normally sit out of sight underneath the base, if fitted near the PCB end of the existing leads.

This addition makes the heatbed completely removable and will ease replacing Kapton and carrying out other maintenance on the Fisher. This arrangement has little chance of becoming accidentally disconected as the JST plugs and sockets are quite firm once fully engaged. If you have not used JST connectors before, I suggest you purchase a crimping tool, rather than try to solder the JST plug's contacts. Works a treat!

Edited 1 time(s). Last edit at 06/25/2016 04:20PM by SSMagic.

SSMagic

Fisher Beta, upgraded to Fisher 1 with heatbed and full fan control

This addition makes the heatbed completely removable and will ease replacing Kapton and carrying out other maintenance on the Fisher. This arrangement has little chance of becoming accidentally disconected as the JST plugs and sockets are quite firm once fully engaged. If you have not used JST connectors before, I suggest you purchase a crimping tool, rather than try to solder the JST plug's contacts. Works a treat!

Edited 1 time(s). Last edit at 06/25/2016 04:20PM by SSMagic.

SSMagic

Fisher Beta, upgraded to Fisher 1 with heatbed and full fan control

|

Re: Fisher heatbed July 16, 2016 02:15PM |

Registered: 8 years ago Posts: 83 |

Finally, one month later (i'm not using it everyday), some news about my heated bed.

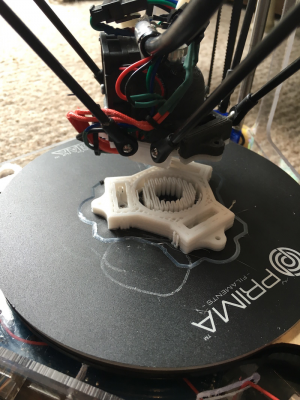

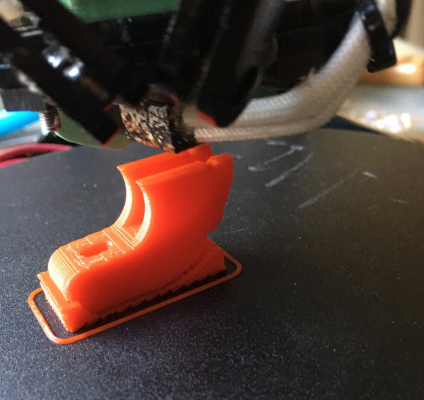

I tried with my worst filament, a red PLA from Prima3D

After some tests with Kapton tape,there was no grip at all.

I installed the BuildTak, bed at 70 and filament 200, the filament is sticking well.

I can finally finish my spool with other things than failed parts!

Here is an example : a reworked part to replace the acrylic arm from the extruder.

This kind of part with small footprint was impossible before

I enjoy it

I tried with my worst filament, a red PLA from Prima3D

After some tests with Kapton tape,there was no grip at all.

I installed the BuildTak, bed at 70 and filament 200, the filament is sticking well.

I can finally finish my spool with other things than failed parts!

Here is an example : a reworked part to replace the acrylic arm from the extruder.

This kind of part with small footprint was impossible before

I enjoy it

|

Re: Fisher heatbed July 18, 2016 10:39AM |

Registered: 8 years ago Posts: 301 |

With my home made heat bed I'm using 4mm glass from the local glass company with a little hair spray for PLA or ABS juice for ABS and its working great. For ABS I have a cardboard box folder into a hexagon that forms a make shift enclosure which has made a world of difference.

DC42 Kossel 330mm x 2meters

My Thingiverse Creations

DC42 Kossel 330mm x 2meters

My Thingiverse Creations

|

Re: Fisher heatbed September 03, 2016 04:35PM |

Registered: 8 years ago Posts: 3 |

|

Re: Fisher heatbed September 04, 2016 08:11AM |

Registered: 13 years ago Posts: 119 |

Hello Steve,

The homed height in config.heatbed.g was set a little high. It has now been reduced to 161mm and updated on github. See the M665 command to adjust.

Sorry for the trouble caused.

[emaker.io]

[emaker.limited]

The homed height in config.heatbed.g was set a little high. It has now been reduced to 161mm and updated on github. See the M665 command to adjust.

Sorry for the trouble caused.

[emaker.io]

[emaker.limited]

|

Re: Fisher heatbed September 04, 2016 09:10AM |

Registered: 8 years ago Posts: 3 |

|

Re: Fisher heatbed October 17, 2016 12:21PM |

Registered: 7 years ago Posts: 12 |

|

Re: Fisher heatbed October 17, 2016 03:08PM |

Registered: 7 years ago Posts: 21 |

The sd card I was using became corrupted and I reformatted to remove issues. After re-loading the Firmware and other folders onto the card, amending the config g file to ensure correct height of the nozzle from the heatbed and other settings I re-inserted the sd card into the fisher. Unfortunately it no longer picks up the heatbed on the DWC Panel. I added the command M305 P2 R4700 to thermistor category under the previous M305 command for the nozzle but the heatbed is still not showing on the DWC Panel. Thanks in anticipation.

|

Re: Fisher heatbed October 17, 2016 03:33PM |

Registered: 10 years ago Posts: 14,672 |

Quote

Gary J

The sd card I was using became corrupted and I reformatted to remove issues. After re-loading the Firmware and other folders onto the card, amending the config g file to ensure correct height of the nozzle from the heatbed and other settings I re-inserted the sd card into the fisher. Unfortunately it no longer picks up the heatbed on the DWC Panel. I added the command M305 P2 R4700 to thermistor category under the previous M305 command for the nozzle but the heatbed is still not showing on the DWC Panel. Thanks in anticipation.

Sounds like you may still have a M140 H-1 command in your config.g file. If so, remove it or comment it out.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Fisher heatbed October 17, 2016 04:12PM |

Registered: 7 years ago Posts: 21 |

|

Re: Fisher heatbed October 18, 2016 02:38AM |

Registered: 9 years ago Posts: 189 |

|

Re: Fisher heatbed October 18, 2016 04:14AM |

Registered: 8 years ago Posts: 301 |

For ABS I put a little masking tape under the fan duct and then put a cardboard enclosure around the machine to keep some heat in and avoid drafts, I'm still very much experimenting with ABS but have managed to print the gear bearing successfully. [www.thingiverse.com]

DC42 Kossel 330mm x 2meters

My Thingiverse Creations

DC42 Kossel 330mm x 2meters

My Thingiverse Creations

|

Re: Fisher heatbed October 20, 2016 11:04AM |

Registered: 7 years ago Posts: 12 |

I bought the kit from emaker.io and am very impressed. Very easy to build and easy instructions to follow. Jean-Marc was able to respond very quickly to a quick question I had.

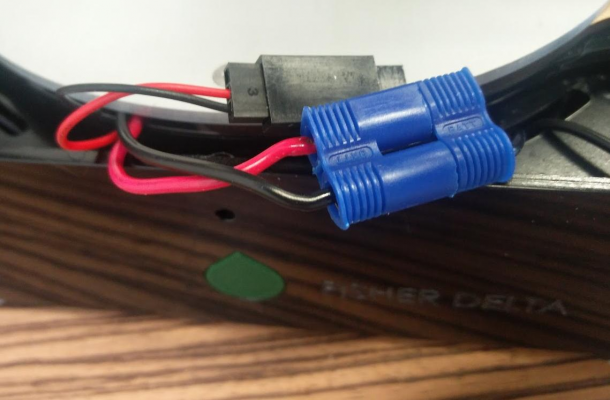

I've made a slight modification to mine and added an EC3 connector and RC servo connector to the wires of the heatbed. This is in case I want to fully remove the bed to remove intricate prints or clean the bed or maybe go back to non-heat bed.

I printed my first 20x20mm cube in ABS this morning and am very impressed it worked first time!

Edited 3 time(s). Last edit at 10/21/2016 06:25AM by AndyKay.

I've made a slight modification to mine and added an EC3 connector and RC servo connector to the wires of the heatbed. This is in case I want to fully remove the bed to remove intricate prints or clean the bed or maybe go back to non-heat bed.

I printed my first 20x20mm cube in ABS this morning and am very impressed it worked first time!

Edited 3 time(s). Last edit at 10/21/2016 06:25AM by AndyKay.

|

Re: Fisher heatbed November 14, 2016 08:51AM |

Registered: 7 years ago Posts: 21 |

Hi All

Recently purchased 3mm float glass for the Fisher to place on top of the heatbed. I need to fasten the glass to stop it moving when printing but I would rather not use using glues etc. The issue which I sure you are all aware of is that there is minimal space to apply bulldog or similar clips.

Does anyone have any suggestions as to what clips I can use, I tried printing some with PLA but the are very brittle and break easily.

Your help is much appreciated.

Recently purchased 3mm float glass for the Fisher to place on top of the heatbed. I need to fasten the glass to stop it moving when printing but I would rather not use using glues etc. The issue which I sure you are all aware of is that there is minimal space to apply bulldog or similar clips.

Does anyone have any suggestions as to what clips I can use, I tried printing some with PLA but the are very brittle and break easily.

Your help is much appreciated.

Sorry, only registered users may post in this forum.