Printing unsupported material

Posted by Wired1

|

Printing unsupported material August 17, 2012 07:24AM |

Registered: 11 years ago Posts: 525 |

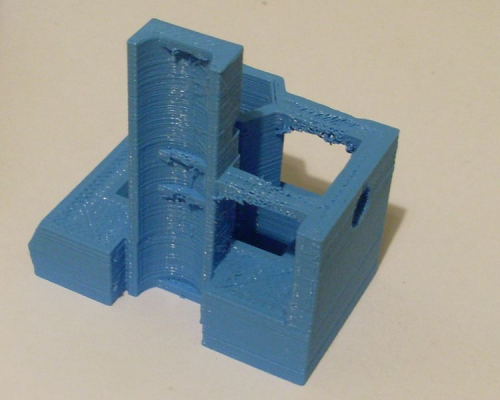

What is the trick to printing unsupported parts or spans? I printed out a spare x-axis idler this evening and it is useable but the two bridges from the uprights to where the pulley bolts on are a bit ugly and a lot of the PLA just sagged.

_________________________________________________________________________________________

Richmond, New Zealand

Thingiverse ~ YouTube

_________________________________________________________________________________________

Richmond, New Zealand

Thingiverse ~ YouTube

|

Re: Printing unsupported material August 17, 2012 04:25PM |

Registered: 13 years ago Posts: 862 |

|

Re: Printing unsupported material August 17, 2012 04:41PM |

Registered: 11 years ago Posts: 525 |

I think I need to play around with the bridging settings in Slic3r - speed it up a bit, aim the fan a bit better.

I also printed this with about 80% fill and three perimeters I think so I will try 1 perimeter and higher fill.

_________________________________________________________________________________________

Richmond, New Zealand

Thingiverse ~ YouTube

I also printed this with about 80% fill and three perimeters I think so I will try 1 perimeter and higher fill.

_________________________________________________________________________________________

Richmond, New Zealand

Thingiverse ~ YouTube

|

Re: Printing unsupported material August 18, 2012 12:02AM |

Registered: 11 years ago Posts: 525 |

Just to make it interesting I also updated my Slic3r to version 9 this morning and set it up to print the same piece with 1 perimeter, 100% fill and ticked the "add support material" then went out for five hours. Unfortunately the latest version of Slic3r by default turns off the hot bed after the first layer so at some point in the morning, about the fourth layer by the look of it, the piece separated from the print bed and slipped around all over the place so when I got back this afternoon there was a brown blob where my part wshould have been.

So I have carefully gone through all the setup options again and set it to keep the hot bed on this time. I have 1 perimeter, 80% fill, 0.3 layer height and ticked the support material option so I'll put up a photo in a couple of hours time when it reprints the x-axis idler.

_________________________________________________________________________________________

Richmond, New Zealand

Thingiverse ~ YouTube

So I have carefully gone through all the setup options again and set it to keep the hot bed on this time. I have 1 perimeter, 80% fill, 0.3 layer height and ticked the support material option so I'll put up a photo in a couple of hours time when it reprints the x-axis idler.

_________________________________________________________________________________________

Richmond, New Zealand

Thingiverse ~ YouTube

|

Re: Printing unsupported material August 18, 2012 01:56AM |

Registered: 11 years ago Posts: 525 |

OK that was a waste of time, I stopped it before it could get too far along. Adding support material means it adds extra PLA strips in every hole and crevice it can find so you end up with heaps of extra material to snap out then trim with a razor.

So I've gone back to no support, 1 perimeter, 50% fill and slowed the bridge speed down to 30. The fan and hot bed are both on.

_________________________________________________________________________________________

Richmond, New Zealand

Thingiverse ~ YouTube

So I've gone back to no support, 1 perimeter, 50% fill and slowed the bridge speed down to 30. The fan and hot bed are both on.

_________________________________________________________________________________________

Richmond, New Zealand

Thingiverse ~ YouTube

|

Re: Printing unsupported material August 18, 2012 02:40AM |

Registered: 11 years ago Posts: 525 |

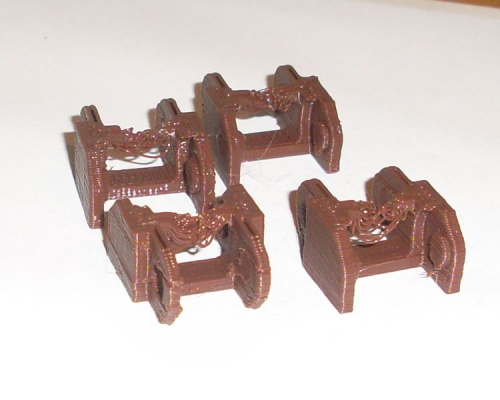

So now I'm printing a small part for a cable chain which has a bridge at the top.

This was done with bridge speed of 30, fill 50% and 1 perimeter. Fan and hotbed on.

_________________________________________________________________________________________

Richmond, New Zealand

Thingiverse ~ YouTube

This was done with bridge speed of 30, fill 50% and 1 perimeter. Fan and hotbed on.

_________________________________________________________________________________________

Richmond, New Zealand

Thingiverse ~ YouTube

|

Re: Printing unsupported material August 18, 2012 03:57AM |

Registered: 11 years ago Posts: 525 |

Second print, bridge speed 60, eveything else the same.

No noticeable difference.

_________________________________________________________________________________________

Richmond, New Zealand

Thingiverse ~ YouTube

No noticeable difference.

_________________________________________________________________________________________

Richmond, New Zealand

Thingiverse ~ YouTube

|

Re: Printing unsupported material August 18, 2012 04:04AM |

Admin Registered: 13 years ago Posts: 7,008 |

|

Re: Printing unsupported material August 18, 2012 04:34AM |

Registered: 11 years ago Posts: 525 |

I'll try that, slowing to 30 that is. I'm printing at 185 but my fan isn't as efficient as it could be.

I just discovered my nozzle was set to .5mm instead of 0.35mm following the Slic3r upgrade this morning so that will probably make a difference too

Anyway, print 3: I increased perimeter to 2, and changed the fan to always on. Slightly less sag.

I think the next print with the correct nozle size will help as the strand will be thinner.

_________________________________________________________________________________________

Richmond, New Zealand

Thingiverse ~ YouTube

I just discovered my nozzle was set to .5mm instead of 0.35mm following the Slic3r upgrade this morning so that will probably make a difference too

Anyway, print 3: I increased perimeter to 2, and changed the fan to always on. Slightly less sag.

I think the next print with the correct nozle size will help as the strand will be thinner.

_________________________________________________________________________________________

Richmond, New Zealand

Thingiverse ~ YouTube

|

Re: Printing unsupported material August 18, 2012 05:41AM |

Registered: 11 years ago Posts: 525 |

So fourth set came out much better. Two of the four links printed slipped on the hot bed but even they had near perfect bridges.

Settings on this final print were 0.2mm layer height, 2 perimeters, 3 solid layers, 30% fill and probably mist critical - 0.35mm nozzle.

Edited 1 time(s). Last edit at 08/18/2012 05:42AM by Wired1.

_________________________________________________________________________________________

Richmond, New Zealand

Thingiverse ~ YouTube

Settings on this final print were 0.2mm layer height, 2 perimeters, 3 solid layers, 30% fill and probably mist critical - 0.35mm nozzle.

Edited 1 time(s). Last edit at 08/18/2012 05:42AM by Wired1.

_________________________________________________________________________________________

Richmond, New Zealand

Thingiverse ~ YouTube

|

Re: Printing unsupported material August 18, 2012 06:36PM |

Registered: 11 years ago Posts: 525 |

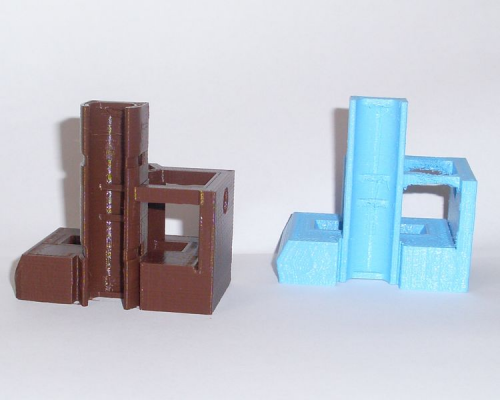

Got it sorted although 30% fill bothers me so I might increase that. Still on 2 perimeters and a layer height of 0.2 which means it takes a while to print. Increasing fill density will futrher increase the time taken but these things have to be strong.

The brown one is straight off the plate by the way, no trimming yet, no need to anyway. The bridges look like they were printed the other way up they are so soilid and no hole droop either.

Edited 1 time(s). Last edit at 08/18/2012 06:37PM by Wired1.

_________________________________________________________________________________________

Richmond, New Zealand

Thingiverse ~ YouTube

The brown one is straight off the plate by the way, no trimming yet, no need to anyway. The bridges look like they were printed the other way up they are so soilid and no hole droop either.

Edited 1 time(s). Last edit at 08/18/2012 06:37PM by Wired1.

_________________________________________________________________________________________

Richmond, New Zealand

Thingiverse ~ YouTube

|

Re: Printing unsupported material August 18, 2012 09:25PM |

Registered: 13 years ago Posts: 862 |

I only use 25% fill on those parts and they are plenty strong enough anything over 30% would be overkill. I do use 3 perimeters though.

Remember that the skinny sections even at 25% fill are near enough solid with 3 perimeters. It's only the base which is really 25% and since that doesn't do anything its fine. That brown one looks really good, your really getting ahead with your printing now, wish I had the time to catch up but at the moment it's impossible. Keep up the good work

__________________________________________________________________________

Experimenting in 3D in New Zealand

Remember that the skinny sections even at 25% fill are near enough solid with 3 perimeters. It's only the base which is really 25% and since that doesn't do anything its fine. That brown one looks really good, your really getting ahead with your printing now, wish I had the time to catch up but at the moment it's impossible. Keep up the good work

__________________________________________________________________________

Experimenting in 3D in New Zealand

|

Re: Printing unsupported material August 18, 2012 10:56PM |

Registered: 11 years ago Posts: 525 |

Thanks Gary, it is a steep learning curve but this is the best way to learn - ie maximum cock-ups.

I will adjust my fill and perimeters as you suggest and it make sense, if the perimeter is thicker the inside is just some added bracing. The top and bottom layers are set separately on Slic3r so I will set them to 3 as well then it's well-wrapped.

_________________________________________________________________________________________

Richmond, New Zealand

Thingiverse ~ YouTube

I will adjust my fill and perimeters as you suggest and it make sense, if the perimeter is thicker the inside is just some added bracing. The top and bottom layers are set separately on Slic3r so I will set them to 3 as well then it's well-wrapped.

_________________________________________________________________________________________

Richmond, New Zealand

Thingiverse ~ YouTube

|

Re: Printing unsupported material August 19, 2012 01:01AM |

Registered: 13 years ago Posts: 862 |

Sorry, only registered users may post in this forum.