Auto Bed Leveling issues

Posted by Marcus.Couceiro

|

Auto Bed Leveling issues December 09, 2018 09:36PM |

Registered: 6 years ago Posts: 26 |

Dear Gentlemen,

I would like your help to see if we can solve the following issue. Here it goes:

I built a t-slot 3d printer using the Ultimaker type as a template. The bed goes down as it prints and when I home Z it goes to Z_max which is located at the bottom of the frame. Everything works as it should and I decided to implement the Auto Bed Leveling feature.

So far I was unable to make it work and that´s why I request your help. I am using Auto Bed Leveling Bilinear with only one point for the sake of initial calibration.

When homed to Z, Repetier shows 172mm in the Z_axis and the procedure I am trying to do is as follow:

- Issue a G29 Command. The Probe comes to the (0,0) coordinate, where a metal stand with 15mm height is sitting, and the bed starts to move up until the Capacitive Probe triggers. It repeats once again and then gives the value18.6mm. I can see that the bed is lower then 18.6mm but Repetier shows 20.2mm. The distance between the capacitive probe and the nozzle is 3.5mm (capacitive probe higher than nozzle) and the capcitive probe triggers around 7mm from the metal stand;

- I manually command the table to move to Z=0 and, once it reaches 0, I can measure 18.6mm from the nozzle to the table.

I have already entered 18.6mm as Z_offset but it did not solve the problem. I´ve also tried -18.6mm but that does not seem to work either. Basically, no matter the number I put as Z_PROBE_OFFSET_FROM_EXTRUDER I end up having 18.6mm between the nozzle and the bed.

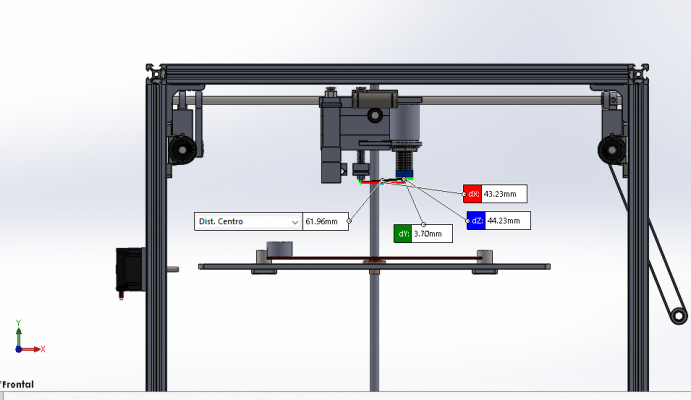

I am using Marlin 1.1.9 and Repetier as Host. I´ve attached a Picture showing my current assembly and the code can be seen hereafter. I´ve removed parts of the code since they are no relevant.

Marcus

Edited 1 time(s). Last edit at 12/09/2018 09:40PM by Marcus.Couceiro.

I would like your help to see if we can solve the following issue. Here it goes:

I built a t-slot 3d printer using the Ultimaker type as a template. The bed goes down as it prints and when I home Z it goes to Z_max which is located at the bottom of the frame. Everything works as it should and I decided to implement the Auto Bed Leveling feature.

So far I was unable to make it work and that´s why I request your help. I am using Auto Bed Leveling Bilinear with only one point for the sake of initial calibration.

When homed to Z, Repetier shows 172mm in the Z_axis and the procedure I am trying to do is as follow:

- Issue a G29 Command. The Probe comes to the (0,0) coordinate, where a metal stand with 15mm height is sitting, and the bed starts to move up until the Capacitive Probe triggers. It repeats once again and then gives the value18.6mm. I can see that the bed is lower then 18.6mm but Repetier shows 20.2mm. The distance between the capacitive probe and the nozzle is 3.5mm (capacitive probe higher than nozzle) and the capcitive probe triggers around 7mm from the metal stand;

- I manually command the table to move to Z=0 and, once it reaches 0, I can measure 18.6mm from the nozzle to the table.

I have already entered 18.6mm as Z_offset but it did not solve the problem. I´ve also tried -18.6mm but that does not seem to work either. Basically, no matter the number I put as Z_PROBE_OFFSET_FROM_EXTRUDER I end up having 18.6mm between the nozzle and the bed.

I am using Marlin 1.1.9 and Repetier as Host. I´ve attached a Picture showing my current assembly and the code can be seen hereafter. I´ve removed parts of the code since they are no relevant.

/** * Marlin 3D Printer Firmware * Copyright (C) 2016 MarlinFirmware [https://github.com/MarlinFirmware/Marlin] * * Based on Sprinter and grbl. * Copyright (C) 2011 Camiel Gubbels / Erik van der Zalm * * This program is free software: you can redistribute it and/or modify * it under the terms of the GNU General Public License as published by * the Free Software Foundation, either version 3 of the License, or * (at your option) any later version. * * This program is distributed in the hope that it will be useful, * but WITHOUT ANY WARRANTY; without even the implied warranty of * MERCHANTABILITY or FITNESS FOR A PARTICULAR PURPOSE. See the * GNU General Public License for more details. * * You should have received a copy of the GNU General Public License * along with this program. If not, see [www.gnu.org]. * */ /** * Configuration.h * * Basic settings such as: * * - Type of electronics * - Type of temperature sensor * - Printer geometry * - Endstop configuration * - LCD controller * - Extra features * * Advanced settings can be found in Configuration_adv.h * */ #ifndef CONFIGURATION_H #define CONFIGURATION_H #define CONFIGURATION_H_VERSION 010109 //=========================================================================== //============================= Getting Started ============================= //=========================================================================== /** * Here are some standard links for getting your machine calibrated: * * [reprap.org] * [youtu.be] * [calculator.josefprusa.cz] * [reprap.org] * [www.thingiverse.com] * [sites.google.com] * [www.thingiverse.com] */ //=========================================================================== //============================= DELTA Printer =============================== //=========================================================================== // For a Delta printer start with one of the configuration files in the // example_configurations/delta directory and customize for your machine. // //=========================================================================== //============================= SCARA Printer =============================== //=========================================================================== // For a SCARA printer start with the configuration files in // example_configurations/SCARA and customize for your machine. // // @section info // User-specified version info of this build to display in [Pronterface, etc] terminal window during // startup. Implementation of an idea by Prof Braino to inform user that any changes made to this // build by the user have been successfully uploaded into firmware. #define STRING_CONFIG_H_AUTHOR "(none, default config)" // Who made the changes. #define SHOW_BOOTSCREEN #define STRING_SPLASH_LINE1 SHORT_BUILD_VERSION // will be shown during bootup in line 1 #define STRING_SPLASH_LINE2 WEBSITE_URL // will be shown during bootup in line 2 /** * *** VENDORS PLEASE READ *** * * Marlin allows you to add a custom boot image for Graphical LCDs. * With this option Marlin will first show your custom screen followed * by the standard Marlin logo with version number and web URL. * * We encourage you to take advantage of this new feature and we also * respectfully request that you retain the unmodified Marlin boot screen. */ // Enable to show the bitmap in Marlin/_Bootscreen.h on startup. //#define SHOW_CUSTOM_BOOTSCREEN // Enable to show the bitmap in Marlin/_Statusscreen.h on the status screen. //#define CUSTOM_STATUS_SCREEN_IMAGE // @section machine /** * Select the serial port on the board to use for communication with the host. * This allows the connection of wireless adapters (for instance) to non-default port pins. * Serial port 0 is always used by the Arduino bootloader regardless of this setting. * * :[0, 1, 2, 3, 4, 5, 6, 7] */ #define SERIAL_PORT 0 /** * This setting determines the communication speed of the printer. * * 250000 works in most cases, but you might try a lower speed if * you commonly experience drop-outs during host printing. * You may try up to 1000000 to speed up SD file transfer. * * :[2400, 9600, 19200, 38400, 57600, 115200, 250000, 500000, 1000000] */ #define BAUDRATE 115200 // Enable the Bluetooth serial interface on AT90USB devices //#define BLUETOOTH // The following define selects which electronics board you have. // Please choose the name from boards.h that matches your setup #ifndef MOTHERBOARD #define MOTHERBOARD BOARD_RAMPS_14_EEB #endif // Optional custom name for your RepStrap or other custom machine // Displayed in the LCD "Ready" message //#define CUSTOM_MACHINE_NAME "Marcus Printer" // Define this to set a unique identifier for this printer, (Used by some programs to differentiate between machines) // You can use an online service to generate a random UUID. (eg [www.uuidgenerator.net]) //#define MACHINE_UUID "00000000-0000-0000-0000-000000000000" // @section extruder // This defines the number of extruders // :[1, 2, 3, 4, 5] #define EXTRUDERS 2 // Generally expected filament diameter (1.75, 2.85, 3.0, ...). Used for Volumetric, Filament Width Sensor, etc. #define DEFAULT_NOMINAL_FILAMENT_DIA 1.75 // For Cyclops or any "multi-extruder" that shares a single nozzle. //#define SINGLENOZZLE /** * Průša MK2 Single Nozzle Multi-Material Multiplexer, and variants. * * This device allows one stepper driver on a control board to drive * two to eight stepper motors, one at a time, in a manner suitable * for extruders. * * This option only allows the multiplexer to switch on tool-change. * Additional options to configure custom E moves are pending. */ //#define MK2_MULTIPLEXER #if ENABLED(MK2_MULTIPLEXER) // Override the default DIO selector pins here, if needed. // Some pins files may provide defaults for these pins. //#define E_MUX0_PIN 40 // Always Required //#define E_MUX1_PIN 42 // Needed for 3 to 8 steppers //#define E_MUX2_PIN 44 // Needed for 5 to 8 steppers #endif // A dual extruder that uses a single stepper motor //#define SWITCHING_EXTRUDER #if ENABLED(SWITCHING_EXTRUDER) #define SWITCHING_EXTRUDER_SERVO_NR 0 #define SWITCHING_EXTRUDER_SERVO_ANGLES { 0, 90 } // Angles for E0, E1[, E2, E3] #if EXTRUDERS > 3 #define SWITCHING_EXTRUDER_E23_SERVO_NR 1 #endif #endif // A dual-nozzle that uses a servomotor to raise/lower one of the nozzles //#define SWITCHING_NOZZLE #if ENABLED(SWITCHING_NOZZLE) #define SWITCHING_NOZZLE_SERVO_NR 0 #define SWITCHING_NOZZLE_SERVO_ANGLES { 0, 90 } // Angles for E0, E1 //#define HOTEND_OFFSET_Z { 0.0, 0.0 } #endif /** * Two separate X-carriages with extruders that connect to a moving part * via a magnetic docking mechanism. Requires SOL1_PIN and SOL2_PIN. */ //#define PARKING_EXTRUDER #if ENABLED(PARKING_EXTRUDER) #define PARKING_EXTRUDER_SOLENOIDS_INVERT // If enabled, the solenoid is NOT magnetized with applied voltage #define PARKING_EXTRUDER_SOLENOIDS_PINS_ACTIVE LOW // LOW or HIGH pin signal energizes the coil #define PARKING_EXTRUDER_SOLENOIDS_DELAY 250 // Delay (ms) for magnetic field. No delay if 0 or not defined. #define PARKING_EXTRUDER_PARKING_X { -78, 184 } // X positions for parking the extruders #define PARKING_EXTRUDER_GRAB_DISTANCE 1 // mm to move beyond the parking point to grab the extruder #define PARKING_EXTRUDER_SECURITY_RAISE 5 // Z-raise before parking #define HOTEND_OFFSET_Z { 0.0, 1.3 } // Z-offsets of the two hotends. The first must be 0. #endif /** * "Mixing Extruder" * - Adds a new code, M165, to set the current mix factors. * - Extends the stepping routines to move multiple steppers in proportion to the mix. * - Optional support for Repetier Firmware M163, M164, and virtual extruder. * - This implementation supports only a single extruder. * - Enable DIRECT_MIXING_IN_G1 for Pia Taubert's reference implementation */ //#define MIXING_EXTRUDER #if ENABLED(MIXING_EXTRUDER) #define MIXING_STEPPERS 2 // Number of steppers in your mixing extruder #define MIXING_VIRTUAL_TOOLS 16 // Use the Virtual Tool method with M163 and M164 //#define DIRECT_MIXING_IN_G1 // Allow ABCDHI mix factors in G1 movement commands #endif // Offset of the extruders (uncomment if using more than one and relying on firmware to position when changing). // The offset has to be X=0, Y=0 for the extruder 0 hotend (default extruder). // For the other hotends it is their distance from the extruder 0 hotend. //#define HOTEND_OFFSET_X {0.0, 25.00} // (in mm) for each extruder, offset of the hotend on the X axis //#define HOTEND_OFFSET_Y {0.0, 0.00} // (in mm) for each extruder, offset of the hotend on the Y axis // @section machine /** * Select your power supply here. Use 0 if you haven't connected the PS_ON_PIN * * 0 = No Power Switch * 1 = ATX * 2 = X-Box 360 203Watts (the blue wire connected to PS_ON and the red wire to VCC) * * :{ 0:'No power switch', 1:'ATX', 2:'X-Box 360' } */ #define POWER_SUPPLY 0 #if POWER_SUPPLY > 0 // Enable this option to leave the PSU off at startup. // Power to steppers and heaters will need to be turned on with M80. //#define PS_DEFAULT_OFF //#define AUTO_POWER_CONTROL // Enable automatic control of the PS_ON pin #if ENABLED(AUTO_POWER_CONTROL) #define AUTO_POWER_FANS // Turn on PSU if fans need power #define AUTO_POWER_E_FANS #define AUTO_POWER_CONTROLLERFAN #define POWER_TIMEOUT 30 #endif #endif // @section temperature //=========================================================================== //============================= Mechanical Settings ========================= //=========================================================================== // @section machine // Uncomment one of these options to enable CoreXY, CoreXZ, or CoreYZ kinematics // either in the usual order or reversed //#define COREXY //#define COREXZ //#define COREYZ //#define COREYX //#define COREZX //#define COREZY //=========================================================================== //============================== Endstop Settings =========================== //=========================================================================== // @section homing // Specify here all the endstop connectors that are connected to any endstop or probe. // Almost all printers will be using one per axis. Probes will use one or more of the // extra connectors. Leave undefined any used for non-endstop and non-probe purposes. #define USE_XMIN_PLUG //#define USE_YMIN_PLUG #define USE_ZMIN_PLUG //#define USE_XMAX_PLUG #define USE_YMAX_PLUG #define USE_ZMAX_PLUG // Enable pullup for all endstops to prevent a floating state #define ENDSTOPPULLUPS #if DISABLED(ENDSTOPPULLUPS) // Disable ENDSTOPPULLUPS to set pullups individually //#define ENDSTOPPULLUP_XMAX //#define ENDSTOPPULLUP_YMAX //#define ENDSTOPPULLUP_ZMAX //#define ENDSTOPPULLUP_XMIN //#define ENDSTOPPULLUP_YMIN //#define ENDSTOPPULLUP_ZMIN //#define ENDSTOPPULLUP_ZMIN_PROBE #endif // Mechanical endstop with COM to ground and NC to Signal uses "false" here (most common setup). #define X_MIN_ENDSTOP_INVERTING true // set to true to invert the logic of the endstop. #define Y_MIN_ENDSTOP_INVERTING true // set to true to invert the logic of the endstop. #define Z_MIN_ENDSTOP_INVERTING false // set to true to invert the logic of the endstop. #define X_MAX_ENDSTOP_INVERTING false // set to true to invert the logic of the endstop. #define Y_MAX_ENDSTOP_INVERTING true // set to true to invert the logic of the endstop. #define Z_MAX_ENDSTOP_INVERTING true // set to true to invert the logic of the endstop. #define Z_MIN_PROBE_ENDSTOP_INVERTING false // set to true to invert the logic of the probe. /** * Stepper Drivers * * These settings allow Marlin to tune stepper driver timing and enable advanced options for * stepper drivers that support them. You may also override timing options in Configuration_adv.h. * * A4988 is assumed for unspecified drivers. * * Options: A4988, DRV8825, LV8729, L6470, TB6560, TB6600, TMC2100, * TMC2130, TMC2130_STANDALONE, TMC2208, TMC2208_STANDALONE, * TMC26X, TMC26X_STANDALONE, TMC2660, TMC2660_STANDALONE, * TMC5130, TMC5130_STANDALONE * :['A4988', 'DRV8825', 'LV8729', 'L6470', 'TB6560', 'TB6600', 'TMC2100', 'TMC2130', 'TMC2130_STANDALONE', 'TMC2208', 'TMC2208_STANDALONE', 'TMC26X', 'TMC26X_STANDALONE', 'TMC2660', 'TMC2660_STANDALONE', 'TMC5130', 'TMC5130_STANDALONE'] */ //#define X_DRIVER_TYPE A4988 //#define Y_DRIVER_TYPE A4988 //#define Z_DRIVER_TYPE A4988 //#define X2_DRIVER_TYPE A4988 //#define Y2_DRIVER_TYPE A4988 //#define Z2_DRIVER_TYPE A4988 //#define E0_DRIVER_TYPE A4988 //#define E1_DRIVER_TYPE A4988 //#define E2_DRIVER_TYPE A4988 //#define E3_DRIVER_TYPE A4988 //#define E4_DRIVER_TYPE A4988 // Enable this feature if all enabled endstop pins are interrupt-capable. // This will remove the need to poll the interrupt pins, saving many CPU cycles. //#define ENDSTOP_INTERRUPTS_FEATURE /** * Endstop Noise Filter * * Enable this option if endstops falsely trigger due to noise. * NOTE: Enabling this feature means adds an error of +/-0.2mm, so homing * will end up at a slightly different position on each G28. This will also * reduce accuracy of some bed probes. * For mechanical switches, the better approach to reduce noise is to install * a 100 nanofarads ceramic capacitor in parallel with the switch, making it * essentially noise-proof without sacrificing accuracy. * This option also increases MCU load when endstops or the probe are enabled. * So this is not recommended. USE AT YOUR OWN RISK. * (This feature is not required for common micro-switches mounted on PCBs * based on the Makerbot design, since they already include the 100nF capacitor.) */ //#define ENDSTOP_NOISE_FILTER //============================================================================= //============================== Movement Settings ============================ //============================================================================= // @section motion /** * Default Settings * * These settings can be reset by M502 * * Note that if EEPROM is enabled, saved values will override these. */ /** * With this option each E stepper can have its own factors for the * following movement settings. If fewer factors are given than the * total number of extruders, the last value applies to the rest. */ //#define DISTINCT_E_FACTORS /** * Default Axis Steps Per Unit (steps/mm) * Override with M92 * X, Y, Z, E0 [, E1[, E2[, E3[, E4]]]] */ #define DEFAULT_AXIS_STEPS_PER_UNIT { 80, 80, 400, 120 } /** * Default Max Feed Rate (mm/s) * Override with M203 * X, Y, Z, E0 [, E1[, E2[, E3[, E4]]]] */ #define DEFAULT_MAX_FEEDRATE { 80, 80, 5, 100 } /** * Default Max Acceleration (change/s) change = mm/s * (Maximum start speed for accelerated moves) * Override with M201 * X, Y, Z, E0 [, E1[, E2[, E3[, E4]]]] */ #define DEFAULT_MAX_ACCELERATION { 200, 200, 100, 10000 } /** * Default Acceleration (change/s) change = mm/s * Override with M204 * * M204 P Acceleration * M204 R Retract Acceleration * M204 T Travel Acceleration */ #define DEFAULT_ACCELERATION 200 // X, Y, Z and E acceleration for printing moves #define DEFAULT_RETRACT_ACCELERATION 3000 // E acceleration for retracts #define DEFAULT_TRAVEL_ACCELERATION 200 // X, Y, Z acceleration for travel (non printing) moves /** * Default Jerk (mm/s) * Override with M205 X Y Z E * * "Jerk" specifies the minimum speed change that requires acceleration. * When changing speed and direction, if the difference is less than the * value set here, it may happen instantaneously. */ #define DEFAULT_XJERK 2.5 #define DEFAULT_YJERK 2.5 #define DEFAULT_ZJERK 0.3 #define DEFAULT_EJERK 5.0 /** * S-Curve Acceleration * * This option eliminates vibration during printing by fitting a Bézier * curve to move acceleration, producing much smoother direction changes. * * See [github.com] */ #define S_CURVE_ACCELERATION //=========================================================================== //============================= Z Probe Options ============================= //=========================================================================== // @section probes // // See [marlinfw.org] // /** * Z_MIN_PROBE_USES_Z_MIN_ENDSTOP_PIN * * Enable this option for a probe connected to the Z Min endstop pin. */ #define Z_MIN_PROBE_USES_Z_MIN_ENDSTOP_PIN /** * Z_MIN_PROBE_ENDSTOP * * Enable this option for a probe connected to any pin except Z-Min. * (By default Marlin assumes the Z-Max endstop pin.) * To use a custom Z Probe pin, set Z_MIN_PROBE_PIN below. * * - The simplest option is to use a free endstop connector. * - Use 5V for powered (usually inductive) sensors. * * - RAMPS 1.3/1.4 boards may use the 5V, GND, and Aux4->D32 pin: * - For simple switches connect... * - normally-closed switches to GND and D32. * - normally-open switches to 5V and D32. * * WARNING: Setting the wrong pin may have unexpected and potentially * disastrous consequences. Use with caution and do your homework. * */ //#define Z_MIN_PROBE_ENDSTOP /** * Probe Type * * Allen Key Probes, Servo Probes, Z-Sled Probes, FIX_MOUNTED_PROBE, etc. * Activate one of these to use Auto Bed Leveling below. */ /** * The "Manual Probe" provides a means to do "Auto" Bed Leveling without a probe. * Use G29 repeatedly, adjusting the Z height at each point with movement commands * or (with LCD_BED_LEVELING) the LCD controller. */ //#define PROBE_MANUALLY //#define MANUAL_PROBE_START_Z 0.2 /** * A Fix-Mounted Probe either doesn't deploy or needs manual deployment. * (e.g., an inductive probe or a nozzle-based probe-switch.) */ #define FIX_MOUNTED_PROBE /** * Z Servo Probe, such as an endstop switch on a rotating arm. */ //#define Z_PROBE_SERVO_NR 0 // Defaults to SERVO 0 connector. //#define Z_SERVO_ANGLES {70,0} // Z Servo Deploy and Stow angles /** * The BLTouch probe uses a Hall effect sensor and emulates a servo. */ //#define BLTOUCH #if ENABLED(BLTOUCH) //#define BLTOUCH_DELAY 375 // (ms) Enable and increase if needed #endif /** * Enable one or more of the following if probing seems unreliable. * Heaters and/or fans can be disabled during probing to minimize electrical * noise. A delay can also be added to allow noise and vibration to settle. * These options are most useful for the BLTouch probe, but may also improve * readings with inductive probes and piezo sensors. */ //#define PROBING_HEATERS_OFF // Turn heaters off when probing #if ENABLED(PROBING_HEATERS_OFF) //#define WAIT_FOR_BED_HEATER // Wait for bed to heat back up between probes (to improve accuracy) #endif //#define PROBING_FANS_OFF // Turn fans off when probing //#define DELAY_BEFORE_PROBING 200 // (ms) To prevent vibrations from triggering piezo sensors // A probe that is deployed and stowed with a solenoid pin (SOL1_PIN) //#define SOLENOID_PROBE // A sled-mounted probe like those designed by Charles Bell. //#define Z_PROBE_SLED //#define SLED_DOCKING_OFFSET 5 // The extra distance the X axis must travel to pickup the sled. 0 should be fine but you can push it further if you'd like. // // For Z_PROBE_ALLEN_KEY see the Delta example configurations. // /** * Z Probe to nozzle (X,Y) offset, relative to (0, 0). * X and Y offsets must be integers. * * In the following example the X and Y offsets are both positive: * #define X_PROBE_OFFSET_FROM_EXTRUDER 10 * #define Y_PROBE_OFFSET_FROM_EXTRUDER 10 * * +-- BACK ---+ * | | * L | (+) P | R <-- probe (20,20) * E | | I * F | (-) N (+) | G <-- nozzle (10,10) * T | | H * | (-) | T * | | * O-- FRONT --+ * (0,0) */ #define X_PROBE_OFFSET_FROM_EXTRUDER 73 // X offset: -left +right [of the nozzle] #define Y_PROBE_OFFSET_FROM_EXTRUDER -44 // Y offset: -front +behind [the nozzle] #define Z_PROBE_OFFSET_FROM_EXTRUDER 0 // Z offset: -below +above [the nozzle] // Certain types of probes need to stay away from edges #define MIN_PROBE_EDGE -62 // X and Y axis travel speed (mm/m) between probes #define XY_PROBE_SPEED 8000 // Feedrate (mm/m) for the first approach when double-probing (MULTIPLE_PROBING == 2) #define Z_PROBE_SPEED_FAST HOMING_FEEDRATE_Z // Feedrate (mm/m) for the "accurate" probe of each point #define Z_PROBE_SPEED_SLOW (Z_PROBE_SPEED_FAST / 2) // The number of probes to perform at each point. // Set to 2 for a fast/slow probe, using the second probe result. // Set to 3 or more for slow probes, averaging the results. #define MULTIPLE_PROBING 2 /** * Z probes require clearance when deploying, stowing, and moving between * probe points to avoid hitting the bed and other hardware. * Servo-mounted probes require extra space for the arm to rotate. * Inductive probes need space to keep from triggering early. * * Use these settings to specify the distance (mm) to raise the probe (or * lower the bed). The values set here apply over and above any (negative) * probe Z Offset set with Z_PROBE_OFFSET_FROM_EXTRUDER, M851, or the LCD. * Only integer values >= 1 are valid here. * * Example: `M851 Z-5` with a CLEARANCE of 4 => 9mm from bed to nozzle. * But: `M851 Z+1` with a CLEARANCE of 2 => 2mm from bed to nozzle. */ #define Z_CLEARANCE_DEPLOY_PROBE 20 // Z Clearance for Deploy/Stow #define Z_CLEARANCE_BETWEEN_PROBES 20 // Z Clearance between probe points #define Z_CLEARANCE_MULTI_PROBE 5 // Z Clearance between multiple probes //#define Z_AFTER_PROBING 5 // Z position after probing is done #define Z_PROBE_LOW_POINT 0 // Farthest distance below the trigger-point to go before stopping // For M851 give a range for adjusting the Z probe offset #define Z_PROBE_OFFSET_RANGE_MIN -50 #define Z_PROBE_OFFSET_RANGE_MAX 50 // Enable the M48 repeatability test to test probe accuracy //#define Z_MIN_PROBE_REPEATABILITY_TEST // For Inverting Stepper Enable Pins (Active Low) use 0, Non Inverting (Active High) use 1 // :{ 0:'Low', 1:'High' } #define X_ENABLE_ON 0 #define Y_ENABLE_ON 0 #define Z_ENABLE_ON 0 #define E_ENABLE_ON 0 // For all extruders // Disables axis stepper immediately when it's not being used. // WARNING: When motors turn off there is a chance of losing position accuracy! #define DISABLE_X false #define DISABLE_Y false #define DISABLE_Z false // Warn on display about possibly reduced accuracy //#define DISABLE_REDUCED_ACCURACY_WARNING // @section extruder #define DISABLE_E false // For all extruders #define DISABLE_INACTIVE_EXTRUDER true // Keep only the active extruder enabled. // @section machine // Invert the stepper direction. Change (or reverse the motor connector) if an axis goes the wrong way. #define INVERT_X_DIR true #define INVERT_Y_DIR true #define INVERT_Z_DIR false // @section extruder // For direct drive extruder v9 set to true, for geared extruder set to false. #define INVERT_E0_DIR false #define INVERT_E1_DIR false #define INVERT_E2_DIR false #define INVERT_E3_DIR false #define INVERT_E4_DIR false // @section homing //#define NO_MOTION_BEFORE_HOMING // Inhibit movement until all axes have been homed //#define UNKNOWN_Z_NO_RAISE // Don't raise Z (lower the bed) if Z is "unknown." For beds that fall when Z is powered off. //#define Z_HOMING_HEIGHT 4 // (in mm) Minimal z height before homing (G28) for Z clearance above the bed, clamps, ... // Be sure you have this distance over your Z_MAX_POS in case. // Direction of endstops when homing; 1=MAX, -1=MIN // :[-1,1] #define X_HOME_DIR -1 #define Y_HOME_DIR 1 #define Z_HOME_DIR 1 // @section machine // The size of the print bed #define X_BED_SIZE 270 #define Y_BED_SIZE 180 // Travel limits (mm) after homing, corresponding to endstop positions. #define X_MIN_POS -80 #define Y_MIN_POS 0 #define Z_MIN_POS 0 #define X_MAX_POS X_BED_SIZE #define Y_MAX_POS Y_BED_SIZE #define Z_MAX_POS 172 /** * Software Endstops * * - Prevent moves outside the set machine bounds. * - Individual axes can be disabled, if desired. * - X and Y only apply to Cartesian robots. * - Use 'M211' to set software endstops on/off or report current state */ // Min software endstops constrain movement within minimum coordinate bounds #define MIN_SOFTWARE_ENDSTOPS #if ENABLED(MIN_SOFTWARE_ENDSTOPS) #define MIN_SOFTWARE_ENDSTOP_X #define MIN_SOFTWARE_ENDSTOP_Y #define MIN_SOFTWARE_ENDSTOP_Z #endif // Max software endstops constrain movement within maximum coordinate bounds #define MAX_SOFTWARE_ENDSTOPS #if ENABLED(MAX_SOFTWARE_ENDSTOPS) #define MAX_SOFTWARE_ENDSTOP_X #define MAX_SOFTWARE_ENDSTOP_Y #define MAX_SOFTWARE_ENDSTOP_Z #endif #if ENABLED(MIN_SOFTWARE_ENDSTOPS) || ENABLED(MAX_SOFTWARE_ENDSTOPS) //#define SOFT_ENDSTOPS_MENU_ITEM // Enable/Disable software endstops from the LCD #endif /** * Filament Runout Sensors * Mechanical or opto endstops are used to check for the presence of filament. * * RAMPS-based boards use SERVO3_PIN for the first runout sensor. * For other boards you may need to define FIL_RUNOUT_PIN, FIL_RUNOUT2_PIN, etc. * By default the firmware assumes HIGH=FILAMENT PRESENT. */ //#define FILAMENT_RUNOUT_SENSOR #if ENABLED(FILAMENT_RUNOUT_SENSOR) #define NUM_RUNOUT_SENSORS 1 // Number of sensors, up to one per extruder. Define a FIL_RUNOUT#_PIN for each. #define FIL_RUNOUT_INVERTING false // set to true to invert the logic of the sensor. #define FIL_RUNOUT_PULLUP // Use internal pullup for filament runout pins. #define FILAMENT_RUNOUT_SCRIPT "M600" #endif //=========================================================================== //=============================== Bed Leveling ============================== //=========================================================================== // @section calibrate /** * Choose one of the options below to enable G29 Bed Leveling. The parameters * and behavior of G29 will change depending on your selection. * * If using a Probe for Z Homing, enable Z_SAFE_HOMING also! * * - AUTO_BED_LEVELING_3POINT * Probe 3 arbitrary points on the bed (that aren't collinear) * You specify the XY coordinates of all 3 points. * The result is a single tilted plane. Best for a flat bed. * * - AUTO_BED_LEVELING_LINEAR * Probe several points in a grid. * You specify the rectangle and the density of sample points. * The result is a single tilted plane. Best for a flat bed. * * - AUTO_BED_LEVELING_BILINEAR * Probe several points in a grid. * You specify the rectangle and the density of sample points. * The result is a mesh, best for large or uneven beds. * * - AUTO_BED_LEVELING_UBL (Unified Bed Leveling) * A comprehensive bed leveling system combining the features and benefits * of other systems. UBL also includes integrated Mesh Generation, Mesh * Validation and Mesh Editing systems. * * - MESH_BED_LEVELING * Probe a grid manually * The result is a mesh, suitable for large or uneven beds. (See BILINEAR.) * For machines without a probe, Mesh Bed Leveling provides a method to perform * leveling in steps so you can manually adjust the Z height at each grid-point. * With an LCD controller the process is guided step-by-step. */ //#define AUTO_BED_LEVELING_3POINT //#define AUTO_BED_LEVELING_LINEAR #define AUTO_BED_LEVELING_BILINEAR //#define AUTO_BED_LEVELING_UBL //#define MESH_BED_LEVELING /** * Normally G28 leaves leveling disabled on completion. Enable * this option to have G28 restore the prior leveling state. */ //#define RESTORE_LEVELING_AFTER_G28 /** * Enable detailed logging of G28, G29, M48, etc. * Turn on with the command 'M111 S32'. * NOTE: Requires a lot of PROGMEM! */ //#define DEBUG_LEVELING_FEATURE #if ENABLED(MESH_BED_LEVELING) || ENABLED(AUTO_BED_LEVELING_BILINEAR) || ENABLED(AUTO_BED_LEVELING_UBL) // Gradually reduce leveling correction until a set height is reached, // at which point movement will be level to the machine's XY plane. // The height can be set with M420 Z #define ENABLE_LEVELING_FADE_HEIGHT // For Cartesian machines, instead of dividing moves on mesh boundaries, // split up moves into short segments like a Delta. This follows the // contours of the bed more closely than edge-to-edge straight moves. #define SEGMENT_LEVELED_MOVES #define LEVELED_SEGMENT_LENGTH 5.0 // (mm) Length of all segments (except the last one) /** * Enable the G26 Mesh Validation Pattern tool. */ //#define G26_MESH_VALIDATION #if ENABLED(G26_MESH_VALIDATION) #define MESH_TEST_NOZZLE_SIZE 0.4 // (mm) Diameter of primary nozzle. #define MESH_TEST_LAYER_HEIGHT 0.2 // (mm) Default layer height for the G26 Mesh Validation Tool. #define MESH_TEST_HOTEND_TEMP 205.0 // (°C) Default nozzle temperature for the G26 Mesh Validation Tool. #define MESH_TEST_BED_TEMP 60.0 // (°C) Default bed temperature for the G26 Mesh Validation Tool. #endif #endif #if ENABLED(AUTO_BED_LEVELING_LINEAR) || ENABLED(AUTO_BED_LEVELING_BILINEAR) // Set the number of grid points per dimension. #define GRID_MAX_POINTS_X 1 #define GRID_MAX_POINTS_Y GRID_MAX_POINTS_X // Set the boundaries for probing (where the probe can reach). #define LEFT_PROBE_BED_POSITION 15 #define RIGHT_PROBE_BED_POSITION 180 #define FRONT_PROBE_BED_POSITION 10 #define BACK_PROBE_BED_POSITION 135 // Probe along the Y axis, advancing X after each column //#define PROBE_Y_FIRST #if ENABLED(AUTO_BED_LEVELING_BILINEAR) // Beyond the probed grid, continue the implied tilt? // Default is to maintain the height of the nearest edge. //#define EXTRAPOLATE_BEYOND_GRID // // Experimental Subdivision of the grid by Catmull-Rom method. // Synthesizes intermediate points to produce a more detailed mesh. // //#define ABL_BILINEAR_SUBDIVISION #if ENABLED(ABL_BILINEAR_SUBDIVISION) // Number of subdivisions between probe points #define BILINEAR_SUBDIVISIONS 3 #endif #endif #elif ENABLED(AUTO_BED_LEVELING_UBL) //=========================================================================== //========================= Unified Bed Leveling ============================ //=========================================================================== //#define MESH_EDIT_GFX_OVERLAY // Display a graphics overlay while editing the mesh #define MESH_INSET 1 // Set Mesh bounds as an inset region of the bed #define GRID_MAX_POINTS_X 10 // Don't use more than 15 points per axis, implementation limited. #define GRID_MAX_POINTS_Y GRID_MAX_POINTS_X #define UBL_MESH_EDIT_MOVES_Z // Sophisticated users prefer no movement of nozzle #define UBL_SAVE_ACTIVE_ON_M500 // Save the currently active mesh in the current slot on M500 //#define UBL_Z_RAISE_WHEN_OFF_MESH 2.5 // When the nozzle is off the mesh, this value is used // as the Z-Height correction value. #elif ENABLED(MESH_BED_LEVELING) //=========================================================================== //=================================== Mesh ================================== //=========================================================================== #define MESH_INSET 10 // Set Mesh bounds as an inset region of the bed #define GRID_MAX_POINTS_X 3 // Don't use more than 7 points per axis, implementation limited. #define GRID_MAX_POINTS_Y GRID_MAX_POINTS_X //#define MESH_G28_REST_ORIGIN // After homing all axes ('G28' or 'G28 XYZ') rest Z at Z_MIN_POS #endif // BED_LEVELING /** * Points to probe for all 3-point Leveling procedures. * Override if the automatically selected points are inadequate. */ #if ENABLED(AUTO_BED_LEVELING_3POINT) || ENABLED(AUTO_BED_LEVELING_UBL) //#define PROBE_PT_1_X 15 //#define PROBE_PT_1_Y 180 //#define PROBE_PT_2_X 15 //#define PROBE_PT_2_Y 20 //#define PROBE_PT_3_X 170 //#define PROBE_PT_3_Y 20 #endif /** * Add a bed leveling sub-menu for ABL or MBL. * Include a guided procedure if manual probing is enabled. */ //#define LCD_BED_LEVELING #if ENABLED(LCD_BED_LEVELING) #define MBL_Z_STEP 0.025 // Step size while manually probing Z axis. #define LCD_PROBE_Z_RANGE 4 // Z Range centered on Z_MIN_POS for LCD Z adjustment #endif // Add a menu item to move between bed corners for manual bed adjustment //#define LEVEL_BED_CORNERS #if ENABLED(LEVEL_BED_CORNERS) #define LEVEL_CORNERS_INSET 30 // (mm) An inset for corner leveling //#define LEVEL_CENTER_TOO // Move to the center after the last corner #endif /** * Commands to execute at the end of G29 probing. * Useful to retract or move the Z probe out of the way. */ //#define Z_PROBE_END_SCRIPT "G1 Z10 F12000\nG1 X15 Y330\nG1 Z0.5\nG1 Z10" // @section homing // The center of the bed is at (X=0, Y=0) //#define BED_CENTER_AT_0_0 // Manually set the home position. Leave these undefined for automatic settings. // For DELTA this is the top-center of the Cartesian print volume. //#define MANUAL_X_HOME_POS 0 //#define MANUAL_Y_HOME_POS 0 //#define MANUAL_Z_HOME_POS 0 // Use "Z Safe Homing" to avoid homing with a Z probe outside the bed area. // // With this feature enabled: // // - Allow Z homing only after X and Y homing AND stepper drivers still enabled. // - If stepper drivers time out, it will need X and Y homing again before Z homing. // - Move the Z probe (or nozzle) to a defined XY point before Z Homing when homing all axes (G28). // - Prevent Z homing when the Z probe is outside bed area. // //#define Z_SAFE_HOMING #if ENABLED(Z_SAFE_HOMING) #define Z_SAFE_HOMING_X_POINT ((X_BED_SIZE) / 2) // X point for Z homing when homing all axes (G28). #define Z_SAFE_HOMING_Y_POINT ((Y_BED_SIZE) / 2) // Y point for Z homing when homing all axes (G28). #endif // Homing speeds (mm/m) #define HOMING_FEEDRATE_XY (50*60) #define HOMING_FEEDRATE_Z (4*60) // @section calibrate /** * Bed Skew Compensation * * This feature corrects for misalignment in the XYZ axes. * * Take the following steps to get the bed skew in the XY plane: * 1. Print a test square (e.g., [www.thingiverse.com]) * 2. For XY_DIAG_AC measure the diagonal A to C * 3. For XY_DIAG_BD measure the diagonal B to D * 4. For XY_SIDE_AD measure the edge A to D * * Marlin automatically computes skew factors from these measurements. * Skew factors may also be computed and set manually: * * - Compute AB : SQRT(2*AC*AC+2*BD*BD-4*AD*AD)/2 * - XY_SKEW_FACTOR : TAN(PI/2-ACOS((AC*AC-AB*AB-AD*AD)/(2*AB*AD))) * * If desired, follow the same procedure for XZ and YZ. * Use these diagrams for reference: * * Y Z Z * ^ B-------C ^ B-------C ^ B-------C * | / / | / / | / / * | / / | / / | / / * | A-------D | A-------D | A-------D * +-------------->X +-------------->X +-------------->Y * XY_SKEW_FACTOR XZ_SKEW_FACTOR YZ_SKEW_FACTOR */ //#define SKEW_CORRECTION #if ENABLED(SKEW_CORRECTION) // Input all length measurements here: #define XY_DIAG_AC 282.8427124746 #define XY_DIAG_BD 282.8427124746 #define XY_SIDE_AD 200 // Or, set the default skew factors directly here // to override the above measurements: #define XY_SKEW_FACTOR 0.0 //#define SKEW_CORRECTION_FOR_Z #if ENABLED(SKEW_CORRECTION_FOR_Z) #define XZ_DIAG_AC 282.8427124746 #define XZ_DIAG_BD 282.8427124746 #define YZ_DIAG_AC 282.8427124746 #define YZ_DIAG_BD 282.8427124746 #define YZ_SIDE_AD 200 #define XZ_SKEW_FACTOR 0.0 #define YZ_SKEW_FACTOR 0.0 #endif // Enable this option for M852 to set skew at runtime //#define SKEW_CORRECTION_GCODE #endif //============================================================================= //============================= Additional Features =========================== //============================================================================= // @section extras // // EEPROM // // The microcontroller can store settings in the EEPROM, e.g. max velocity... // M500 - stores parameters in EEPROM // M501 - reads parameters from EEPROM (if you need reset them after you changed them temporarily). // M502 - reverts to the default "factory settings". You still need to store them in EEPROM afterwards if you want to. // #define EEPROM_SETTINGS // Enable for M500 and M501 commands //#define DISABLE_M503 // Saves ~2700 bytes of PROGMEM. Disable for release! #define EEPROM_CHITCHAT // Give feedback on EEPROM commands. Disable to save PROGMEM. // // Host Keepalive // // When enabled Marlin will send a busy status message to the host // every couple of seconds when it can't accept commands. // #define HOST_KEEPALIVE_FEATURE // Disable this if your host doesn't like keepalive messages #define DEFAULT_KEEPALIVE_INTERVAL 2 // Number of seconds between "busy" messages. Set with M113. #define BUSY_WHILE_HEATING // Some hosts require "busy" messages even during heatingThank you all for any information you can provide.

Marcus

Edited 1 time(s). Last edit at 12/09/2018 09:40PM by Marcus.Couceiro.

|

Re: Auto Bed Leveling issues December 10, 2018 05:44AM |

Registered: 7 years ago Posts: 759 |

The Z offset value that is stored in the eeprom will over ride your updates in the config.h

You can use the built in eeprom editor in repetier host to update the z offset (marlin uses a negative value here, so -18.6)

or you can send the following comands to the printer to update the eeprom with the settings in config.h

M502 ;read config.h values

M500 ;store values to eeprom

You can use the built in eeprom editor in repetier host to update the z offset (marlin uses a negative value here, so -18.6)

or you can send the following comands to the printer to update the eeprom with the settings in config.h

M502 ;read config.h values

M500 ;store values to eeprom

|

Re: Auto Bed Leveling issues December 10, 2018 05:54AM |

Registered: 6 years ago Posts: 26 |

|

Re: Auto Bed Leveling issues December 10, 2018 03:16PM |

Registered: 6 years ago Posts: 1,863 |

Quote

Marcus.Couceiro

First, M851 Z-18.6, then M500, then M502 and finally M501 to make sure the value used is the one sent with M851 command.

That did not solve the problem.

Marcus

Let see if I have this correct you issue a G29, the Probe homes at 0,0 where a 15mm metal stand is sitting on the bed.

This will put you 15mm above the bed plus your Z Clearance of 20mm for Deploy/Stow. At this point you should be 35mm above the bed.

#define Z_CLEARANCE_DEPLOY_PROBE 20 // Z Clearance for Deploy/Stow

Unless you lower the Z-Axis to zero, Then you should be at 15mm above the bed or the height of the metal stand.

Plus the difference between Height of the capacitive probe around 7mm and the Nozzle 3.5mm.

#define Z_PROBE_OFFSET_FROM_EXTRUDER 0 // Z offset: -below [the nozzle]

Your Z-Probe offset should be set to -3.5mm, the distance between the Probe and the Nozzle.

This then places your Nozzle on the 15mm metal stand. With you current settings that in order to get to the bed you would have to drop 18.5mm

Am I understanding what you posted.

This is the order in which you preform the steps, "the M502 Restore to Factory" in the Middle is re-setting your new Z-Offset

First, M502 then M851 Z-18.6, then M500 finally M501 if you want to make sure the value used is the one sent with M851 command.

Edited 2 time(s). Last edit at 12/10/2018 05:13PM by Roberts_Clif.

Computer Programmer / Electronics Technician

|

Re: Auto Bed Leveling issues December 10, 2018 04:01PM |

Registered: 6 years ago Posts: 26 |

Hi Robert,

Not sure if

this is a suggestion or this is what I did previously? Could you clarify?

I guess you are correct in your understanding. The problem is that I never get 18.5mm above the bed. I am always higher than that.

Regards,

Marcus

Not sure if

Quote

this is the order in which you preform the steps, M502 Restore to Factory in the Middle of your setting your new Z-Offset

this is a suggestion or this is what I did previously? Could you clarify?

Quote

Am I understanding what you posted.

I guess you are correct in your understanding. The problem is that I never get 18.5mm above the bed. I am always higher than that.

Regards,

Marcus

|

Re: Auto Bed Leveling issues December 10, 2018 05:00PM |

Registered: 6 years ago Posts: 26 |

Hey Gentlemen,

Not sure if good news but at least something different.

With #define Z_PROBE_OFFSET_FROM_EXTRUDER 0 // Z offset: -below [the nozzle], sent a G29 command and waited for the result (only one point to speed up the process). Got 18.78mm. Added 3.5mm to this and sent M851 Z-22.28, M500 and then a M501 to make sure it was saved.

Moved the extruder to (100,100) and Z to 10. As it looked ok, started sending decreasing Z and got the nozzle exactly touching the bed.

Homed Z again and sent another G29. After probing, got the value -3.495mm. Sent the nozzle to (100,100) and lowered Z to 0. Now I get around 15mm from the nozzle to the bed.

Guess we are getting close but need some help in here.

Regards

Marcus

Not sure if good news but at least something different.

With #define Z_PROBE_OFFSET_FROM_EXTRUDER 0 // Z offset: -below [the nozzle], sent a G29 command and waited for the result (only one point to speed up the process). Got 18.78mm. Added 3.5mm to this and sent M851 Z-22.28, M500 and then a M501 to make sure it was saved.

Moved the extruder to (100,100) and Z to 10. As it looked ok, started sending decreasing Z and got the nozzle exactly touching the bed.

Homed Z again and sent another G29. After probing, got the value -3.495mm. Sent the nozzle to (100,100) and lowered Z to 0. Now I get around 15mm from the nozzle to the bed.

Guess we are getting close but need some help in here.

Regards

Marcus

|

Re: Auto Bed Leveling issues December 10, 2018 05:53PM |

Registered: 6 years ago Posts: 26 |

Ok, got lost again.

After the issue with the value -3.495mm, I repeated everything again.

Set #define Z_PROBE_OFFSET_FROM_EXTRUDER 0 // Z offset: -below [the nozzle], sent a G29 command and waited for the result (only one point to speed up the process). Got 18.78mm. Added 3.5mm to this and sent M851 Z-22.28, M500 and then a M501 to make sure it was saved.

Moved the extruder to (100,100) and Z to 10. As it looked ok, started sending decreasing Z and got the nozzle exactly touching the bed.

Sent Z Home. Sent G29 again and now, everytime the probe is about to sense (I can see how close it is from the metal Stand) I get a Probe Fail.

Enabled Debug and had the following

Any Ideas? I think I am out of them now.

Cheers!

Marcus

After the issue with the value -3.495mm, I repeated everything again.

Set #define Z_PROBE_OFFSET_FROM_EXTRUDER 0 // Z offset: -below [the nozzle], sent a G29 command and waited for the result (only one point to speed up the process). Got 18.78mm. Added 3.5mm to this and sent M851 Z-22.28, M500 and then a M501 to make sure it was saved.

Moved the extruder to (100,100) and Z to 10. As it looked ok, started sending decreasing Z and got the nozzle exactly touching the bed.

Sent Z Home. Sent G29 again and now, everytime the probe is about to sense (I can see how close it is from the metal Stand) I get a Probe Fail.

Enabled Debug and had the following

20:13:03.196 : echoEBUG:LEVELING 20:13:12.392 : N19 G29*42 20:13:12.392 : current_position=(-80.00, 180.00, 172.00) : >>> G29 20:13:12.402 : Machine Type: Cartesian 20:13:12.402 : Probe: FIX_MOUNTED_PROBE 20:13:12.402 : Probe Offset X:73 Y:-44 Z:-22.13 (Right-Front & Below Nozzle) 20:13:12.402 : Auto Bed Leveling: BILINEAR (disabled) 20:13:12.412 : current_position=(-80.00, 180.00, 172.00) : set_probe_deployed 20:13:12.412 : deploy: 1 20:13:12.412 : do_probe_raise(20.00) 20:13:12.422 : >>> do_blocking_move_to(-80.00, 180.00, 172.00) 20:13:12.422 : <<< do_blocking_move_to 20:13:12.432 : current_position=(-80.00, 180.00, 172.00) : setup_for_endstop_or_probe_move 20:13:12.432 : reset_bed_level 20:13:12.432 : >>> probe_pt(15.00, 10.00, raise, 0, probe_relative) 20:13:12.442 : current_position=(-80.00, 180.00, 172.00) : 20:13:12.442 : >>> do_blocking_move_to(-58.00, 54.00, 172.00) 20:13:14.470 : <<< do_blocking_move_to 20:13:14.480 : current_position=(-58.00, 54.00, 172.00) : set_probe_deployed 20:13:14.480 : deploy: 1 20:13:14.490 : current_position=(-58.00, 54.00, 172.00) : >>> run_z_probe 20:13:14.490 : current_position=(-58.00, 54.00, 172.00) : >>> do_probe_move 20:13:14.490 : >>> do_blocking_move_to(-58.00, 54.00, 22.13) 20:13:52.134 : <<< do_blocking_move_to 20:13:52.144 : current_position=(-58.00, 54.00, 22.13) : sync_plan_position 20:13:52.144 : current_position=(-58.00, 54.00, 22.13) : <<< do_probe_move 20:13:52.144 : FAST Probe fail! 20:13:52.154 : current_position=(-58.00, 54.00, 22.13) : <<< run_z_probe 20:13:52.154 : >>> do_blocking_move_to(-58.00, 54.00, 42.13) 20:13:57.311 : <<< do_blocking_move_to 20:13:57.311 : Error

robing failed

Any Ideas? I think I am out of them now.

Cheers!

Marcus

|

Re: Auto Bed Leveling issues December 10, 2018 08:54PM |

Registered: 6 years ago Posts: 1,863 |

Quote

Marcus.Couceiro

Ok, got lost again.

Set #define Z_PROBE_OFFSET_FROM_EXTRUDER 0 // Z offset: -below [the nozzle], sent a G29 command and waited for the result (only one point to speed up the process). Got 18.78mm. Added 3.5mm to this and sent M851 Z-22.28, M500 and then a M501 to make sure it was saved.

Marcus

Let's Try it this way!

First, Read Firmware Defaults : Send M502

Second, Set Your New Z values : Send M851 Z-22.28

Third, Save settings to EEProm : Send M500

Optional

Forth, Restore Settings from EEProm : Send M501

Fifth, Report Settings From EEProm : Send M503

Sample of my M503 below

Send: M503 Recv: echo: G21 ; Units in mm Recv: echo: M149 C ; Units in Celsius Recv: Recv: echo: Filament settings: Disabled Recv: echo: M200 D1.75 Recv: echo: M200 D0 Recv: echo: Steps per unit: Recv: echo: M92 X80.00 Y80.00 Z1600.00 E94.50 Recv: echo: Maximum feedrates (units/s): Recv: echo: M203 X200.00 Y200.00 Z5.00 E25.00 Recv: echo: Maximum Acceleration (units/s2): Recv: echo: M201 X3000 Y3000 Z100 E3000 Recv: echo: Acceleration (units/s2): P R T Recv: echo: M204 P3000.00 R3000.00 T3000.00 Recv: echo: Advanced: S T B X Z E Recv: echo: M205 S0.00 T0.00 B20000 X5.00 Y5.00 Z0.40 E5.00 Recv: echo: Home offset: Recv: echo: M206 X0.00 Y0.00 Z0.00 Recv: echo: Auto Bed Leveling: Recv: echo: M420 S0 Z10.00 Recv: echo: Material heatup parameters: Recv: echo: M145 S0 H199 B45 F0 Recv: echo: M145 S1 H228 B96 F0 Recv: echo: PID settings: Recv: echo: M301 P22.20 I1.08 D114.00 Recv: echo: Z-Probe Offset (mm): Recv: echo: M851 Z-0.50

Edited 4 time(s). Last edit at 12/10/2018 09:40PM by Roberts_Clif.

Computer Programmer / Electronics Technician

|

Re: Auto Bed Leveling issues December 11, 2018 06:48AM |

Registered: 6 years ago Posts: 26 |

Hi Roberts,

Thank you for your patience. Here are the results, as you suggested:

With these settings, everytime I send a G29 I get a Fail Probe!!. See below:

Does it make any sense to you guys?

Thanks,

Marcus

Thank you for your patience. Here are the results, as you suggested:

08:57:41.265 : N20 M502*22 08:57:41.265 : echo:Hardcoded Default Settings Loaded 08:57:58.046 : N21 M851 Z-22.13*103 08:58:01.304 : N22 M500*22 08:58:01.854 : echoettings Stored (667 bytes; crc 11866) 08:58:22.030 : N23 M501*22 08:58:22.050 : echo:V55 stored settings retrieved (667 bytes; crc 11866) 08:58:22.060 : echo: G21 ; (mm) 08:58:22.060 : echo:Filament settings: Disabled 08:58:22.060 : echo: M200 D1.75 08:58:22.060 : echo: M200 T1 D1.75 08:58:22.060 : echo: M200 D0 08:58:22.060 : echo

teps per unit: 08:58:22.070 : echo: M92 X80.00 Y80.00 Z400.00 E120.00 08:58:22.070 : echo:Maximum feedrates (units/s): 08:58:22.070 : echo: M203 X80.00 Y80.00 Z100.00 E100.00 08:58:22.080 : echo:Maximum Acceleration (units/s2): 08:58:22.080 : echo: M201 X200 Y200 Z100 E10000 08:58:22.090 : echo:Acceleration (units/s2): P R T 08:58:22.090 : echo: M204 P200.00 R3000.00 T200.00 08:58:22.100 : echo:Advanced: B S T X Y Z E 08:58:22.110 : echo: M205 B20000 S0.00 T0.00 X2.50 Y2.50 Z0.30 E5.00 08:58:22.110 : echo:Home offset: 08:58:22.110 : echo: M206 X0.00 Y0.00 Z0.00 08:58:22.110 : echo:Hotend offsets: 08:58:22.110 : echo: M218 T1 X0.00 Y0.00 08:58:22.120 : echo:Auto Bed Leveling: 08:58:22.120 : echo: M420 S0 08:58:22.120 : echo

ID settings: 08:58:22.120 : echo: M301 P31.73 I2.21 D113.72 08:58:22.130 : echo: M304 P129.46 I10.33 D405.67 08:58:22.130 : echo:Z-Probe Offset (mm): 08:58:22.130 : echo: M851 Z-22.13 08:58:26.279 : N24 M503*19 08:58:26.279 : echo: G21 ; (mm) 08:58:26.279 : echo:Filament settings: Disabled 08:58:26.279 : echo: M200 D1.75 08:58:26.289 : echo: M200 T1 D1.75 08:58:26.289 : echo: M200 D0 08:58:26.289 : echo

teps per unit: 08:58:26.289 : echo: M92 X80.00 Y80.00 Z400.00 E120.00 08:58:26.299 : echo:Maximum feedrates (units/s): 08:58:26.299 : echo: M203 X80.00 Y80.00 Z100.00 E100.00 08:58:26.309 : echo:Maximum Acceleration (units/s2): 08:58:26.309 : echo: M201 X200 Y200 Z100 E10000 08:58:26.309 : echo:Acceleration (units/s2): P R T 08:58:26.319 : echo: M204 P200.00 R3000.00 T200.00 08:58:26.329 : echo:Advanced: B S T X Y Z E 08:58:26.329 : echo: M205 B20000 S0.00 T0.00 X2.50 Y2.50 Z0.30 E5.00 08:58:26.329 : echo:Home offset: 08:58:26.339 : echo: M206 X0.00 Y0.00 Z0.00 08:58:26.339 : echo:Hotend offsets: 08:58:26.339 : echo: M218 T1 X0.00 Y0.00 08:58:26.339 : echo:Auto Bed Leveling: 08:58:26.339 : echo: M420 S0 08:58:26.349 : echo

ID settings: 08:58:26.349 : echo: M301 P31.73 I2.21 D113.72 08:58:26.349 : echo: M304 P129.46 I10.33 D405.67 08:58:26.349 : echo:Z-Probe Offset (mm): 08:58:26.349 : echo: M851 Z-22.13

With these settings, everytime I send a G29 I get a Fail Probe!!. See below:

09:43:06.583 : N35 G29*36 09:43:06.583 : current_position=(100.00, 100.00, 25.00) : >>> G29 09:43:06.594 : Machine Type: Cartesian 09:43:06.594 : Probe: FIX_MOUNTED_PROBE 09:43:06.594 : Probe Offset X:73 Y:-44 Z:-22.13 (Right-Front & Below Nozzle) 09:43:06.604 : Auto Bed Leveling: BILINEAR (disabled) 09:43:06.604 : current_position=(100.00, 100.00, 25.00) : set_probe_deployed 09:43:06.604 : deploy: 1 09:43:06.614 : do_probe_raise(20.00) 09:43:06.614 : >>> do_blocking_move_to(100.00, 100.00, 42.13) 09:43:09.622 : <<< do_blocking_move_to 09:43:09.632 : >>> do_blocking_move_to(100.00, 100.00, 42.13) 09:43:09.632 : <<< do_blocking_move_to 09:43:09.642 : current_position=(100.00, 100.00, 42.13) : setup_for_endstop_or_probe_move 09:43:09.642 : >>> probe_pt(180.00, 10.00, raise, 0, probe_relative) 09:43:09.642 : current_position=(100.00, 100.00, 42.13) : 09:43:09.652 : >>> do_blocking_move_to(107.00, 54.00, 42.13) 09:43:10.662 : <<< do_blocking_move_to 09:43:10.671 : current_position=(107.00, 54.00, 42.13) : set_probe_deployed 09:43:10.671 : deploy: 1 09:43:10.681 : current_position=(107.00, 54.00, 42.13) : >>> run_z_probe 09:43:10.681 : current_position=(107.00, 54.00, 42.13) : >>> do_probe_move 09:43:10.681 : >>> do_blocking_move_to(107.00, 54.00, 22.13) 09:43:14.201 : <<< do_blocking_move_to 09:43:14.201 : current_position=(107.00, 54.00, 22.13) : sync_plan_position 09:43:14.211 : current_position=(107.00, 54.00, 22.13) : <<< do_probe_move 09:43:14.211 : FAST Probe fail! 09:43:14.211 : current_position=(107.00, 54.00, 22.13) : <<< run_z_probe 09:43:14.221 : >>> do_blocking_move_to(107.00, 54.00, 42.13) 09:43:17.719 : <<< do_blocking_move_to 09:43:17.719 : Errorrobing failed 09:43:17.719 : <<< probe_pt 09:43:17.719 : current_position=(107.00, 54.00, 42.13) : set_probe_deployed 09:43:17.729 : deploy: 0 09:43:17.729 : >>> do_blocking_move_to(107.00, 54.00, 42.13) 09:43:17.729 : <<< do_blocking_move_to 09:43:17.739 : current_position=(107.00, 54.00, 42.13) : > probing complete 09:43:17.739 : current_position=(107.00, 54.00, 42.13) : clean_up_after_endstop_or_probe_move 09:43:17.739 : <<< G29 09:43:17.749 : X:107.00 Y:54.00 Z:42.13 E:0.00 Count X:8560 Y:4320 Z:16852

Does it make any sense to you guys?

Thanks,

Marcus

|

Re: Auto Bed Leveling issues December 11, 2018 01:19PM |

Registered: 6 years ago Posts: 1,863 |

|

Re: Auto Bed Leveling issues December 11, 2018 03:42PM |

Registered: 6 years ago Posts: 26 |

|

Re: Auto Bed Leveling issues December 11, 2018 04:26PM |

Registered: 6 years ago Posts: 26 |

Ok Guys,

Found the culprit. It was this line

Doing my first test now and the bed went correctly to 0.33mm, which was my first layer height.

Thank you all for the help you provided.

Regards,

Marcus

Found the culprit. It was this line

#define Z_PROBE_LOW_POINT -10 // Farthest distance below the trigger-point to go before stopping.When the errors were occurring I had the value set to zero (0). I changed to -10mm and now I can calibrate all points.

Doing my first test now and the bed went correctly to 0.33mm, which was my first layer height.

Thank you all for the help you provided.

Regards,

Marcus

Sorry, only registered users may post in this forum.