Marlin/RAMPS movement issue

Posted by kc8iqw

|

Marlin/RAMPS movement issue February 26, 2019 01:05PM |

Registered: 5 years ago Posts: 30 |

I'm sure I'm missing something obvious.

I've built a Frankenvinci using a RAMPS 1.6 board and respective Arduino controller (and a custom built board for endstops and extruder cooling but I digress). What I'm having an absolute fit is with the Z movement and positioning. I have this configured for Min/Max and have disable the min (letting the home sensors do their work) at the suggestion of someone in another forum.

// The size of the print bed

#define X_BED_SIZE 237

#define Y_BED_SIZE 217

// Travel limits (mm) after homing, corresponding to endstop positions.

//#define X_MIN_POS -12

//#define Y_MIN_POS -12

//#define Z_MIN_POS -2

#define X_MAX_POS X_BED_SIZE

#define Y_MAX_POS Y_BED_SIZE

#define Z_MAX_POS 200

My issue is all of my layers are being squished together and making a blob vaguely resembling a cube (20X20X20 test cube). As best as I can tell setting M92 Z to either 2560 or 4000 seems to make no difference. Current values as set by M92 and soon to be by firmware defaults: #define DEFAULT_AXIS_STEPS_PER_UNIT { 200, 200, 2560, 89 }

I've built a Frankenvinci using a RAMPS 1.6 board and respective Arduino controller (and a custom built board for endstops and extruder cooling but I digress). What I'm having an absolute fit is with the Z movement and positioning. I have this configured for Min/Max and have disable the min (letting the home sensors do their work) at the suggestion of someone in another forum.

// The size of the print bed

#define X_BED_SIZE 237

#define Y_BED_SIZE 217

// Travel limits (mm) after homing, corresponding to endstop positions.

//#define X_MIN_POS -12

//#define Y_MIN_POS -12

//#define Z_MIN_POS -2

#define X_MAX_POS X_BED_SIZE

#define Y_MAX_POS Y_BED_SIZE

#define Z_MAX_POS 200

My issue is all of my layers are being squished together and making a blob vaguely resembling a cube (20X20X20 test cube). As best as I can tell setting M92 Z to either 2560 or 4000 seems to make no difference. Current values as set by M92 and soon to be by firmware defaults: #define DEFAULT_AXIS_STEPS_PER_UNIT { 200, 200, 2560, 89 }

|

Re: Marlin/RAMPS movement issue February 26, 2019 04:26PM |

Registered: 6 years ago Posts: 1,863 |

Question On the Z-Axis when nozzle is touching the Bed and it is turned 360 degrees so the nozzle is moving away from the bed.

How far did the nozzle move. If the answer is 1.25mm then you have a 8mm all thread lead screw 8 x 1.25

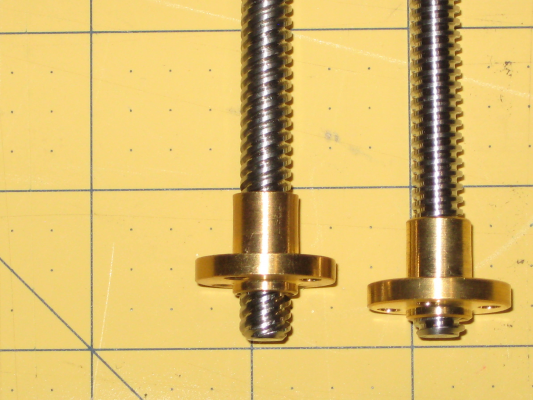

My lead screw will move 2mm as shown in the image below on the right and the most common lead screw will move 8mm as shown in the image below on the Left

Description of your lead screw 8X1.25 - 2560

My led Screw T8X2 single start = 1600 - Right

Other T8X8 : Four Start - Left 400

Post a photo of your lead screw if you are still confused.

Now for the reason I decided on the T8X2 Single Start.

Every vibration near the 3D Printer would cause the Z-Axis to become out of alignment. So I was spending more time realigning than 3D Printing.

T8-8 Lead-screw Drop with Gravity

[youtu.be]

Edited 2 time(s). Last edit at 02/26/2019 05:04PM by Roberts_Clif.

Computer Programmer / Electronics Technician

How far did the nozzle move. If the answer is 1.25mm then you have a 8mm all thread lead screw 8 x 1.25

My lead screw will move 2mm as shown in the image below on the right and the most common lead screw will move 8mm as shown in the image below on the Left

Description of your lead screw 8X1.25 - 2560

My led Screw T8X2 single start = 1600 - Right

Other T8X8 : Four Start - Left 400

Post a photo of your lead screw if you are still confused.

Now for the reason I decided on the T8X2 Single Start.

Every vibration near the 3D Printer would cause the Z-Axis to become out of alignment. So I was spending more time realigning than 3D Printing.

T8-8 Lead-screw Drop with Gravity

[youtu.be]

Edited 2 time(s). Last edit at 02/26/2019 05:04PM by Roberts_Clif.

Computer Programmer / Electronics Technician

|

Re: Marlin/RAMPS movement issue February 27, 2019 09:33AM |

Registered: 5 years ago Posts: 30 |

Quote

Roberts_Clif

Question On the Z-Axis when nozzle is touching the Bed and it is turned 360 degrees so the nozzle is moving away from the bed.

How far did the nozzle move. If the answer is 1.25mm then you have a 8mm all thread lead screw 8 x 1.25

My lead screw will move 2mm as shown in the image below on the right and the most common lead screw will move 8mm as shown in the image below on the Left

Description of your lead screw 8X1.25 - 2560

My led Screw T8X2 single start = 1600 - Right

Other T8X8 : Four Start - Left 400

Thanks, this helped me ensure 2560 is the correct setting. Now this deepens the mystery of why it's squashing the layers and making an absolute mess.

Edited 1 time(s). Last edit at 02/27/2019 09:34AM by kc8iqw.

|

Re: Marlin/RAMPS movement issue February 27, 2019 09:44AM |

Admin Registered: 13 years ago Posts: 6,998 |

Z max feed rate is to high, so it skips when moving z?

/**

* Default Max Feed Rate (mm/s)

* Override with M203

* X, Y, Z, E0 [, E1[, E2[, E3[, E4]]]]

*/

#define DEFAULT_MAX_FEEDRATE { 300, 300, 5, 25 }

this is the 5 in this example..

not sure what it should be for your lead screw, but if you lower it to say 3 and it works, you can slowly raise it again till it breaks.

Can also be changed with gcode

M203: Set maximum feedrate

eg M203 Z3 but this doesn't survive a board reset.

Edited 1 time(s). Last edit at 02/27/2019 09:53AM by Dust.

/**

* Default Max Feed Rate (mm/s)

* Override with M203

* X, Y, Z, E0 [, E1[, E2[, E3[, E4]]]]

*/

#define DEFAULT_MAX_FEEDRATE { 300, 300, 5, 25 }

this is the 5 in this example..

not sure what it should be for your lead screw, but if you lower it to say 3 and it works, you can slowly raise it again till it breaks.

Can also be changed with gcode

M203: Set maximum feedrate

eg M203 Z3 but this doesn't survive a board reset.

Edited 1 time(s). Last edit at 02/27/2019 09:53AM by Dust.

|

Re: Marlin/RAMPS movement issue February 27, 2019 10:03AM |

Registered: 6 years ago Posts: 1,863 |

Let's try to solve this for you OK.

Before we can do this more information in require.

Most can be deturmined by you configuration.h file. Could you upload to a file share like Google Drive please, and post a link.

Several things can stop the Z axis from traveling upwards, the lead screws are binding.

Many tests can determine if the lead screws are indeed binding. The Z-Axis Carriage is too heavy for the steppers used.

The Lead screws are warped or nicked and causing binding. The 8mm nut in the Z-Axis lead-screw mount are misaligned.

One is to manually turn the lead screws from top to bottom and see if at any position if feels harder to turn the lead screws.

Another test with the printer homed raise the Z- Axis to max then lower to the bed several times.

When Z-Axis is moving from the bed in a single long sweep, returning to the bed in a slower fashion of 10mm steps as not to crash into the bed if steps were missed.

If you can hear the stepper motors clicking then the stepper missed a step, and we can assume the the lead screw is binding.

Although a short video of you raising the Z-Axis and lowering may show enough and can be posted with the configuration.h file.

Computer Programmer / Electronics Technician

Before we can do this more information in require.

Most can be deturmined by you configuration.h file. Could you upload to a file share like Google Drive please, and post a link.

Several things can stop the Z axis from traveling upwards, the lead screws are binding.

Many tests can determine if the lead screws are indeed binding. The Z-Axis Carriage is too heavy for the steppers used.

The Lead screws are warped or nicked and causing binding. The 8mm nut in the Z-Axis lead-screw mount are misaligned.

One is to manually turn the lead screws from top to bottom and see if at any position if feels harder to turn the lead screws.

Another test with the printer homed raise the Z- Axis to max then lower to the bed several times.

When Z-Axis is moving from the bed in a single long sweep, returning to the bed in a slower fashion of 10mm steps as not to crash into the bed if steps were missed.

If you can hear the stepper motors clicking then the stepper missed a step, and we can assume the the lead screw is binding.

Although a short video of you raising the Z-Axis and lowering may show enough and can be posted with the configuration.h file.

Computer Programmer / Electronics Technician

|

Re: Marlin/RAMPS movement issue February 27, 2019 11:11AM |

Registered: 5 years ago Posts: 30 |

I'll look into uploading a Z-Movement video possibly after work. All of the steppers and the bed were moving/working flawlessly prior to the DaVinci motherboard CPU failing (it wouldn't turn on anything except the case light). Z movement seems perfectly smooth and as far as I've tested, moves the correct distance away from the extruder. The extruder does click sometimes and I'm tearing it apart today to see if there is a clog somewhere binding the material. Unless my thermistor is seriously jacked up (by over 1K ohms), which I doubt because it's fairly new and e3d v6, it's reading correctly with my DMM.

I've uploaded the configuration.h and configuration_adv.h as I've tweaked both.

Configuration.h

Configuration_adv.h

I've uploaded the configuration.h and configuration_adv.h as I've tweaked both.

Configuration.h

Configuration_adv.h

|

Re: Marlin/RAMPS movement issue February 27, 2019 01:27PM |

Registered: 6 years ago Posts: 1,863 |

I see DUST Posted.

It is the Default Max Feed Rate.

It is an easy test you should preform. most likely he is correct.

My Confusion began when I saw a lead-screw with 8 x 1.25 mm, further examining your default Max Feed Rate 8

Edited 1 time(s). Last edit at 02/27/2019 01:34PM by Roberts_Clif.

Computer Programmer / Electronics Technician

It is the Default Max Feed Rate.

It is an easy test you should preform. most likely he is correct.

My Confusion began when I saw a lead-screw with 8 x 1.25 mm, further examining your default Max Feed Rate 8

Edited 1 time(s). Last edit at 02/27/2019 01:34PM by Roberts_Clif.

Computer Programmer / Electronics Technician

|

Re: Marlin/RAMPS movement issue February 27, 2019 01:54PM |

Registered: 5 years ago Posts: 30 |

Quote

Roberts_Clif

I see DUST Posted.

It is the Default Max Feed Rate.

It is an easy test you should preform. most likely he is correct.

My Confusion began when I saw a lead-screw with 8 x 1.25 mm, further examining your default Max Feed Rate 8

Ok, as soon as I check to make sure the extruder doesn't have a jam, I'll give this a go. It wouldn't surprise me if it had some partial jam the way it was acting before I unplugged it for vacation and the subsequent board failure when I plugged it back in. This is a setting that didn't have much of an explanation (or was obvious to me at least) so I left it alone.

|

Re: Marlin/RAMPS movement issue February 27, 2019 03:35PM |

Registered: 5 years ago Posts: 30 |

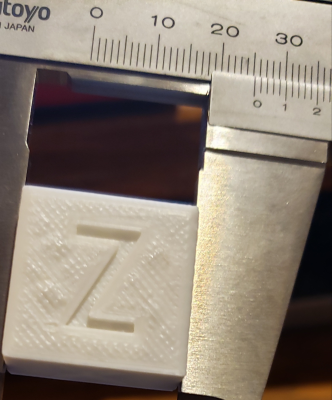

Well it's for sure one heck of an improvement, but something is still amiss. It's wide X and Y by 4mm and short Z by 11. It's also missing a lot in the top/bottom layers (which may be the software setup since it lost all of my original settings).

|

Re: Marlin/RAMPS movement issue February 27, 2019 04:43PM |

Registered: 6 years ago Posts: 1,863 |

|

Re: Marlin/RAMPS movement issue February 27, 2019 05:07PM |

Registered: 5 years ago Posts: 30 |

M203 Z3 was the change preventing the disaster in my first picture. Now I suppose the question is why is the Z axis squished so much.

I fixed the infilling by setting the extruder's stepping up. (M92 E200) I'm in the process of calibrating it via this method Extruder Calibration to ensure the correct stepping for the extruder.

Current Values:

M92 X200.00 Y200.00 Z2560.00 E170.00

M203 X300.00 Y300.00 Z3.00 E25.00

(if it matters) M201 X3000 Y3000 Z100 E10000

Edited 1 time(s). Last edit at 02/27/2019 05:18PM by kc8iqw.

I fixed the infilling by setting the extruder's stepping up. (M92 E200) I'm in the process of calibrating it via this method Extruder Calibration to ensure the correct stepping for the extruder.

Current Values:

M92 X200.00 Y200.00 Z2560.00 E170.00

M203 X300.00 Y300.00 Z3.00 E25.00

(if it matters) M201 X3000 Y3000 Z100 E10000

Edited 1 time(s). Last edit at 02/27/2019 05:18PM by kc8iqw.

|

Re: Marlin/RAMPS movement issue February 27, 2019 05:21PM |

Registered: 6 years ago Posts: 1,863 |

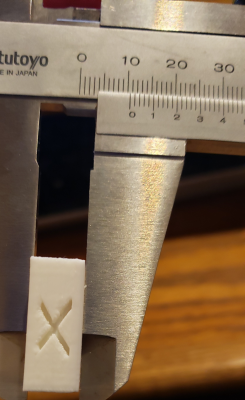

Post a photo of you lead screws get then clear, visible.

If you have Calipers post measurements. If not measure with what you have and post.

Does not have to be perfect just get close.

P.S. Technician Class To

Edited 1 time(s). Last edit at 02/27/2019 05:24PM by Roberts_Clif.

Computer Programmer / Electronics Technician

If you have Calipers post measurements. If not measure with what you have and post.

Does not have to be perfect just get close.

P.S. Technician Class To

Edited 1 time(s). Last edit at 02/27/2019 05:24PM by Roberts_Clif.

Computer Programmer / Electronics Technician

|

Re: Marlin/RAMPS movement issue February 27, 2019 05:32PM |

Registered: 5 years ago Posts: 30 |

Quote

Roberts_Clif

Post a photo of you lead screws get then clear, visible.

If you have Calipers post measurements. If not measure with what you have and post.

Does not have to be perfect just get close.

P.S. Technician Class To

Just found my calipers. I've regenerated the gcode, slowing down the printer and putting the extrusion back to 100%. Also, I didn't think to re-level the bed after the adjustments (it was quite off). Should have the results in about 30 mins.

|

Re: Marlin/RAMPS movement issue February 27, 2019 06:23PM |

Registered: 5 years ago Posts: 30 |

Screw: I measured a "grease imprint" as 1.25mm as well as what I've read elsewhere this is stock for Davinci 1.0a (mine is a 1.0). I will attempt to locate my gauge for this as well (I'll be danged if I recall what it's called).

Here's the latest print. X and Y are identical in size so I chose only to post 1 of them.

Bottom: (I think I can fix this by adjusting various settings in my slicer Cura)

Here's the latest print. X and Y are identical in size so I chose only to post 1 of them.

Bottom: (I think I can fix this by adjusting various settings in my slicer Cura)

|

Re: Marlin/RAMPS movement issue February 27, 2019 08:22PM |

Admin Registered: 13 years ago Posts: 6,998 |

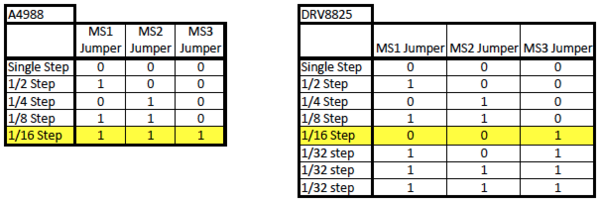

When things are out by a factor of 2,4,8 or 16 is normally that your micro stepping isn't as you thought it was.

This looks to be what is wrong with your Z

You can either change the the micro stepping on Z axis or adjust the steps/mm

Since you have your Z steps/mm set to 2560, that would imply that you think you have 1/16th micro stepping

So try 5120.00 steps/mm first as that is 1/32 micro stepping

This could also be caused by using 400 step per revolution stepper motors vs the normal 200 step per revolution.

Edited 1 time(s). Last edit at 02/27/2019 08:23PM by Dust.

This looks to be what is wrong with your Z

You can either change the the micro stepping on Z axis or adjust the steps/mm

Since you have your Z steps/mm set to 2560, that would imply that you think you have 1/16th micro stepping

So try 5120.00 steps/mm first as that is 1/32 micro stepping

This could also be caused by using 400 step per revolution stepper motors vs the normal 200 step per revolution.

Edited 1 time(s). Last edit at 02/27/2019 08:23PM by Dust.

|

Re: Marlin/RAMPS movement issue February 27, 2019 09:00PM |

Registered: 6 years ago Posts: 1,863 |

What is see is a cube that is 25mm X 25mm X 10mm.

With the current settings your default axis steps would look like this, Have no way to guess the extruder at this point.

#define DEFAULT_AXIS_STEPS_PER_UNIT { 160, 160, 5120, 89 }

Looks like jumper setup for Stepper is changing between XY and Z steppers in 1/16 micro-step and not 1/8 micro-step.

Looks like the XY is jumper-ed for 1/8 and Z is jumper-ed for 1/16

I am just guessing here by what I am seeing.

Does the Controller have stepper motor jumpers.

Found this

[www.techmonkeybusiness.com]

Edited 1 time(s). Last edit at 02/27/2019 09:00PM by Roberts_Clif.

Computer Programmer / Electronics Technician

With the current settings your default axis steps would look like this, Have no way to guess the extruder at this point.

#define DEFAULT_AXIS_STEPS_PER_UNIT { 160, 160, 5120, 89 }

Looks like jumper setup for Stepper is changing between XY and Z steppers in 1/16 micro-step and not 1/8 micro-step.

Looks like the XY is jumper-ed for 1/8 and Z is jumper-ed for 1/16

I am just guessing here by what I am seeing.

Does the Controller have stepper motor jumpers.

Found this

[www.techmonkeybusiness.com]

Edited 1 time(s). Last edit at 02/27/2019 09:00PM by Roberts_Clif.

Computer Programmer / Electronics Technician

|

Re: Marlin/RAMPS movement issue February 27, 2019 09:25PM |

Registered: 5 years ago Posts: 30 |

Quote

Roberts_Clif

What is see is a cube that is 25mm X 25mm X 10mm.

With the current settings your default axis steps would look like this, Have no way to guess the extruder at this point.

#define DEFAULT_AXIS_STEPS_PER_UNIT { 160, 160, 5120, 89 }

Looks like jumper setup for Stepper is changing between XY and Z steppers in 1/16 micro-step and not 1/8 micro-step.

Looks like the XY is jumper-ed for 1/8 and Z is jumper-ed for 1/16

I am just guessing here by what I am seeing.

Does the Controller have stepper motor jumpers.

Found this

[www.techmonkeybusiness.com]

That was my basic guide, but there is a lot of information missing. All jumpers are in place on my RAMPS board for all drivers. ya had me questioning my sanity there for a min. They are all 1.8 deg steppers (200steps/rotation) despite being slightly different models (verified via the datasheet). What's interesting is a datasheet i found. It says for the drv8825 (which I have) they are all optioned wrong, but x,y work with the calculator on Prusia's site given the belts, gearing etc but would explain why the normal settings for the frankenvinci doesn't work. I'm trying 5120 to see if that helps. I'm running the steppers at .5 which should give it enough current to not miss steps.

I figured out the extuder as 170 or 171, testing to be done between the 2.

|

Re: Marlin/RAMPS movement issue February 27, 2019 09:40PM |

Admin Registered: 13 years ago Posts: 6,998 |

The microstepping jumpers are different from the A4988 and the DRV8825

|

Re: Marlin/RAMPS movement issue February 27, 2019 09:45PM |

Registered: 5 years ago Posts: 30 |

I think I know why the XY work, I inadvertently gamed the calculator. 1/16 at 8 pulley teeth and 1/32 at 16 teeth both yield 200. I had assumed I had 8 but on further investigation I actually very likely have 16 (since I can count more than 8 but can't get accurate w/o removing one) so they too are running 1/32 stepping as the jumper setup indicates RAMPS setup through 1.4. I have the 1.6, but they are for all intents and purposes the same as 1.4 with a few power/heat management upgrades.

|

Re: Marlin/RAMPS movement issue February 27, 2019 09:48PM |

Registered: 5 years ago Posts: 30 |

Yup, that's the image I found. Dang I should write a how-to updated for the newer Marlin and using different drivers and also explaining how I came to the end result (e.g referencing the calculators on prusa's site etc). There's no one clear picture for the entire process.

It's heating up ready for printing at 5120 so we'll see.

|

Re: Marlin/RAMPS movement issue February 27, 2019 10:40PM |

Registered: 5 years ago Posts: 30 |

Well, Z seems fixed although I have horrible top/bottom layers. It printed a 20mm height, but I'm not sure why X/Y are printing making it 24.4mm. It should be a perfect 20x20x20mm cube. I'm wondering if it's overstepping somehow as when I do corner leveling it goes too far and "clicks" the belt on XY. I suppose I should remove one of the belts and count the actual teeth since 16 doesn't seem correct.

Could that be cause by a wrong X_MIN and Y_MIN or does those not really matter for positioning on the bed since it has endstops?

Could that be cause by a wrong X_MIN and Y_MIN or does those not really matter for positioning on the bed since it has endstops?

|

Re: Marlin/RAMPS movement issue February 27, 2019 10:58PM |

Admin Registered: 13 years ago Posts: 6,998 |

X and Y are steps/mm issues

you have to match the hardware to the firmware. ie what type of belts, how many teeth on your pullies, microstepping etc.

I see in a earlier post you have 200.00 step/mm since you say your getting 24.4 when it should be 20 you need to reduce the steps/mm

20/24.4*200 = 163.93442623 wich is quite a weird steps/mm

So my guess would be you have T2.5 belts with 16 teeth pullies, 1/32 micro stepping so the steps/mm should be 160

"Could that be cause by a wrong X_MIN and Y_MIN or does those not really matter for positioning on the bed since it has endstops?"

This is only positioning on the bed.

Edited 1 time(s). Last edit at 02/27/2019 11:02PM by Dust.

you have to match the hardware to the firmware. ie what type of belts, how many teeth on your pullies, microstepping etc.

I see in a earlier post you have 200.00 step/mm since you say your getting 24.4 when it should be 20 you need to reduce the steps/mm

20/24.4*200 = 163.93442623 wich is quite a weird steps/mm

So my guess would be you have T2.5 belts with 16 teeth pullies, 1/32 micro stepping so the steps/mm should be 160

"Could that be cause by a wrong X_MIN and Y_MIN or does those not really matter for positioning on the bed since it has endstops?"

This is only positioning on the bed.

Edited 1 time(s). Last edit at 02/27/2019 11:02PM by Dust.

|

Re: Marlin/RAMPS movement issue February 27, 2019 11:20PM |

Registered: 5 years ago Posts: 30 |

Quote

Dust

X and Y are steps/mm issues

you have to match the hardware to the firmware. ie what type of belts, how many teeth on your pullies, microstepping etc.

I see in a earlier post you have 200.00 step/mm since you say your getting 24.4 when it should be 20 you need to reduce the steps/mm

20/24.4*200 = 163.93442623 wich is quite a weird steps/mm

So my guess would be you have T2.5 belts with 16 teeth pullies, 1/32 micro stepping so the steps/mm should be 160

"Could that be cause by a wrong X_MIN and Y_MIN or does those not really matter for positioning on the bed since it has endstops?"

This is only positioning on the bed.

Close T2 belt with 20 teeth pulleys but it's 160 regardless. I pulled one of the belts and counted the teeth. The belt, a 720-S2M, is a 2mm pitch according to what I can find.

It's not printing in the middle now, but that's a minor issue. If I understand this correctly X_MIN and Y_MIN tell the software the distance from the endstops to the edge of the bed?

Another semi-related question, does 1/32 cause the steppers to produce more noise when moving vs 1/16 stepping? e.g. the faster it moves the more noise it makes? It seems pretty quiet when printing, but when it travels it's quite loud.

|

Re: Marlin/RAMPS movement issue February 28, 2019 12:01AM |

Admin Registered: 13 years ago Posts: 6,998 |

"It's not printing in the middle now, but that's a minor issue. If I understand this correctly X_MIN and Y_MIN tell the software the distance from the endstops to the edge of the bed?"\

to the edge of the printing area, yes. You also need your correct bed dimensions in your slicing software

"Another semi-related question, does 1/32 cause the steppers to produce more noise when moving vs 1/16 stepping? e.g. the faster it moves the more noise it makes? It seems pretty quiet when printing, but when it travels it's quite loud."

more micro stepping is generally more quieter. But limits the maximum obtainable speed.

loudness is also a factor of the current limit. more current it can overcome more friction but it is louder.

most tune for max current steppers can take, but I tune for just over where it moves correctly (ie min current for normal operation)

Edited 1 time(s). Last edit at 02/28/2019 12:03AM by Dust.

to the edge of the printing area, yes. You also need your correct bed dimensions in your slicing software

"Another semi-related question, does 1/32 cause the steppers to produce more noise when moving vs 1/16 stepping? e.g. the faster it moves the more noise it makes? It seems pretty quiet when printing, but when it travels it's quite loud."

more micro stepping is generally more quieter. But limits the maximum obtainable speed.

loudness is also a factor of the current limit. more current it can overcome more friction but it is louder.

most tune for max current steppers can take, but I tune for just over where it moves correctly (ie min current for normal operation)

Edited 1 time(s). Last edit at 02/28/2019 12:03AM by Dust.

|

Re: Marlin/RAMPS movement issue February 28, 2019 01:27PM |

Registered: 5 years ago Posts: 30 |

|

Re: Marlin/RAMPS movement issue February 28, 2019 02:09PM |

Registered: 6 years ago Posts: 1,863 |

|

Re: Marlin/RAMPS movement issue February 28, 2019 02:39PM |

Registered: 5 years ago Posts: 30 |

|

Re: Marlin/RAMPS movement issue February 28, 2019 05:37PM |

Registered: 5 years ago Posts: 30 |

Well it's printing near flawlessly except it has this 1 odd defect that is only on the bottom, leading Y edge and only the first 10 or so layers. It looks like warping except it's shrunk not only up but in on that edge as well. Not sure if any of the hard settings we've been adjusting affect that, but I would like ya'lls input.

Thank you both SO much for helping me get it to this point.

Thank you both SO much for helping me get it to this point.

|

Re: Marlin/RAMPS movement issue February 28, 2019 09:59PM |

Registered: 6 years ago Posts: 1,863 |

Help for those wavy Z lines would be couplers alignment, or a flexible coupler like this one.

Looks to me like over heating could be nozzle or hot bed to hot and printing too slowly.

I would start a new thread for any other problems so the forum users know what you need help with.

Computer Programmer / Electronics Technician

Looks to me like over heating could be nozzle or hot bed to hot and printing too slowly.

I would start a new thread for any other problems so the forum users know what you need help with.

Computer Programmer / Electronics Technician

|

Re: Marlin/RAMPS movement issue February 28, 2019 10:26PM |

Registered: 5 years ago Posts: 30 |

Sorry, only registered users may post in this forum.