Setup Marlin on DIY printer - Mega2560 TCM2209 z-probe

Posted by cysign

|

Re: Setup Marlin on DIY printer - Mega2560 TCM2209 z-probe November 25, 2020 03:46AM |

Admin Registered: 13 years ago Posts: 7,000 |

|

Re: Setup Marlin on DIY printer - Mega2560 TCM2209 z-probe November 26, 2020 05:32AM |

Registered: 8 years ago Posts: 90 |

Didn't have much time yesterday, so I only quick-checked heaters of hotends, and bed.

I had to swap cables on the hotends and now they seem to work properly - even with fans activated when hot

Heatbed becomed hot, too. But there seems to be problems with the sensor. It doesn't show the real temperature and after a while Marlin reports a failure. Im not sure if its the wrong type of sensor of if it's placed in a bad position.

And extruder steppers dont make any movement. Have to check the config, again.

Will endstops trigger while I'm moving the axis manually on the menu? Or is there any hidden endstop-test-menu?

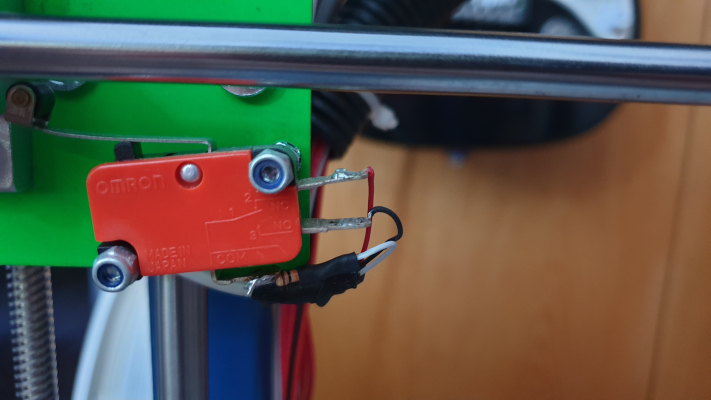

My endstops have labeled the pinout on the outside, so I don't expect problems here:

Edited 2 time(s). Last edit at 11/26/2020 05:50AM by cysign.

I had to swap cables on the hotends and now they seem to work properly - even with fans activated when hot

Heatbed becomed hot, too. But there seems to be problems with the sensor. It doesn't show the real temperature and after a while Marlin reports a failure. Im not sure if its the wrong type of sensor of if it's placed in a bad position.

And extruder steppers dont make any movement. Have to check the config, again.

Will endstops trigger while I'm moving the axis manually on the menu? Or is there any hidden endstop-test-menu?

My endstops have labeled the pinout on the outside, so I don't expect problems here:

Edited 2 time(s). Last edit at 11/26/2020 05:50AM by cysign.

|

Re: Setup Marlin on DIY printer - Mega2560 TCM2209 z-probe November 26, 2020 08:01AM |

Admin Registered: 13 years ago Posts: 7,000 |

Use the force, I mean gcode

M119 reports status of end stops as seen by the controller.

simple make sure no end stops are triggered and send a M119 All should report open

Then hold down a end stop switch with finger and send another M119, the end stop your are holding should now say triggered.

repeat for all endstops.

M119 reports status of end stops as seen by the controller.

simple make sure no end stops are triggered and send a M119 All should report open

Then hold down a end stop switch with finger and send another M119, the end stop your are holding should now say triggered.

repeat for all endstops.

|

Re: Setup Marlin on DIY printer - Mega2560 TCM2209 z-probe November 26, 2020 10:01AM |

Registered: 8 years ago Posts: 90 |

Thats exactly what I need. Can I send the commands using PlattformIO? Or Arduino serial monitor? Or do I have to use a GCode-sender (like Universal GCode Sender)?

//Edit: On PlattformIO I only got an error when trying to open serial monitor.

So hereS what ArduinoIDE says to M149:

Looks like I didn't activate endstops. And I wonder why there's only one runout sensor. Have to check config-file, again

//Edit: Here's my current config:

digitalinventions.de/files/pics/3Dprinter/20201126_1653h_marlin_2072_config_IronBot.zip

What I like to do now:

I. check endstops (are they activated? why can't I see them on M119?)

II. move extruder-steppers (both don't seem to be alive - no movement here, maybe runoutsensors configured wrong? But this shouldn't impact manual movement, right?)

III. find out what to change to make headbed heating properly (change sensor type or change sensor position)

Edited 4 time(s). Last edit at 11/26/2020 11:42AM by cysign.

//Edit: On PlattformIO I only got an error when trying to open serial monitor.

So hereS what ArduinoIDE says to M149:

Marlin 2.0.7.2 echo: Last Updated: 2020-10-15 | Author: CySign echo:Compiled: Nov 26 2020 echo: Free Memory: 3586 PlannerBufferBytes: 1200 echo:Hardcoded Default Settings Loaded echo: G21 ; Units in mm (mm) echo: M149 C ; Units in Celsius echo:; Filament settings: Disabled echo: M200 T0 D1.75 echo: M200 T1 D1.75 echo: M200 S0 echo:; Steps per unit: echo: M92 X55.00 Y55.00 Z400.00 echo: M92 T0 E40.00 echo: M92 T1 E98.00 echo:; Maximum feedrates (units/s): echo: M203 X100.00 Y100.00 Z100.00 echo: M203 T0 E100.00 echo: M203 T1 E100.00 echo:; Maximum Acceleration (units/s2): echo: M201 X3000.00 Y3000.00 Z3000.00 echo: M201 T0 E3000.00 echo: M201 T1 E3000.00 echo:; Acceleration (units/s2): P R T echo: M204 P3000.00 R3000.00 T3000.00 echo:; Advanced: B S T J echo: M205 B20000.00 S0.00 T0.00 J0.01 echo:; Home offset: echo: M206 X0.00 Y0.00 Z0.00 echo:; Hotend offsets: echo: M218 T1 X0.00 Y0.00 Z0.000 echo:; Mesh Bed Leveling: echo: M420 S0 Z0.00 echo:; Material heatup parameters: echo: M145 S0 H180 B70 echo: M145 S1 H240 B110 echo:; PID settings: echo: M301 P22.20 I1.08 D114.00 echo: M301 P22.20 I1.08 D114.00 echo:; Filament load/unload lengths: echo: M603 T0 L0.00 U100.00 echo: M603 T1 L0.00 U100.00 echo:; Tool-changing: echo: Z2.00 echo:; Filament runout sensor: echo: M412 S1 echo:No SD card

Looks like I didn't activate endstops. And I wonder why there's only one runout sensor. Have to check config-file, again

//Edit: Here's my current config:

digitalinventions.de/files/pics/3Dprinter/20201126_1653h_marlin_2072_config_IronBot.zip

What I like to do now:

I. check endstops (are they activated? why can't I see them on M119?)

II. move extruder-steppers (both don't seem to be alive - no movement here, maybe runoutsensors configured wrong? But this shouldn't impact manual movement, right?)

III. find out what to change to make headbed heating properly (change sensor type or change sensor position)

Edited 4 time(s). Last edit at 11/26/2020 11:42AM by cysign.

|

Re: Setup Marlin on DIY printer - Mega2560 TCM2209 z-probe November 26, 2020 11:07AM |

Registered: 8 years ago Posts: 90 |

Well, find out I needed to enable CR in Arduino Serial for Marlin to react to Gcode commands.

So I found the solution for I.

M119 reports:

//edit: Well, I removed the formerly attached 10K resistor from my endstop-switches and swapped ground/Vcc for proper triggering. Also I figured out I had to change X-min/-max for proper detection

//edit2: Okay, I refined steps/unit to get proper movements. Also my 5 endstops work fine right now. It's time to check z-probe

//edit3:

Actually all 5 endstops work, but z-probe sucks:

I used a voltage devider by two resistors to get 5V-HIGH out of 12V output as far as I remember. But now high seems to be about 3V w/o voltage devider, while low is about 0.xV.

Have to check my z-probe before I go on...

//edit4: Took some time, but now, as I changed the cable, I do get 3,4V when z-probe is close to my bed. Good news: that's quite enough to trigger properly

It's time to check why my extruders don't move.

Edited 8 time(s). Last edit at 11/26/2020 06:54PM by cysign.

So I found the solution for I.

M119 reports:

Reporting endstop status x_min: TRIGGERED x_max: TRIGGERED y_min: TRIGGERED y_max: TRIGGERED z_min: open z_max: TRIGGERED filament: open filament 2: open ok

//edit: Well, I removed the formerly attached 10K resistor from my endstop-switches and swapped ground/Vcc for proper triggering. Also I figured out I had to change X-min/-max for proper detection

//edit2: Okay, I refined steps/unit to get proper movements. Also my 5 endstops work fine right now. It's time to check z-probe

//edit3:

Actually all 5 endstops work, but z-probe sucks:

M119 19:40:38.791 > Reporting endstop status 19:40:38.794 > x_min: TRIGGERED 19:40:38.794 > x_max: open 19:40:38.794 > y_min: TRIGGERED 19:40:38.794 > y_max: open 19:40:38.794 > z_min: TRIGGERED 19:40:38.826 > z_max: TRIGGERED 19:40:38.826 > filament: open 19:40:38.826 > filament 2: open 19:40:38.826 > ok M119 19:42:19.127 > Reporting endstop status 19:42:19.127 > x_min: open 19:42:19.128 > x_max: open 19:42:19.128 > y_min: open 19:42:19.128 > y_max: open 19:42:19.136 > z_min: TRIGGERED 19:42:19.136 > z_max: open 19:42:19.136 > filament: open 19:42:19.136 > filament 2: open 19:42:19.136 > ok

I used a voltage devider by two resistors to get 5V-HIGH out of 12V output as far as I remember. But now high seems to be about 3V w/o voltage devider, while low is about 0.xV.

Have to check my z-probe before I go on...

//edit4: Took some time, but now, as I changed the cable, I do get 3,4V when z-probe is close to my bed. Good news: that's quite enough to trigger properly

M119 00:43:47.639 > Reporting endstop status 00:43:47.639 > x_min: open 00:43:47.647 > x_max: open 00:43:47.647 > y_min: open 00:43:47.647 > y_max: open 00:43:47.647 > z_min: TRIGGERED 00:43:47.647 > z_max: open 00:43:47.647 > filament: open 00:43:47.647 > filament 2: open 00:43:47.647 > ok M119 00:43:54.903 > Reporting endstop status 00:43:54.903 > x_min: open 00:43:54.904 > x_max: open 00:43:54.904 > y_min: open 00:43:54.904 > y_max: open 00:43:54.911 > z_min: open 00:43:54.911 > z_max: open 00:43:54.911 > filament: open 00:43:54.911 > filament 2: open 00:43:54.911 > ok

It's time to check why my extruders don't move.

Edited 8 time(s). Last edit at 11/26/2020 06:54PM by cysign.

|

Re: Setup Marlin on DIY printer - Mega2560 TCM2209 z-probe November 26, 2020 07:52PM |

Registered: 8 years ago Posts: 90 |

Still no idea, why my extruder-steppers and runout-sensors don't work.

pins_Ramps.h line 65:

pins_Ramps.h line 256:

Here's my current code:

digitalinventions.de/files/pics/3Dprinter/20201127_0144h_IronBot_Marlin_2.0.7.2.zip

Though I configured Servo 3 pin, and #define FIL_RUNOUT_PIN I couldn't get any signals from runout sensors.

And I still can't get my extruder's steppers move from the manual move menu

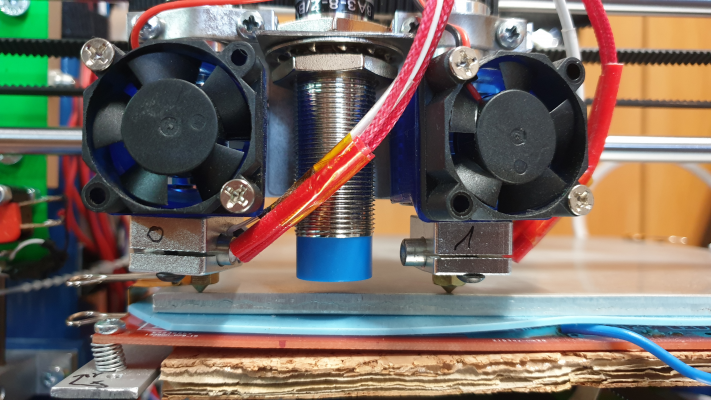

My extruder0 has a 0.3mm nozzle, whilst extruder1 has a 0.4mm nozzle. Where may I put this values?

Edited 3 time(s). Last edit at 11/26/2020 08:00PM by cysign.

* RAMPS-based boards use SERVO3_PIN for the first runout sensor. * For other boards you may need to define FIL_RUNOUT_PIN, FIL_RUNOUT2_PIN, etc.

pins_Ramps.h line 65:

//

// Servos

//

#ifndef SERVO0_PIN

#ifdef IS_RAMPS_13

#define SERVO0_PIN 7

#else

#define SERVO0_PIN 11

#endif

#endif

#ifndef SERVO1_PIN

#define SERVO1_PIN 4

#endif

#ifndef SERVO2_PIN

#define SERVO2_PIN 5

#endif

#ifndef SERVO3_PIN

#define SERVO3_PIN 6

#endif

pins_Ramps.h line 256:

// RAMPS 1.4 DIO 4 on the servos connector #ifndef FIL_RUNOUT_PIN #define FIL_RUNOUT_PIN 6 #define FIL_RUNOUT2_PIN 11 #endif

Here's my current code:

digitalinventions.de/files/pics/3Dprinter/20201127_0144h_IronBot_Marlin_2.0.7.2.zip

Though I configured Servo 3 pin, and #define FIL_RUNOUT_PIN I couldn't get any signals from runout sensors.

And I still can't get my extruder's steppers move from the manual move menu

My extruder0 has a 0.3mm nozzle, whilst extruder1 has a 0.4mm nozzle. Where may I put this values?

Edited 3 time(s). Last edit at 11/26/2020 08:00PM by cysign.

|

Re: Setup Marlin on DIY printer - Mega2560 TCM2209 z-probe November 27, 2020 10:28AM |

Registered: 8 years ago Posts: 90 |

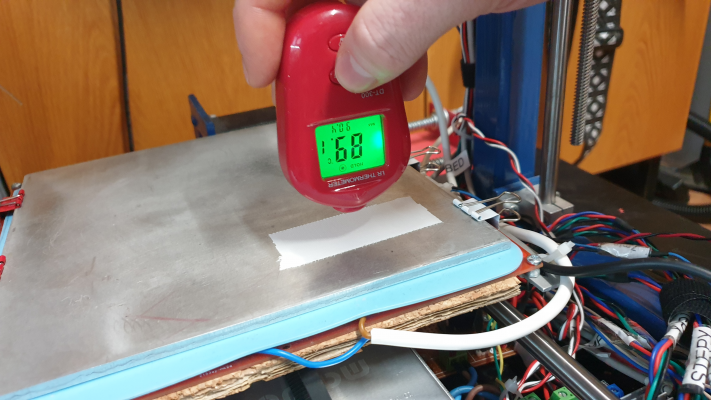

Heatbed-sensor was floating in air below heatbed. Now it's attached properly.

Just got the bed-temp-error, again. It was supposed to be 71°C out of 80°C. Manual measurement says I got 91°C when the error occured. Probably I configurated the wrong sensor.

(observe the tape, without it temperature would be badly wrong because of IR reflections on aluminum...)

Still no progress on Filament steppers, runout sensors, and configuring nozzle

//Edit:

Heatbed was set to 80°C.

#define TEMP_SENSOR_BED 1047

Here are shown and measured values:

Display/ir-thermometer

56/60 => difference: 4°C

59/62 => 3°C

62/69 => 7°C

63/79 => 16°C

64/80 => 16°C

65/81 => 16°C

69/86 => 17°C

70/89 => 19°C

71/88 => 17°C (maybe measurementfailure...)

73/91 => 18°C

when heating failed ir-thermometer shows: 90.1°C

Above 60°C the temperatures have a bigger and bigger difference.

//edit:

I guess I'll change the sensor of the bed. Heres what I have here, but I can't remember which type the yellow one is:

Maybe the PT2-100 might be the best choice, as the metal case of the other PT100s might include more delay in measuring.

//edit: Finally some progress on the runout-sensors. I didn't know I had to activate the servo-pins Vcc. It's a jumper that needs to be set (next to extruder0 stepper connectors).

And I figured out, one runout sensor has a broken cable. Time to fix it

//edit: Yesssss! Runoutsensors do work

Edited 10 time(s). Last edit at 11/27/2020 04:07PM by cysign.

Just got the bed-temp-error, again. It was supposed to be 71°C out of 80°C. Manual measurement says I got 91°C when the error occured. Probably I configurated the wrong sensor.

(observe the tape, without it temperature would be badly wrong because of IR reflections on aluminum...)

Still no progress on Filament steppers, runout sensors, and configuring nozzle

//Edit:

Heatbed was set to 80°C.

#define TEMP_SENSOR_BED 1047

Here are shown and measured values:

Display/ir-thermometer

56/60 => difference: 4°C

59/62 => 3°C

62/69 => 7°C

63/79 => 16°C

64/80 => 16°C

65/81 => 16°C

69/86 => 17°C

70/89 => 19°C

71/88 => 17°C (maybe measurementfailure...)

73/91 => 18°C

when heating failed ir-thermometer shows: 90.1°C

Above 60°C the temperatures have a bigger and bigger difference.

//edit:

I guess I'll change the sensor of the bed. Heres what I have here, but I can't remember which type the yellow one is:

Maybe the PT2-100 might be the best choice, as the metal case of the other PT100s might include more delay in measuring.

//edit: Finally some progress on the runout-sensors. I didn't know I had to activate the servo-pins Vcc. It's a jumper that needs to be set (next to extruder0 stepper connectors).

And I figured out, one runout sensor has a broken cable. Time to fix it

//edit: Yesssss! Runoutsensors do work

M119 21:49:47.711 > Reporting endstop status 21:49:47.711 > x_min: TRIGGERED 21:49:47.712 > x_max: open 21:49:47.712 > y_min: TRIGGERED 21:49:47.719 > y_max: open 21:49:47.719 > z_min: TRIGGERED 21:49:47.719 > z_max: TRIGGERED 21:49:47.719 > filament: TRIGGERED 21:49:47.719 > filament 2: open 21:49:47.719 > ok M119 21:49:29.368 > Reporting endstop status 21:49:29.368 > x_min: TRIGGERED 21:49:29.369 > x_max: open 21:49:29.369 > y_min: TRIGGERED 21:49:29.377 > y_max: open 21:49:29.377 > z_min: TRIGGERED 21:49:29.377 > z_max: TRIGGERED 21:49:29.377 > filament: open 21:49:29.377 > filament 2: TRIGGERED 21:49:29.377 > ok

Edited 10 time(s). Last edit at 11/27/2020 04:07PM by cysign.

|

Re: Setup Marlin on DIY printer - Mega2560 TCM2209 z-probe November 27, 2020 05:22PM |

Registered: 8 years ago Posts: 90 |

Well, I replaced the (maybe) PT1000 from the bed with one of the PT2-100 - but it showed 0°C at ambient temperature. I couldnt get it running properly. So I swapped back to the maybe PT1000. If there a coefficient I could adjust for getting the right temperature @100°C? Since I know ~78°C is 100°C it wouldn't be a big deal for me to work with it. But I'd like to get proper temperatures on my bed as soon as possible.

I figured out, the position of the sensor and a thermal conductive pad do a good job on the bed. But still there's a drift in high temperature...Which sensor should I buy to get accurate?

Now Im going to solve the extruder-stepper-problem.

Edited 1 time(s). Last edit at 11/27/2020 05:46PM by cysign.

I figured out, the position of the sensor and a thermal conductive pad do a good job on the bed. But still there's a drift in high temperature...Which sensor should I buy to get accurate?

Now Im going to solve the extruder-stepper-problem.

Edited 1 time(s). Last edit at 11/27/2020 05:46PM by cysign.

|

Re: Setup Marlin on DIY printer - Mega2560 TCM2209 z-probe November 28, 2020 07:15PM |

Registered: 8 years ago Posts: 90 |

Running a simple testing-sketch, I verified the drivers, steppers, and the Arduinoboard are working.

Maybe I just don't understand how to move extruders?

=>motion =>move axis => extruder tells me extruder is too cold, but I can proceed and setup a distance in millimeters. Nothing happens. But display shows "Extruder Bed", which I couldn't figure out what it is.

=>motion =>move axis => extruder1/2 show only a distance like all other axis.

But still nothing happens.

Uploaded my updated config files:

digitalinventions.de/files/pics/3Dprinter/20201129_0112h_IronBot_Marlin_2.0.7.2.zip

//edit: Extruder steppers are working

Damn is it slow. I urgently need to adjust steps per unit. I guess prevent_cold_extrusion settings preventet it from moving (I put some filament in the sensors, so Marlin 'thinks' there's filament in...

Homing is x/y min and z max.

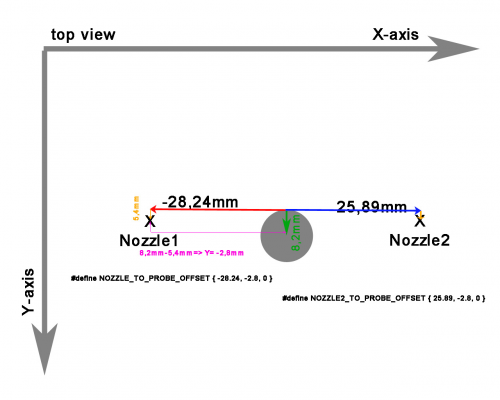

I noticed my homing position is (-52 | -15 | 0) and my travellimits have to be (244 | 190 | 222) to avoid crashing my clamps, spoken from the position of my probe.

I don't know which point would be my orientation on my X slider? I could either choose Nozzle1, probe or nozzle2?

//edit2:

Here's what I do understand:

// inductive z-probe turns LED on test-position: z:1,4mm

// both nozzles touch heatbed on same position: z:0,7mm

#define NOZZLE_TO_PROBE_OFFSET { 28.84, -2.8, 0.7 }

#define NOZZLE2_TO_PROBE_OFFSET { 28.89, -2.8, 0.7 }

Edited 5 time(s). Last edit at 11/28/2020 08:47PM by cysign.

int E1_STEP_PIN= 36;

int E1_DIR_PIN= 34;

int E1_ENABLE_PIN= 30;

int E0_STEP_PIN= 26;

int E0_DIR_PIN= 28;

int E0_ENABLE_PIN= 24;

int Licht_PIN= 13;

void setup() {

pinMode(E1_STEP_PIN, OUTPUT);

pinMode(E1_DIR_PIN, OUTPUT);

pinMode(E1_ENABLE_PIN, OUTPUT);

pinMode(E0_STEP_PIN, OUTPUT);

pinMode(E0_DIR_PIN, OUTPUT);

pinMode(E0_ENABLE_PIN, OUTPUT);

pinMode(Licht_PIN, OUTPUT);

digitalWrite(E0_ENABLE_PIN, LOW);

digitalWrite(E1_ENABLE_PIN, LOW);

digitalWrite(E0_DIR_PIN, HIGH);

digitalWrite(E1_DIR_PIN, HIGH);

}

void loop() {

digitalWrite(Licht_PIN, HIGH);

digitalWrite(E0_STEP_PIN, HIGH);

digitalWrite(E1_STEP_PIN, HIGH);

delayMicroseconds(250);

digitalWrite(Licht_PIN, LOW);

digitalWrite(E0_STEP_PIN, LOW);

digitalWrite(E1_STEP_PIN, LOW);

delayMicroseconds(250);

}

Maybe I just don't understand how to move extruders?

=>motion =>move axis => extruder tells me extruder is too cold, but I can proceed and setup a distance in millimeters. Nothing happens. But display shows "Extruder Bed", which I couldn't figure out what it is.

=>motion =>move axis => extruder1/2 show only a distance like all other axis.

But still nothing happens.

Uploaded my updated config files:

digitalinventions.de/files/pics/3Dprinter/20201129_0112h_IronBot_Marlin_2.0.7.2.zip

//edit: Extruder steppers are working

Damn is it slow. I urgently need to adjust steps per unit. I guess prevent_cold_extrusion settings preventet it from moving (I put some filament in the sensors, so Marlin 'thinks' there's filament in...

Homing is x/y min and z max.

I noticed my homing position is (-52 | -15 | 0) and my travellimits have to be (244 | 190 | 222) to avoid crashing my clamps, spoken from the position of my probe.

I don't know which point would be my orientation on my X slider? I could either choose Nozzle1, probe or nozzle2?

//edit2:

Here's what I do understand:

// inductive z-probe turns LED on test-position: z:1,4mm

// both nozzles touch heatbed on same position: z:0,7mm

#define NOZZLE_TO_PROBE_OFFSET { 28.84, -2.8, 0.7 }

#define NOZZLE2_TO_PROBE_OFFSET { 28.89, -2.8, 0.7 }

Edited 5 time(s). Last edit at 11/28/2020 08:47PM by cysign.

|

Re: Setup Marlin on DIY printer - Mega2560 TCM2209 z-probe November 29, 2020 04:31AM |

Admin Registered: 13 years ago Posts: 7,000 |

you cannot move E without the hotend being hot, unless you turn that safety feature off.

M302 ; report current cold extrusion state

M302 P0 ; enable cold extrusion checking

M302 P1 ; disable cold extrusion checking

"Extruder Bed" is a lcd bug, Which I fixed 4 days ago... still only in bugfix.

[github.com]

"NOZZLE2_TO_PROBE_OFFSET" you can't just make up defines

Its always relative to first nozzle

M302 ; report current cold extrusion state

M302 P0 ; enable cold extrusion checking

M302 P1 ; disable cold extrusion checking

"Extruder Bed" is a lcd bug, Which I fixed 4 days ago... still only in bugfix.

[github.com]

"NOZZLE2_TO_PROBE_OFFSET" you can't just make up defines

Its always relative to first nozzle

|

Re: Setup Marlin on DIY printer - Mega2560 TCM2209 z-probe December 01, 2020 05:01PM |

Registered: 8 years ago Posts: 90 |

So it has to be

A new bed-temp sensor should arrive tomorrow. I ordered an "Thermistor NTC 3950 100k" - hope to get proper bed temperatures then to testprint, soon.

My bed heats up to ~120°C. So I guess I should build a housing for my printer to start with ABS?

For the moment I'm only interestes on ABS (for acetone-smoothing).

Thanks again for your support

#define NOZZLE_TO_PROBE_OFFSET { 28.84, -2.8, 0.7 }

#define NOZZLE_TO_NOZZLE2_OFFSET {54.25 , 0, 0 }

?A new bed-temp sensor should arrive tomorrow. I ordered an "Thermistor NTC 3950 100k" - hope to get proper bed temperatures then to testprint, soon.

My bed heats up to ~120°C. So I guess I should build a housing for my printer to start with ABS?

For the moment I'm only interestes on ABS (for acetone-smoothing).

Thanks again for your support

|

Re: Setup Marlin on DIY printer - Mega2560 TCM2209 z-probe December 03, 2020 04:19PM |

Registered: 8 years ago Posts: 90 |

Just mounted the new sensor, but I always do get bed temperature alerts like this, though temperature has only 2-4°C drift:

Any ideas on this?

Sensor is set to

Terminay says:

I thought my electronics-fan (for the stepper drivers) could provoke a temperature drop which is indicated by this message...but Im not quite sure

I found this in configuration_adv.h:

//edit: Defining nozzle-offset as

Edited 3 time(s). Last edit at 12/03/2020 04:34PM by cysign.

Any ideas on this?

Sensor is set to

#define TEMP_SENSOR_BED 13

Terminay says:

22:21:39.810 > Error:Heating failed, system stopped! Heater_ID: bed 22:21:41.925 > Errorrinter halted. kill() called!

I thought my electronics-fan (for the stepper drivers) could provoke a temperature drop which is indicated by this message...but Im not quite sure

I found this in configuration_adv.h:

#if ENABLED(THERMAL_PROTECTION_BED) #define THERMAL_PROTECTION_BED_PERIOD 20 // Seconds #define THERMAL_PROTECTION_BED_HYSTERESIS 4 // Degrees Celsius // stock value: 2

/** * As described above, except for the bed (M140/M190/M303). */ #define WATCH_BED_TEMP_PERIOD 60 // Seconds #define WATCH_BED_TEMP_INCREASE 1 // Degrees Celsius // stock value: 2 #endif

//edit: Defining nozzle-offset as

#define NOZZLE_TO_PROBE_OFFSET { 28.84, -2.7, 0 } // was 2.8

#define NOZZLE2_TO_PROBE_OFFSET { 54,19, 0, 0 } // was 2.8 // then -28.89

compiled well, but I have no clue how to check this.Edited 3 time(s). Last edit at 12/03/2020 04:34PM by cysign.

|

Re: Setup Marlin on DIY printer - Mega2560 TCM2209 z-probe December 17, 2020 07:00PM |

Registered: 8 years ago Posts: 90 |

Oh, I ment

I filled in my filament and extruding works.

I wanted to start a bedleveling-testprint and adjust nozzle-height (z-offset between nozzle and probe) using babysteps. But Im still unable to print.

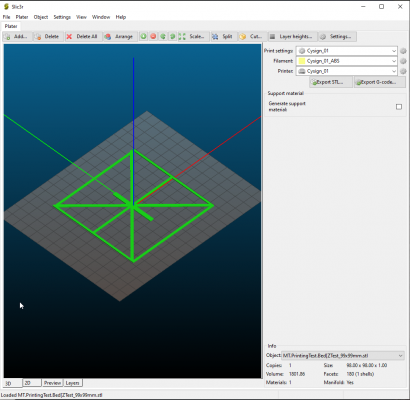

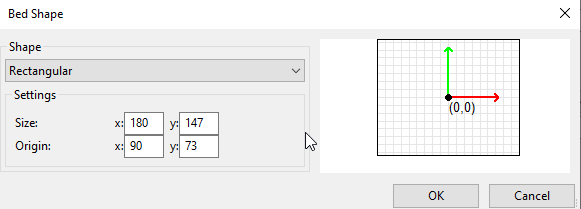

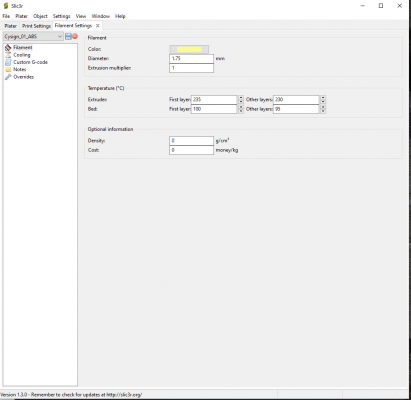

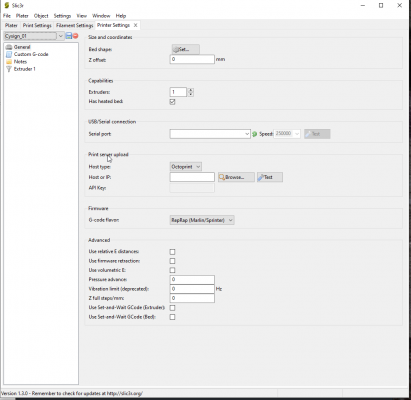

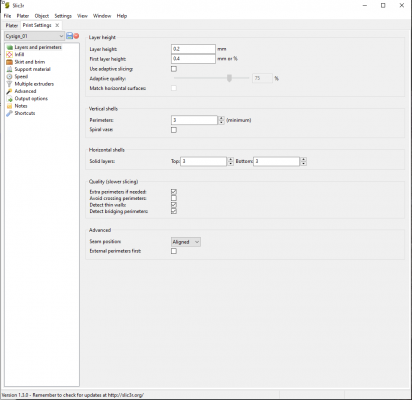

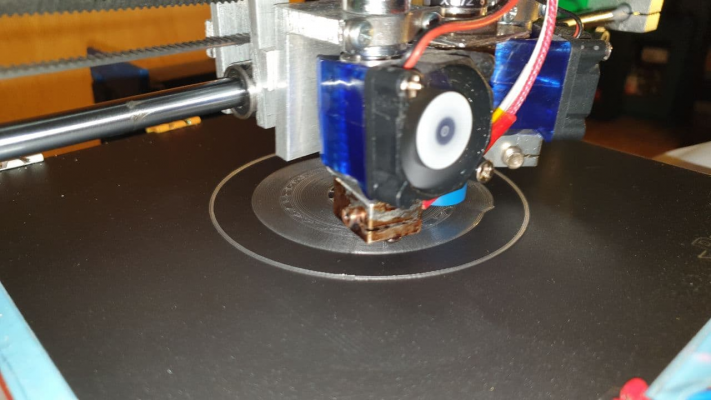

I use slic3r (or shall I better use cura?) and configured my printable area and set map to center (so print should start from middle of my bed).

When I open this gcode-file, my printer starts homing and then one of the motors exceeds limits (dont know which one, yet).

Might it any endstop?

Then theres an strange automatic filament-change. I guess this might depend on my gcode-file? But I'm not sure...

I have my config files and the printing file attached here:

[www.digitalinventions.de]

Here you can see what my printer is doing:

[youtu.be]

I was happy the filament was in my extruder...so I wouldn't never activate change filament on every print

Edited 1 time(s). Last edit at 12/17/2020 07:05PM by cysign.

#define NOZZLE_TO_PROBE_OFFSET... #define NOZZLE_TO_NOZZLE2_OFFSET...

I filled in my filament and extruding works.

I wanted to start a bedleveling-testprint and adjust nozzle-height (z-offset between nozzle and probe) using babysteps. But Im still unable to print.

I use slic3r (or shall I better use cura?) and configured my printable area and set map to center (so print should start from middle of my bed).

When I open this gcode-file, my printer starts homing and then one of the motors exceeds limits (dont know which one, yet).

Might it any endstop?

Then theres an strange automatic filament-change. I guess this might depend on my gcode-file? But I'm not sure...

I have my config files and the printing file attached here:

[www.digitalinventions.de]

Here you can see what my printer is doing:

[youtu.be]

I was happy the filament was in my extruder...so I wouldn't never activate change filament on every print

Edited 1 time(s). Last edit at 12/17/2020 07:05PM by cysign.

|

Re: Setup Marlin on DIY printer - Mega2560 TCM2209 z-probe December 17, 2020 10:21PM |

Admin Registered: 13 years ago Posts: 7,000 |

|

Re: Setup Marlin on DIY printer - Mega2560 TCM2209 z-probe December 18, 2020 02:05PM |

Registered: 8 years ago Posts: 90 |

Yes, seems like that's the trick  Set Origin to (0|0) and print starts like exspected - ~2-4mm above the printing bed. Also I adjusted z-axis speed.

Set Origin to (0|0) and print starts like exspected - ~2-4mm above the printing bed. Also I adjusted z-axis speed.

Looks like it starts to print, but after the first line it has an automated filamentchange. I still have no idea how to disable this.

//Edit: I didn't find any M600 command in the gcode - so is it a marlin setting?

Edited 1 time(s). Last edit at 12/18/2020 02:06PM by cysign.

Set Origin to (0|0) and print starts like exspected - ~2-4mm above the printing bed. Also I adjusted z-axis speed.

Set Origin to (0|0) and print starts like exspected - ~2-4mm above the printing bed. Also I adjusted z-axis speed.Looks like it starts to print, but after the first line it has an automated filamentchange. I still have no idea how to disable this.

//Edit: I didn't find any M600 command in the gcode - so is it a marlin setting?

Edited 1 time(s). Last edit at 12/18/2020 02:06PM by cysign.

|

Re: Setup Marlin on DIY printer - Mega2560 TCM2209 z-probe December 18, 2020 02:28PM |

Registered: 8 years ago Posts: 90 |

|

Re: Setup Marlin on DIY printer - Mega2560 TCM2209 z-probe December 18, 2020 04:01PM |

Registered: 8 years ago Posts: 90 |

|

Re: Setup Marlin on DIY printer - Mega2560 TCM2209 z-probe December 18, 2020 06:24PM |

Registered: 8 years ago Posts: 90 |

|

Re: Setup Marlin on DIY printer - Mega2560 TCM2209 z-probe December 18, 2020 10:35PM |

Registered: 8 years ago Posts: 90 |

|

Re: Setup Marlin on DIY printer - Mega2560 TCM2209 z-probe December 20, 2020 08:49AM |

Registered: 8 years ago Posts: 90 |

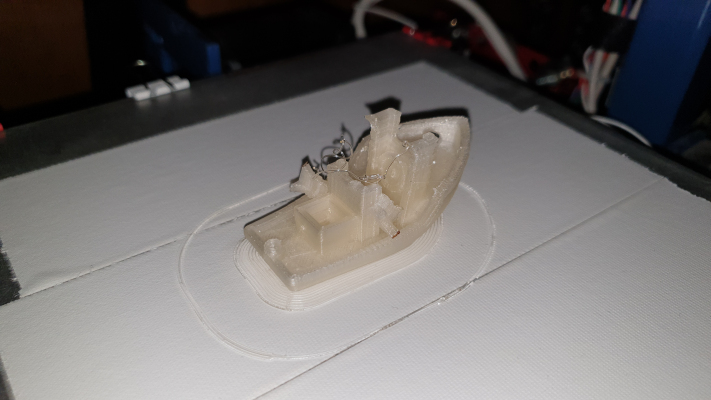

Woohoo, using some hairspray on my heatbed @50°C works perfect - gluestick was too uneven and had a lot of disadvantages which plopped my part off the bed. Spray a little bit hairspray, remove with some tissue whats too much...and the print sticks perfect:

To get this result I had to manually tweak while printing:

1st layer: 115% flow, 50% speed, use hairspray (and remove whats too much)

next layers: 75% speed, 100%flow, after some layers boosted speed to 100%.

Also I removed my second nozzle, to avoid it crashing my part (thought this was the problem - but now as my Print works fine, I should re-attach it...).

Now its time for even more finetuning:

Looks like my filament is too cold on the thin things on the top. SO I try to print at 50% there in my next test or I set my filament temperature 5°C hotter.

But it's not the right place to discuss this in the firmware-topic

A friend sent me this quality guide: [www.simplify3d.com]

I'm working on all my issues first to get a proper and clean print, before I attach my second nozzle, again.

Thanks for all of your help to get this thing alive!

The last weeks have been frustrating when I got stuck on some problems I had no idea how to solve.

I figured out, there are a lot of videos about single problems, but in most cases you have to figure out they're using any setting, your machine doesn't have. They have other hardware or other firmware versions (please guys, always add the firmwareversion to your beautiful youtube videos!).

But then there's this beautiful forum that makes impossible things possible.

Thank you a lot!

Edited 1 time(s). Last edit at 12/20/2020 09:03AM by cysign.

To get this result I had to manually tweak while printing:

1st layer: 115% flow, 50% speed, use hairspray (and remove whats too much)

next layers: 75% speed, 100%flow, after some layers boosted speed to 100%.

Also I removed my second nozzle, to avoid it crashing my part (thought this was the problem - but now as my Print works fine, I should re-attach it...).

Now its time for even more finetuning:

Looks like my filament is too cold on the thin things on the top. SO I try to print at 50% there in my next test or I set my filament temperature 5°C hotter.

But it's not the right place to discuss this in the firmware-topic

A friend sent me this quality guide: [www.simplify3d.com]

I'm working on all my issues first to get a proper and clean print, before I attach my second nozzle, again.

Thanks for all of your help to get this thing alive!

The last weeks have been frustrating when I got stuck on some problems I had no idea how to solve.

I figured out, there are a lot of videos about single problems, but in most cases you have to figure out they're using any setting, your machine doesn't have. They have other hardware or other firmware versions (please guys, always add the firmwareversion to your beautiful youtube videos!).

But then there's this beautiful forum that makes impossible things possible.

Thank you a lot!

Edited 1 time(s). Last edit at 12/20/2020 09:03AM by cysign.

|

Re: Setup Marlin on DIY printer - Mega2560 TCM2209 z-probe December 24, 2020 01:51AM |

Registered: 8 years ago Posts: 90 |

I have a strange problem:

Some hours ago, I started a print. While the printer was homing, I double-presses the rotary encoder and since it wasn't printing gcode, it didnt show z-probe-offset, but z-level.

Since then I'm stuck on printing a perfect raft, followed by printing all other layers at 4.65mm. So my extruder grinds filament while there can't be attached more filament to this layer.

To assure its no gcode-problem I sliced another model and started to print it, but it shows the same behavior.

Is this a hidden Marlin feature or may I have found a bug?

//Edit:

Heres the gcode:

www.digitalinventions.de/files/pics/3Dprinter/CFFFP_TempCalTower240.gcode

Edited 2 time(s). Last edit at 12/24/2020 08:57PM by cysign.

Some hours ago, I started a print. While the printer was homing, I double-presses the rotary encoder and since it wasn't printing gcode, it didnt show z-probe-offset, but z-level.

Since then I'm stuck on printing a perfect raft, followed by printing all other layers at 4.65mm. So my extruder grinds filament while there can't be attached more filament to this layer.

To assure its no gcode-problem I sliced another model and started to print it, but it shows the same behavior.

Is this a hidden Marlin feature or may I have found a bug?

//Edit:

M503 07:54:35.172 > echo: G21 ; Units in mm (mm) 07:54:35.175 > echo: M149 C ; Units in Celsius 07:54:35.175 > 07:54:35.175 > echo:; Filament settings: Disabled 07:54:35.176 > echo: M200 T0 D1.75 07:54:35.176 > echo: M200 T1 D1.75 07:54:35.178 > echo: M200 S0 07:54:35.178 > echo:; Steps per unit: 07:54:35.179 > echo: M92 X80.00 Y80.00 Z400.00 07:54:35.183 > echo: M92 T0 E747.60 07:54:35.183 > echo: M92 T1 E98.00 07:54:35.183 > echo:; Maximum feedrates (units/s): 07:54:35.188 > echo: M203 X70.00 Y70.00 Z7.00 07:54:35.188 > echo: M203 T0 E20.00 07:54:35.188 > echo: M203 T1 E10.00 07:54:35.188 > echo:; Maximum Acceleration (units/s2): 07:54:35.217 > echo: M201 X3000.00 Y3000.00 Z3000.00 07:54:35.217 > echo: M201 T0 E3000.00 07:54:35.217 > echo: M201 T1 E3000.00 07:54:35.217 > echo:; Acceleration (units/s2): P R T 07:54:35.217 > echo: M204 P2000.00 R2000.00 T2000.00 07:54:35.217 > echo:; Advanced: B S T J 07:54:35.217 > echo: M205 B20000.00 S0.00 T0.00 J0.01 07:54:35.217 > echo:; Home offset: 07:54:35.217 > echo: M206 X0.00 Y0.00 Z4.65 07:54:35.217 > echo:; Hotend offsets: 07:54:35.217 > echo: M218 T1 X0.00 Y0.00 Z0.000 07:54:35.217 > echo:; Auto Bed Leveling: 07:54:35.217 > echo: M420 S0 Z0.00 07:54:35.217 > echo: G29 W I0 J0 Z2.57750 07:54:35.217 > echo: G29 W I1 J0 Z2.63500 07:54:35.217 > echo: G29 W I2 J0 Z2.66500 07:54:35.217 > echo: G29 W I0 J1 Z2.49000 07:54:35.217 > echo: G29 W I1 J1 Z2.56750 07:54:35.217 > echo: G29 W I2 J1 Z2.59250 07:54:35.220 > echo: G29 W I0 J2 Z2.26250 07:54:35.220 > echo: G29 W I1 J2 Z2.38500 07:54:35.221 > echo: G29 W I2 J2 Z2.40000 07:54:35.221 > echo:; Material heatup parameters: 07:54:35.223 > echo: M145 S0 H180 B70 07:54:35.223 > echo: M145 S1 H235 B110 07:54:35.224 > echo:; PID settings: 07:54:35.226 > echo: M301 P22.20 I1.08 D114.00 07:54:35.240 > echo: M301 P22.20 I1.08 D114.00 07:54:35.240 > echo:; Z-Probe Offset (mm): 07:54:35.240 > echo: M851 X28.84 Y2.70 Z0.20 07:54:35.240 > echo:; Filament load/unload lengths: 07:54:35.240 > echo: M603 T0 L500.00 U800.00 07:54:35.240 > echo: M603 T1 L500.00 U800.00 07:54:35.240 > echo:; Tool-changing: 07:54:35.240 > echo: Z2.00 07:54:35.240 > echo:; Filament runout sensor: 07:54:35.240 > echo: M412 S0 D37.00 07:54:35.240 > ok

Heres the gcode:

www.digitalinventions.de/files/pics/3Dprinter/CFFFP_TempCalTower240.gcode

Edited 2 time(s). Last edit at 12/24/2020 08:57PM by cysign.

|

Re: Setup Marlin on DIY printer - Mega2560 TCM2209 z-probe December 24, 2020 08:07PM |

Registered: 8 years ago Posts: 90 |

I tried another object using Slic3r (previously I was using cura which I really liked for its modern interface and gcode viewer....after I started using Slic3r). But again: Im stuck on 4.65mm in my print. All other movements seem to be fine.

Axis and sensors do work fine (during homing + bed leveling).

Is there a "disable z-axis" setting in Marlin?

Or shall I report an issue on Github?

Axis and sensors do work fine (during homing + bed leveling).

Is there a "disable z-axis" setting in Marlin?

Or shall I report an issue on Github?

|

Re: Setup Marlin on DIY printer - Mega2560 TCM2209 z-probe December 24, 2020 09:33PM |

Registered: 8 years ago Posts: 90 |

After reflashing Marlin didnt bring any progress, I now lowered the z-speed. As I was incrementing X/Y-speed the last days, maybe the z was too fast while printing so I lost steps? But I would have thought I woule have hear something like this... Waiting for the heatbed to warm up, again

|

Re: Setup Marlin on DIY printer - Mega2560 TCM2209 z-probe December 24, 2020 10:12PM |

Registered: 8 years ago Posts: 90 |

Changing z-speed max doesnt help

Still: First 2-3 layers look pretty well, then the z-movement is missing (means I can see z-movements in regard to bed level, but the z-level isn't increasing and my extruder is grinding the filament).

Edited 3 time(s). Last edit at 12/24/2020 10:18PM by cysign.

Still: First 2-3 layers look pretty well, then the z-movement is missing (means I can see z-movements in regard to bed level, but the z-level isn't increasing and my extruder is grinding the filament).

Edited 3 time(s). Last edit at 12/24/2020 10:18PM by cysign.

|

Re: Setup Marlin on DIY printer - Mega2560 TCM2209 z-probe December 25, 2020 11:49PM |

Registered: 8 years ago Posts: 90 |

|

Re: Setup Marlin on DIY printer - Mega2560 TCM2209 z-probe December 26, 2020 08:13PM |

Registered: 8 years ago Posts: 90 |

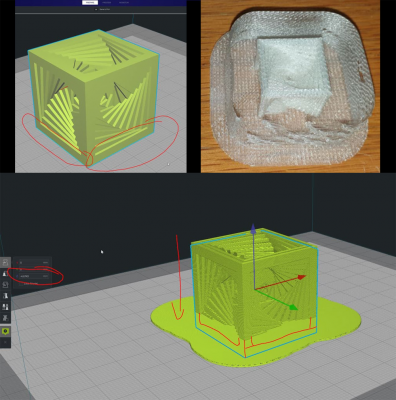

Looks like I found out whats wrong: After rafting, the bottom of my model fails, as my height is about 4,65mm, where it starts to print.

Anyhow I must have a wrong setting. I would exspect the printer to set Z=0 after rafting or to move the object up to not cut away the bottom:

So it has to be a cura-setting?

//edit: the picture on the bottom shows the part moved to z = -4,x. This is what the printed result looks like.

Edited 2 time(s). Last edit at 12/27/2020 05:09PM by cysign.

Anyhow I must have a wrong setting. I would exspect the printer to set Z=0 after rafting or to move the object up to not cut away the bottom:

So it has to be a cura-setting?

//edit: the picture on the bottom shows the part moved to z = -4,x. This is what the printed result looks like.

Edited 2 time(s). Last edit at 12/27/2020 05:09PM by cysign.

|

Re: Setup Marlin on DIY printer - Mega2560 TCM2209 z-probe December 28, 2020 08:45AM |

Registered: 8 years ago Posts: 90 |

I just recorded a small video of the printer's behavior:

https://youtu.be/vQkE3Z16EZI

Also I uploaded an archive:

http://www.digitalinventions.de/files/temp/IronBot_Cura_Marlin_Problem_first_4.65mm.zip

This file contains:

-Marlin-config

-Marlin-config_adv

-screenshot cura-settings for printer (like start/end gcode)

-3d object I sliced and printed

-M503 marlin printer status

-3mf cura-project-file

-gcode-file

Swapping G28 (homing) and G29 (bed leveling) didn't help.

It was recommended here: [community.ultimaker.com]

Might the z-height of my printer in the config-file be the problem? When probing, you can see the values on the display. But I couldn't see 4.65mm anywhere except the M503 status home-offset (see M503 file).

What else could I do?

//edit: In the cura forum I added the M503 output after powering on, after homing, after bedleveling and after homing, again. Maybe this helps?

On the video you can see the display is really, really long showing 4.65mm. Extruder _is_ working, but filamentflow is blocked by nozzle touching raft. To avoid too much filament grinding, I set flow to 70%. I will change this later, wenn the 4.65mm problem is solved.

Edited 2 time(s). Last edit at 12/28/2020 10:33AM by cysign.

https://youtu.be/vQkE3Z16EZI

Also I uploaded an archive:

http://www.digitalinventions.de/files/temp/IronBot_Cura_Marlin_Problem_first_4.65mm.zip

This file contains:

-Marlin-config

-Marlin-config_adv

-screenshot cura-settings for printer (like start/end gcode)

-3d object I sliced and printed

-M503 marlin printer status

-3mf cura-project-file

-gcode-file

Swapping G28 (homing) and G29 (bed leveling) didn't help.

It was recommended here: [community.ultimaker.com]

Might the z-height of my printer in the config-file be the problem? When probing, you can see the values on the display. But I couldn't see 4.65mm anywhere except the M503 status home-offset (see M503 file).

What else could I do?

//edit: In the cura forum I added the M503 output after powering on, after homing, after bedleveling and after homing, again. Maybe this helps?

On the video you can see the display is really, really long showing 4.65mm. Extruder _is_ working, but filamentflow is blocked by nozzle touching raft. To avoid too much filament grinding, I set flow to 70%. I will change this later, wenn the 4.65mm problem is solved.

Edited 2 time(s). Last edit at 12/28/2020 10:33AM by cysign.

|

Re: Setup Marlin on DIY printer - Mega2560 TCM2209 z-probe December 28, 2020 06:19PM |

Registered: 8 years ago Posts: 90 |

I finally started a bug report on github: [github.com]

|

Re: Setup Marlin on DIY printer - Mega2560 TCM2209 z-probe December 28, 2020 07:38PM |

Registered: 8 years ago Posts: 90 |

|

Re: Setup Marlin on DIY printer - Mega2560 TCM2209 z-probe January 22, 2021 03:31PM |

Registered: 8 years ago Posts: 90 |

Sorry, only registered users may post in this forum.