CoreXY printer intermittant level shifts45 degrees

Posted by dlc60

|

CoreXY printer intermittant level shifts45 degrees June 14, 2020 11:52PM |

Registered: 7 years ago Posts: 619 |

I have a scratch built CoreXY that I recently completed. For a couple of weeks it has worked flawlessly, but now I am getting intermittent diagonal layer shifts toward the "X" stepper (the right one looking from the front). I know this is the direction traveled when the X stepper is running and the Y stepper is not. It seems to happen "mostly" on larger models, more compact models 90% of the time will print fine.

When I see the print go wrong, I cancel it. Cancel.g tells the carriage to home X/Y. But, while it homes the X, it gets ALMOST to the Y home switch, but stops before it gets there. Is this related?

My frame is 300mmx400mm using 37oz.in(26Ncm) 12V 0.4Amp 1.8deg steppers.

Controller: Duet 2 Maestro, running the steppers at 800ma

Acceleration 1000mm/s^2

Jerk 15mm/s

Max travel speed 120mm/s (print speed typically under 40mm/s)

I do not think that it is mechanical, I am using a pretty typical (unstacked) CoreXY design, and this is a pretty small printer (200mm bed). Nothing seems to be binding, grinding, catching or skipping when I move it manually. But definitely have heard the "bonking" sound of a stepper balking or a belt skip on a pulley. I don't THINK that my belts are either too tight or too loose, they feel the same as another CoreXY machine that I have. My idlers are free moving and there is nothing, that I can see, that is binding.

CoreXY printers are new to me, I have only had them for the last two months or so. I am not sure where to go to troubleshoot this problem. I have read enough to know that a 45 degree shift to the "back right" means that the "X" stepper is moving when the "Y" stepper is not moving. So, if both steppers should be moving and the "Y" stepper jams, that would shift everything to the diagonal pointing to the "X" stepper. The steppers get a little warm, nothing to worry about. The "bonking" sound sounds like the motor is either balking, or trying to move too fast and the belt is skipping.

Does anyone have a process that they use to troubleshoot this kind of thing? Is my current too low, acceleration too high, steppers too weak, ???

I don't usually start replacing mechanical things when trouble starts, belts, pulleys and motors are really reliable. What are some good steps to take in settings or speeds that can point me to a cause?

Troubleshooting:

I increased the current. No effect.

I reduced accel down to 200mm/s No effect.

I reduced jerk down to 5mm/s No effect.

I have slowed my speeds down by 30% No effect.

When I abort the print, I hear the printer "gronk" like a belt skip as it tries, and fails to home X/Y - It almost never homes Y all the way, but does home the X.

So, now I AM thinking something is catching in the mechanical system - Time for a tear-down?

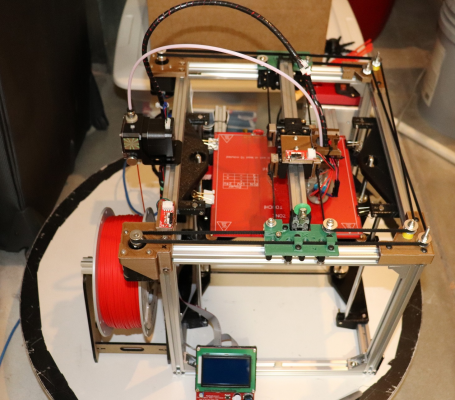

This is my machine

Here is a bad print

Here is a good print (from the same time period.)

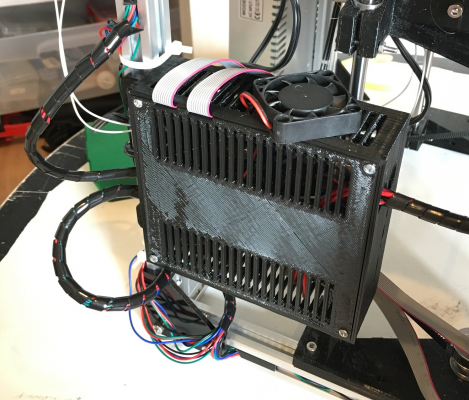

Checking my timeline, I think my problems started when I dressed the cables and put the Maestro in this enclosure (with a fan).

Many thanks,

DLC

Edited 1 time(s). Last edit at 06/15/2020 11:01AM by dlc60.

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

When I see the print go wrong, I cancel it. Cancel.g tells the carriage to home X/Y. But, while it homes the X, it gets ALMOST to the Y home switch, but stops before it gets there. Is this related?

My frame is 300mmx400mm using 37oz.in(26Ncm) 12V 0.4Amp 1.8deg steppers.

Controller: Duet 2 Maestro, running the steppers at 800ma

Acceleration 1000mm/s^2

Jerk 15mm/s

Max travel speed 120mm/s (print speed typically under 40mm/s)

I do not think that it is mechanical, I am using a pretty typical (unstacked) CoreXY design, and this is a pretty small printer (200mm bed). Nothing seems to be binding, grinding, catching or skipping when I move it manually. But definitely have heard the "bonking" sound of a stepper balking or a belt skip on a pulley. I don't THINK that my belts are either too tight or too loose, they feel the same as another CoreXY machine that I have. My idlers are free moving and there is nothing, that I can see, that is binding.

CoreXY printers are new to me, I have only had them for the last two months or so. I am not sure where to go to troubleshoot this problem. I have read enough to know that a 45 degree shift to the "back right" means that the "X" stepper is moving when the "Y" stepper is not moving. So, if both steppers should be moving and the "Y" stepper jams, that would shift everything to the diagonal pointing to the "X" stepper. The steppers get a little warm, nothing to worry about. The "bonking" sound sounds like the motor is either balking, or trying to move too fast and the belt is skipping.

Does anyone have a process that they use to troubleshoot this kind of thing? Is my current too low, acceleration too high, steppers too weak, ???

I don't usually start replacing mechanical things when trouble starts, belts, pulleys and motors are really reliable. What are some good steps to take in settings or speeds that can point me to a cause?

Troubleshooting:

I increased the current. No effect.

I reduced accel down to 200mm/s No effect.

I reduced jerk down to 5mm/s No effect.

I have slowed my speeds down by 30% No effect.

When I abort the print, I hear the printer "gronk" like a belt skip as it tries, and fails to home X/Y - It almost never homes Y all the way, but does home the X.

So, now I AM thinking something is catching in the mechanical system - Time for a tear-down?

This is my machine

Here is a bad print

Here is a good print (from the same time period.)

Checking my timeline, I think my problems started when I dressed the cables and put the Maestro in this enclosure (with a fan).

Many thanks,

DLC

Edited 1 time(s). Last edit at 06/15/2020 11:01AM by dlc60.

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

|

Re: CoreXY printer intermittant level shifts45 degrees June 16, 2020 12:03PM |

Registered: 7 years ago Posts: 558 |

If it only happens on large prints, you could be experiencing temp issues on the driver chip for a particular motor?

Section_M305_Set_temperature_sensor_parameters

The other thing to check would be touch your X and Y motors while your running. If either are too hot to hold onto for an extended period of time, your probably running them at too high a current setting and if they won't function at a lower current, then your motors probably don't have enough torque or require cooling directly on the motor itself.

Section_M305_Set_temperature_sensor_parameters

Note: If your running RepRapFirmware 3.0 or higher, the above is a little different and you'd have to create the Virtual Sensor yourself with other G-Codes.Quote

Section_M305_Set_temperature_sensor_parameters

- Channel 1000 is the on-chip microcontroller temperature sensor

- Channel 1001 represents the temperature warning and overheat flags on the TMC2660, TMC2224 or other smart drivers on the Duet main board. It reads 0C when there is no warning, 100C if any driver reports over-temperature warning , and 150C if any driver reports over temperature shutdown.

- Channel 1002 is as channel 1001 but for drivers on the Duex 2 or Duex 5 expansion board.

Virtual heaters 100, 101 and 102 are preconfigured to use temperature sensor channels 1000, 1001 and 1002 respectively.

If you send the following command:

M305 P101

you should get the response "Heater 101 uses TMC2660 temperature warnings sensor channel 1001". But as this virtual heater has no name, it doesn't show up in DWC. You can fix that by sending:

M305 P101 S"Drivers"

After that, if you go to the "Extra" tab in DWC (where is says Tools/Heaters/Extra), you will see "Drivers" as an entry.

The other thing to check would be touch your X and Y motors while your running. If either are too hot to hold onto for an extended period of time, your probably running them at too high a current setting and if they won't function at a lower current, then your motors probably don't have enough torque or require cooling directly on the motor itself.

|

Re: CoreXY printer intermittant level shifts45 degrees June 16, 2020 01:54PM |

Registered: 7 years ago Posts: 619 |

Quote

PDBeal

If it only happens on large prints, you could be experiencing temp issues on the driver chip for a particular motor?

Section_M305_Set_temperature_sensor_parameters

Note: If your running RepRapFirmware 3.0 or higher, the above is a little different and you'd have to create the Virtual Sensor yourself with other G-Codes.Quote

Section_M305_Set_temperature_sensor_parameters

- Channel 1000 is the on-chip microcontroller temperature sensor

- Channel 1001 represents the temperature warning and overheat flags on the TMC2660, TMC2224 or other smart drivers on the Duet main board. It reads 0C when there is no warning, 100C if any driver reports over-temperature warning , and 150C if any driver reports over temperature shutdown.

- Channel 1002 is as channel 1001 but for drivers on the Duex 2 or Duex 5 expansion board.

Virtual heaters 100, 101 and 102 are preconfigured to use temperature sensor channels 1000, 1001 and 1002 respectively.

If you send the following command:

M305 P101

you should get the response "Heater 101 uses TMC2660 temperature warnings sensor channel 1001". But as this virtual heater has no name, it doesn't show up in DWC. You can fix that by sending:

M305 P101 S"Drivers"

After that, if you go to the "Extra" tab in DWC (where is says Tools/Heaters/Extra), you will see "Drivers" as an entry.

The other thing to check would be touch your X and Y motors while your running. If either are too hot to hold onto for an extended period of time, your probably running them at too high a current setting and if they won't function at a lower current, then your motors probably don't have enough torque or require cooling directly on the motor itself.

Thanks for the suggestions - and the troubleshooting hints. I have an enclosure fan running and the board never gets very hot. My stepper barely get warm - that was the first thing that I checked, they only got a little warm when I increased their current to 1.0Amp, which didn't help the problem either.

Question: The Duet defaults to using "interpolation", would turning that off and just microstepping do anything of value for troubleshooting this?

Thanks all,

DLC

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

Re: CoreXY printer intermittant level shifts45 degrees Re: CoreXY printer intermittant level shifts45 degrees August 12, 2020 01:35AM |

Registered: 7 years ago Posts: 619 |

I finally figured it out. It was a purely mechanical issue, and really subtle, but obvious once I stumbled upon the reason.

I use Exoslide hardware for my motion control slides. I had to come up with totally custom pieces for my CoreXY, but hey, who hates a challenge?

Anyway. This was a scratch built, parts from the bin, whatever was lying around and crafting up the rest. I had gotten the Exoslide stuff for a Bowden Delta upgrade a while ago, but since I am on a CoreXY kick, I repurposed them. About 6 months or so after I bought the Exoslide stuff they creator of them sent gratis upgrades for the plastic rolling hardware on the bearings. He said that the original ones were discovered to crack after only modest use, the new ones won't. I shrugged it off and put the parts in the bin. See where this is going?

Cut to the chase. What happened in that one of the rollers cracked and blew off of the slide, creating an uneven rail glide. At high speeds, at just the right time, the slide would bind, generating a horrific noise from the pulley belt skip. I discovered the problem while wandering around my lab in bare feet and stepping on the cracked wheel rim. Forehead slap! I replaced all the rollers on that slide, now there are no problems, I have upped the accel, jerk and speed of the system and things that would never get more than 1/3 done before messing up, work fine.

Moral of the story: When the manufacturer says something is faulty, here put this on instead, do it.

DLC

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

I use Exoslide hardware for my motion control slides. I had to come up with totally custom pieces for my CoreXY, but hey, who hates a challenge?

Anyway. This was a scratch built, parts from the bin, whatever was lying around and crafting up the rest. I had gotten the Exoslide stuff for a Bowden Delta upgrade a while ago, but since I am on a CoreXY kick, I repurposed them. About 6 months or so after I bought the Exoslide stuff they creator of them sent gratis upgrades for the plastic rolling hardware on the bearings. He said that the original ones were discovered to crack after only modest use, the new ones won't. I shrugged it off and put the parts in the bin. See where this is going?

Cut to the chase. What happened in that one of the rollers cracked and blew off of the slide, creating an uneven rail glide. At high speeds, at just the right time, the slide would bind, generating a horrific noise from the pulley belt skip. I discovered the problem while wandering around my lab in bare feet and stepping on the cracked wheel rim. Forehead slap! I replaced all the rollers on that slide, now there are no problems, I have upped the accel, jerk and speed of the system and things that would never get more than 1/3 done before messing up, work fine.

Moral of the story: When the manufacturer says something is faulty, here put this on instead, do it.

DLC

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

Sorry, only registered users may post in this forum.