Hotend heater control circuit

Posted by reprapprochina-liang

|

Hotend heater control circuit December 28, 2018 09:57AM |

Registered: 7 years ago Posts: 13 |

Hello, guys,

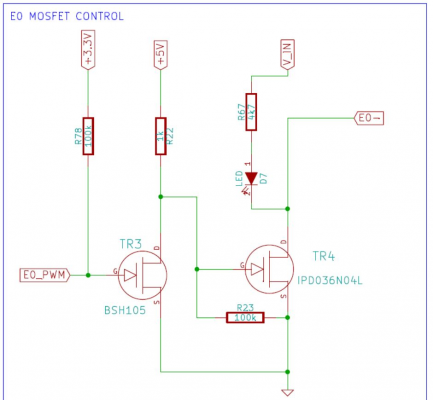

Dose anyone know about the hot end control circuit?

I want to know why need two MOSFET?

What do R78 and R23 do in this circuit? what will happen if I remove them?

Thank you.

Dose anyone know about the hot end control circuit?

I want to know why need two MOSFET?

What do R78 and R23 do in this circuit? what will happen if I remove them?

Thank you.

|

Re: Hotend heater control circuit December 28, 2018 12:05PM |

Admin Registered: 16 years ago Posts: 13,884 |

... the bigger MOSFET needs more than the 3.3V from the Arduino -- so this is a "Darlington-style"-pair ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Hotend heater control circuit December 28, 2018 11:01PM |

Registered: 7 years ago Posts: 13 |

|

Re: Hotend heater control circuit December 29, 2018 04:39AM |

Admin Registered: 16 years ago Posts: 13,884 |

... look into the datasheets of the MOSFETs - high current MOSFETs needs 5V or more for proper operation.

The arduino outputs only 3,3V, what's not enough to activate the high current MOSFET ... so the smaller "logic level" MOSFET switches the driving 5V for the bigger one OFF, when activated with 3,3V...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

The arduino outputs only 3,3V, what's not enough to activate the high current MOSFET ... so the smaller "logic level" MOSFET switches the driving 5V for the bigger one OFF, when activated with 3,3V...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Hotend heater control circuit January 03, 2019 11:09AM |

Registered: 6 years ago Posts: 1,007 |

Quote

VDX

... the bigger MOSFET needs more than the 3.3V from the Arduino -- so this is a "Darlington-style"-pair ...

Sorry, not a Darlington !

Just teasing you, I know that in fact you know.

Edited 2 time(s). Last edit at 01/03/2019 11:12AM by MKSA.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: Hotend heater control circuit January 03, 2019 11:15AM |

Registered: 10 years ago Posts: 14,672 |

Quote

reprapprochina-liang

I want to know why need two MOSFET?

What do R78 and R23 do in this circuit? what will happen if I remove them?

Thank you.

As has already been said, the first mosfet is to boost the signal from 3.3V to 5V.

R78 ensures that when the Duet starts up, the heater defaults to being off. But as the MCU already has an internal pullup resistor which is enabled at reset, it could be omitted. R23 is redundant.

That design has a number of disadvantages, for example, slow turn-on time and excessively fast turn-off time of the main mosfet, and the heaters turn on if the 3.3V rail is shorted to ground. So I used a different design in the Duet WiFi.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Hotend heater control circuit January 03, 2019 11:33AM |

Registered: 6 years ago Posts: 1,007 |

Quote

dc42

....

That design has a number of disadvantages, for example, slow turn-on time and excessively fast turn-off time of the main mosfet, and the heaters turn on if the 3.3V rail is shorted to ground. So I used a different design in the Duet WiFi.

You use a power Darlington ?

Wondering, what is the issue with fast turn-off ? Is the inductance of the bed loops etc such that you experience transients ???

Edited 1 time(s). Last edit at 01/04/2019 02:14AM by MKSA.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: Hotend heater control circuit January 04, 2019 03:28AM |

Registered: 10 years ago Posts: 14,672 |

The issue with fast turn off is that the inductance of the bed heater and associated wiring causes a voltage spike when the MOSFET turns off, which exceeds the drain voltage rating of the bed heater MOSFET, causing it to avalanche. The energy involved is small and almost certainly below the avalanche rating of the MOSFET, but it and the fast change in current generate EMI.

The Duet 085 added a resistor in series with the gate of the power MOSFET to control the turn-off time. The Duet WiFi uses a separate chip to level shift and buffer the gate drive signal, again with a gate series resistor.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

The Duet 085 added a resistor in series with the gate of the power MOSFET to control the turn-off time. The Duet WiFi uses a separate chip to level shift and buffer the gate drive signal, again with a gate series resistor.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Hotend heater control circuit January 04, 2019 10:23AM |

Registered: 6 years ago Posts: 1,007 |

Quote

dc42

The issue with fast turn off is that the inductance of the bed heater and associated wiring causes a voltage spike when the MOSFET turns off, which exceeds the drain voltage rating of the bed heater MOSFET, causing it to avalanche. The energy involved is small and almost certainly below the avalanche rating of the MOSFET, but it and the fast change in current generate EMI.

The Duet 085 added a resistor in series with the gate of the power MOSFET to control the turn-off time. The Duet WiFi uses a separate chip to level shift and buffer the gate drive signal, again with a gate series resistor.

What I thought, I measured about 10 microH for my bed. The MKS SBASE uses TC427 Power MOSFET Drivers for that, at least they did that OK.

As the saying goes: "The devil is in the detail".

Edited 1 time(s). Last edit at 01/04/2019 10:26AM by MKSA.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

Sorry, only registered users may post in this forum.