The "three wires suspended" hangprinter

Posted by tswallen

|

The "three wires suspended" hangprinter October 08, 2019 08:51AM |

Registered: 4 years ago Posts: 2 |

Hey there Tobben

I've taken a real interest in your hangprinter. I think the design is innovative, accessible and powerful. Great work.

I want to print a house with a hangprinter. Examples include this and this.

The current design has a printable area that shrinks as the structure becomes taller. As you can see here, the guide wires restrict movement.

When I pictured a hangprinter I imagined a design that looked like this or this. I think an extruder suspended by three wires is much simpler and solves the issue of a narrowing printable area.

But here's the thing... nobody uses this design. I suspect the reason you've arrived at your current design is because of trial and error (plus some clever engineering). I suspect you've tried the "three wire suspended" design before and found it was inaccurate or hard to control.

I have two questions for you Tobben:

1. If you had to print a house with a hangprinter, how would you do it? how would you design it? how would you optimise the printable area?

2. What would be required to make the "three wires suspended" design work? Is it a matter of weight, tension and better firmware? Is there anything that can be added to improve it?

These are burning questions I could not answer by reading your blog or watching your YouTube videos.

Cheers

Tom

I've taken a real interest in your hangprinter. I think the design is innovative, accessible and powerful. Great work.

I want to print a house with a hangprinter. Examples include this and this.

The current design has a printable area that shrinks as the structure becomes taller. As you can see here, the guide wires restrict movement.

When I pictured a hangprinter I imagined a design that looked like this or this. I think an extruder suspended by three wires is much simpler and solves the issue of a narrowing printable area.

But here's the thing... nobody uses this design. I suspect the reason you've arrived at your current design is because of trial and error (plus some clever engineering). I suspect you've tried the "three wire suspended" design before and found it was inaccurate or hard to control.

I have two questions for you Tobben:

1. If you had to print a house with a hangprinter, how would you do it? how would you design it? how would you optimise the printable area?

2. What would be required to make the "three wires suspended" design work? Is it a matter of weight, tension and better firmware? Is there anything that can be added to improve it?

These are burning questions I could not answer by reading your blog or watching your YouTube videos.

Cheers

Tom

|

Re: The "three wires suspended" hangprinter October 11, 2019 05:00AM |

Registered: 8 years ago Posts: 96 |

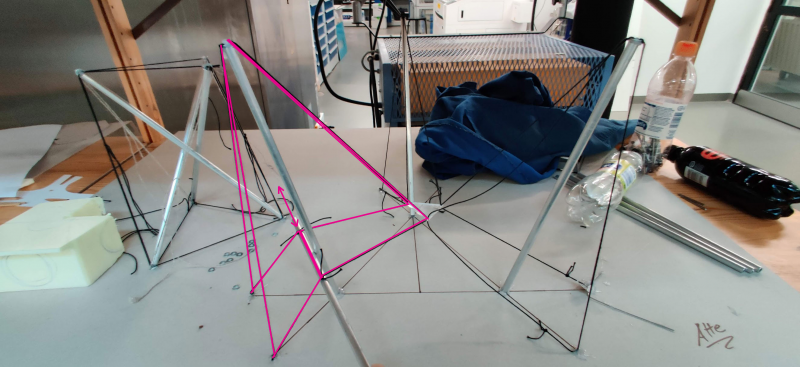

Recently, I've been thinking about the same approach to the frame design. Basically I want overcome the necessity of having a structure at a high point above the print surface. My current frame design has almost all the mechanics and electronics attached to the base plate that is installed at the tip of three legs. It has proved to be difficult to calibrate and to maintain, since its in 2,5 m height. Currently I'm playing with different ideas, and one of them you can see in the pics down below.

I've replaced the D-lines with separate lines that are going to the beam tips. Those would mainly be used for lifting the effector. The bottom lines would handle the XY-axis movement be as in Tobben's design.

And since we want to be able reshape the print volume from conical to cylindrical, we need to be able to lift the ABC-line anchor points on the fly. One solution could be a cross beam to the vertical beams, that a) reroutes the lines and b) moves along the vertical beam. The cross beam would need to have bearings, but that's only a mechanical detail.

I'm no mechanical engineer, but I assume that this construction would work quite reliably until the angle of the top lines to the vertical beam gets bigger than 45 degree. But that would be already pretty high and the shape of the print volume would be cylindrical.

Any ideas? Comments?

I've replaced the D-lines with separate lines that are going to the beam tips. Those would mainly be used for lifting the effector. The bottom lines would handle the XY-axis movement be as in Tobben's design.

And since we want to be able reshape the print volume from conical to cylindrical, we need to be able to lift the ABC-line anchor points on the fly. One solution could be a cross beam to the vertical beams, that a) reroutes the lines and b) moves along the vertical beam. The cross beam would need to have bearings, but that's only a mechanical detail.

I'm no mechanical engineer, but I assume that this construction would work quite reliably until the angle of the top lines to the vertical beam gets bigger than 45 degree. But that would be already pretty high and the shape of the print volume would be cylindrical.

Any ideas? Comments?

|

Re: The "three wires suspended" hangprinter October 11, 2019 11:52AM |

Moderator Registered: 10 years ago Posts: 401 |

Cool!

@tswallen

1. If I had to print a house with Hangprinter, my first approach would be to just scale everything up.

I'd have to put all motors, spools and electronics somewhere near the ground, so not up in the D-anchor though.

If I had to increase the build volume, I would pause and move the ABC anchors up mid print, like I did when printing the Babel Tower.

2. The "three wires suspended" design will work, it will just be a bit wobbly.

With cable driven robots, lines in more directions means stiffness and acceleration in more directions.

With three lines going upwards as your only means to exert force on your effector, you will for example not have stiffness against forces pushing upwards on your effector from below.

You max acceleration will always be limited by gravity, and when you get close to vertically below one of your anchors, you'll find that xy-accelerations get very very slow.

To get stiffness downwards you could add a spring loaded pole that pushes downwards on your effector.

The pole can also help you accelerate faster in all positions.

For example the Flying Sky Delta (https://sites.google.com/site/3dprinterlist/delta-3d-printers/wire-suspended-deltas/flying-skydelta) and the Tetra uses poles with success.

@atmark

Hm... Line driven effectors can not go above the highest anchor regardless of the frame shape.

Print height per frame height is optimal if the high anchor is placed vertically above the print volume.

It does look a bit like you've replaced a structure with one high point above the print surface, with another structure that has three points even higher above the print surface.

The six anchor points you get lines in six directions, which is better than HP's four.

If you manage to get your three high anchors stiff, then you can reach very high accelerations and very good effector stiffness.

torbjornludvigsen.com

@tswallen

1. If I had to print a house with Hangprinter, my first approach would be to just scale everything up.

I'd have to put all motors, spools and electronics somewhere near the ground, so not up in the D-anchor though.

If I had to increase the build volume, I would pause and move the ABC anchors up mid print, like I did when printing the Babel Tower.

2. The "three wires suspended" design will work, it will just be a bit wobbly.

With cable driven robots, lines in more directions means stiffness and acceleration in more directions.

With three lines going upwards as your only means to exert force on your effector, you will for example not have stiffness against forces pushing upwards on your effector from below.

You max acceleration will always be limited by gravity, and when you get close to vertically below one of your anchors, you'll find that xy-accelerations get very very slow.

To get stiffness downwards you could add a spring loaded pole that pushes downwards on your effector.

The pole can also help you accelerate faster in all positions.

For example the Flying Sky Delta (https://sites.google.com/site/3dprinterlist/delta-3d-printers/wire-suspended-deltas/flying-skydelta) and the Tetra uses poles with success.

@atmark

Hm... Line driven effectors can not go above the highest anchor regardless of the frame shape.

Print height per frame height is optimal if the high anchor is placed vertically above the print volume.

It does look a bit like you've replaced a structure with one high point above the print surface, with another structure that has three points even higher above the print surface.

The six anchor points you get lines in six directions, which is better than HP's four.

If you manage to get your three high anchors stiff, then you can reach very high accelerations and very good effector stiffness.

torbjornludvigsen.com

|

Re: The "three wires suspended" hangprinter October 11, 2019 03:03PM |

Registered: 8 years ago Posts: 96 |

@tobben

Yes, you're right about the replacement of one structure with another. And also its not optimal in regard to the achievable height. But, I believe we would be able to get more usable print volume that way. Also, for the Hangprinter's concept core essence of scalablity, it is nessecary to be independent of the high point structure directly above the print surface. If one wants to scale up the print volume (and this is in my opinion what the Hangprinter is about) it gets really fast really expensive if you want to print something in size of a house. You would have to build a big, stable structure first and thats not applicable for temporal print spots.

What you need is a simple, sturdy structure, that is easy to transport and to set up. I've been looking into Tensegrity structures lately, that relay only on compressed struts and tensioned lines/cables. In fact the little structure on the left in my pics above is the simplest Tensegrity structure possible. It is pretty sturdy already, although the lines are not really tensioned. And if you're going to google the topic, you might want to check the Skylon (London 1951). That's a pretty amazing thing

Edited 1 time(s). Last edit at 10/11/2019 03:05PM by atmark.

Yes, you're right about the replacement of one structure with another. And also its not optimal in regard to the achievable height. But, I believe we would be able to get more usable print volume that way. Also, for the Hangprinter's concept core essence of scalablity, it is nessecary to be independent of the high point structure directly above the print surface. If one wants to scale up the print volume (and this is in my opinion what the Hangprinter is about) it gets really fast really expensive if you want to print something in size of a house. You would have to build a big, stable structure first and thats not applicable for temporal print spots.

What you need is a simple, sturdy structure, that is easy to transport and to set up. I've been looking into Tensegrity structures lately, that relay only on compressed struts and tensioned lines/cables. In fact the little structure on the left in my pics above is the simplest Tensegrity structure possible. It is pretty sturdy already, although the lines are not really tensioned. And if you're going to google the topic, you might want to check the Skylon (London 1951). That's a pretty amazing thing

Edited 1 time(s). Last edit at 10/11/2019 03:05PM by atmark.

|

Re: The "three wires suspended" hangprinter October 12, 2019 06:01AM |

Moderator Registered: 10 years ago Posts: 401 |

It might be easier and cheaper to build three tall Tensegrity structures than to build one tall tetrahedron. I don't know.

I find tetrahedrons very simple, sturdy, easy to transport and to set up.

I guess I would need to see it hands-on, or see a very detailed construction video, to be convinced that a tensegrity structure can be either simpler, sturdier, easier to transport or easier to set up.

Looks cool though

torbjornludvigsen.com

I find tetrahedrons very simple, sturdy, easy to transport and to set up.

I guess I would need to see it hands-on, or see a very detailed construction video, to be convinced that a tensegrity structure can be either simpler, sturdier, easier to transport or easier to set up.

Looks cool though

torbjornludvigsen.com

|

Re: The "three wires suspended" hangprinter October 12, 2019 06:38PM |

Registered: 4 years ago Posts: 2 |

@tobben and @atmark thanks!

@tobben

In the babel tower example, have you considered an automated way of shifting the ABC anchors up?

In the "three wires suspended" design, does more weight on the extruder = more downward force = more stability = same effect as spring pole?

@atmark

I think I can see what is going on here, lots of wires though... do you have more photos?

@tobben

In the babel tower example, have you considered an automated way of shifting the ABC anchors up?

In the "three wires suspended" design, does more weight on the extruder = more downward force = more stability = same effect as spring pole?

@atmark

I think I can see what is going on here, lots of wires though... do you have more photos?

|

Re: The "three wires suspended" hangprinter October 13, 2019 05:16AM |

Moderator Registered: 10 years ago Posts: 401 |

Yes, you could build anchor units with motors that shift the anchor position on a given command.

For the Babel Tower print, this unit would have to be extremely slim, and mountable along the wall, since space was scarce, but it's sure possible.

More weight on the effector does not give the same effect as a spring pole.

Weight can only ever give accelerations limited by the gravitational constant, and vertically downwards.

A spring pole can give different accelerations in different directions, depending on the spring and the placement.

Mass also gives you a larger momemtum in XY-directions, which again limits your accelerations.

A spring pole does not add much momentum for movements in the XY-directions.

So if you add mass on the effector, you need more XY-directed (as well as Z-directed) force to accelerate and decelerate your effector.

If you add a spring pole, you only need more force in the opposite direction of the spring pole pushing force (probably close to Z-directed when you're close to the origin).

torbjornludvigsen.com

For the Babel Tower print, this unit would have to be extremely slim, and mountable along the wall, since space was scarce, but it's sure possible.

More weight on the effector does not give the same effect as a spring pole.

Weight can only ever give accelerations limited by the gravitational constant, and vertically downwards.

A spring pole can give different accelerations in different directions, depending on the spring and the placement.

Mass also gives you a larger momemtum in XY-directions, which again limits your accelerations.

A spring pole does not add much momentum for movements in the XY-directions.

So if you add mass on the effector, you need more XY-directed (as well as Z-directed) force to accelerate and decelerate your effector.

If you add a spring pole, you only need more force in the opposite direction of the spring pole pushing force (probably close to Z-directed when you're close to the origin).

torbjornludvigsen.com

Sorry, only registered users may post in this forum.