Hangprinter version 3

Posted by tobben

|

Re: Hangprinter version 3 May 30, 2018 01:39PM |

Registered: 5 years ago Posts: 79 |

|

Re: Hangprinter version 3 May 30, 2018 03:17PM |

Registered: 13 years ago Posts: 8 |

|

Re: Hangprinter version 3 May 30, 2018 03:48PM |

Registered: 5 years ago Posts: 79 |

|

Re: Hangprinter version 3 May 31, 2018 12:55PM |

Registered: 10 years ago Posts: 4 |

Hello everybody!

Special cheers to Torbjørn!!

I'm an old sculptor Yuris Lesnik, an eternal squatter I'm in Paris.

3d printing 4 years of experiments direction to transforming elastic forms printing with filaflex TPE as this robot

Well, I fell sick with the idea to hang a printer. Waiting for parcel from tropical-labs 4 steppers with Mechaduinos.

Time to print the spool gears!

which are highlighted last? if there is no difference, if I hang a large room size or build a pocket hung printer?

does this matter, to change the reduction for different heights Z ?

in general, all greetings!

I'll bother you with stupid questions.

I do not understand anything in electronics.

and besides a complete idiot in grammar.

Yuris.

Special cheers to Torbjørn!!

I'm an old sculptor Yuris Lesnik, an eternal squatter I'm in Paris.

3d printing 4 years of experiments direction to transforming elastic forms printing with filaflex TPE as this robot

Well, I fell sick with the idea to hang a printer. Waiting for parcel from tropical-labs 4 steppers with Mechaduinos.

Time to print the spool gears!

which are highlighted last? if there is no difference, if I hang a large room size or build a pocket hung printer?

does this matter, to change the reduction for different heights Z ?

in general, all greetings!

I'll bother you with stupid questions.

I do not understand anything in electronics.

and besides a complete idiot in grammar.

Yuris.

|

Re: Hangprinter version 3 May 31, 2018 03:15PM |

Registered: 10 years ago Posts: 401 |

Hello Yuris, and a big welcome to this forum thread and the Hangprinter community!

I'm not sure if I understand your question. There's no difference between the four spool gears. If you want to adjust the number of teeth on the spool gears, check out line 53 in parameters.scad:

[github.com]

Pictures and videos of your build are greatly appreciated!

No worries, just keep posting questions until we get your electronics working

torbjornludvigsen.com

I'm not sure if I understand your question. There's no difference between the four spool gears. If you want to adjust the number of teeth on the spool gears, check out line 53 in parameters.scad:

[github.com]

Pictures and videos of your build are greatly appreciated!

No worries, just keep posting questions until we get your electronics working

torbjornludvigsen.com

|

Re: Hangprinter version 3 June 01, 2018 06:32AM |

Registered: 5 years ago Posts: 79 |

Mechaduino questions:

Situation:

Arduino is flashed and Pronterface recognizes the printer.

All mechaduinos are wired and the firmware is flashed. Every motor has its I2C name and after a callibration routine the look up table has been replaced before mounting the motors.

Questions "callibration":

Do I have to callibrate each motor again after mounting the "motor brackets" to the "top plate"? Or maybe after assembling everything in the room with cables (strings/fire line) and anchors?

Questions "torque mode":

How to apply torque mode? Do I have to set torque mode via Arduino IDE (serial monitor) for each motor? Can I communicate to the Mechaduinos via Pronterface? There is a torque mode button on the HAW version of Pronterface. What is this button for?

Edited 1 time(s). Last edit at 06/01/2018 06:33AM by Dahah.

Situation:

Arduino is flashed and Pronterface recognizes the printer.

All mechaduinos are wired and the firmware is flashed. Every motor has its I2C name and after a callibration routine the look up table has been replaced before mounting the motors.

Questions "callibration":

Do I have to callibrate each motor again after mounting the "motor brackets" to the "top plate"? Or maybe after assembling everything in the room with cables (strings/fire line) and anchors?

Questions "torque mode":

How to apply torque mode? Do I have to set torque mode via Arduino IDE (serial monitor) for each motor? Can I communicate to the Mechaduinos via Pronterface? There is a torque mode button on the HAW version of Pronterface. What is this button for?

Edited 1 time(s). Last edit at 06/01/2018 06:33AM by Dahah.

|

Re: Hangprinter version 3 June 01, 2018 06:52AM |

Registered: 10 years ago Posts: 401 |

Hi!

Yes, you have to do a calibration after mounting your anchors in the room. The Marlin firmware needs to know the xyz-position of each anchor. See here for some instructions on how to do this anchor localization calibration: [github.com]

Before testing out torque mode check that all motors turn in the right direction:

G6 A10 ; Should let out 10 mm of line on the A spool

G6 A-10 ; Should wind in 10 mm of line on the A spool

G6 B10 ; Should let out 10 mm of line on the B spool

G6 B-10 ; Should wind in 10 mm of line on the B spool

G6 C10 ; Should let out 10 mm of line on the C spool

G6 C-10 ; Should wind in 10 mm of line on the C spool

G6 D10 ; Should let out 10 mm of line on the D spool

G6 D-10 ; Should wind in 10 mm of line on the D spool

If one or more motors turn the wrong way then change the true/false values on these four lines and reflash Marlin until all motors move in the correct directions:

[github.com]

You control torque mode with the G95 command. For example:

G95 A10 ; Sets the A-motor in torque mode applying 10 units of torque.

G95 B15 C15 D20 ; Sets B, C, and D-motors in torque mode.

G95 A0 B0 C0 D0 ; Sets ABCD motors back into position mode

The maximum amount of torque is 255, but i don't recommend ever going above 40.

If you keep the mouse above the buttons in HAW-Pronterface, a little textbox will show up that tells you what exact gcode the button will send if pressed.

G95 are sent from Marlin to the Mechaduinos via the i2c wires. More on what the i2c bus is used for here:

[github.com]

Best regards

Edited 1 time(s). Last edit at 06/01/2018 06:53AM by tobben.

torbjornludvigsen.com

Yes, you have to do a calibration after mounting your anchors in the room. The Marlin firmware needs to know the xyz-position of each anchor. See here for some instructions on how to do this anchor localization calibration: [github.com]

Before testing out torque mode check that all motors turn in the right direction:

G6 A10 ; Should let out 10 mm of line on the A spool

G6 A-10 ; Should wind in 10 mm of line on the A spool

G6 B10 ; Should let out 10 mm of line on the B spool

G6 B-10 ; Should wind in 10 mm of line on the B spool

G6 C10 ; Should let out 10 mm of line on the C spool

G6 C-10 ; Should wind in 10 mm of line on the C spool

G6 D10 ; Should let out 10 mm of line on the D spool

G6 D-10 ; Should wind in 10 mm of line on the D spool

If one or more motors turn the wrong way then change the true/false values on these four lines and reflash Marlin until all motors move in the correct directions:

[github.com]

You control torque mode with the G95 command. For example:

G95 A10 ; Sets the A-motor in torque mode applying 10 units of torque.

G95 B15 C15 D20 ; Sets B, C, and D-motors in torque mode.

G95 A0 B0 C0 D0 ; Sets ABCD motors back into position mode

The maximum amount of torque is 255, but i don't recommend ever going above 40.

If you keep the mouse above the buttons in HAW-Pronterface, a little textbox will show up that tells you what exact gcode the button will send if pressed.

G95 are sent from Marlin to the Mechaduinos via the i2c wires. More on what the i2c bus is used for here:

[github.com]

Best regards

Edited 1 time(s). Last edit at 06/01/2018 06:53AM by tobben.

torbjornludvigsen.com

|

Re: Hangprinter version 3 June 01, 2018 07:37AM |

Registered: 5 years ago Posts: 79 |

|

Re: Hangprinter version 3 June 01, 2018 02:19PM |

Registered: 5 years ago Posts: 79 |

Ok, I realized I am some steps before callibrating and torque mode. This project makes me so enthusiastic. I wish it will run soon!

Back to reality:

Pronterface recognizes the printer and I can connect. But if I put in the 12V power the motors start to vibrate. Sometimes its just one motor, sometimes all four and all four have been quiet once. I did not touch anything between switching 12 V on and off. I am prettty shure I wired it correctly. What could be the problem?

Before I could control the motors firmware via Arduino IDE (Serial Monitor). Mechaduinos callibration mode worked as well, but with a different power wiring. I checked everything twice on the actual wiring. It is like it should and there are no shorts. Changing the power supply did not solve the problem, too. First I used a LED power supply, then I used an ATX power supply. What could be the error?

Edited 4 time(s). Last edit at 06/01/2018 03:32PM by Dahah.

Back to reality:

Pronterface recognizes the printer and I can connect. But if I put in the 12V power the motors start to vibrate. Sometimes its just one motor, sometimes all four and all four have been quiet once. I did not touch anything between switching 12 V on and off. I am prettty shure I wired it correctly. What could be the problem?

Before I could control the motors firmware via Arduino IDE (Serial Monitor). Mechaduinos callibration mode worked as well, but with a different power wiring. I checked everything twice on the actual wiring. It is like it should and there are no shorts. Changing the power supply did not solve the problem, too. First I used a LED power supply, then I used an ATX power supply. What could be the error?

Edited 4 time(s). Last edit at 06/01/2018 03:32PM by Dahah.

|

Re: Hangprinter version 3 June 02, 2018 08:10AM |

Registered: 8 years ago Posts: 96 |

Hi folks

I'm an industrial design student and fablab assistant at the Metropolia University of Applied Sciences in Helsinki. Currently I'm building the Hangprinter so we can quickly fabricate life size objects in our lab. I'm still waiting for couple of vitamins to arrive, but in the meantime I've already began to assemble the ceiling unit. You can have a look here [photos.app.goo.gl]

I haven't made a decision about the control board yet. The Duet will be a definite way to go in future, but I'm not sure about it yet. Have you used it already? RAMPS will be most likely the best supported way. I have also a Makerbase Gen-L v1 laying around here, I might give it a try...

Having thought about the anchor lines, and their invisibility in special, I had this idea of attaching laser line modules parallel to the anchor lines, so that they light up them and the floor beneath. Like marking an area of danger and because... you got to have lasers

Atte

I'm an industrial design student and fablab assistant at the Metropolia University of Applied Sciences in Helsinki. Currently I'm building the Hangprinter so we can quickly fabricate life size objects in our lab. I'm still waiting for couple of vitamins to arrive, but in the meantime I've already began to assemble the ceiling unit. You can have a look here [photos.app.goo.gl]

I haven't made a decision about the control board yet. The Duet will be a definite way to go in future, but I'm not sure about it yet. Have you used it already? RAMPS will be most likely the best supported way. I have also a Makerbase Gen-L v1 laying around here, I might give it a try...

Having thought about the anchor lines, and their invisibility in special, I had this idea of attaching laser line modules parallel to the anchor lines, so that they light up them and the floor beneath. Like marking an area of danger and because... you got to have lasers

Atte

|

Re: Hangprinter version 3 June 02, 2018 09:36AM |

Registered: 5 years ago Posts: 79 |

In the end the wooden frame wont be used for now. After understanding more about the cables (fire line) and the geometry of the printer I decided to hang it to the sealing as soon as the electronics/software run. It will be more practical on the sealing if the printer is not in use. Of course I am planning to use it intense but my space is kind of limited......

Edited 3 time(s). Last edit at 06/02/2018 11:59AM by Dahah.

Edited 3 time(s). Last edit at 06/02/2018 11:59AM by Dahah.

|

Re: Hangprinter version 3 June 02, 2018 11:23AM |

Registered: 10 years ago Posts: 401 |

@Dahah

Your motors are likely vibrating because the PID-values (pKp, pKi, pKd) are set too aggressive for your motor. Try setting pKd to zero and lower your pKp until you get rid of the vibration, then increase pKd again. Some buzzing when unloaded isn't critical for performance, its just a bit annoying when the printer is idle...

@atmark

Nice pics =D

I happened to put the spools upside down on the spool cores when I shot photos for the assembly manual. (sry for that). I see that you've done that too.

Looking forward to seeing more of your build as it progresses!

torbjornludvigsen.com

Your motors are likely vibrating because the PID-values (pKp, pKi, pKd) are set too aggressive for your motor. Try setting pKd to zero and lower your pKp until you get rid of the vibration, then increase pKd again. Some buzzing when unloaded isn't critical for performance, its just a bit annoying when the printer is idle...

@atmark

Nice pics =D

I happened to put the spools upside down on the spool cores when I shot photos for the assembly manual. (sry for that). I see that you've done that too.

Looking forward to seeing more of your build as it progresses!

torbjornludvigsen.com

|

Re: Hangprinter version 3 June 02, 2018 01:22PM |

Registered: 5 years ago Posts: 79 |

|

Re: Hangprinter version 3 June 02, 2018 05:47PM |

Registered: 10 years ago Posts: 401 |

You can use the same PID values for A, B, C, and D. Need is a strong word. You probably don't have to tune your PID values at all unless you're annoyed by the buzzing

torbjornludvigsen.com

torbjornludvigsen.com

|

Re: Hangprinter version 3 June 03, 2018 01:16AM |

Registered: 8 years ago Posts: 96 |

@tobben

Thanks. Next week new pics. Got yesterday the carbon fibre beams

I might have missed it while reading through the thread, but what was your reason to switch from screw fastening to zip ties for holding the mover together? Secondly, have you thought about having moving anchor points, which would be fixed on linear rails. In a manner that would allow to drive them up and down along the d-axis and therefore allow a bigger build height for rectangular objects?

Edited 1 time(s). Last edit at 06/03/2018 01:16AM by atmark.

Thanks. Next week new pics. Got yesterday the carbon fibre beams

I might have missed it while reading through the thread, but what was your reason to switch from screw fastening to zip ties for holding the mover together? Secondly, have you thought about having moving anchor points, which would be fixed on linear rails. In a manner that would allow to drive them up and down along the d-axis and therefore allow a bigger build height for rectangular objects?

Edited 1 time(s). Last edit at 06/03/2018 01:16AM by atmark.

|

Re: Hangprinter version 3 June 03, 2018 03:34AM |

Registered: 5 years ago Posts: 79 |

@ atmark I thought abot the same. That would be a great feature! But it does not fully support the design principles of the actual design, because you will need electronics on the ground and a connection to the mainboard (RAMPS/Arduino) for those vertical anchor axis. Maybe as an add on for people who dont mind having electronics on the anchors? I guess one could build it at low cost using fire line to transport the vertikal mover. Like in some Delta RepRap (Kossel/Rostock) designs.

I could contribute in mechanical design and prototyping if we can find a group of people who wants to work on vertical moving anchor points!

How complicate would it be to implement vertical moving anchors in the Marlin firmware? I guess one wouldn't need three stepper drivers or Mechaduinos (Maybe its better to move the anchor axis with cheap stepper drivers?) One stepper driver to drive all three motors could be enough. So this could run on RAMPS without changing the electronics (exept one more stepper driver and endstops).

A good group would be:

a) mechanical design

b) electronics design

c) firmware integration

d) prototyping and testing

My hangprinter doesnt run right now so I have to work on that first. But I would love to participate in the development of vertical moving anchors. I hope I can get my machine run, soon........

Edited 5 time(s). Last edit at 06/03/2018 05:42AM by Dahah.

I could contribute in mechanical design and prototyping if we can find a group of people who wants to work on vertical moving anchor points!

How complicate would it be to implement vertical moving anchors in the Marlin firmware? I guess one wouldn't need three stepper drivers or Mechaduinos (Maybe its better to move the anchor axis with cheap stepper drivers?) One stepper driver to drive all three motors could be enough. So this could run on RAMPS without changing the electronics (exept one more stepper driver and endstops).

A good group would be:

a) mechanical design

b) electronics design

c) firmware integration

d) prototyping and testing

My hangprinter doesnt run right now so I have to work on that first. But I would love to participate in the development of vertical moving anchors. I hope I can get my machine run, soon........

Edited 5 time(s). Last edit at 06/03/2018 05:42AM by Dahah.

|

Re: Hangprinter version 3 June 03, 2018 05:15AM |

Registered: 5 years ago Posts: 79 |

There's a need to change the vibration. It is very strong and everything on the platform vibrates heavily. I am afraid it will loosen the screws over time. And it is very annoying.....

I set the PID like you adviced. But even with pKd=0 and pKp=0.1 the motor vibrates. No change during the step down tuning of the pKp value.

What could be the problem?

Edited 3 time(s). Last edit at 06/03/2018 08:05AM by Dahah.

I set the PID like you adviced. But even with pKd=0 and pKp=0.1 the motor vibrates. No change during the step down tuning of the pKp value.

What could be the problem?

Edited 3 time(s). Last edit at 06/03/2018 08:05AM by Dahah.

|

Re: Hangprinter version 3 June 04, 2018 02:24AM |

Registered: 5 years ago Posts: 79 |

I tried some things to find the error. I changed the 12V/5V level shifter. The motors still vibrate.

If I disconnect the 5V VIN on the Mechaduino with the 12V connected the vibration stops. I tested another wire for 5V Vin connection. The motors still vibrate.

So it seems the vibration comes from the Mechaduino board. What could be the problem?

If I disconnect the 5V VIN on the Mechaduino with the 12V connected the vibration stops. I tested another wire for 5V Vin connection. The motors still vibrate.

So it seems the vibration comes from the Mechaduino board. What could be the problem?

|

Re: Hangprinter version 3 June 05, 2018 02:18AM |

Registered: 8 years ago Posts: 96 |

@dahah

We should keep this in mind. I will also build the printer first and then come back to this upgrade.

I've already talked to our lab staff about this option and about the place the printer will be set up at. It will be a prime spot Where also the public can observe it in action. So @tobben, I think you'll get some headlines later on this year.

Where also the public can observe it in action. So @tobben, I think you'll get some headlines later on this year.

We should keep this in mind. I will also build the printer first and then come back to this upgrade.

I've already talked to our lab staff about this option and about the place the printer will be set up at. It will be a prime spot

Where also the public can observe it in action. So @tobben, I think you'll get some headlines later on this year.

Where also the public can observe it in action. So @tobben, I think you'll get some headlines later on this year.

|

Re: Hangprinter version 3 June 05, 2018 07:59AM |

Registered: 10 years ago Posts: 4 |

tobben questions.

I wanted to understand if there is any changes, or improvements for spool gears, if you plan to change the gear ratio.

if my dream to hang a heavy extruder, Perhaps I need to change the torque for D

all this comes from the thought that it will be very expensive to print with PLA,

We need a cheap material for large prints.

concrete pottery gyps.

can we hang in the center 10kg? would be better 15kg.?

what will happen?

I wanted to understand if there is any changes, or improvements for spool gears, if you plan to change the gear ratio.

if my dream to hang a heavy extruder, Perhaps I need to change the torque for D

all this comes from the thought that it will be very expensive to print with PLA,

We need a cheap material for large prints.

concrete pottery gyps.

can we hang in the center 10kg? would be better 15kg.?

what will happen?

|

Re: Hangprinter version 3 June 05, 2018 09:05AM |

Registered: 10 years ago Posts: 4 |

>>>There's a need to change the vibration. It is very strong and everything on the platform vibrates heavily. I am afraid it will loosen the screws over time. And it is very annoying..... winking smiley

<<<<< a video would be nice to watch, with all the musical vibrations.

you're scaring me. I can not refuse, I'm waiting for steppers.

<<<<< a video would be nice to watch, with all the musical vibrations.

you're scaring me. I can not refuse, I'm waiting for steppers.

|

Re: Hangprinter version 3 June 05, 2018 12:22PM |

Registered: 5 years ago Posts: 79 |

|

Re: Hangprinter version 3 June 07, 2018 07:45AM |

Registered: 5 years ago Posts: 79 |

Anyway, I made a video with one motor plugged and vibration. Maybe the sound tells the problem.

[www.youtube.com]

If I start a print from pronterface with all motors plugged it works, but the vibration is still there and with four motors the resonance is stronger. One knows that frequency from other machines. Where does that frequency come from?

I am reading now into PID Tuning.[home.hit.no]

Does anyone has an idea what could be the problem. Is it maybe the frequency in the position PID values? It is set to 30 hertz.

Is it maybe no PID value at all?

[www.youtube.com]

If I start a print from pronterface with all motors plugged it works, but the vibration is still there and with four motors the resonance is stronger. One knows that frequency from other machines. Where does that frequency come from?

I am reading now into PID Tuning.[home.hit.no]

Does anyone has an idea what could be the problem. Is it maybe the frequency in the position PID values? It is set to 30 hertz.

Is it maybe no PID value at all?

|

Re: Hangprinter version 3 June 09, 2018 02:22AM |

Registered: 5 years ago Posts: 79 |

So finally I solved the problem. It was something between stupid faults and maybe a lot of different Arduino IDEs on different systems and maybe some magic

*** No PID or other difficulities. It was my fault and I do not know exactly what it was. I just repeated a lot of steps very concentrated and in the end it worked.

My printer is up the sealing and I try to figure out how to callibrate Marlin for line build up and geometry data.

I understand the auto callibration in general/basic. Does the Python script for simulation run on HAW without installing additional software? If so, how can I open the simulation in HAW?

Do I have to collect specific points when I repeat the routine , for example the anchor?

*from git hub

"Data collection depends on Mechaduinos and well calibrated line buildup compensation. As of Jan 31, 2018, this is the procedure:

- Go into torque mode on all motors: G95 A35 B35 C35 D35. Adjust torque magnitude as you prefer.

- Drag mover to the origin and zero counters: G92 X0 Y0 Z0

- Mark reference point for all encoders: G96 A B C D (Stock Marlin accepts G96 as a short hand for G96 A B C D)

- Repeat 13 - ca 20 times:

- Drag mover to position of data point collection. //specific points or random but different points?

- Collect data point: M114 S1 (Old firmwares, before Feb 6, 2018 used: G97 A B C D)

Edited 6 time(s). Last edit at 06/10/2018 07:41PM by Dahah.

*** No PID or other difficulities. It was my fault and I do not know exactly what it was. I just repeated a lot of steps very concentrated and in the end it worked.

My printer is up the sealing and I try to figure out how to callibrate Marlin for line build up and geometry data.

I understand the auto callibration in general/basic. Does the Python script for simulation run on HAW without installing additional software? If so, how can I open the simulation in HAW?

Do I have to collect specific points when I repeat the routine , for example the anchor?

*from git hub

"Data collection depends on Mechaduinos and well calibrated line buildup compensation. As of Jan 31, 2018, this is the procedure:

- Go into torque mode on all motors: G95 A35 B35 C35 D35. Adjust torque magnitude as you prefer.

- Drag mover to the origin and zero counters: G92 X0 Y0 Z0

- Mark reference point for all encoders: G96 A B C D (Stock Marlin accepts G96 as a short hand for G96 A B C D)

- Repeat 13 - ca 20 times:

- Drag mover to position of data point collection. //specific points or random but different points?

- Collect data point: M114 S1 (Old firmwares, before Feb 6, 2018 used: G97 A B C D)

Edited 6 time(s). Last edit at 06/10/2018 07:41PM by Dahah.

|

Re: Hangprinter version 3 June 10, 2018 06:21PM |

Registered: 5 years ago Posts: 79 |

|

Re: Hangprinter version 3 June 11, 2018 11:41AM |

Registered: 5 years ago Posts: 79 |

Torque mode was save  But one motor doesnt switch to torque mode but works well in position mode. I have to flash the mechaduino again I guess. That will be a difficult task under the sealing. Z-hight is about 4.2 m.

But one motor doesnt switch to torque mode but works well in position mode. I have to flash the mechaduino again I guess. That will be a difficult task under the sealing. Z-hight is about 4.2 m.

Here's how Win10 (should work for Mac and Linux as well ) users, who like GUIs can use the python simulation for auto calibration:

) users, who like GUIs can use the python simulation for auto calibration:

Download and install Anaconda for Python 2.7 : [www.anaconda.com]

Open Anaconda Navigator

Launch the Spider option

Open the .py file in Spider (-> file -> open)

Fill in your data points.

Press the green play button (green triangle)

A pop up screen appears. Just leave everything as it is and click ok.

In the lower right corner of the spyder app you will find your calibration values in the console window

Edited 3 time(s). Last edit at 06/11/2018 11:46AM by Dahah.

But one motor doesnt switch to torque mode but works well in position mode. I have to flash the mechaduino again I guess. That will be a difficult task under the sealing. Z-hight is about 4.2 m.

But one motor doesnt switch to torque mode but works well in position mode. I have to flash the mechaduino again I guess. That will be a difficult task under the sealing. Z-hight is about 4.2 m. Here's how Win10 (should work for Mac and Linux as well

) users, who like GUIs can use the python simulation for auto calibration:

) users, who like GUIs can use the python simulation for auto calibration:Download and install Anaconda for Python 2.7 : [www.anaconda.com]

Open Anaconda Navigator

Launch the Spider option

Open the .py file in Spider (-> file -> open)

Fill in your data points.

Press the green play button (green triangle)

A pop up screen appears. Just leave everything as it is and click ok.

In the lower right corner of the spyder app you will find your calibration values in the console window

Edited 3 time(s). Last edit at 06/11/2018 11:46AM by Dahah.

|

Re: Hangprinter version 3 June 12, 2018 06:58PM |

Registered: 5 years ago Posts: 79 |

Ok, I found the answer to the data points question in this video at 04:05 [www.youtube.com]

random but different exept the middle point/zero

random but different exept the middle point/zero

|

Re: Hangprinter version 3 June 13, 2018 02:54AM |

Registered: 8 years ago Posts: 5,232 |

I must admit, I haven't spend much time following this thread. But now you have your own category, I have to ask:

In the early pages, I saw a pic with huge herringbone gears mounted on a wooden plate. ( aka. noisy )

Has this changed over time? Has someone made it quieter with belts& pulleys?

Edited 1 time(s). Last edit at 06/13/2018 02:54AM by o_lampe.

In the early pages, I saw a pic with huge herringbone gears mounted on a wooden plate. ( aka. noisy )

Has this changed over time? Has someone made it quieter with belts& pulleys?

Edited 1 time(s). Last edit at 06/13/2018 02:54AM by o_lampe.

|

Re: Hangprinter version 3 June 13, 2018 03:13PM |

Moderator Registered: 10 years ago Posts: 401 |

Hi all!

@Dahah

Sounds like you might have flashed the wrong calibration tables on some of your Mechaduinos or something? Good that the noise went away anyways

The Mechaduino that doesn't enter torque mode probably doesn't get the signal sent via the i2c bus. I suspect a loose cable.

Yes, you can run the calibration script in HAWs. My full Hangprinter dev tool chain is there, configured and installed.

And on collect data points: Send G96 when nozzle is at the origin, then collect data at random positions. Too tight collection points, or a too regular pattern could make the optimization algorithm fail.

@o_lampe

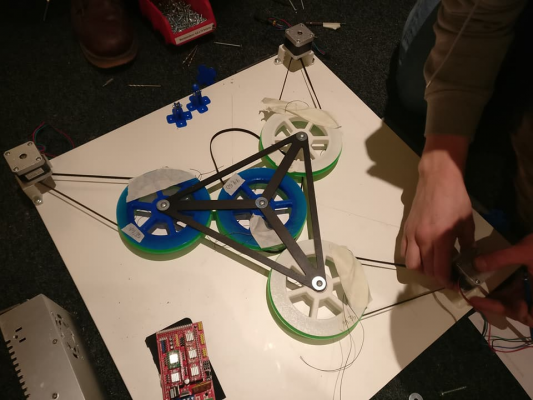

Yes, it's noisy. Well aligned gears and a bit of grease solves gets rid of the worst, but still. The gears have been made narrower, but are still quite wide. Yes, an experimental one with belts was assembled in February.

Design and image by Alexander Osika. I can't link to the discussion here, since the fb word has been banned from use.

Edited 1 time(s). Last edit at 06/13/2018 03:18PM by tobben.

torbjornludvigsen.com

@Dahah

Sounds like you might have flashed the wrong calibration tables on some of your Mechaduinos or something? Good that the noise went away anyways

The Mechaduino that doesn't enter torque mode probably doesn't get the signal sent via the i2c bus. I suspect a loose cable.

Yes, you can run the calibration script in HAWs. My full Hangprinter dev tool chain is there, configured and installed.

And on collect data points: Send G96 when nozzle is at the origin, then collect data at random positions. Too tight collection points, or a too regular pattern could make the optimization algorithm fail.

@o_lampe

Yes, it's noisy. Well aligned gears and a bit of grease solves gets rid of the worst, but still. The gears have been made narrower, but are still quite wide. Yes, an experimental one with belts was assembled in February.

Design and image by Alexander Osika. I can't link to the discussion here, since the fb word has been banned from use.

Edited 1 time(s). Last edit at 06/13/2018 03:18PM by tobben.

torbjornludvigsen.com

|

Re: Hangprinter version 3 June 14, 2018 12:06AM |

Registered: 8 years ago Posts: 5,232 |

Sorry, only registered users may post in this forum.