Hangprinter version 3

Posted by tobben

|

Re: Hangprinter version 3 February 09, 2019 10:27AM |

Registered: 5 years ago Posts: 8 |

Hi guys just wanted to post a quick troubleshooting guide. Since most issues with the hangprinter are the same.

- Heating issues / Overextrusion

1) Calibrate extruder steps.

2) Check wire connections on the extruder end.

- If you're seeing temperature fluctuations:

1) Use thicker wires or double the number of wires connecting to extruder heater

- Bad connections

1) Create a strain relief on the wires on the extruder end ( Hint: Zip ties )

- Motors not working

1) Check connectors. And do a G6 command to test individual motors.

2) Try older version of marlin. Even try the old github hangprinter marlin fork.

- Bad prints, slack, tight lines, vibrations, gross errors in position.

1) Bad calibration. Try to achieve a less than 1mm error in your measurements.

2) Don't use nylon wires. Use the dyneema ones, they're made of ultrahigh-density polyethylene ( balistic fiber ).

3) Slower print speeds

4) Build wooden frame.

5) Use 32 bit board or try klipper with old 8 bit boards ( But at moment there's no kinematic support for the hangprinter)

6) Get creative. Ultrasonic ranger finder to measure distances. 1-2mm steel wire. 3d print a wire tensioner or even use a arduino to measure wire tension.

On a side note. The hangprinter deals better with organic shapes or prints that don't need a great deal of accuracy. Here's a little encouragement video from Saurabh Sogi: [www.youtube.com]

Edited 3 time(s). Last edit at 02/10/2019 03:09PM by LordThingol.

- Heating issues / Overextrusion

1) Calibrate extruder steps.

2) Check wire connections on the extruder end.

- If you're seeing temperature fluctuations:

1) Use thicker wires or double the number of wires connecting to extruder heater

- Bad connections

1) Create a strain relief on the wires on the extruder end ( Hint: Zip ties )

- Motors not working

1) Check connectors. And do a G6 command to test individual motors.

2) Try older version of marlin. Even try the old github hangprinter marlin fork.

- Bad prints, slack, tight lines, vibrations, gross errors in position.

1) Bad calibration. Try to achieve a less than 1mm error in your measurements.

2) Don't use nylon wires. Use the dyneema ones, they're made of ultrahigh-density polyethylene ( balistic fiber ).

3) Slower print speeds

4) Build wooden frame.

5) Use 32 bit board or try klipper with old 8 bit boards ( But at moment there's no kinematic support for the hangprinter)

6) Get creative. Ultrasonic ranger finder to measure distances. 1-2mm steel wire. 3d print a wire tensioner or even use a arduino to measure wire tension.

On a side note. The hangprinter deals better with organic shapes or prints that don't need a great deal of accuracy. Here's a little encouragement video from Saurabh Sogi: [www.youtube.com]

Edited 3 time(s). Last edit at 02/10/2019 03:09PM by LordThingol.

|

Re: Hangprinter version 3 February 16, 2019 08:33AM |

Registered: 5 years ago Posts: 3 |

|

Re: Hangprinter version 3 February 16, 2019 09:16AM |

Moderator Registered: 10 years ago Posts: 401 |

@LordThingol

There's a lot of hours of HP wisdom in that post. Greatly appreciated!

@jaxshah

Awesome work!

torbjornludvigsen.com

There's a lot of hours of HP wisdom in that post. Greatly appreciated!

@jaxshah

Awesome work!

torbjornludvigsen.com

|

Re: Hangprinter version 3 February 21, 2019 11:41PM |

Registered: 5 years ago Posts: 3 |

|

Re: Hangprinter version 3 March 25, 2019 05:20PM |

Registered: 9 years ago Posts: 4 |

|

Re: Hangprinter version 3 March 29, 2019 04:50PM |

Moderator Registered: 10 years ago Posts: 401 |

Not that I know of. I think Trampas might be working on including HP support upstream, but you have to ask him to get the exact status.

torbjornludvigsen.com

torbjornludvigsen.com

|

Re: Hangprinter version 3 April 13, 2019 10:13AM |

Registered: 6 years ago Posts: 15 |

Howdy everyone.

I'm revisiting this project after a long hiatus and moving locations.

Upon setting up the hangprinter again, i'm running into the same issue as I was before where when making Z-axis moves (G1 Zxx), the A, B, and C spools do not move proportionally to keep up with the D spool.

I have checked my stepper drivers and the jumpers were all identical on the bench, and the all appear to be set to 1/16 stepping. (DRV8825).

Does anyone have any suggestions for what to troubleshoot next? I'm so close to the finish line.

Calibration values below:

ANCHOR_A_Y -1345

ANCHOR_A_Z -116

ANCHOR_B_X 1165

ANCHOR_B_Y 632

ANCHOR_B_Z -116

ANCHOR_C_X -760

ANCHOR_C_Y 1105

ANCHOR_C_Z -116

ANCHOR_D_Z 2064

EDIT: It appears that my DRV8825s are still stuck in 1/32 stepping even after changing the jumpers around.

Edited 1 time(s). Last edit at 04/14/2019 11:42AM by Alandaeta.

I'm revisiting this project after a long hiatus and moving locations.

Upon setting up the hangprinter again, i'm running into the same issue as I was before where when making Z-axis moves (G1 Zxx), the A, B, and C spools do not move proportionally to keep up with the D spool.

I have checked my stepper drivers and the jumpers were all identical on the bench, and the all appear to be set to 1/16 stepping. (DRV8825).

Does anyone have any suggestions for what to troubleshoot next? I'm so close to the finish line.

Calibration values below:

ANCHOR_A_Y -1345

ANCHOR_A_Z -116

ANCHOR_B_X 1165

ANCHOR_B_Y 632

ANCHOR_B_Z -116

ANCHOR_C_X -760

ANCHOR_C_Y 1105

ANCHOR_C_Z -116

ANCHOR_D_Z 2064

EDIT: It appears that my DRV8825s are still stuck in 1/32 stepping even after changing the jumpers around.

Edited 1 time(s). Last edit at 04/14/2019 11:42AM by Alandaeta.

|

Re: Hangprinter version 3 April 21, 2019 09:07PM |

Registered: 6 years ago Posts: 15 |

After some more digging. I replaced my DRV8825 drivers with A4988s, which have a maximum of 1/16 stepping, and put the jumpers back in place.

Similar behavior after updating the firmware and everything, so I suspect maybe I have some funky values somewhere in the firmware where they shouldn't be.

Next troubleshooting will be to re-calibrate and then start from scratch with the firmware.

Thanks for coming to my TED talk.

Similar behavior after updating the firmware and everything, so I suspect maybe I have some funky values somewhere in the firmware where they shouldn't be.

Next troubleshooting will be to re-calibrate and then start from scratch with the firmware.

Thanks for coming to my TED talk.

|

Re: Hangprinter version 3 April 28, 2019 08:34PM |

Registered: 7 years ago Posts: 558 |

One thing you might want to check, underneath the jumpers some of the Chinese ramps boards have a small trace connecting the pins without the jumper. I’ve seen it on two of my ramps boards from two different sources. You can’t see it unless you pry off that black plastic that’s usually underneath the jumper. Since you said your other drivers were stuck in in 1/32 mode it might explain some strange behavior.

|

Re: Hangprinter version 3 May 02, 2019 10:53AM |

Registered: 9 years ago Posts: 4 |

I'm having problems getting my printer to react properly to G95 and G96 commands through Pronterface. I'm using smart steppers running the SmartStepper Subtree from the hangprinter repository. Everytime I issue a G95 or G96 command the printer will drop its connection with pronterface and reboot. I'm using the SCL and SDA lines from the LCD screen header through a level shifter to the ramps board. Connections were checked and rechecked. Printer reacts to G6 and G1 commands fine. Not sure what to check next, anyone have any ideas?

|

Re: Hangprinter version 3 May 02, 2019 01:59PM |

Moderator Registered: 10 years ago Posts: 401 |

Hm. Then it sounds like those pins were not initialized properly by the firmware.

Do you have MECHADUINO_I2C_COMMANDS defined in your Configuration.h?

torbjornludvigsen.com

Do you have MECHADUINO_I2C_COMMANDS defined in your Configuration.h?

torbjornludvigsen.com

|

Re: Hangprinter version 3 May 02, 2019 06:04PM |

Registered: 9 years ago Posts: 4 |

|

Re: Hangprinter version 3 May 03, 2019 07:05AM |

Registered: 9 years ago Posts: 4 |

|

Re: Hangprinter version 3 May 04, 2019 11:53AM |

Moderator Registered: 10 years ago Posts: 401 |

Yes, definitely use gitlab Openscad_Version_3 versions of the firmwares. Otherwise you'll bump into problems I don't recognize and can't fix.

torbjornludvigsen.com

torbjornludvigsen.com

|

Re: Hangprinter version 3 May 12, 2019 08:24PM |

Registered: 6 years ago Posts: 15 |

Howdy all.

Starting to narrow down my issues hopefully.

Re-calibrated again, sanity check says +-3mm this time, so i'm feeling pretty good about it.

Drivers are all now confirmed to be in 1/16, no issues there.

The behavior i'm seeing is this:

Move -Y = lose tension

Move +Y = gain tension

Move -X = lose tension

Move +X = gain tension

Move +Z = lose tension

Move -Z = gain tension

Might be a rookie question, but is there a proper steps/mm setting in the firmware that needs to be adjusted?

Starting to narrow down my issues hopefully.

Re-calibrated again, sanity check says +-3mm this time, so i'm feeling pretty good about it.

Drivers are all now confirmed to be in 1/16, no issues there.

The behavior i'm seeing is this:

Move -Y = lose tension

Move +Y = gain tension

Move -X = lose tension

Move +X = gain tension

Move +Z = lose tension

Move -Z = gain tension

Might be a rookie question, but is there a proper steps/mm setting in the firmware that needs to be adjusted?

|

Re: Hangprinter version 3 May 13, 2019 09:42AM |

Moderator Registered: 10 years ago Posts: 401 |

Hi, steps/mm settings are not used by the Hangprinter.

The behavior you describe sounds like something is up with the anchor position calibration values. Are you measuring manually? If yes, then the most common mistake is to not measure between the right pivot points.

Are you measuring from the point where the line enters the effector, to the point where the line hits the anchor?

torbjornludvigsen.com

The behavior you describe sounds like something is up with the anchor position calibration values. Are you measuring manually? If yes, then the most common mistake is to not measure between the right pivot points.

Are you measuring from the point where the line enters the effector, to the point where the line hits the anchor?

torbjornludvigsen.com

|

Re: Hangprinter version 3 May 13, 2019 10:33AM |

Registered: 6 years ago Posts: 15 |

Thanks for the quick reply!

I was measuring manually, values reported in mm in the firmware.

I followed the attached diagram for where my measurement points were.

All measurements were taken at the same Z-height.

The sanity check came back within +-3mm.

Edited 1 time(s). Last edit at 05/13/2019 10:33AM by Alandaeta.

I was measuring manually, values reported in mm in the firmware.

I followed the attached diagram for where my measurement points were.

All measurements were taken at the same Z-height.

The sanity check came back within +-3mm.

Edited 1 time(s). Last edit at 05/13/2019 10:33AM by Alandaeta.

|

Re: Hangprinter version 3 May 13, 2019 10:39AM |

Moderator Registered: 10 years ago Posts: 401 |

Great!

Was the nozzle was at the origin when the measurements were taken?

Have you also measured the Z-values (not depicted in the diagram)?

torbjornludvigsen.com

Was the nozzle was at the origin when the measurements were taken?

Have you also measured the Z-values (not depicted in the diagram)?

torbjornludvigsen.com

|

Re: Hangprinter version 3 May 13, 2019 12:21PM |

Registered: 6 years ago Posts: 15 |

Yes!

The nozzle was at the origin. (Everything appeared to be parallel and centered)

I measured my AZ BZ and CZ values from the print surface to the top of the mover.

My DZ was measured from the top of one of the D-line idlers to the top of the mover.

It's got to be something easy i'm missing.

The nozzle was at the origin. (Everything appeared to be parallel and centered)

I measured my AZ BZ and CZ values from the print surface to the top of the mover.

My DZ was measured from the top of one of the D-line idlers to the top of the mover.

It's got to be something easy i'm missing.

|

Re: Hangprinter version 3 May 13, 2019 02:23PM |

Moderator Registered: 10 years ago Posts: 401 |

Nice. Only error is that Az, Bz, and Cz should be measured from where line enters mover to where line enters anchor.

Not sure if that error is enough to explain the behavior you're observing, but at least fixing it is a good start

Edited 1 time(s). Last edit at 05/13/2019 02:26PM by tobben.

torbjornludvigsen.com

Not sure if that error is enough to explain the behavior you're observing, but at least fixing it is a good start

Edited 1 time(s). Last edit at 05/13/2019 02:26PM by tobben.

torbjornludvigsen.com

|

Re: Hangprinter version 3 May 15, 2019 12:55PM |

Registered: 8 years ago Posts: 96 |

Hey

Just the other day I upgraded my Hangprinter with a new mover that includes corner clamps with mechanical advance. Also I switched the anchor points. In the configuration.h I changed the mechanical advance setting from 1, 1, 1, 1 to 2, 2, 2, 2? Is this correct.

I needed to change also the lines since the old ones weren't long enough. The A, B and C lines measure now 14m the D-line 6m. Those values went into the config file. Now I have few question...

1. The A, B and C-line rotational adjustment is quite obviously handled by pulling the line between the anchors either to the left or the right. But how about the D-line adjustment? I haven't seen any solutions for that? Is there one?

2. I have strange issues with the autocalibration script. When trying the standard method I don't get any results. The other method outputs some data, but the estimations are off by several meters!? I was using 21 datapoints collected at random positions at random levels. There must be something wrong I'm doing, I just don't know what.

Any ideas?

Just the other day I upgraded my Hangprinter with a new mover that includes corner clamps with mechanical advance. Also I switched the anchor points. In the configuration.h I changed the mechanical advance setting from 1, 1, 1, 1 to 2, 2, 2, 2? Is this correct.

I needed to change also the lines since the old ones weren't long enough. The A, B and C lines measure now 14m the D-line 6m. Those values went into the config file. Now I have few question...

1. The A, B and C-line rotational adjustment is quite obviously handled by pulling the line between the anchors either to the left or the right. But how about the D-line adjustment? I haven't seen any solutions for that? Is there one?

2. I have strange issues with the autocalibration script. When trying the standard method I don't get any results. The other method outputs some data, but the estimations are off by several meters!? I was using 21 datapoints collected at random positions at random levels. There must be something wrong I'm doing, I just don't know what.

Any ideas?

|

Re: Hangprinter version 3 May 15, 2019 01:16PM |

Moderator Registered: 10 years ago Posts: 401 |

Yes, if you use corner clamps from HP4, then 2, 2, 2, 2 is correct.

D-line adjustment for HP4 doesn't have a good solution yet. If you have any progress with it, please track it here: [gitlab.com]

The autocalibration script acts like that if it can't find any optima at all. I have never used Marlin with 2 ,2, 2, 2 mechanical advantage, so I'm not entirely sure why your data is not good.

Do some sanity checking of M114 S1 output.

- Put mover at origin and do g96.

- Put mover at (0, 100, 0) and do M114 S1

- Does the A-motor report something close to 100?

- Put mover at (0, 0, 100) and do M114 S1

- Does the D-motor report close to -100?

If yes, try removing your latest data points one by one until the script starts to converge again. I have noticed that errors tend to accumulate if one is collecting data over a long-ish period. It probably depends on lines not winding/unwinding in a repeatable enough manner. If the line is very tight or very slack when rolled onto the spool, we pay an accuracy penalty when that line is unrolled again.

My work-around on the HP4 has been to go to origin and do g96 between each collected data point. Not really satisfactory, but might help your situation.

torbjornludvigsen.com

D-line adjustment for HP4 doesn't have a good solution yet. If you have any progress with it, please track it here: [gitlab.com]

The autocalibration script acts like that if it can't find any optima at all. I have never used Marlin with 2 ,2, 2, 2 mechanical advantage, so I'm not entirely sure why your data is not good.

Do some sanity checking of M114 S1 output.

- Put mover at origin and do g96.

- Put mover at (0, 100, 0) and do M114 S1

- Does the A-motor report something close to 100?

- Put mover at (0, 0, 100) and do M114 S1

- Does the D-motor report close to -100?

If yes, try removing your latest data points one by one until the script starts to converge again. I have noticed that errors tend to accumulate if one is collecting data over a long-ish period. It probably depends on lines not winding/unwinding in a repeatable enough manner. If the line is very tight or very slack when rolled onto the spool, we pay an accuracy penalty when that line is unrolled again.

My work-around on the HP4 has been to go to origin and do g96 between each collected data point. Not really satisfactory, but might help your situation.

torbjornludvigsen.com

|

Re: Hangprinter version 3 May 15, 2019 02:52PM |

Registered: 8 years ago Posts: 96 |

Ok, thanks Tobben. I'll look into your suggestions tomorrow.

I don't think this has anything to do with Marlin&mechanical advance. I had same issues last time I tried the autocalibration with standard hp3.

Now that you mention unwinding/winding the spools, I have to admit that two of the spools don't rewind them freely when in torque mode... We'll see.

I'll figure out something for the D-line adjustment. My new mover is now a prototype of the one I suggested couple of months ago. All corner clamps and the center piece are printed out of carbon fibre petg. It feels quite stiff already, but I had big trouble fitting the v groove bearings as the material won't flex a bit

I don't think this has anything to do with Marlin&mechanical advance. I had same issues last time I tried the autocalibration with standard hp3.

Now that you mention unwinding/winding the spools, I have to admit that two of the spools don't rewind them freely when in torque mode... We'll see.

I'll figure out something for the D-line adjustment. My new mover is now a prototype of the one I suggested couple of months ago. All corner clamps and the center piece are printed out of carbon fibre petg. It feels quite stiff already, but I had big trouble fitting the v groove bearings as the material won't flex a bit

|

Re: Hangprinter version 3 May 19, 2019 08:51AM |

Registered: 8 years ago Posts: 96 |

Well, I think adjusting the spools did the job. They were fitted too tightly to the motor gears and that prevented them from rewinding properly in torque mode. As a result I wasn't able to get accurate data points for the autocalibration script. Now that I finally got it calibrated it seems to work perfectly.

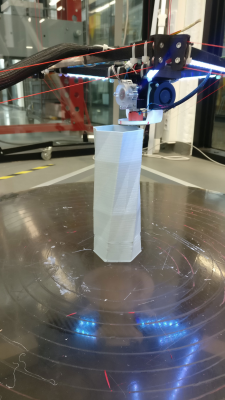

As I write, the printer is printing a vase. Currently at Z 380 mm and with almost flawless surface quality

At the beginning I tested few speed overrides, but the quality went down quite rapid.

Print speed is 60 mm/s and I ramped up to 150%

As I write, the printer is printing a vase. Currently at Z 380 mm and with almost flawless surface quality

At the beginning I tested few speed overrides, but the quality went down quite rapid.

Print speed is 60 mm/s and I ramped up to 150%

|

Re: Hangprinter version 3 May 19, 2019 08:59AM |

Moderator Registered: 10 years ago Posts: 401 |

Awesome! Congrats on successful debugging =)

Looks like you downloaded those corner clamps before June 7, 2018 More recent versions are a bit stiffer (see [gitlab.com]) I stiffened them up before I actually had any practical problems, so yours might just work problem-free anyways. I'm interested to hear if your ABC lines bend your corner clamps over time or not

More recent versions are a bit stiffer (see [gitlab.com]) I stiffened them up before I actually had any practical problems, so yours might just work problem-free anyways. I'm interested to hear if your ABC lines bend your corner clamps over time or not

torbjornludvigsen.com

Looks like you downloaded those corner clamps before June 7, 2018

More recent versions are a bit stiffer (see [gitlab.com]) I stiffened them up before I actually had any practical problems, so yours might just work problem-free anyways. I'm interested to hear if your ABC lines bend your corner clamps over time or not

More recent versions are a bit stiffer (see [gitlab.com]) I stiffened them up before I actually had any practical problems, so yours might just work problem-free anyways. I'm interested to hear if your ABC lines bend your corner clamps over time or not

torbjornludvigsen.com

|

Re: Hangprinter version 3 May 19, 2019 03:54PM |

Registered: 8 years ago Posts: 96 |

Actually, this my own design, but it is based on your older design. I added a third slot for the center beams that connect the extruder carriage to the mover. I'll add some new pics on wednesday. If you like, I can share the design. Althpugj, it will undergo few redesigns when I get the time for it. It's still missing stress relief for the cables, a signle, magnetic, connector for all cables. And the fan duct doesn't work well. Or actually, it works too well. After the fans kick in, the heater can't maintain the temperature which results in system kill due to thermal runaway protection...

Next I will connect the precision piezo as z min endstop. Then it should be possible to do auto leveling by the nozzle. I still have this issue that the nozzle starts to lift the farther I go from the origin.

Next I will connect the precision piezo as z min endstop. Then it should be possible to do auto leveling by the nozzle. I still have this issue that the nozzle starts to lift the farther I go from the origin.

|

Re: Hangprinter version 3 May 24, 2019 03:21AM |

Registered: 8 years ago Posts: 96 |

Hey, does anyone have experience in attaching a z probe to the hangprinter. I'm working currently with the precision piezo orion module which measures the z height by the nozzle tip. It's already attached to the extruder, but I'm having issues configuring the firmware. There's a tutorial on thingiverse how to tweak Marlin, but after doing the changes it won't compile. I'll put the compiler outpur here when I get to the printer. Maybe you, Tobben, have a solution?

Edited 1 time(s). Last edit at 05/24/2019 03:24AM by atmark.

Edited 1 time(s). Last edit at 05/24/2019 03:24AM by atmark.

|

Re: Hangprinter version 3 May 25, 2019 09:05AM |

Registered: 8 years ago Posts: 96 |

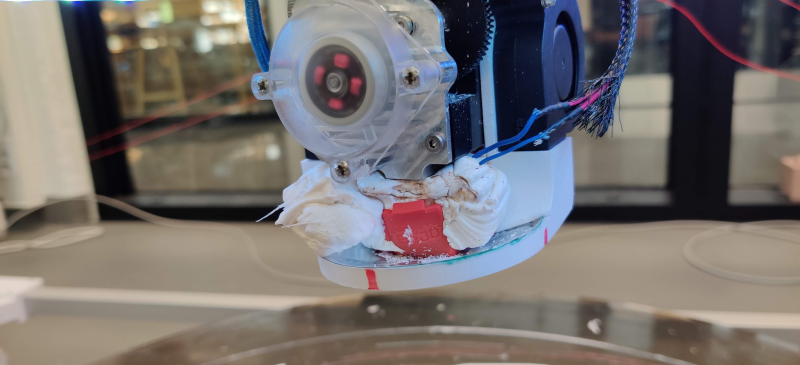

Ok, major disaster...

One line snapped while printing overnight

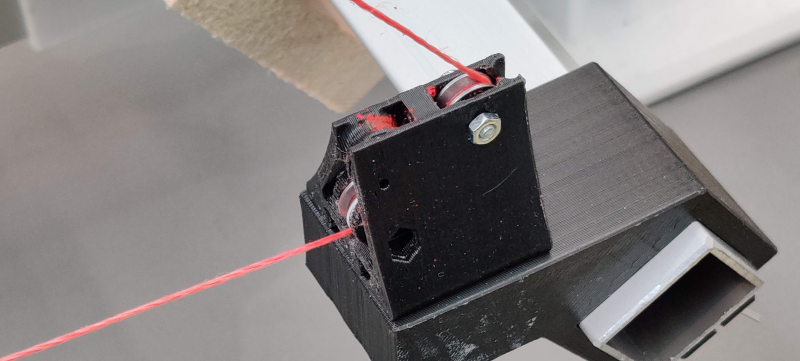

And the culprit seems to be here in picture

The line sheared at the point where it enters the anchor at the top. Also for some reason the line at the bottom has been almost torn apart. It's the only line looking like this. Maybe the bearings are faulty or something. Anyway, I think there should be a safety measurement to kill the system, if a line should ever snap. @tobben is it possible to recognize such event by comparing the motor torques to each other?

One line snapped while printing overnight

And the culprit seems to be here in picture

The line sheared at the point where it enters the anchor at the top. Also for some reason the line at the bottom has been almost torn apart. It's the only line looking like this. Maybe the bearings are faulty or something. Anyway, I think there should be a safety measurement to kill the system, if a line should ever snap. @tobben is it possible to recognize such event by comparing the motor torques to each other?

|

Re: Hangprinter version 3 May 25, 2019 09:36AM |

Moderator Registered: 10 years ago Posts: 401 |

Oh crap

If the line jumps off the bearing, it wears down very quickly. It's not possible to use motor torques to recognize such an event, since a slightly mis-calibrated machine will also have close to zero torque in many positions. But we need to think harder about a anchor design where lines are guaranteed to always stay on the bearing, within a wide range of 3d angles.

The planned Cartesian position feedback feature would solve many problems, emergency stop upon snapped lines are one of them. [gitlab.com]

torbjornludvigsen.com

If the line jumps off the bearing, it wears down very quickly. It's not possible to use motor torques to recognize such an event, since a slightly mis-calibrated machine will also have close to zero torque in many positions. But we need to think harder about a anchor design where lines are guaranteed to always stay on the bearing, within a wide range of 3d angles.

The planned Cartesian position feedback feature would solve many problems, emergency stop upon snapped lines are one of them. [gitlab.com]

torbjornludvigsen.com

|

Re: Hangprinter version 3 June 22, 2019 07:30PM |

Registered: 4 years ago Posts: 11 |

hey everyone!

I ve been following the project for about a half year now. Sounds super exciting to me (ie my compliments to tob and all the other involved members, developers, testers and enthusiasts ! Im not very skilled at 3d printing but I believe I will learn as I go as Im too messy to do proper preperations when it comes to just about anything. But than, hey - I read all (yes, all 14

! Im not very skilled at 3d printing but I believe I will learn as I go as Im too messy to do proper preperations when it comes to just about anything. But than, hey - I read all (yes, all 14  ) pages of this thread, tob's blog, clicked on most of the links wherever i could, and started printing the parts, and am about to start oredring electronic components and hardware bits. I must admit, reading through all of this wasnt easy but helped me clarifed quite a bit. I feel I have an understanding of whats going on even though im missing a lot of details, whereas before i was just missing it all and only had this awesome 3d animation from hangprinter website going on and on in my head

) pages of this thread, tob's blog, clicked on most of the links wherever i could, and started printing the parts, and am about to start oredring electronic components and hardware bits. I must admit, reading through all of this wasnt easy but helped me clarifed quite a bit. I feel I have an understanding of whats going on even though im missing a lot of details, whereas before i was just missing it all and only had this awesome 3d animation from hangprinter website going on and on in my head

my motivation is to print full scale gallery exhibition on the spot using this machine, photogrametry, and heaps of luck. I also like the "style" with which printer seems to print as exposing the technology of 3d printing by leaving imperfect traces behind makes it actually more human and accessible to me.

anyways, just wanted to share my enthusiasm here

im doing a shopping list right now and the aliexpress mid year sale ends in 2 days so im hoping to get some insights before that, but that may be too optimistic of a wish

still, i ll post here again in a bit

cheers for now!

mizu

I ve been following the project for about a half year now. Sounds super exciting to me (ie my compliments to tob and all the other involved members, developers, testers and enthusiasts

! Im not very skilled at 3d printing but I believe I will learn as I go as Im too messy to do proper preperations when it comes to just about anything. But than, hey - I read all (yes, all 14

! Im not very skilled at 3d printing but I believe I will learn as I go as Im too messy to do proper preperations when it comes to just about anything. But than, hey - I read all (yes, all 14  ) pages of this thread, tob's blog, clicked on most of the links wherever i could, and started printing the parts, and am about to start oredring electronic components and hardware bits. I must admit, reading through all of this wasnt easy but helped me clarifed quite a bit. I feel I have an understanding of whats going on even though im missing a lot of details, whereas before i was just missing it all and only had this awesome 3d animation from hangprinter website going on and on in my head

) pages of this thread, tob's blog, clicked on most of the links wherever i could, and started printing the parts, and am about to start oredring electronic components and hardware bits. I must admit, reading through all of this wasnt easy but helped me clarifed quite a bit. I feel I have an understanding of whats going on even though im missing a lot of details, whereas before i was just missing it all and only had this awesome 3d animation from hangprinter website going on and on in my head

my motivation is to print full scale gallery exhibition on the spot using this machine, photogrametry, and heaps of luck. I also like the "style" with which printer seems to print as exposing the technology of 3d printing by leaving imperfect traces behind makes it actually more human and accessible to me.

anyways, just wanted to share my enthusiasm here

im doing a shopping list right now and the aliexpress mid year sale ends in 2 days so im hoping to get some insights before that, but that may be too optimistic of a wish

still, i ll post here again in a bit

cheers for now!

mizu

Sorry, only registered users may post in this forum.