Hangprinter version 3

Posted by tobben

|

Re: Hangprinter version 3 June 22, 2019 09:10PM |

Registered: 4 years ago Posts: 11 |

back again with bag full of questions

as i said, i aim to order most of my parts from aliexpress, mostly from makerbase and trianble labs. Still as Tob's BOM asks for either too a general item or explicitly different item, Id like to confirm a few things before actually placing the order. Here comes...

1) Ramps + arduino mega 1.4/1.6 vs mks gen L

I know BOM asks for RAMPS plus arduino mega. wouldnt Makerspace's mks gen L (aliexpress) do just as well if not better though? I hear there's less hassle with it (plus i may use other hardware from them) but haven't heared of anyone from hangprinter community praising/using it.

if it may not be such a good option after all than should i get ramps 1.4 or 1.6?

2) mechanduino (clones)

makerbase, as you surely know, manufactures mechanduino clones that come hooked to nema17 42 steps stepper already (aliexpress). now, as it is a clone, it should behave the same way (although they told me some pins are weired differently). anyways, does anyone has any experience with them? would you recommend using them or would you not? (id appreciate (expert) guesses too

3) extruder+hotend

im looking at this triangle lab e3d volcano ripp (aliexpress) . i would like to get the whole "set 5" (need to scroll down to see the desription of various sets) which includes extreuder, hotend, motor, and fan. I read its a "good fake" as much of an oxymoron as it sounds. any voices against it?

Id be super happy if someone could get back to me with any opinion or experience. i should be fine with other bits of the puzzle for now, but really can't make up my mind on mentioned topics.

Best,

Mizu

as i said, i aim to order most of my parts from aliexpress, mostly from makerbase and trianble labs. Still as Tob's BOM asks for either too a general item or explicitly different item, Id like to confirm a few things before actually placing the order. Here comes...

1) Ramps + arduino mega 1.4/1.6 vs mks gen L

I know BOM asks for RAMPS plus arduino mega. wouldnt Makerspace's mks gen L (aliexpress) do just as well if not better though? I hear there's less hassle with it (plus i may use other hardware from them) but haven't heared of anyone from hangprinter community praising/using it.

if it may not be such a good option after all than should i get ramps 1.4 or 1.6?

2) mechanduino (clones)

makerbase, as you surely know, manufactures mechanduino clones that come hooked to nema17 42 steps stepper already (aliexpress). now, as it is a clone, it should behave the same way (although they told me some pins are weired differently). anyways, does anyone has any experience with them? would you recommend using them or would you not? (id appreciate (expert) guesses too

3) extruder+hotend

im looking at this triangle lab e3d volcano ripp (aliexpress) . i would like to get the whole "set 5" (need to scroll down to see the desription of various sets) which includes extreuder, hotend, motor, and fan. I read its a "good fake" as much of an oxymoron as it sounds. any voices against it?

Id be super happy if someone could get back to me with any opinion or experience. i should be fine with other bits of the puzzle for now, but really can't make up my mind on mentioned topics.

Best,

Mizu

|

Re: Hangprinter version 3 June 26, 2019 03:16PM |

Moderator Registered: 10 years ago Posts: 401 |

Hello pvsfa!

1) The HP3 should work with any electronics that with 5 stepper drivers or more.

If you plan to use Mechaduinos/Smart Steppers, then you must also have access to i2c pins and step/dir pins. Not all electronics provide that.

Very few have tried anything other than RAMPS, so you might bump into something, but most probably not much.

I've used some RAMBO boards myself, and it was quite smooth. Just configure Marlin right, and it should work out of the box.

2) I haven't tried clones, and I wouldn't recommend them. You will run into some slight differences, and unless you're an electronics engineer, you'll have to ask for help and wait for answers... These boards are quite tricky to make right. I recommend proper Smart Stepper bought from misfittech.net

3) If you don't plan to print much with the HP, then a Volcano clone might be the perfect fit. I do recommend a proper SuperVolcano to anyone who plans to print more than just a few demo objects. The proper hot ends will typically perform much better. They will give you more nice looking prints with less hassle, and last much longer. It might be a super good clone, but it would be the first one that I ever saw. It is very very tricky to make these parts both good and cheap at the same time. If you have to prioritize because you really can't afford originals, then buy a genuine heat break, genuine heater cartridge, and genuine thermistor. You might need a genuine heater block to make everything fit as it should.

I will not be able to support you easily if you have cloned parts, as they could have a very wide range of hard-to-debug faults.

Best regards

torbjornludvigsen.com

1) The HP3 should work with any electronics that with 5 stepper drivers or more.

If you plan to use Mechaduinos/Smart Steppers, then you must also have access to i2c pins and step/dir pins. Not all electronics provide that.

Very few have tried anything other than RAMPS, so you might bump into something, but most probably not much.

I've used some RAMBO boards myself, and it was quite smooth. Just configure Marlin right, and it should work out of the box.

2) I haven't tried clones, and I wouldn't recommend them. You will run into some slight differences, and unless you're an electronics engineer, you'll have to ask for help and wait for answers... These boards are quite tricky to make right. I recommend proper Smart Stepper bought from misfittech.net

3) If you don't plan to print much with the HP, then a Volcano clone might be the perfect fit. I do recommend a proper SuperVolcano to anyone who plans to print more than just a few demo objects. The proper hot ends will typically perform much better. They will give you more nice looking prints with less hassle, and last much longer. It might be a super good clone, but it would be the first one that I ever saw. It is very very tricky to make these parts both good and cheap at the same time. If you have to prioritize because you really can't afford originals, then buy a genuine heat break, genuine heater cartridge, and genuine thermistor. You might need a genuine heater block to make everything fit as it should.

I will not be able to support you easily if you have cloned parts, as they could have a very wide range of hard-to-debug faults.

Best regards

torbjornludvigsen.com

|

Re: Hangprinter version 3 July 01, 2019 12:59AM |

Registered: 8 years ago Posts: 96 |

Hi pvsfa

Those extruder clones might come as a cheap ootion, but from my experience the extruder/hotend combo is a critical component where you really should invest in quality hardware. For example e3d or Bondtech. I once ordered e3d Titan clones from China and they were so badly manufactured that they were practically not usable. Since then I'm sticking with e3d. It saves you the hassle, trust me.

Those extruder clones might come as a cheap ootion, but from my experience the extruder/hotend combo is a critical component where you really should invest in quality hardware. For example e3d or Bondtech. I once ordered e3d Titan clones from China and they were so badly manufactured that they were practically not usable. Since then I'm sticking with e3d. It saves you the hassle, trust me.

|

Re: Hangprinter version 3 July 25, 2019 05:38AM |

Registered: 8 years ago Posts: 96 |

Hey

Do you have had similar issues with print quality than I had with the last project (still going on)?

The skin was partly separated from the printed object and that caused issues during post-processing (sanding, etc.) It affected only the outermost wall, the inner walls were connected as they should have been.

Here's a picture of the crime scene. Any suggestions are warmly welcome, since I'm about to start the next project soon.

Do you have had similar issues with print quality than I had with the last project (still going on)?

The skin was partly separated from the printed object and that caused issues during post-processing (sanding, etc.) It affected only the outermost wall, the inner walls were connected as they should have been.

Here's a picture of the crime scene. Any suggestions are warmly welcome, since I'm about to start the next project soon.

|

Re: Hangprinter version 3 July 29, 2019 09:47AM |

Moderator Registered: 10 years ago Posts: 401 |

Interesting! Haven't seen this issue before, at least not this much.

It would be interesting to know if the effector travelled in different directions on outer versus non-outer walls.

Could it be that the plastic trace will look different when going clock-wise versus counter-clock-wise?

Other than that, I would experiment with trying to make the nozzle mounting more rigid.

torbjornludvigsen.com

It would be interesting to know if the effector travelled in different directions on outer versus non-outer walls.

Could it be that the plastic trace will look different when going clock-wise versus counter-clock-wise?

Other than that, I would experiment with trying to make the nozzle mounting more rigid.

torbjornludvigsen.com

|

Re: Hangprinter version 3 August 03, 2019 01:47PM |

Registered: 8 years ago Posts: 96 |

The last project was sliced with cura 3.6 and the gcode wasn't as smooth as the code produced by simplify3d. The printhead jittered quite alot when printing the cura code. Also the print speed might have been a bit too high. But the biggest improvement so far has been the huge 1000 mm dia silicone heater mat, which I got installed a week ago. No more issues with first layer adhesion.

Edited 2 time(s). Last edit at 08/03/2019 01:49PM by atmark.

Edited 2 time(s). Last edit at 08/03/2019 01:49PM by atmark.

|

Re: Hangprinter version 3 August 06, 2019 04:03AM |

Registered: 8 years ago Posts: 96 |

|

Re: Hangprinter version 3 September 03, 2019 02:24PM |

Registered: 8 years ago Posts: 21 |

Hello Tobben and others! A university on the East Coast U.S. is trying to build some hangprinters. Students at GMU's solar car team are trying to print a fairing for their car with one!

I'm trying to lend them a hand, but the documentation on hangprinter.org seems to be focused on a closed-loop build. They're trying to avoid buying Mechaduinos or the like, and I can't seem to find information on it. Where should I be looking?

Edited 1 time(s). Last edit at 09/03/2019 07:55PM by kenblu24.

I'm trying to lend them a hand, but the documentation on hangprinter.org seems to be focused on a closed-loop build. They're trying to avoid buying Mechaduinos or the like, and I can't seem to find information on it. Where should I be looking?

Edited 1 time(s). Last edit at 09/03/2019 07:55PM by kenblu24.

|

Re: Hangprinter version 3 September 04, 2019 01:34PM |

Moderator Registered: 10 years ago Posts: 401 |

Hello!

This thread and the facebook group contains most of the info. Tom's videos use closed loop. And all the blog posts I wrote before going closed-loop. Good luck with your builds!

torbjornludvigsen.com

This thread and the facebook group contains most of the info. Tom's videos use closed loop. And all the blog posts I wrote before going closed-loop. Good luck with your builds!

torbjornludvigsen.com

|

Re: Hangprinter version 3 October 12, 2019 04:47AM |

Registered: 8 years ago Posts: 96 |

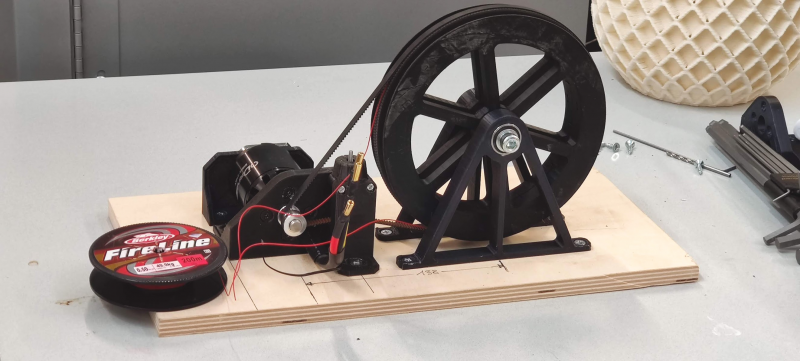

I'm currently designing a bracket for the HP4 bldc servo motor and the spool, and I wanted to share my tests so far.

The bracket is meant for the ODrive D5065 motor. My goal is to design a single motion unit, that includes the motor, a belt tensioner and the spool system in one rigid frame, which I probably am going to lasercut out of sheet metal. For now, I'm still thinking about the spool system. If you look few posts back in this thread, there was a discussion about the constant radius of the spool and how to compensate the line build up. An idea I had, was to route the line in a small groove in the middle of the GT2 spool, in the way that the belt is pressing it against the spool as you can see in the last pic.

I just tried to block the spool from rotating and pulled the line as hard as I could and it didn't move at all

It's still too early to say this concept works, but it is a promising start. It might be, that constant line movement is going to bite into the belt and it fails that way. You'll never know. What I'll do next is rerouting the end of the line onto a second spool, which I most likely will attach onto the same spool axle. And that spool will rotate independently from the first one. I was also thinking to spring load it, so that the excess line is always spooled up as the line moves.

The bracket is meant for the ODrive D5065 motor. My goal is to design a single motion unit, that includes the motor, a belt tensioner and the spool system in one rigid frame, which I probably am going to lasercut out of sheet metal. For now, I'm still thinking about the spool system. If you look few posts back in this thread, there was a discussion about the constant radius of the spool and how to compensate the line build up. An idea I had, was to route the line in a small groove in the middle of the GT2 spool, in the way that the belt is pressing it against the spool as you can see in the last pic.

I just tried to block the spool from rotating and pulled the line as hard as I could and it didn't move at all

It's still too early to say this concept works, but it is a promising start. It might be, that constant line movement is going to bite into the belt and it fails that way. You'll never know. What I'll do next is rerouting the end of the line onto a second spool, which I most likely will attach onto the same spool axle. And that spool will rotate independently from the first one. I was also thinking to spring load it, so that the excess line is always spooled up as the line moves.

|

Re: Hangprinter version 3 October 12, 2019 06:25AM |

Moderator Registered: 10 years ago Posts: 401 |

Cool!

Independent spool units are nice.

If you can place them at the anchors (instead of having all several spools at one anchor), you will get less line flex, since there will be less suspended line in the air.

Good idea to pinch the line under the belt.

That might actually work very well =D

You could pinch it for several rounds (along a helix groove), or just increase the spool radius, if one round of pinched line isn't enough.

It might be a challenge assure zero slippage over time, since both line and belt will change properties as they get old/worn down.

Some data on that would be super interesting, like accelerating a 5kg weight quickly up and down 1 m 10000 times or something.

Using high accelerations would be interesting because the belt will flex/contract a bit when tension changes, and I don't know how it will affect the line.

Hopefully very little.

Anyways, that might be a very nice upgrade of the spool system

torbjornludvigsen.com

Independent spool units are nice.

If you can place them at the anchors (instead of having all several spools at one anchor), you will get less line flex, since there will be less suspended line in the air.

Good idea to pinch the line under the belt.

That might actually work very well =D

You could pinch it for several rounds (along a helix groove), or just increase the spool radius, if one round of pinched line isn't enough.

It might be a challenge assure zero slippage over time, since both line and belt will change properties as they get old/worn down.

Some data on that would be super interesting, like accelerating a 5kg weight quickly up and down 1 m 10000 times or something.

Using high accelerations would be interesting because the belt will flex/contract a bit when tension changes, and I don't know how it will affect the line.

Hopefully very little.

Anyways, that might be a very nice upgrade of the spool system

torbjornludvigsen.com

|

Re: Hangprinter version 3 October 12, 2019 07:00AM |

Registered: 8 years ago Posts: 96 |

Thanks!

I just put a heavy weight on the line and looked first if the line holds, and after I couldn't see any slipping, I bounced the whole system until the line snapped Video: testing slipping

No slipping what so ever

I believe the line should be able to handle 40 kg of drag, so friction-wise I can't see any issues. Obviously the long term failure rate is a question mark, but I think it might work quite well because the line isn't cutting radially into the belt. The only force is applied axially and the belt is pressed by the line by only 0,25 mm

Your idea of hooking some weight on the line and do some repetitive acceleration testing sounds very good! I'll try to set up the electronics next week. What values would you suggest for weight, speed and acceleration?

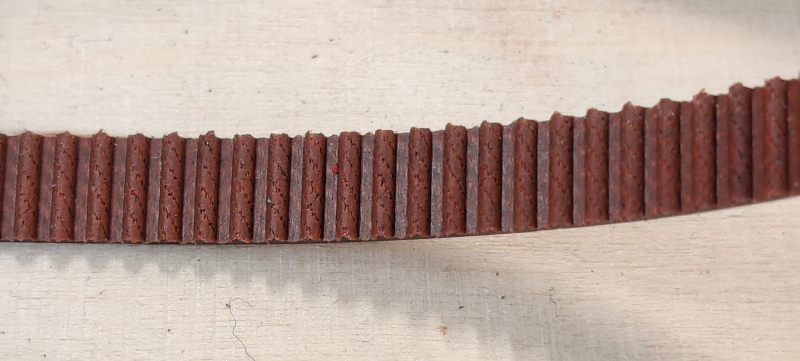

Here are also some close ups of the GT2 spool and the belt directly after the test. For the spool I used Octofiber PETG-CF.

I just put a heavy weight on the line and looked first if the line holds, and after I couldn't see any slipping, I bounced the whole system until the line snapped Video: testing slipping

No slipping what so ever

I believe the line should be able to handle 40 kg of drag, so friction-wise I can't see any issues. Obviously the long term failure rate is a question mark, but I think it might work quite well because the line isn't cutting radially into the belt. The only force is applied axially and the belt is pressed by the line by only 0,25 mm

Your idea of hooking some weight on the line and do some repetitive acceleration testing sounds very good! I'll try to set up the electronics next week. What values would you suggest for weight, speed and acceleration?

Here are also some close ups of the GT2 spool and the belt directly after the test. For the spool I used Octofiber PETG-CF.

|

Re: Hangprinter version 3 October 12, 2019 11:14AM |

Moderator Registered: 10 years ago Posts: 401 |

Woah, that's even more friction than I imagined. Impressive!

CF enforced plastics have a quite rough surface.

Where did the line snap?

Was it the CF that wore down the line?

Since I would be aiming for HP usage, I'd test numbers relevant to the application first.

I'd use ca 50% more weight, speed and acceleration than my HP4 prototype is experiencing.

So ca 5 kg of weight, accelerate 15 m/s² , up to 1 m/s. Use a distance of 1 m up and down, say 10k times.

That's a 3h test. You could go crazy and just let it run all night if you're feeling confident

It would also be interesting to know if the mechanism works with pure PLA.

A spool out of PLA printed hot (say 240 C) would give much less friction than the PLA-CF in your prototype, I guess.

It would be interesting to know if it would still be enough, or if the CF is required.

Images like the one you showed would be a very interesting part of the result.

In particular, if the line does slip, I'm interested in how damaged the belt gets.

Also interesting to know if a slipping line cuts into the spool.

The mechanism is interesting in it's own right, so if the HP4 application proves to be well within limits of the mechanism, I would have done additional tests.

Like, measuring a slowly applied force up until the line breaks or starts slipping, or until the plastic spool breaks.

(Film a weight that is hooked onto a one end of a line, and pulled. Could capture both force and amount of slip/flex in one shot.)

Abruptly applied force is also interesting (requires a high-speed camera, or a weight that can store a max value).

torbjornludvigsen.com

CF enforced plastics have a quite rough surface.

Where did the line snap?

Was it the CF that wore down the line?

Since I would be aiming for HP usage, I'd test numbers relevant to the application first.

I'd use ca 50% more weight, speed and acceleration than my HP4 prototype is experiencing.

So ca 5 kg of weight, accelerate 15 m/s² , up to 1 m/s. Use a distance of 1 m up and down, say 10k times.

That's a 3h test. You could go crazy and just let it run all night if you're feeling confident

It would also be interesting to know if the mechanism works with pure PLA.

A spool out of PLA printed hot (say 240 C) would give much less friction than the PLA-CF in your prototype, I guess.

It would be interesting to know if it would still be enough, or if the CF is required.

Images like the one you showed would be a very interesting part of the result.

In particular, if the line does slip, I'm interested in how damaged the belt gets.

Also interesting to know if a slipping line cuts into the spool.

The mechanism is interesting in it's own right, so if the HP4 application proves to be well within limits of the mechanism, I would have done additional tests.

Like, measuring a slowly applied force up until the line breaks or starts slipping, or until the plastic spool breaks.

(Film a weight that is hooked onto a one end of a line, and pulled. Could capture both force and amount of slip/flex in one shot.)

Abruptly applied force is also interesting (requires a high-speed camera, or a weight that can store a max value).

torbjornludvigsen.com

|

Re: Hangprinter version 3 October 12, 2019 12:37PM |

Registered: 8 years ago Posts: 96 |

Yeah, I was quite amazed too to be honest.

The line snapped 5 mm before the knot I made to hold the weight. So the CF spool didn't have any effect on the snapping. I'm aware of the abrasive nature of CF, so it's not said that it could not happen, but in this case it didn't. I can print a new spool out of PLA, no problem. It will be interesting to test it.

Let's see how I can setup a test rig. The motion repetition won't be a big issue once I get to setup the ODrive board and Duet. Is the firmware easy to install? Then, I assume a simple gcode does the magic?

Btw, I wrote you yesterday a mail, but it's still in my to be sent folder (I forgot that the schools network is down for maintanance for couple of days) anyway, I wrote that I ordered braided PE fishing line that is two-colored (yellow/black), so it has a repetitive weave pattern, which could be used for line length readout with a IR sensor, as black plastic does not reflect IR light very well. That's why the material of black plastic can't be identified in automated recycling. Different plastics reflect IR light differently.

So, additionally to the mechanics I was thinking about position feedback via sensor readout. Whats your opinion on that? There was also some discussion about measuring the line tension. Could that be useful to integrate in the motion system? At school we have a quite big range of sensors and other electronic equipment for prototyping. You can check technIcal details at Seeedstudio Grove

You can hook these sensors very easy to arduino, rasbi, etc.

The line snapped 5 mm before the knot I made to hold the weight. So the CF spool didn't have any effect on the snapping. I'm aware of the abrasive nature of CF, so it's not said that it could not happen, but in this case it didn't. I can print a new spool out of PLA, no problem. It will be interesting to test it.

Let's see how I can setup a test rig. The motion repetition won't be a big issue once I get to setup the ODrive board and Duet. Is the firmware easy to install? Then, I assume a simple gcode does the magic?

Btw, I wrote you yesterday a mail, but it's still in my to be sent folder (I forgot that the schools network is down for maintanance for couple of days) anyway, I wrote that I ordered braided PE fishing line that is two-colored (yellow/black), so it has a repetitive weave pattern, which could be used for line length readout with a IR sensor, as black plastic does not reflect IR light very well. That's why the material of black plastic can't be identified in automated recycling. Different plastics reflect IR light differently.

So, additionally to the mechanics I was thinking about position feedback via sensor readout. Whats your opinion on that? There was also some discussion about measuring the line tension. Could that be useful to integrate in the motion system? At school we have a quite big range of sensors and other electronic equipment for prototyping. You can check technIcal details at Seeedstudio Grove

You can hook these sensors very easy to arduino, rasbi, etc.

|

Re: Hangprinter version 3 October 13, 2019 05:28AM |

Moderator Registered: 10 years ago Posts: 401 |

Yes, the firmware should be straight forward to install. Just use the Duet2CombinedFirmware.bin you find in the repo (https://gitlab.com/tobben/hangprinter/tree/version_4_dev/firmware/RepRapFirmware), and follow standard Duet installation procedure. Gcode should to the magic, yes  Be aware that your ODrive configuration will affect the movements. Max acceleration, max speed, step size etc needs to be configured correctly in the ODrive firmware. There's an example that matches my specific motors here: [gitlab.com] Follow the official ODrive documentation to find numbers that match your motors.

Be aware that your ODrive configuration will affect the movements. Max acceleration, max speed, step size etc needs to be configured correctly in the ODrive firmware. There's an example that matches my specific motors here: [gitlab.com] Follow the official ODrive documentation to find numbers that match your motors.

If the fishing line has any flex at all, this will affect the readings. So if the line (and hence the pattern) is stretched out, you might wind in 10.1 mm when you thought you did only 10.0.

On the other hand, since you're detecting the pattern, you'll know when you have unwound the same segment of fishing line, regardless of how stretched it was when wound and unwound.

This makes the system immune to a family of errors where flex is "stored" on the spool when wound in under heavy load.

The line will always be twisted though. How would the system cope with that?

And how would it behave if the line got very slack? Could we route the line through a very thin transparent tube, to keep it from kinking under the sensor?

For such a sensor to be useful, it would need to be very fool proof since so many weird things can happen during a print.

torbjornludvigsen.com

Be aware that your ODrive configuration will affect the movements. Max acceleration, max speed, step size etc needs to be configured correctly in the ODrive firmware. There's an example that matches my specific motors here: [gitlab.com] Follow the official ODrive documentation to find numbers that match your motors.

Be aware that your ODrive configuration will affect the movements. Max acceleration, max speed, step size etc needs to be configured correctly in the ODrive firmware. There's an example that matches my specific motors here: [gitlab.com] Follow the official ODrive documentation to find numbers that match your motors.If the fishing line has any flex at all, this will affect the readings. So if the line (and hence the pattern) is stretched out, you might wind in 10.1 mm when you thought you did only 10.0.

On the other hand, since you're detecting the pattern, you'll know when you have unwound the same segment of fishing line, regardless of how stretched it was when wound and unwound.

This makes the system immune to a family of errors where flex is "stored" on the spool when wound in under heavy load.

The line will always be twisted though. How would the system cope with that?

And how would it behave if the line got very slack? Could we route the line through a very thin transparent tube, to keep it from kinking under the sensor?

For such a sensor to be useful, it would need to be very fool proof since so many weird things can happen during a print.

torbjornludvigsen.com

|

Re: Hangprinter version 3 October 13, 2019 05:35AM |

Registered: 8 years ago Posts: 96 |

|

Re: Hangprinter version 3 November 20, 2019 08:21PM |

Registered: 9 years ago Posts: 29 |

Hi,

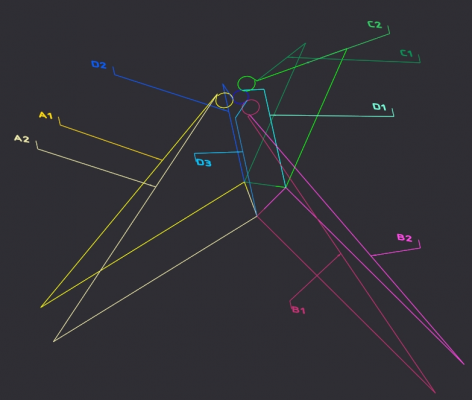

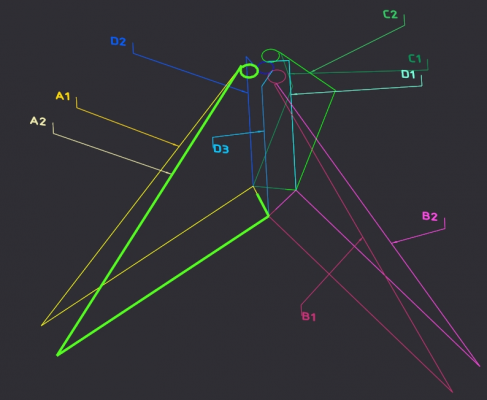

i am trying to build a HangPrinter too and i had a lot of hours spent searching and watching images, videos and build documentation for hardware, firmware, software. The hardest thing for me was to figure out how lines are installed properly. I did not built my hangprinter in real for now but planning to do it (sourcing hardware and so on). I drew some sketch for lines and wanted you to ask if understood it correctly.

As far as i know there are 9 lines in total

* A1 + A2 => 2 lines on one spool

* B1 + B2 => 2 lines on one spool

* C1 + C2 => 2 lines on one spool

* D1, D2, D3 => 3 lines on one spool

to better follow i just marked the full A2 path for example. You can see that A2 joins A1 again at the effector (triangle).

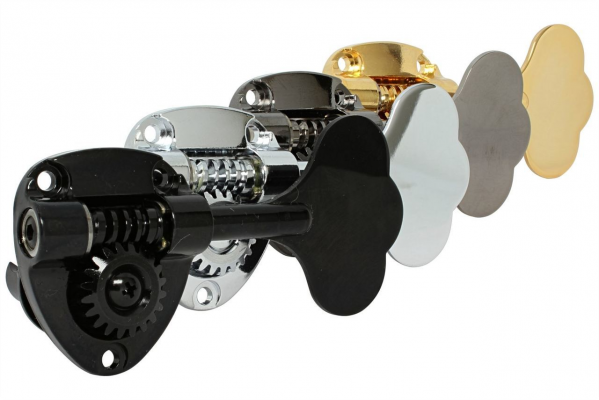

I saw in Chris Basement videos that the A1+A2, B1+B2 and C1+C2 have a common knot on the effector slider each, while D1,D2,D3 have there own slider for each. So in total there are 6 sliders (by the way i thought using guitar tuner mechanics for this use case)

I'm happy to retrieve your feedback.

cheers, Mario :-)

i am trying to build a HangPrinter too and i had a lot of hours spent searching and watching images, videos and build documentation for hardware, firmware, software. The hardest thing for me was to figure out how lines are installed properly. I did not built my hangprinter in real for now but planning to do it (sourcing hardware and so on). I drew some sketch for lines and wanted you to ask if understood it correctly.

As far as i know there are 9 lines in total

* A1 + A2 => 2 lines on one spool

* B1 + B2 => 2 lines on one spool

* C1 + C2 => 2 lines on one spool

* D1, D2, D3 => 3 lines on one spool

to better follow i just marked the full A2 path for example. You can see that A2 joins A1 again at the effector (triangle).

I saw in Chris Basement videos that the A1+A2, B1+B2 and C1+C2 have a common knot on the effector slider each, while D1,D2,D3 have there own slider for each. So in total there are 6 sliders (by the way i thought using guitar tuner mechanics for this use case)

I'm happy to retrieve your feedback.

cheers, Mario :-)

|

Re: Hangprinter version 3 November 21, 2019 07:26AM |

Moderator Registered: 10 years ago Posts: 401 |

|

Re: Hangprinter version 3 January 21, 2020 09:17AM |

Registered: 4 years ago Posts: 11 |

Hey all!

recently I managed to get a hangprinter running (moving to be specific). I still have quite some work to do - code and finetuning - but i was wondering whether anyone, @tobben especially, would be interested in trying to get all the available hp3 documentation in one place? also perhaps adding a few tips for noobs like me wouldnt hurt. i am happy to set out for that and even though i might just go and do it, i dont see much point in that unless this would be coordinated with comunity and developer(s) as no one would ever even get to know such efforts exist. so now... is there a way someone besides you, tob, can eddit hangprinter.org documentation (in a sense of adding to it?) would it be a good idea to create a wiki page wher all the links and tips could rest at one place? but than, can this be linked from official channels so those interested would actually be able to find it?

im possitive this could save some good deal of time, counting in days, even weeks

or is the case that hpv4 is fully underway and no more development should be "wasted" on v3?

looking forward hearing what you guys have to say. i really just wish for this project to grow, and i believe a decent semi-centralised documentation platforn may add to that

www.michalmitro.com

postmedia practice

recently I managed to get a hangprinter running (moving to be specific). I still have quite some work to do - code and finetuning - but i was wondering whether anyone, @tobben especially, would be interested in trying to get all the available hp3 documentation in one place? also perhaps adding a few tips for noobs like me wouldnt hurt. i am happy to set out for that and even though i might just go and do it, i dont see much point in that unless this would be coordinated with comunity and developer(s) as no one would ever even get to know such efforts exist. so now... is there a way someone besides you, tob, can eddit hangprinter.org documentation (in a sense of adding to it?) would it be a good idea to create a wiki page wher all the links and tips could rest at one place? but than, can this be linked from official channels so those interested would actually be able to find it?

im possitive this could save some good deal of time, counting in days, even weeks

or is the case that hpv4 is fully underway and no more development should be "wasted" on v3?

looking forward hearing what you guys have to say. i really just wish for this project to grow, and i believe a decent semi-centralised documentation platforn may add to that

www.michalmitro.com

postmedia practice

|

Re: Hangprinter version 3 January 21, 2020 02:19PM |

Moderator Registered: 10 years ago Posts: 401 |

Hi pvsfa!

I honestly don't know how people manage to get the Hangprinters working given the state of the documentation. You must have searched for and found little pieces of information in very many different places. Like it says in the repo, this project does not yet have any stable branch. So no easy entry point for newcomers.

Right now there has been a long pause in HP development for myself, both HP4 and HP3 development. Don't count on very much from me for a while still.

If you know how to use git, you could always create pull requests to the documentation in the repo:

[gitlab.com]

The most good looking and flexible way to document would be to serve something nice on hangprinter.org/doc.

Git does increase the threshold for participation though, so doing self-hosted and self-made webpage documentation requires a lot of effort and dedication.

If you don't like to use time consuming tools like git and raw html, I still think it's best to keep the documentation close to the source, so I suggest trying the Gitlab wiki functionality:

[gitlab.com]

torbjornludvigsen.com

I honestly don't know how people manage to get the Hangprinters working given the state of the documentation. You must have searched for and found little pieces of information in very many different places. Like it says in the repo, this project does not yet have any stable branch. So no easy entry point for newcomers.

Right now there has been a long pause in HP development for myself, both HP4 and HP3 development. Don't count on very much from me for a while still.

If you know how to use git, you could always create pull requests to the documentation in the repo:

[gitlab.com]

The most good looking and flexible way to document would be to serve something nice on hangprinter.org/doc.

Git does increase the threshold for participation though, so doing self-hosted and self-made webpage documentation requires a lot of effort and dedication.

If you don't like to use time consuming tools like git and raw html, I still think it's best to keep the documentation close to the source, so I suggest trying the Gitlab wiki functionality:

[gitlab.com]

torbjornludvigsen.com

|

Re: Hangprinter version 3 January 22, 2020 01:01AM |

Registered: 8 years ago Posts: 96 |

Hi

Centralized documentation would be needed and I was already planning to setup up one on Dozuki, but it is a really time consuming task. Time that I currently don't have...

I have though a lot of images I made during the build process, those might help a lot. Hangprinter Google Photos

But then, there's also a lot undocumented stuff, that you learn once you've build the printer and have operated it for a while. I'm still in the process of learning.

It would be wise to document that knowledge as well, but a day (still) has only 24 hours... If you like, I can give you access to the Dozuki site, so we can work together on the documentation

Centralized documentation would be needed and I was already planning to setup up one on Dozuki, but it is a really time consuming task. Time that I currently don't have...

I have though a lot of images I made during the build process, those might help a lot. Hangprinter Google Photos

But then, there's also a lot undocumented stuff, that you learn once you've build the printer and have operated it for a while. I'm still in the process of learning.

It would be wise to document that knowledge as well, but a day (still) has only 24 hours... If you like, I can give you access to the Dozuki site, so we can work together on the documentation

|

Re: Hangprinter version 3 January 24, 2020 10:36AM |

Registered: 4 years ago Posts: 11 |

Hey!

we may just start a new thread here that would at least have all the links with description of what can be found where. that should be easy.

i could also add my hints other not so skilled builders may find youseful (wish i knew a month back )

)

same could go for everybody else. it might turn out well... or not, but lets give it a shot?

otherwise, shurely a centralised site withk nowledge base pictures and instructions, like you re describing it would definitely be an ultimate goal! we may get there one day i hope

we may just start a new thread here that would at least have all the links with description of what can be found where. that should be easy.

i could also add my hints other not so skilled builders may find youseful (wish i knew a month back

)

)same could go for everybody else. it might turn out well... or not, but lets give it a shot?

otherwise, shurely a centralised site withk nowledge base pictures and instructions, like you re describing it would definitely be an ultimate goal! we may get there one day i hope

|

Re: Hangprinter version 3 March 10, 2020 05:59PM |

Registered: 4 years ago Posts: 11 |

Quote

atmark

Centralized documentation would be needed and I was already planning to setup up one on Dozuki, but it is a really time consuming task. Time that I currently don't have...

I have though a lot of images I made during the build process, those might help a lot. Hangprinter Google Photos

But then, there's also a lot undocumented stuff, that you learn once you've build the printer and have operated it for a while. I'm still in the process of learning.

It would be wise to document that knowledge as well, but a day (still) has only 24 hours... If you like, I can give you access to the Dozuki site, so we can work together on the documentation

I finally managed to create a separate topic and wrote some of my own tips (for noobs like me). please feel welcome to add some of your wisdom to it

[reprap.org]

Also open to develop this further in different platforms if you got some ideas and a bit of time.

|

Re: Hangprinter version 3 March 12, 2020 01:23AM |

Registered: 8 years ago Posts: 96 |

Quote

pvsfa

Also open to develop this further in different platforms if you got some ideas and a bit of time.

Ok, so the Hangprinter documentation could be maintained here [hangprinter.dozuki.com]

Personally, I like the style Prusa and e3d-online are doing. Lots of images, each and every step is documented, simple and plain instructions.

I have also the complete frame and the Hangprinter motion unit modeled in Fusion 360, which make it easy to do blueprint-like renders (á la e3d-online)

Let me know what do you think.

company website // portfolio // project gallery // instagram

|

Re: Hangprinter version 3 July 20, 2020 12:48PM |

Registered: 3 years ago Posts: 1 |

Hi all,

after doing a lot of testings and work i finally put my docs for Hangprinter online -> [wiki.fablabchemnitz.de]

and some video sources: [videos.stadtfabrikanten.org]

after doing a lot of testings and work i finally put my docs for Hangprinter online -> [wiki.fablabchemnitz.de]

and some video sources: [videos.stadtfabrikanten.org]

|

Re: Hangprinter version 3 July 20, 2020 03:26PM |

Admin Registered: 16 years ago Posts: 13,884 |

... great images!

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Hangprinter version 3 August 10, 2020 05:17PM |

Registered: 4 years ago Posts: 11 |

Quote

atmark

Quote

pvsfa

Also open to develop this further in different platforms if you got some ideas and a bit of time.

Ok, so the Hangprinter documentation could be maintained here [hangprinter.dozuki.com]

Personally, I like the style Prusa and e3d-online are doing. Lots of images, each and every step is documented, simple and plain instructions.

I have also the complete frame and the Hangprinter motion unit modeled in Fusion 360, which make it easy to do blueprint-like renders (á la e3d-online)

Let me know what do you think.

Hey!

sorry been busy with life

just looked at the link and it seems quite empty to me..?

But would definitely be happy if someting with nice pictures and step by step was available

also would still love to build your transportable stand for hangprinter. would you have a moment to put out BOM and instructions?

cheers

mizu

|

Re: Hangprinter version 3 August 10, 2020 05:19PM |

Registered: 4 years ago Posts: 11 |

Quote

leyghis

Hi all,

after doing a lot of testings and work i finally put my docs for Hangprinter online -> [wiki.fablabchemnitz.de]

and some video sources: [videos.stadtfabrikanten.org]

Hey!

nice build!

these are some great resources too!

would you mind posting a link to this thread:

[reprap.org]

i started it specifically for instructions and tips purposes

keep it up!

mizu

|

Re: Hangprinter version 3 August 13, 2020 01:21AM |

Registered: 8 years ago Posts: 96 |

Hi

Well, yes, the dozuki site is empty since I haven't got the time to document stuff there. Doing proper documentation is a whole new project and unfortunately something you can't get done in only a moment. I've always had the plan to open source the frame and that will also happen, but currently I'm too busy with another project.

So, maybe in winter when I get more spare time

company website // portfolio // project gallery // instagram

Well, yes, the dozuki site is empty since I haven't got the time to document stuff there. Doing proper documentation is a whole new project and unfortunately something you can't get done in only a moment. I've always had the plan to open source the frame and that will also happen, but currently I'm too busy with another project.

So, maybe in winter when I get more spare time

company website // portfolio // project gallery // instagram

Sorry, only registered users may post in this forum.