Hangprinter version 3

Posted by tobben

|

Re: Hangprinter version 3 December 07, 2017 01:22PM |

Registered: 6 years ago Posts: 48 |

|

Re: Hangprinter version 3 December 07, 2017 10:45PM |

Registered: 6 years ago Posts: 2 |

|

Re: Hangprinter version 3 December 11, 2017 08:00PM |

Registered: 6 years ago Posts: 48 |

|

Re: Hangprinter version 3 December 11, 2017 09:15PM |

Registered: 6 years ago Posts: 48 |

So it's hanging can we get some photos of the way the ankers are attached to the hanger and how the hanger is tied to the 3 d lines.

[photos.app.goo.gl]

[photos.app.goo.gl]

|

Re: Hangprinter version 3 December 12, 2017 09:20AM |

Registered: 10 years ago Posts: 401 |

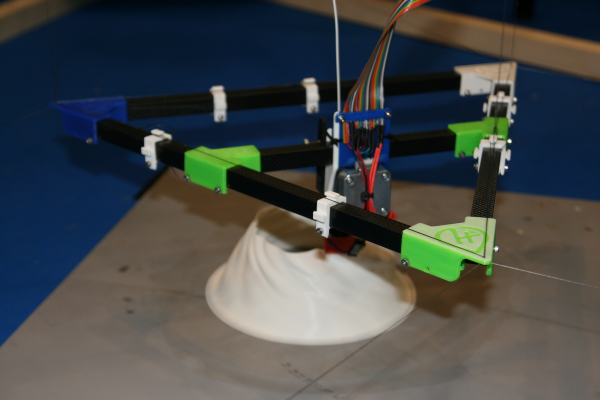

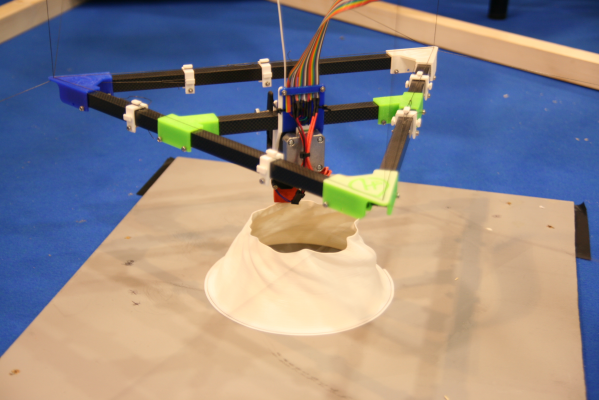

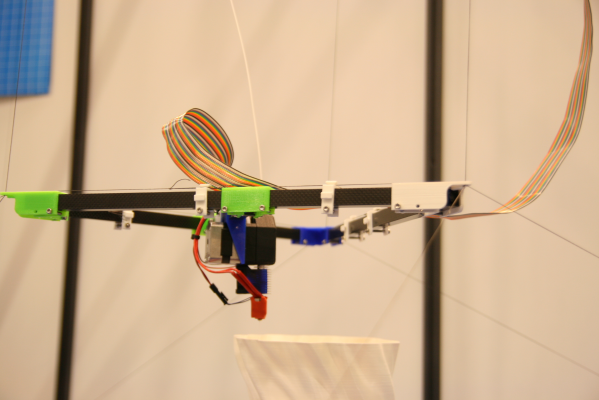

Ok, these ones are the best I have right now:

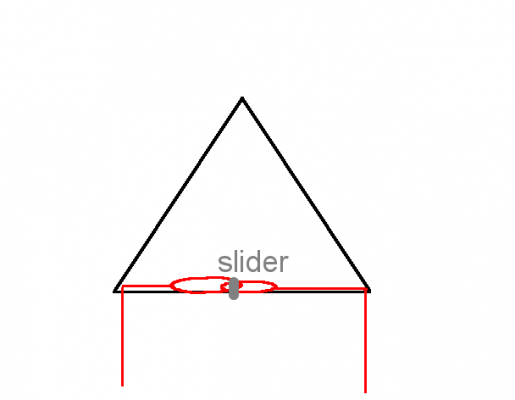

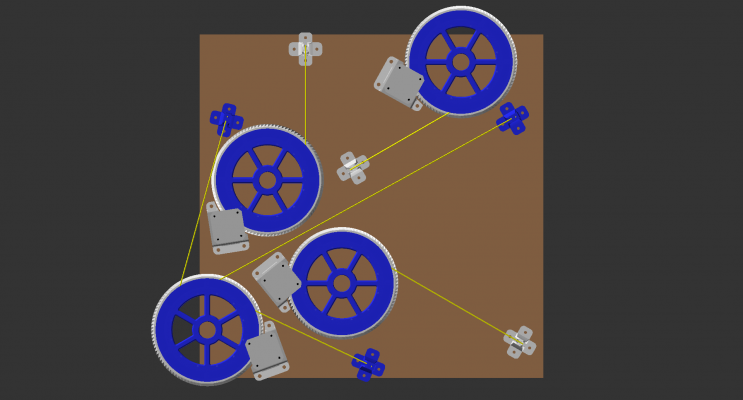

Basically one pair of for example A-lines enters their closest corner_clamps from below. They then turn 90 degrees towards each other and meet on the upper side of the beam. Tie a loop in the ends of each A-line and attach both to the same beam slider. Slide that beam slider back and forth until your mover is in parallel with your A-anchor linerollers. An attempt to visualize A-line routing from above using Tux Paint:

D-lines enter corner_clamps from above, through the same hole as ABC-lines. Thread D-lines through the tunnel+track and attach (on the inside of the beam) each D-line to its own beam slider. Slide the D-sliders back and forth until your mover is level/horizontal.

Lastly tighten the screws of all six beam sliders.

Edited 1 time(s). Last edit at 12/12/2017 09:44AM by tobben.

torbjornludvigsen.com

Basically one pair of for example A-lines enters their closest corner_clamps from below. They then turn 90 degrees towards each other and meet on the upper side of the beam. Tie a loop in the ends of each A-line and attach both to the same beam slider. Slide that beam slider back and forth until your mover is in parallel with your A-anchor linerollers. An attempt to visualize A-line routing from above using Tux Paint:

D-lines enter corner_clamps from above, through the same hole as ABC-lines. Thread D-lines through the tunnel+track and attach (on the inside of the beam) each D-line to its own beam slider. Slide the D-sliders back and forth until your mover is level/horizontal.

Lastly tighten the screws of all six beam sliders.

Edited 1 time(s). Last edit at 12/12/2017 09:44AM by tobben.

torbjornludvigsen.com

|

Re: Hangprinter version 3 December 12, 2017 10:50AM |

Registered: 10 years ago Posts: 401 |

Some people have asked for better guidance on the ceiling unit layout. I have hesitated with publishing this layout, because D-linerollers are the only ones that need to be placed out precisely. They should be placed out using the alignment methods documented earlier in this thread.

Anyways, I made an orthogonal render png in Openscad:

torbjornludvigsen.com

Anyways, I made an orthogonal render png in Openscad:

torbjornludvigsen.com

|

Re: Hangprinter version 3 December 12, 2017 09:41PM |

Registered: 6 years ago Posts: 48 |

|

Re: Hangprinter version 3 December 13, 2017 12:25PM |

Registered: 6 years ago Posts: 48 |

|

Re: Hangprinter version 3 December 13, 2017 04:38PM |

Registered: 6 years ago Posts: 48 |

|

Re: Hangprinter version 3 December 14, 2017 08:34AM |

Registered: 10 years ago Posts: 401 |

We've been using 0.8 and 1.2 nozzles. We've used 1.75 mm filament, but 3 mm is fine too. Speeds from 20 to 60 mm/s. I recommend big layer heigths (> 0.5 mm). Otherwise use same settings as with other printers, just remember to set the correct nozzle size. And be aware that big solid first layers are hard to print. Consider if you can get by with 0 solid first layers.

Regards,

torbjornludvigsen.com

Regards,

torbjornludvigsen.com

|

Re: Hangprinter version 3 December 14, 2017 09:06AM |

Registered: 6 years ago Posts: 48 |

|

Re: Hangprinter version 3 December 14, 2017 02:44PM |

Registered: 6 years ago Posts: 48 |

|

Re: Hangprinter version 3 December 14, 2017 03:29PM |

Registered: 6 years ago Posts: 48 |

|

Re: Hangprinter version 3 December 16, 2017 09:31PM |

Registered: 6 years ago Posts: 48 |

So it's moving will be printing tomorrow [photos.app.goo.gl]

|

Re: Hangprinter version 3 December 17, 2017 05:20AM |

Registered: 10 years ago Posts: 401 |

Cool, good work! Looks like it's moving smoothly

Have you set up the i2c addresses on the Mechaduinos? If you have, then you should be able to use a few special gcodes if you want. Short crash course:

Torque mode: G95 A-30 should make A motor wind in line with a low force. G95 B-50 winds in B with high force. G95 A0 puts motor A back into step/dir mode. Test enabling torque mode on one motor at a time to see that the correct Mechaduino board receives the correct instruction. When you know all work, try issuing G95 A-35 B-35 C-35 D-35 which should allow you to drag the mover around by hand. Speeds up homing alot.

Some specials mostly used during auto-calibration:

G96 A B C D marks a reference point on encoder readings from ABCD motors. G97 A B C D reads out length travelled along each axis since your last reference point was put out. G98 A B C D saves the same values into the internal line_lengths variable in firmware. It assumes G96 was issued in origo at a time when lines were tight.

torbjornludvigsen.com

Have you set up the i2c addresses on the Mechaduinos? If you have, then you should be able to use a few special gcodes if you want. Short crash course:

Torque mode: G95 A-30 should make A motor wind in line with a low force. G95 B-50 winds in B with high force. G95 A0 puts motor A back into step/dir mode. Test enabling torque mode on one motor at a time to see that the correct Mechaduino board receives the correct instruction. When you know all work, try issuing G95 A-35 B-35 C-35 D-35 which should allow you to drag the mover around by hand. Speeds up homing alot.

Some specials mostly used during auto-calibration:

G96 A B C D marks a reference point on encoder readings from ABCD motors. G97 A B C D reads out length travelled along each axis since your last reference point was put out. G98 A B C D saves the same values into the internal line_lengths variable in firmware. It assumes G96 was issued in origo at a time when lines were tight.

torbjornludvigsen.com

|

Re: Hangprinter version 3 December 18, 2017 11:43PM |

Registered: 6 years ago Posts: 95 |

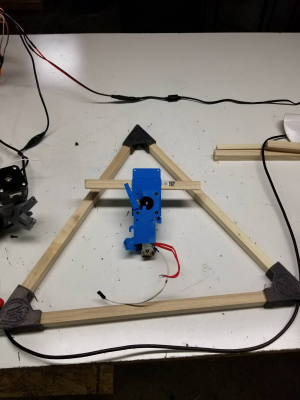

The build begins...

I have the mover and extruder all together. A note for the US builders, Lowe's stores have 5/8" square poplar stock. If you scale the mover parts up 2% they fit perfect. Now I am just waiting on some V groove bearings and I should be ready to go. I should have most of the top plate together this week. I am going to attempt to use the Prusa extruder design. If I can get his working, I will more than likely try to do another tutorial for version 3. Pretty excited for this one.

Chris

[www.youtube.com]

I have the mover and extruder all together. A note for the US builders, Lowe's stores have 5/8" square poplar stock. If you scale the mover parts up 2% they fit perfect. Now I am just waiting on some V groove bearings and I should be ready to go. I should have most of the top plate together this week. I am going to attempt to use the Prusa extruder design. If I can get his working, I will more than likely try to do another tutorial for version 3. Pretty excited for this one.

Chris

[www.youtube.com]

|

Re: Hangprinter version 3 December 19, 2017 09:04AM |

Registered: 6 years ago Posts: 48 |

|

Re: Hangprinter version 3 December 19, 2017 09:19AM |

Registered: 10 years ago Posts: 401 |

which is about 12 - 13% of the total mover weight. Wood is easier to work with since you can drill into it. Carbon fiber (and a very light extruder) is a good option if you plan to print close to the edges of the reachable print volume. I also think carbon fiber beams look good and feel good, but this is highly subjective.

I've never noticed a difference in print quality between my wood-beam movers and my carbon fiber movers, but if I pushed them to the limits, I guess carbon fiber would win by a few millimeters extra corner-case accuracy.

Edited 1 time(s). Last edit at 12/19/2017 09:20AM by tobben.

torbjornludvigsen.com

I've never noticed a difference in print quality between my wood-beam movers and my carbon fiber movers, but if I pushed them to the limits, I guess carbon fiber would win by a few millimeters extra corner-case accuracy.

Edited 1 time(s). Last edit at 12/19/2017 09:20AM by tobben.

torbjornludvigsen.com

|

Re: Hangprinter version 3 December 23, 2017 07:22AM |

Registered: 10 years ago Posts: 401 |

Hi all!

I CADded an experimental zip tie based corner_clamp. I won't be able to test it myself during Christmas, but here it is: [github.com]

Also, I added an untested nut trap to beam_slider. Feel free: [github.com]

torbjornludvigsen.com

I CADded an experimental zip tie based corner_clamp. I won't be able to test it myself during Christmas, but here it is: [github.com]

Also, I added an untested nut trap to beam_slider. Feel free: [github.com]

torbjornludvigsen.com

|

Re: Hangprinter version 3 December 27, 2017 03:49PM |

Registered: 6 years ago Posts: 14 |

Hi All,

I am located in Los Angeles. I'm going to be diving into a build soon. I'm trying to document and improve the build process. I have called the berkley filerline manufacture in the US. In converting the line used the .5 line is 110lbs test and it is not made or available in any way in the US. I'm reaching out to the UK and Germany to see about getting some and I will be talking to a hollywood stunt coordinator to see if there is a reasonably priced alternative here. Is there anyone in the US that is interested if I can get it imported?

Thank you

I am located in Los Angeles. I'm going to be diving into a build soon. I'm trying to document and improve the build process. I have called the berkley filerline manufacture in the US. In converting the line used the .5 line is 110lbs test and it is not made or available in any way in the US. I'm reaching out to the UK and Germany to see about getting some and I will be talking to a hollywood stunt coordinator to see if there is a reasonably priced alternative here. Is there anyone in the US that is interested if I can get it imported?

Thank you

|

Re: Hangprinter version 3 December 27, 2017 03:59PM |

Registered: 6 years ago Posts: 14 |

Tobben,

My CF tubes are 500 & 300mm. If I make the mover ( FH = Flying Head ), I will use this convention going forward, without cutting them down what changes? Understanding the board layout changes for the size difference. Is there any thing else I will need to do for a different size FH it will it be accounted for during the calibration? Also I have ordered the Silent Step Sticks I should have them soon. Are they supported in the current Marlin you have in git? I hope to order Mechaduinos in the next 45 days.

Thank you

My CF tubes are 500 & 300mm. If I make the mover ( FH = Flying Head ), I will use this convention going forward, without cutting them down what changes? Understanding the board layout changes for the size difference. Is there any thing else I will need to do for a different size FH it will it be accounted for during the calibration? Also I have ordered the Silent Step Sticks I should have them soon. Are they supported in the current Marlin you have in git? I hope to order Mechaduinos in the next 45 days.

Thank you

|

Re: Hangprinter version 3 December 27, 2017 04:13PM |

Registered: 6 years ago Posts: 14 |

@dc42

I will be heavily documenting my build - If you want to lend or donate a controller I'd be glad to test it. I'm going to design a pre-done board layout and try to come up with a CNC pattern. I already have a slide in mount for stock Arduino / Ramps, so exchanging the electronics is 1 optional screw besides the terminals. I could do the same for the Duet WiFi. I also have a similar mount for the Raspberry Pi. The board also will include handles and a ceiling pre-mount system. You mount the Pre-mount to the ceiling and mount the "main board" to the pre-mount in a slide in manner. OSMS . - Overhead Speed Mounting System

Thank you

I will be heavily documenting my build - If you want to lend or donate a controller I'd be glad to test it. I'm going to design a pre-done board layout and try to come up with a CNC pattern. I already have a slide in mount for stock Arduino / Ramps, so exchanging the electronics is 1 optional screw besides the terminals. I could do the same for the Duet WiFi. I also have a similar mount for the Raspberry Pi. The board also will include handles and a ceiling pre-mount system. You mount the Pre-mount to the ceiling and mount the "main board" to the pre-mount in a slide in manner. OSMS . - Overhead Speed Mounting System

Thank you

|

Re: Hangprinter version 3 December 27, 2017 05:40PM |

Registered: 10 years ago Posts: 401 |

Hello and welcome 3dprintgeek!

Just measure distances between pivot points as usual when calibrating.

Just measure distances between pivot points as usual when calibrating.

torbjornludvigsen.com

You should not have to do anything differentlyQuote

3dprintgeek

Is there any thing else I will need to do for a different size FH it will it be accounted for during the calibration?

Just measure distances between pivot points as usual when calibrating.

Just measure distances between pivot points as usual when calibrating.Yes, both tmc2130SSS and Mechaduinos are supported in HangprinterMarlin. Be sure to use the Openscad_version_3 branch.Quote

3dprintgeek

Are [tmc2130SilentStepSticks] supported in the current Marlin you have in git?

torbjornludvigsen.com

|

Re: Hangprinter version 3 December 27, 2017 05:57PM |

Registered: 10 years ago Posts: 14,672 |

Quote

3dprintgeek

@dc42

I will be heavily documenting my build - If you want to lend or donate a controller I'd be glad to test it. I'm going to design a pre-done board layout and try to come up with a CNC pattern. I already have a slide in mount for stock Arduino / Ramps, so exchanging the electronics is 1 optional screw besides the terminals. I could do the same for the Duet WiFi. I also have a similar mount for the Raspberry Pi. The board also will include handles and a ceiling pre-mount system. You mount the Pre-mount to the ceiling and mount the "main board" to the pre-mount in a slide in manner. OSMS . - Overhead Speed Mounting System

Thank you

Hi 3dprintgeek,

I'm discussing this with my colleagues and we will get back to you. Are you planning to use conventional stepper motors, or Mechaduinos? If you use Mechaduinos then I guess you wouldn't benefit from the high microstepping TMC2660 drivers on the Duet.

Regards David

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Hangprinter version 3 December 27, 2017 08:36PM |

Registered: 6 years ago Posts: 14 |

David,

I will be building and documenting the builds with stock ramps, and motors first, I will also do Silent step-sticks, and Mechaduinos later if they are still in stock when I'm ready. While providing some excellent features to the hang printer I feel they will for a while be the most exotic build. They require more electronics skill and knowledge than the other builds and the greatest cost. They were on back order for a long time. I also have a install made of Ubuntu Mate with remote access setup on the Raspberry Pi, by passing the need for Octoprint. It allows for the use of many more software options, not that there is anything wrong with Octoprint. i just like more options. I like the option to customize. If you wish to have me include the Duet I will work on documenting a build with it second, placing it before the steps-sticks. I feel it will much easier to take advantage of working with TMC2660s by remoting into the Pi.

Thank you

I will be building and documenting the builds with stock ramps, and motors first, I will also do Silent step-sticks, and Mechaduinos later if they are still in stock when I'm ready. While providing some excellent features to the hang printer I feel they will for a while be the most exotic build. They require more electronics skill and knowledge than the other builds and the greatest cost. They were on back order for a long time. I also have a install made of Ubuntu Mate with remote access setup on the Raspberry Pi, by passing the need for Octoprint. It allows for the use of many more software options, not that there is anything wrong with Octoprint. i just like more options. I like the option to customize. If you wish to have me include the Duet I will work on documenting a build with it second, placing it before the steps-sticks. I feel it will much easier to take advantage of working with TMC2660s by remoting into the Pi.

Thank you

|

Re: Hangprinter version 3 December 27, 2017 09:02PM |

Registered: 6 years ago Posts: 14 |

@Tobben,

Thank you - I will be up soonish as I have what I think are the last parts coming Friday. I have all of my parts printed. I look forward to getting the printer in a useable state. The only hang up is the fireline. Here in the states we have much weaker variants of it, so i will probably start with .38 but hope to import from the UK or find something similar in the US. i suspect it's a safety standards issue here. We are no longer allowed to run with sharp objects. I have been involved with learning from the people who put a man on the moon and we have been reduced to, we will choose what is good for you and then tell you to like it. I will keep you informed as to what is happening.

Thank you

Thank you - I will be up soonish as I have what I think are the last parts coming Friday. I have all of my parts printed. I look forward to getting the printer in a useable state. The only hang up is the fireline. Here in the states we have much weaker variants of it, so i will probably start with .38 but hope to import from the UK or find something similar in the US. i suspect it's a safety standards issue here. We are no longer allowed to run with sharp objects. I have been involved with learning from the people who put a man on the moon and we have been reduced to, we will choose what is good for you and then tell you to like it. I will keep you informed as to what is happening.

Thank you

|

Re: Hangprinter version 3 December 28, 2017 12:31AM |

Registered: 6 years ago Posts: 48 |

We used this it's working fine Piscifun PE Braided Fishing Line 547Yd Blue 120lb Test [www.amazon.com]

|

Re: Hangprinter version 3 December 28, 2017 03:06AM |

Registered: 6 years ago Posts: 14 |

|

Re: Hangprinter version 3 December 28, 2017 06:14AM |

Registered: 6 years ago Posts: 14 |

I found this article describing braid vs fused -

[www.in-fisherman.com]

I'm still working on how to get Fireline in the US.

Thank you

[www.in-fisherman.com]

I'm still working on how to get Fireline in the US.

Thank you

|

Re: Hangprinter version 3 December 28, 2017 03:55PM |

Registered: 6 years ago Posts: 48 |

Sorry, only registered users may post in this forum.