|

Re: Hangprinter version 3 December 28, 2017 04:25PM |

Registered: 6 years ago Posts: 48 |

After talking to the peopleay Berkeley this is the stuff they recommend for 50 pound test

Berkley ProSpec Chrome [www.amazon.com]

Edited 3 time(s). Last edit at 12/28/2017 04:44PM by delloman.

Berkley ProSpec Chrome [www.amazon.com]

Edited 3 time(s). Last edit at 12/28/2017 04:44PM by delloman.

|

Re: Hangprinter version 3 December 28, 2017 04:27PM |

Registered: 10 years ago Posts: 14,672 |

Quote

3dprintgeek

David,

I will be building and documenting the builds with stock ramps, and motors first, I will also do Silent step-sticks, and Mechaduinos later if they are still in stock when I'm ready. While providing some excellent features to the hang printer I feel they will for a while be the most exotic build. They require more electronics skill and knowledge than the other builds and the greatest cost. They were on back order for a long time. I also have a install made of Ubuntu Mate with remote access setup on the Raspberry Pi, by passing the need for Octoprint. It allows for the use of many more software options, not that there is anything wrong with Octoprint. i just like more options. I like the option to customize. If you wish to have me include the Duet I will work on documenting a build with it second, placing it before the steps-sticks. I feel it will much easier to take advantage of working with TMC2660s by remoting into the Pi.

Thank you

Thanks for responding. A Duet WiFi is on its way to you. I look forward to hearing of your experiences with it in a Hangprinter.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Hangprinter version 3 December 28, 2017 06:59PM |

Registered: 6 years ago Posts: 14 |

|

Re: Hangprinter version 3 December 28, 2017 07:09PM |

Registered: 6 years ago Posts: 14 |

|

Re: Hangprinter version 3 December 29, 2017 11:35AM |

Registered: 10 years ago Posts: 401 |

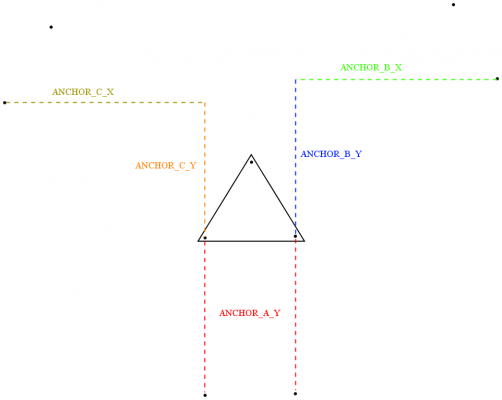

Assuming the figures show the mover from above, I try to aim for Fig. 2, but it works either way.

With Fig 2 configuration, ANCHOR_C_X gets a negative sign, with Fig 1 configuration ANCHOR_B_X gets a negative sign...

torbjornludvigsen.com

With Fig 2 configuration, ANCHOR_C_X gets a negative sign, with Fig 1 configuration ANCHOR_B_X gets a negative sign...

torbjornludvigsen.com

|

Re: Hangprinter version 3 December 29, 2017 02:52PM |

Registered: 6 years ago Posts: 14 |

Tobben,

Thank you for that information.

I watched the HP build videos. This is where the questions are coming from as I get ready to document things and create standards I hope will make it easier to understand the build. Below is a poorly constructed image of the anchors. This approximates the way things were laid out when you measured for the calibration. I was really unclear on what was getting measured. Can you explain it here?

Thank you

Edited 1 time(s). Last edit at 12/29/2017 02:54PM by 3dprintgeek.

Thank you for that information.

I watched the HP build videos. This is where the questions are coming from as I get ready to document things and create standards I hope will make it easier to understand the build. Below is a poorly constructed image of the anchors. This approximates the way things were laid out when you measured for the calibration. I was really unclear on what was getting measured. Can you explain it here?

Thank you

Edited 1 time(s). Last edit at 12/29/2017 02:54PM by 3dprintgeek.

|

Re: Hangprinter version 3 December 29, 2017 06:39PM |

Registered: 10 years ago Posts: 401 |

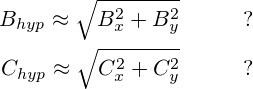

Seen from above, I measured this (B and C might be mirrored, I don't remember):

As a sanity check, I measured the hypothenuses to the B and C anchors, and compared:

The sanity check was ca 10 mm off in both cases.

torbjornludvigsen.com

As a sanity check, I measured the hypothenuses to the B and C anchors, and compared:

The sanity check was ca 10 mm off in both cases.

torbjornludvigsen.com

|

Re: Hangprinter version 3 December 30, 2017 12:07PM |

Registered: 6 years ago Posts: 14 |

|

Re: Hangprinter version 3 January 27, 2018 05:50PM |

Registered: 6 years ago Posts: 95 |

It's alive! I should be up and printing soon, but everything is mounted and moving.

Hang v3 [imgur.com]

[www.youtube.com]

Edited 1 time(s). Last edit at 01/27/2018 05:52PM by brotherchris.

Hang v3 [imgur.com]

[www.youtube.com]

Edited 1 time(s). Last edit at 01/27/2018 05:52PM by brotherchris.

|

Re: Hangprinter version 3 January 27, 2018 07:08PM |

Registered: 10 years ago Posts: 401 |

|

Re: Hangprinter version 3 January 31, 2018 03:31AM |

Registered: 6 years ago Posts: 14 |

I just added this part for using the Duet WiFi on the Hang Printer to Thingiverse:

[www.thingiverse.com]

I still need to test print the parts.

Enjoy

Thank you

[www.thingiverse.com]

I still need to test print the parts.

Enjoy

Thank you

|

Re: Hangprinter version 3 February 01, 2018 10:53AM |

Registered: 6 years ago Posts: 95 |

|

Re: Hangprinter version 3 February 02, 2018 12:47PM |

Registered: 10 years ago Posts: 401 |

|

Re: Hangprinter version 3 February 02, 2018 02:08PM |

Registered: 6 years ago Posts: 95 |

|

Re: Hangprinter version 3 February 04, 2018 11:06AM |

Registered: 6 years ago Posts: 95 |

|

Re: Hangprinter version 3 February 04, 2018 05:17PM |

Registered: 10 years ago Posts: 401 |

Cool! I just viewed 4 minutes right now, will watch the rest tomorrow morning.

I had an experience with a cheap 12V 10A power supply a couple of days ago. It over heated after 30-40 minutes of printing and rebooted my Mega and Mechaduinos. This has never happened when I've used sanely configured stepstick drivers. Should it happen to you, try decreasing motor currents slightly.

I increased the recommendation in the BOM from 10 A to 12.5 A just now to reflect my new experience.

torbjornludvigsen.com

I had an experience with a cheap 12V 10A power supply a couple of days ago. It over heated after 30-40 minutes of printing and rebooted my Mega and Mechaduinos. This has never happened when I've used sanely configured stepstick drivers. Should it happen to you, try decreasing motor currents slightly.

I increased the recommendation in the BOM from 10 A to 12.5 A just now to reflect my new experience.

torbjornludvigsen.com

|

Re: Hangprinter version 3 February 04, 2018 09:26PM |

Registered: 6 years ago Posts: 95 |

|

Re: Hangprinter version 3 February 05, 2018 02:09PM |

Registered: 10 years ago Posts: 401 |

Hey, I watched through it now. It's very clear and gets an amazing amount of detail just right!

Placing the front of the ABC anchor linerollers flush with the anchor mount edge is a good tip for easier calibration later. I recommend also cutting the PTFE tube flush with the printed part front. It gives a sturdier exit point for the line, and a more defined point to measure during calibration.

torbjornludvigsen.com

Placing the front of the ABC anchor linerollers flush with the anchor mount edge is a good tip for easier calibration later. I recommend also cutting the PTFE tube flush with the printed part front. It gives a sturdier exit point for the line, and a more defined point to measure during calibration.

torbjornludvigsen.com

|

Re: Hangprinter version 3 February 05, 2018 03:19PM |

Registered: 6 years ago Posts: 95 |

|

Re: Hangprinter version 3 February 06, 2018 05:21PM |

Registered: 6 years ago Posts: 5 |

Hi All,

I’ll keep it short. First really great work from Toben with this idea. I built a kit (bfb rapman) long ago and wasn’t very pleased with the overall experience mainly because of the poor design on the extruder and also because the board died. Back then I upgraded the machine with arduino_ramps_marlin and I succeeded. Anyways I’m looking again into 3d printing and I’m really excited since there has been great developments.

I’ve been reading the threat and GitHub before trying to build a Hangprinter. The printer (monoprice select mini) which I’m going to use for the parts has 120mmx120mm bed size so I modified the scad files to make the spool_gear 80 teeth and motor_gear 8 teeth (keeping it 1:10), spool_r 36. Besides writing into the firmware the new spool_r what else do I have to change to keep everything working? I’ll be sacrificing too much quality? Is there anything else I’m missing here?

Thanks

I’ll keep it short. First really great work from Toben with this idea. I built a kit (bfb rapman) long ago and wasn’t very pleased with the overall experience mainly because of the poor design on the extruder and also because the board died. Back then I upgraded the machine with arduino_ramps_marlin and I succeeded. Anyways I’m looking again into 3d printing and I’m really excited since there has been great developments.

I’ve been reading the threat and GitHub before trying to build a Hangprinter. The printer (monoprice select mini) which I’m going to use for the parts has 120mmx120mm bed size so I modified the scad files to make the spool_gear 80 teeth and motor_gear 8 teeth (keeping it 1:10), spool_r 36. Besides writing into the firmware the new spool_r what else do I have to change to keep everything working? I’ll be sacrificing too much quality? Is there anything else I’m missing here?

Thanks

|

Re: Hangprinter version 3 February 06, 2018 07:03PM |

Registered: 10 years ago Posts: 401 |

If you use the stock Marlin, you can set exactly those things you have changed (radii and #teeth)  See: [github.com]

See: [github.com]

If you use good old HangprinterMarlin you will get away with only setting radii, since you kept 1:10 teeth.

You risk getting too much line buildup with so small spools. I recommend the 0.36 mm FireLine instead of the 0.5 mm one. Set spool buildup factor accordingly. Mount as short lines as you can, even if this limits your print volume. (And specify mounted line accordingly.)

When mounted, test carefully that the individual axes feed the exact amount of line that you tell it to feed. This can be done with G1 or torque mode (G95). HangprinterMarlin also has G7 which will take spool buildup into account. G6 will ignore buildup, so it can't be used for testing axes' accuracy.

Looking forward to see your build!

torbjornludvigsen.com

See: [github.com]

See: [github.com]If you use good old HangprinterMarlin you will get away with only setting radii, since you kept 1:10 teeth.

You risk getting too much line buildup with so small spools. I recommend the 0.36 mm FireLine instead of the 0.5 mm one. Set spool buildup factor accordingly. Mount as short lines as you can, even if this limits your print volume. (And specify mounted line accordingly.)

When mounted, test carefully that the individual axes feed the exact amount of line that you tell it to feed. This can be done with G1 or torque mode (G95). HangprinterMarlin also has G7 which will take spool buildup into account. G6 will ignore buildup, so it can't be used for testing axes' accuracy.

Looking forward to see your build!

torbjornludvigsen.com

|

Re: Hangprinter version 3 February 07, 2018 12:38AM |

Registered: 6 years ago Posts: 48 |

|

Re: Hangprinter version 3 February 07, 2018 06:33AM |

Registered: 10 years ago Posts: 401 |

I'm sitting with the stock Marlin code now and noticed I had implemented "G6 S2" that will take spool buildup into account (like G7 does in HangprinterMarlin). Had just forgotten to document it...

Delloman is right, so if you don't have Mechaduinos, you must use G7 or G6 S2 to calibrate individual axes.

torbjornludvigsen.com

Delloman is right, so if you don't have Mechaduinos, you must use G7 or G6 S2 to calibrate individual axes.

torbjornludvigsen.com

|

Re: Hangprinter version 3 February 07, 2018 08:40AM |

Registered: 6 years ago Posts: 5 |

|

Re: Hangprinter version 3 February 08, 2018 03:52PM |

Registered: 6 years ago Posts: 95 |

|

Re: Hangprinter version 3 February 09, 2018 04:33AM |

Registered: 10 years ago Posts: 401 |

Hi Chris,

That is just a convention. It is chosen quite at random, but establishing a convention has been useful. It makes possible a sanity check of anchor calibration value signs at compile time (feature in Configuration.h). It also makes it easier to write auto-calibration code that works for everyone. Putting constraints on the non-linear solver, like here, makes it converge faster and in more predictable ways.

Only if we use computer vision in our auto anchor calibration procedure can we throw away conventions about motor order. In that case, we can even put ABC motors on any of the XYZ motor connectors. Not having to track our ABC spools during build would be nice... Let's cheer for @fredrudolf's computer vision work, using PI + PI Cam to calibrate

torbjornludvigsen.com

That is just a convention. It is chosen quite at random, but establishing a convention has been useful. It makes possible a sanity check of anchor calibration value signs at compile time (feature in Configuration.h). It also makes it easier to write auto-calibration code that works for everyone. Putting constraints on the non-linear solver, like here, makes it converge faster and in more predictable ways.

Only if we use computer vision in our auto anchor calibration procedure can we throw away conventions about motor order. In that case, we can even put ABC motors on any of the XYZ motor connectors. Not having to track our ABC spools during build would be nice... Let's cheer for @fredrudolf's computer vision work, using PI + PI Cam to calibrate

torbjornludvigsen.com

|

Re: Hangprinter version 3 February 09, 2018 05:21PM |

Registered: 6 years ago Posts: 95 |

Thanks for the explanation.

Here is a link to the first v3 print vid.

It made it about 130mm before I had a motor skip and I had a layer shift. Probably mis calibration on my part. The first 130mm look way better than I expected, very nice print. In my firmware it looks like line build up is commented out, is that the new default? Or should I turn it on and calibrate it? I am still doing some tuning with the measuring tape. I will keep trying and report back. Let me know what you think.

[imgur.com]

[photos.app.goo.gl]

Chris

Here is a link to the first v3 print vid.

It made it about 130mm before I had a motor skip and I had a layer shift. Probably mis calibration on my part. The first 130mm look way better than I expected, very nice print. In my firmware it looks like line build up is commented out, is that the new default? Or should I turn it on and calibrate it? I am still doing some tuning with the measuring tape. I will keep trying and report back. Let me know what you think.

[imgur.com]

[photos.app.goo.gl]

Chris

|

Re: Hangprinter version 3 February 09, 2018 06:34PM |

Registered: 10 years ago Posts: 401 |

Thanks for notifying me. The buildup compensation is now back on by default.

The print looks great! Congrats! So well deserved!

So well deserved!

I think your wooden sheet (below the glass sheet in the video) can be a great print bed if you cover it in white glue. It's sometimes easier to distribute a thin layer of glue if you dilute it with a little water first.

torbjornludvigsen.com

The print looks great! Congrats!

So well deserved!

So well deserved!I think your wooden sheet (below the glass sheet in the video) can be a great print bed if you cover it in white glue. It's sometimes easier to distribute a thin layer of glue if you dilute it with a little water first.

torbjornludvigsen.com

|

Re: Hangprinter version 3 February 09, 2018 06:59PM |

Registered: 6 years ago Posts: 95 |

|

Re: Hangprinter version 3 February 10, 2018 06:32PM |

Registered: 6 years ago Posts: 15 |

Sorry, only registered users may post in this forum.