|

Concept for a tool changer effector January 05, 2019 04:49AM |

Registered: 8 years ago Posts: 96 |

Hey

I've been busy last year designing, building and testing the frame for Hangprinter. There are still issues to be solved, but eventually the frame will be ready for publishing. Up until that, I'd like to make a proposal for a new effector design. The concept builds on the tool changer idea of e3d. Although the tool changer isn't published yet, I wanted to think ahead how one could be fitted on the Hangprinter.

First the tool changer sled needs to be attached to the effector.

Second you need to consider how it grabs the tool.

Third we need a automatic storage & cleaning station for the tool heads.

Obviously, this is only the hardware part.

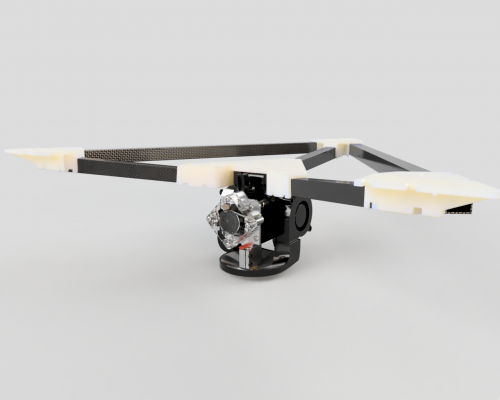

Here's a render of the assembly

As you can see, the front beam is missing. That's on purpose, since the triangle can't be a closed one. We need to route somehow the cables and bowden tubes (or whatever material feed) to a parking position. This will affect stability of the effector, but I'm hoping that the smaller center beams and the carrier plate will compensate it. It isn't tested yet though.

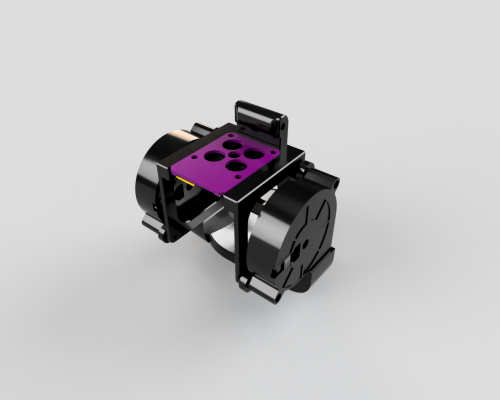

I also designed a compact extruder unit based on the Titan Aero and the Vulcano.

There's also a Precision Piezo Orion sensor which will enable Z-height probing with the nozzle.

And the part cooling is done by two radial fans, which will generate a vortex inside the fan duct (or at least I hope so). I've had many issues with braking fan ducts when they hit the print, so I decided to make the vulnerable parts out of metal sheets. Also for the sake making the duct as low as possible. Metal makes it also possible to bring the outlet as near as possible to the nozzle. This isn't tested yet either, so I can't say if its working the way I want it to.

One thing that need still some attention is the cable management on/within the extruder unit. I'd like to terminate all cables from hotend, thermistor etc. on a single PCB and route them through one single connector to the controller. The connector should be connecting only by contact, that means without any mechanical fixture. I'm having the tool changer in mind here as well. Please give me a hint, if you know of such connectors.

I've been busy last year designing, building and testing the frame for Hangprinter. There are still issues to be solved, but eventually the frame will be ready for publishing. Up until that, I'd like to make a proposal for a new effector design. The concept builds on the tool changer idea of e3d. Although the tool changer isn't published yet, I wanted to think ahead how one could be fitted on the Hangprinter.

First the tool changer sled needs to be attached to the effector.

Second you need to consider how it grabs the tool.

Third we need a automatic storage & cleaning station for the tool heads.

Obviously, this is only the hardware part.

Here's a render of the assembly

As you can see, the front beam is missing. That's on purpose, since the triangle can't be a closed one. We need to route somehow the cables and bowden tubes (or whatever material feed) to a parking position. This will affect stability of the effector, but I'm hoping that the smaller center beams and the carrier plate will compensate it. It isn't tested yet though.

I also designed a compact extruder unit based on the Titan Aero and the Vulcano.

There's also a Precision Piezo Orion sensor which will enable Z-height probing with the nozzle.

And the part cooling is done by two radial fans, which will generate a vortex inside the fan duct (or at least I hope so). I've had many issues with braking fan ducts when they hit the print, so I decided to make the vulnerable parts out of metal sheets. Also for the sake making the duct as low as possible. Metal makes it also possible to bring the outlet as near as possible to the nozzle. This isn't tested yet either, so I can't say if its working the way I want it to.

One thing that need still some attention is the cable management on/within the extruder unit. I'd like to terminate all cables from hotend, thermistor etc. on a single PCB and route them through one single connector to the controller. The connector should be connecting only by contact, that means without any mechanical fixture. I'm having the tool changer in mind here as well. Please give me a hint, if you know of such connectors.

|

Re: Concept for a tool changer effector January 25, 2020 05:19AM |

Registered: 8 years ago Posts: 96 |

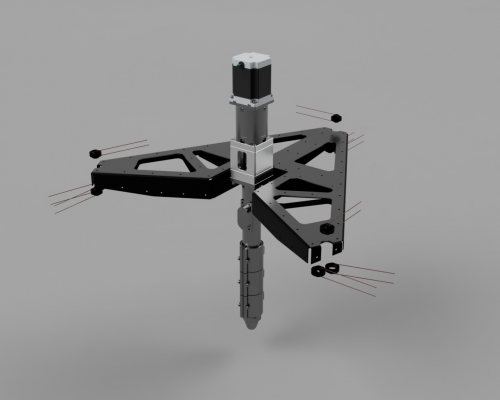

Finally, I got the chance to bring the end effector concept to the next level. I've been dealing with stability issues with the current version which you can see in the renders on top of this thread. The carbon fiber beams were fixed to the joint parts by zip ties, which are a quick and easy thing to work with, but you won't never get a stable joint by using them.

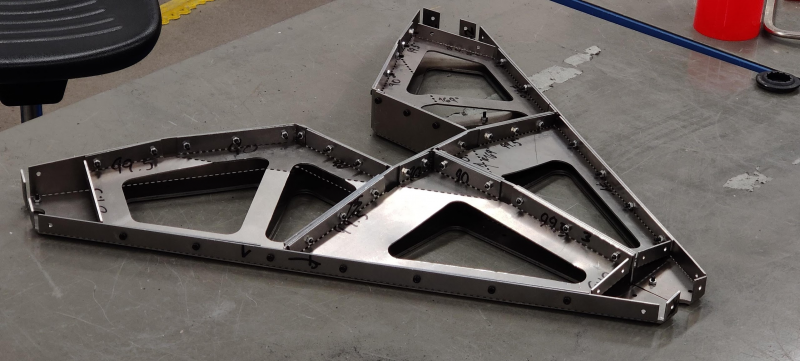

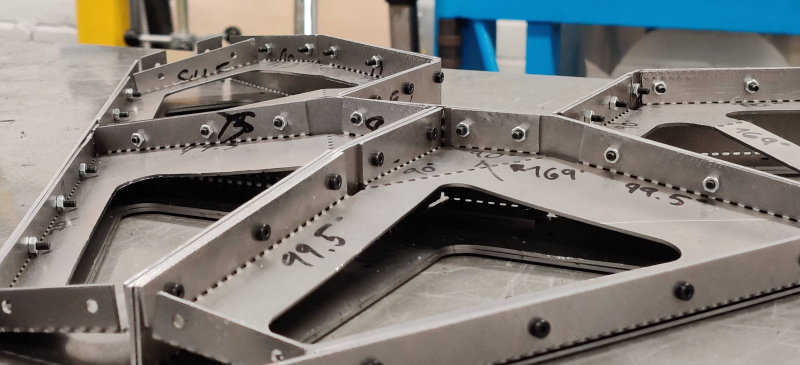

Now, that I am planning to attach a heavy pellet extruder on the end effector, torsional stability becomes a real concern. That's why I have designed an improved version of it using lasercut sheet metal. It consists of 8 parts, that have bend flanges for more rigidity and that are joined by rivets. The weight without an extruder will be around 1500 g, but it includes cnc machined aluminium blocks for the extruder attachment and the line guiding bearings. The sheet metal parts have slots along the bend lines, so you will be able to get a nice and correct bend also without heavy bending tools. The slots will self-guide the bend process.

Once tested (and maybe improved), I can take orders and make a small production series.

Check also the video about lasercutting

Now, that I am planning to attach a heavy pellet extruder on the end effector, torsional stability becomes a real concern. That's why I have designed an improved version of it using lasercut sheet metal. It consists of 8 parts, that have bend flanges for more rigidity and that are joined by rivets. The weight without an extruder will be around 1500 g, but it includes cnc machined aluminium blocks for the extruder attachment and the line guiding bearings. The sheet metal parts have slots along the bend lines, so you will be able to get a nice and correct bend also without heavy bending tools. The slots will self-guide the bend process.

Once tested (and maybe improved), I can take orders and make a small production series.

Check also the video about lasercutting

|

Re: Concept for a tool changer effector January 26, 2020 02:05PM |

Registered: 8 years ago Posts: 96 |

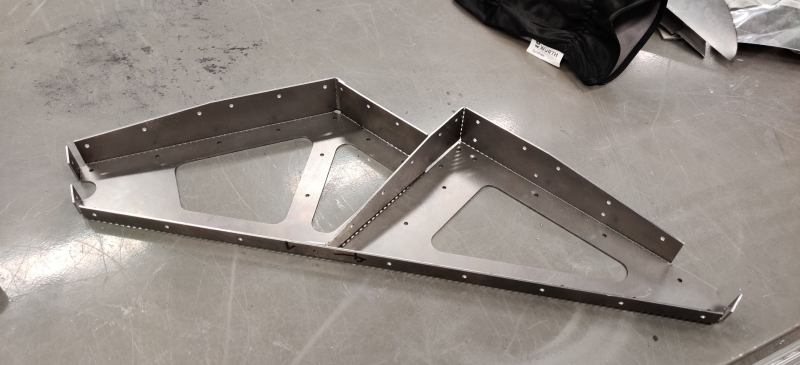

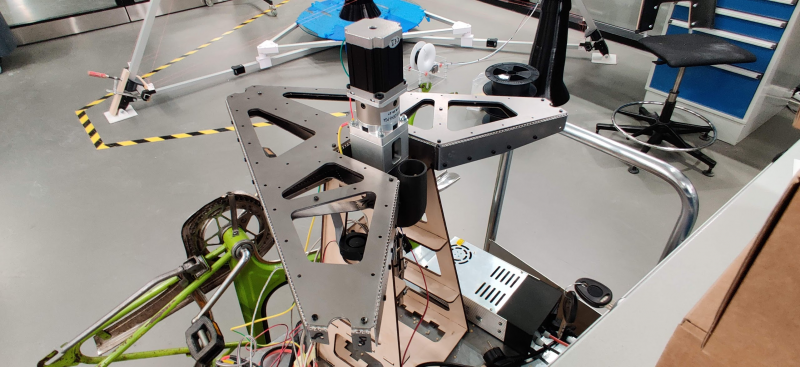

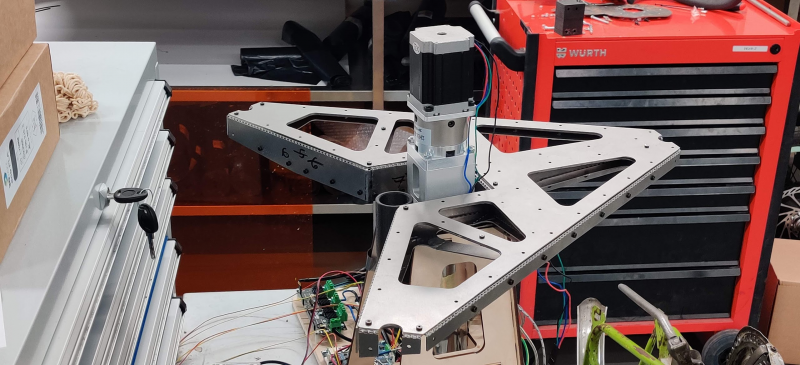

Well, this was fun  Incredible what you can do with lasercut sheet metal!

Incredible what you can do with lasercut sheet metal!

I choose 1.5 mm steel for this, but it turned out to be so sturdy, that 1 mm would have done it too. This is a beast of an end effector XD

Next step painting and then I'll swap the screws for rivets. And after that, I'm going to be able to concentrate on the corner pieces and the extruder holder.

I have parts for 3 extra end effectors, so if you're interested DM me and I'll notify you once everything is ready.

Incredible what you can do with lasercut sheet metal!

Incredible what you can do with lasercut sheet metal!I choose 1.5 mm steel for this, but it turned out to be so sturdy, that 1 mm would have done it too. This is a beast of an end effector XD

Next step painting and then I'll swap the screws for rivets. And after that, I'm going to be able to concentrate on the corner pieces and the extruder holder.

I have parts for 3 extra end effectors, so if you're interested DM me and I'll notify you once everything is ready.

Sorry, only registered users may post in this forum.