Two probes, Underbed for Z height and Z carriage mounted probe for leveling

Posted by leadinglights

|

Two probes, Underbed for Z height and Z carriage mounted probe for leveling July 04, 2020 11:40AM |

Registered: 12 years ago Posts: 1,450 |

I am investigating a new method of probing the build stage for leveling/compensation and for the Z height of the nozzle (or nozzles). I started on this in the general section of the forum [reprap.org] but I think that it should be in this Tech Talk section.

To rehash: Underbed sensors have been used and been found reliable as long as the force at which the sensor triggers is fairly high and the sensors are situated at or beyond the periphery of the bed. If however a higher degree of accuracy is required with a low speed of contact and triggering at low pressures, the dynamics of the plate become unpredictable. Having sensors mounted somewhat inside of the bed makes the situation more unpredictable still and a printer I am working on had a variation in the trigger from first contact ranging between 3 microns to over 50 microns. Part of the reason why this dynamic exists can be seen in a demonstration of "Chladni Plates" such as can be seen on [www.youtube.com] Although that is for a fixed frequency, a single pulse is not less complex in its behaviour.

To get around this I am using only a single underbed sensor and probing only directly above the sensor; a position where the dynamics of the plate are much less troublesome. To get the data for the rest of the bed for leveling or for compensation I am using a second sensor mounted on the print head assembly. Although a proximity sensor could be used I have chosen to use a touch sensor in the hope that this would have less variability than inductive, capacitive, or optical sensors.

Rather than use a simple microswitch I have used a sensor based on the same piezoelectric disks as I use in the underbed sensors. The piezo disk can be used as an analogue senseor so that any unusual behavior can be investigated. It is not necessary in this case to be able to deploy the device as is the case with BL-Touch type and servomotor switches as both of the nozzles can be retracted on my printer allowing the Z carriage to be lowered until contact is found.

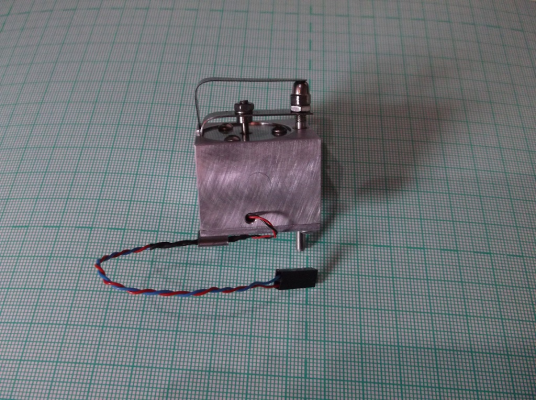

A Proof-of-Concept device has been constructed and is shown in the photo above. Early trials show that the repeatability of this device, or at least the repeatability of the distance from the first contact to triggering, of better than 1/4 of a micron can be expected.

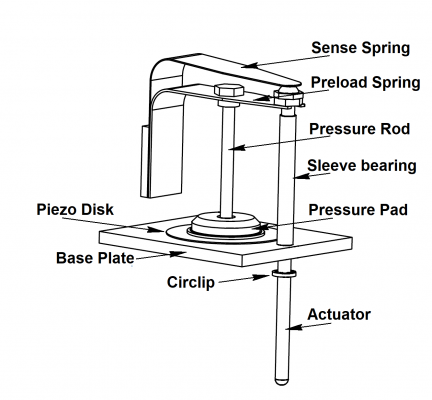

Edit: I have added a drawing to show the operation of the sensor. The body of the device has been omitted for clarity. The preload spring puts a pressure of ca 500 grams on the piezo disk through the pressure rod and pressure pad. The sense spring adds a further pressure of about 10 grams. When the actuator touches the bed there will be a reduction of pressure on the piezo disk

Any comments, suggestions, and constructive criticisms are welcomed.

Mike

Edited 1 time(s). Last edit at 07/05/2020 02:20PM by leadinglights.

To rehash: Underbed sensors have been used and been found reliable as long as the force at which the sensor triggers is fairly high and the sensors are situated at or beyond the periphery of the bed. If however a higher degree of accuracy is required with a low speed of contact and triggering at low pressures, the dynamics of the plate become unpredictable. Having sensors mounted somewhat inside of the bed makes the situation more unpredictable still and a printer I am working on had a variation in the trigger from first contact ranging between 3 microns to over 50 microns. Part of the reason why this dynamic exists can be seen in a demonstration of "Chladni Plates" such as can be seen on [www.youtube.com] Although that is for a fixed frequency, a single pulse is not less complex in its behaviour.

To get around this I am using only a single underbed sensor and probing only directly above the sensor; a position where the dynamics of the plate are much less troublesome. To get the data for the rest of the bed for leveling or for compensation I am using a second sensor mounted on the print head assembly. Although a proximity sensor could be used I have chosen to use a touch sensor in the hope that this would have less variability than inductive, capacitive, or optical sensors.

Rather than use a simple microswitch I have used a sensor based on the same piezoelectric disks as I use in the underbed sensors. The piezo disk can be used as an analogue senseor so that any unusual behavior can be investigated. It is not necessary in this case to be able to deploy the device as is the case with BL-Touch type and servomotor switches as both of the nozzles can be retracted on my printer allowing the Z carriage to be lowered until contact is found.

A Proof-of-Concept device has been constructed and is shown in the photo above. Early trials show that the repeatability of this device, or at least the repeatability of the distance from the first contact to triggering, of better than 1/4 of a micron can be expected.

Edit: I have added a drawing to show the operation of the sensor. The body of the device has been omitted for clarity. The preload spring puts a pressure of ca 500 grams on the piezo disk through the pressure rod and pressure pad. The sense spring adds a further pressure of about 10 grams. When the actuator touches the bed there will be a reduction of pressure on the piezo disk

Any comments, suggestions, and constructive criticisms are welcomed.

Mike

Edited 1 time(s). Last edit at 07/05/2020 02:20PM by leadinglights.

|

Re: Two probes, Underbed for Z height and Z carriage mounted probe for leveling August 15, 2020 06:04AM |

Registered: 12 years ago Posts: 1,450 |

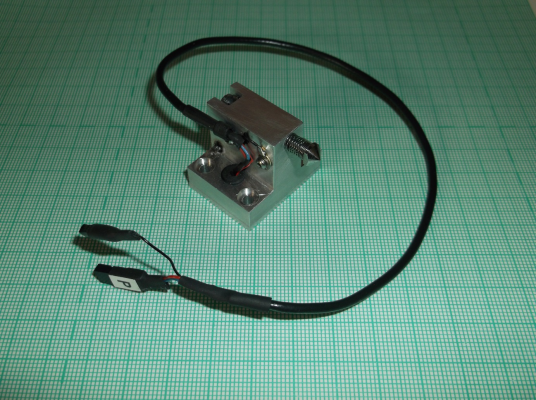

The latest touch probe (photograph below) is sensitive enough to detect the difference between being tapped with a clean metal bar and one with a fingerprint on the surface. I had not expected to see this kind of sensitivity, but it seems like it may be useful for finding problems like badly seated print surfaces etc.

I will put some details in this forum once I have got it running in conjunction with the twin head printing mechanism.

Mike

I will put some details in this forum once I have got it running in conjunction with the twin head printing mechanism.

Mike

|

Re: Two probes, Underbed for Z height and Z carriage mounted probe for leveling October 22, 2020 09:00PM |

Registered: 6 years ago Posts: 1 |

|

Re: Two probes, Underbed for Z height and Z carriage mounted probe for leveling October 23, 2020 01:20PM |

Registered: 12 years ago Posts: 1,450 |

@Mr_Huns, Thank you for your interest. The piezo sensor work is coming on well-ish insofar as it has not given me any unpleasant surprises. The sensor shown in that earlier photo can be seen installed on the Z carriage in [reprap.org]

I wish the rest of it was coming on as well as I seem to be fighting the twin demons of leaks and airlocks on the water cooling. I have just sidled silently away as it seems to be working well but I don't want to attract the attention of the gods of misfortune.

As far as better bed leveling methods go, I think that they all have their strengths and weaknesses - with the exception of accelerometer sensors which I can't find anything good about.

Mike

I wish the rest of it was coming on as well as I seem to be fighting the twin demons of leaks and airlocks on the water cooling. I have just sidled silently away as it seems to be working well but I don't want to attract the attention of the gods of misfortune.

As far as better bed leveling methods go, I think that they all have their strengths and weaknesses - with the exception of accelerometer sensors which I can't find anything good about.

Mike

|

Re: Two probes, Underbed for Z height and Z carriage mounted probe for leveling February 03, 2021 09:57AM |

Registered: 12 years ago Posts: 1,450 |

This project is going on a little slowly but mostly very positively. The accuracy and sensitivity are far better than needed in a 3D printer as the upper touch sensor is able to repeatably detect contact with less than 1 micron of variation. The improvements have mostly been in software with new algorithms for getting a good baseline, and for detecting drift and noise which would make the contact unreliable.

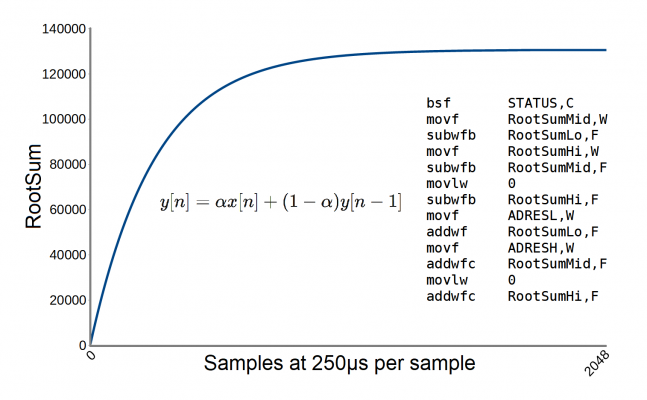

The new baseline algorithm is called an Exponential Moving Average and replaces the True Moving Average that I used in earlier software. The figure below shows the response to a step in input from 0 volts to the middle of the ADC input over a time of about 400 milliseconds. On the figure, there is also the equation and the PIC assembly code routine that generates it in only 13 instructions - a little more than 3 microseconds.

Another change is that the controller now reports if the baseline is steady before the probing operation takes place. This allows the host controller (Arduino etc.) to wait for the shaking from an XY movement to die down before a reading is taken.

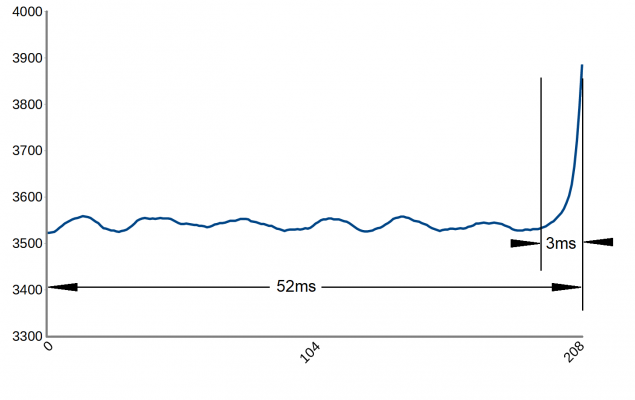

The second figure shows the response to a contact where the contact was at a nozzle speed of 2mm per second. The peak occurs within 3ms of initial contact and is repeatable within ±2 samples.

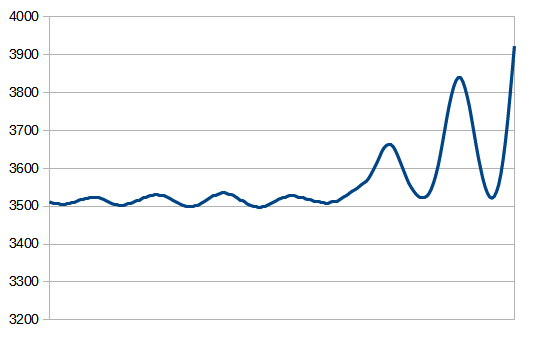

The lower limit of the approach speed now seems to be about 1/4mm per second as shown in the final figure. I think that the thrashing about before contact is a minute sideways movement causing the detector tip to judder in time with pre-existing mechanical vibrations.

Mike

The new baseline algorithm is called an Exponential Moving Average and replaces the True Moving Average that I used in earlier software. The figure below shows the response to a step in input from 0 volts to the middle of the ADC input over a time of about 400 milliseconds. On the figure, there is also the equation and the PIC assembly code routine that generates it in only 13 instructions - a little more than 3 microseconds.

Another change is that the controller now reports if the baseline is steady before the probing operation takes place. This allows the host controller (Arduino etc.) to wait for the shaking from an XY movement to die down before a reading is taken.

The second figure shows the response to a contact where the contact was at a nozzle speed of 2mm per second. The peak occurs within 3ms of initial contact and is repeatable within ±2 samples.

The lower limit of the approach speed now seems to be about 1/4mm per second as shown in the final figure. I think that the thrashing about before contact is a minute sideways movement causing the detector tip to judder in time with pre-existing mechanical vibrations.

Mike

|

Re: Two probes, Underbed for Z height and Z carriage mounted probe for leveling April 01, 2021 01:12PM |

Registered: 12 years ago Posts: 1,450 |

I have just put another video on [www.youtube.com] showing the calibration procedure - or at least the first try at calibration. So far, the normal mix of things that work surprisingly good, like the positional accuracy of the head positioning, along with disasters like two parts trying to be in the same place at the same time.

I would be interested in any comments, questions, and particularly, in any suggestions for improved ways of doing the X and Y offset calibration.

There is also an earlier video [www.youtube.com] which shows more of the actual printer.

Mike

I would be interested in any comments, questions, and particularly, in any suggestions for improved ways of doing the X and Y offset calibration.

There is also an earlier video [www.youtube.com] which shows more of the actual printer.

Mike

Sorry, only registered users may post in this forum.