Maybe the World's Lightest Extruder

Posted by rq3

|

Maybe the World's Lightest Extruder March 02, 2022 06:40PM |

Registered: 4 years ago Posts: 285 |

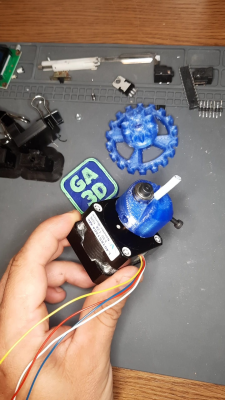

After installing a CNC machined drive bearing carrier on my "standard" NEMA 17 stepper, and doing several prints to verify that these things can be repetitively manufactured at home, I machined a 5mm to 4mm bushing of Grade 5 titanium to adapt it to my recently acquired NEMA 11 stepper.

It works just fine, at 42 grams (the motor is 28 grams, or one ounce). I haven't trimmed the stepper shaft length yet, and to get really silly I could use ceramic drive bearings. Together this would drop the weight to about 38 grams or less, especially after grinding off the useless mounting ears on the stepper. But the three bearings alone are about $200, and I'll have to use a diamond wheel to apply the knife edge to the ceramic flange.

The existing 440C stainless steel knife edge seems to be holding up flawlessly, after several spools of PLA, PETG, ABS, and PC.

I guess I could go to a NEMA 8, if I could find a pancake version.

Notes on assembly: I flipped the knife edged bearing over, so that the knife is nearest the carrier. Since there is absolutely no compliance with the 7075 aluminum carrier (unlike my original PLA version), assembly is otherwise nearly impossible. Flipping the knife edged bearing over makes that go away.

And, although the CNC machined carriers are beautiful, there are, of course, tolerances involved. The bearing clearance is easily fine tuned by chucking the shoulder screws by their heads in a lathe or drill press, and dressing the shoulder diameter with a jeweler's file. About 0.05 mm per screw was about right.

The belleville washers keep everything nice and rigid once the screws are snugged down. I was also surprised to find that belleville washers are easy to machine. I had assumed that they were hardened spring steel. They are not. It's easy to clamp a stack of washers on a mandrel and turn the OD with a carbide lathe tool, or even a file with a drill press.

Edited 4 time(s). Last edit at 03/02/2022 07:06PM by rq3.

It works just fine, at 42 grams (the motor is 28 grams, or one ounce). I haven't trimmed the stepper shaft length yet, and to get really silly I could use ceramic drive bearings. Together this would drop the weight to about 38 grams or less, especially after grinding off the useless mounting ears on the stepper. But the three bearings alone are about $200, and I'll have to use a diamond wheel to apply the knife edge to the ceramic flange.

The existing 440C stainless steel knife edge seems to be holding up flawlessly, after several spools of PLA, PETG, ABS, and PC.

I guess I could go to a NEMA 8, if I could find a pancake version.

Notes on assembly: I flipped the knife edged bearing over, so that the knife is nearest the carrier. Since there is absolutely no compliance with the 7075 aluminum carrier (unlike my original PLA version), assembly is otherwise nearly impossible. Flipping the knife edged bearing over makes that go away.

And, although the CNC machined carriers are beautiful, there are, of course, tolerances involved. The bearing clearance is easily fine tuned by chucking the shoulder screws by their heads in a lathe or drill press, and dressing the shoulder diameter with a jeweler's file. About 0.05 mm per screw was about right.

The belleville washers keep everything nice and rigid once the screws are snugged down. I was also surprised to find that belleville washers are easy to machine. I had assumed that they were hardened spring steel. They are not. It's easy to clamp a stack of washers on a mandrel and turn the OD with a carbide lathe tool, or even a file with a drill press.

Edited 4 time(s). Last edit at 03/02/2022 07:06PM by rq3.

|

Re: Maybe the World's Lightest Extruder March 06, 2022 06:29AM |

Registered: 3 years ago Posts: 92 |

Fabulous! But I still think the posts should be machined as part of the carrier with m3 screws into the top of them to retain the bearings, to eliminate the cost and almost all the weight of the shoulder screws.

Unfortunately I still haven't come up with a machining strategy to make it with my current tools and skills, so I'll probably just stick with the NEMA14 and 3D printed carrier and leave the outrunner version as a theoretical design. Especially since I wouldn't be able to use it anyway since my printer needs a reverse bowden tube. But for printers where the spool is above the extruder, it should be possible to reach below 30 grams with a 2204 outrunner.

Unfortunately I still haven't come up with a machining strategy to make it with my current tools and skills, so I'll probably just stick with the NEMA14 and 3D printed carrier and leave the outrunner version as a theoretical design. Especially since I wouldn't be able to use it anyway since my printer needs a reverse bowden tube. But for printers where the spool is above the extruder, it should be possible to reach below 30 grams with a 2204 outrunner.

|

Re: Maybe the World's Lightest Extruder March 06, 2022 09:40AM |

Registered: 4 years ago Posts: 285 |

Quote

dekutree64

Fabulous! But I still think the posts should be machined as part of the carrier with m3 screws into the top of them to retain the bearings, to eliminate the cost and almost all the weight of the shoulder screws.

Unfortunately I still haven't come up with a machining strategy to make it with my current tools and skills, so I'll probably just stick with the NEMA14 and 3D printed carrier and leave the outrunner version as a theoretical design. Especially since I wouldn't be able to use it anyway since my printer needs a reverse bowden tube. But for printers where the spool is above the extruder, it should be possible to reach below 30 grams with a 2204 outrunner.

As noted above, one of the benefits of using shoulder screws is that you can very easily trim the shoulder diameter to adjust the bearing clearance. It's a one time thing during assembly.

Have you considered threaded aluminum posts for the bearings? You could make them offset, so that rotating them would allow for bearing clearance adjustment. Just a thought.

As a lark, I did a print with 5 micron (0.005mm) layer heights. It took 17.5 hours, and I was very surprised that the schnekenstruder managed the bridge in the opening. I've tried this before with a "standard" gear type extruder, and it didn't work due to the microscopic drive variation from the gears and drive hob.

Edited 1 time(s). Last edit at 03/06/2022 09:42AM by rq3.

|

Re: Maybe the World's Lightest Extruder March 06, 2022 10:43AM |

Registered: 3 years ago Posts: 92 |

Wouldn't it be better to grind more off the cutter bearing flange? I'd rather have the bearings fit onto the posts without any wiggle room.Quote

rq3

As noted above, one of the benefits of using shoulder screws is that you can very easily trim the shoulder diameter to adjust the bearing clearance. It's a one time thing during assembly.

Another way to do fine adjustment is to add shims under the cutter bearing. And flipping it over, as you did. Viewing the CAD model from above orthogonal, you can clearly see how much the blade penetrates the filament as you move the bearing up and down the post.

|

Re: Maybe the World's Lightest Extruder March 06, 2022 03:03PM |

Registered: 4 years ago Posts: 285 |

Quote

dekutree64

Wouldn't it be better to grind more off the cutter bearing flange? I'd rather have the bearings fit onto the posts without any wiggle room.Quote

rq3

As noted above, one of the benefits of using shoulder screws is that you can very easily trim the shoulder diameter to adjust the bearing clearance. It's a one time thing during assembly.

Another way to do fine adjustment is to add shims under the cutter bearing. And flipping it over, as you did. Viewing the CAD model from above orthogonal, you can clearly see how much the blade penetrates the filament as you move the bearing up and down the post.

There's certainly more than one way to skin a cat!

The belleville washers keep the bearings firmly in place once the shoulder screws are snugged down, and you could even use a drop of wicking loctite on the shoulder screw if you were feeling brave. I used wicking Loctite 290 on the shoulder screw threads after assembly, just to ensure that the screws could never back out.

With the shoulder screws and bellevilles, there's not enough "vertical" motion available to make any meaningfull adjustment, at least for my aluminum carrier, and I'd rather just grind the knife edge to a fixed 10.00 +/- 0.01mm diameter and have done with it.

|

Re: Maybe the World's Lightest Extruder March 16, 2022 05:52PM |

Registered: 4 years ago Posts: 285 |

Quote

dekutree64

Fabulous! But I still think the posts should be machined as part of the carrier with m3 screws into the top of them to retain the bearings, to eliminate the cost and almost all the weight of the shoulder screws.

Unfortunately I still haven't come up with a machining strategy to make it with my current tools and skills, so I'll probably just stick with the NEMA14 and 3D printed carrier and leave the outrunner version as a theoretical design. Especially since I wouldn't be able to use it anyway since my printer needs a reverse bowden tube. But for printers where the spool is above the extruder, it should be possible to reach below 30 grams with a 2204 outrunner.

@dekutree64, I'm not seeing the savings. BLDC motors are relatively expensive. For an extruder, they need an encoder. With an encoder, they need a translator between the printer firmware and the motor action, which isn't available in typical firmware like Marlin. They need a lot of current to do what they do, which means thick, heavy, and stiff supply wires. Because they spin at high speed to make their rated power, they need a reduction gear. Although they may be light in mass, their high rotation speed means a lot of inertia, especially with reduction gears. With an encoder, reduction gear, and the associated wiring, the mass savings rapidly disappears.

It appears that the manufacturers are pushing thermal limits to make the claims that they do. Will a BLDC motor survive a 24 hour print?

I've never used one in this application, so plead ignorance. What am I missing?

I've re-installed Blender to open your file, and note that your bearings are all 9mm in diameter. Mine are 10. Why 9? 10mm is the maximum standard bearing diameter that will engage a standard 1.75mm filament at its minimum diameter tolerance, so gives the greatest mechanical advantage of motor torque vs. filament thrust at any particular driver cant angle (arbitrarily 15 degrees in my existing design).

I'd love to hear your thoughts!

I'm looking at another design that will "push on a rope", weighs about 9 grams, and will interface directly with current firmware. It won't be cheap or DIY, which is completely against the idea of RepRap and the Schneckenstruder!

Edited 3 time(s). Last edit at 03/16/2022 05:58PM by rq3.

|

Re: Maybe the World's Lightest Extruder March 16, 2022 08:15PM |

Registered: 3 years ago Posts: 92 |

I've still only sharpened the flange on that one cheap 4x8x3mm bearing months ago, so the 9mm bearings are to go with that. I moved the posts 0.5mm closer to the center so the blade penetration depth is the same.

As for the BLDC motor, they don't necessarily need high current. It depends on how many turns of wire per stator tooth. More turns = more torque for a given current, less turns = more speed for a given voltage. Assuming you use the same mass of copper either way (thinner or thicker wire depending on turn count), the maximum power, torque, and speed are all the same. Just different proportion of voltage and current to get it.

And you don't need an encoder or gearing in this application. Torque to weight ratio is similar between outrunners and steppers at low speed (both are rated much higher than you can actually use). BLDC motors are a kind of coarse stepper, and can be driven open loop at low speed. With the usual three phase winding, you have 6 commutation steps per north-south pair of rotor magnets. So for the motor I'm using with 14 rotor magnets, that's 42 steps per revolution. But to be able to use the standard stepper drivers on 3D printers, you need a different winding scheme which results in 4 steps per north-south pair. 28 steps per revolution gives about 0.05mm per step with my Schnekenstruder carrier, whereas many printers use a 10mm drive hob turned directly by the stepper shaft, giving 10mm*pi/200=0.157mm per full step. So it should be more than enough resolution, assuming microstepping works with this non-standard BLDC winding.

Mostly I just think it looks cool And the total mass should be a little bit less due to screwing straight into the heatsink instead of needing a mount to suspend the motor above it. But the stepper is certainly the better choice for most reprappers since it can use a printed carrier and doesn't involve rewinding a motor.

And the total mass should be a little bit less due to screwing straight into the heatsink instead of needing a mount to suspend the motor above it. But the stepper is certainly the better choice for most reprappers since it can use a printed carrier and doesn't involve rewinding a motor.

I can't wait to see your new extruder design. 9 grams is unreal. I think we need to be more concerned with heatsink/heater block weight at this point

Edited 1 time(s). Last edit at 03/16/2022 08:18PM by dekutree64.

As for the BLDC motor, they don't necessarily need high current. It depends on how many turns of wire per stator tooth. More turns = more torque for a given current, less turns = more speed for a given voltage. Assuming you use the same mass of copper either way (thinner or thicker wire depending on turn count), the maximum power, torque, and speed are all the same. Just different proportion of voltage and current to get it.

And you don't need an encoder or gearing in this application. Torque to weight ratio is similar between outrunners and steppers at low speed (both are rated much higher than you can actually use). BLDC motors are a kind of coarse stepper, and can be driven open loop at low speed. With the usual three phase winding, you have 6 commutation steps per north-south pair of rotor magnets. So for the motor I'm using with 14 rotor magnets, that's 42 steps per revolution. But to be able to use the standard stepper drivers on 3D printers, you need a different winding scheme which results in 4 steps per north-south pair. 28 steps per revolution gives about 0.05mm per step with my Schnekenstruder carrier, whereas many printers use a 10mm drive hob turned directly by the stepper shaft, giving 10mm*pi/200=0.157mm per full step. So it should be more than enough resolution, assuming microstepping works with this non-standard BLDC winding.

Mostly I just think it looks cool

And the total mass should be a little bit less due to screwing straight into the heatsink instead of needing a mount to suspend the motor above it. But the stepper is certainly the better choice for most reprappers since it can use a printed carrier and doesn't involve rewinding a motor.

And the total mass should be a little bit less due to screwing straight into the heatsink instead of needing a mount to suspend the motor above it. But the stepper is certainly the better choice for most reprappers since it can use a printed carrier and doesn't involve rewinding a motor.I can't wait to see your new extruder design. 9 grams is unreal. I think we need to be more concerned with heatsink/heater block weight at this point

Edited 1 time(s). Last edit at 03/16/2022 08:18PM by dekutree64.

|

Re: Maybe the World's Lightest Extruder April 12, 2022 05:17PM |

Registered: 4 years ago Posts: 285 |

Quote

dekutree64

I've still only sharpened the flange on that one cheap 4x8x3mm bearing months ago, so the 9mm bearings are to go with that. I moved the posts 0.5mm closer to the center so the blade penetration depth is the same.

As for the BLDC motor, they don't necessarily need high current. It depends on how many turns of wire per stator tooth. More turns = more torque for a given current, less turns = more speed for a given voltage. Assuming you use the same mass of copper either way (thinner or thicker wire depending on turn count), the maximum power, torque, and speed are all the same. Just different proportion of voltage and current to get it.

And you don't need an encoder or gearing in this application. Torque to weight ratio is similar between outrunners and steppers at low speed (both are rated much higher than you can actually use). BLDC motors are a kind of coarse stepper, and can be driven open loop at low speed. With the usual three phase winding, you have 6 commutation steps per north-south pair of rotor magnets. So for the motor I'm using with 14 rotor magnets, that's 42 steps per revolution. But to be able to use the standard stepper drivers on 3D printers, you need a different winding scheme which results in 4 steps per north-south pair. 28 steps per revolution gives about 0.05mm per step with my Schnekenstruder carrier, whereas many printers use a 10mm drive hob turned directly by the stepper shaft, giving 10mm*pi/200=0.157mm per full step. So it should be more than enough resolution, assuming microstepping works with this non-standard BLDC winding.

Mostly I just think it looks coolAnd the total mass should be a little bit less due to screwing straight into the heatsink instead of needing a mount to suspend the motor above it. But the stepper is certainly the better choice for most reprappers since it can use a printed carrier and doesn't involve rewinding a motor.

I can't wait to see your new extruder design. 9 grams is unreal. I think we need to be more concerned with heatsink/heater block weight at this point

@dekutree64, many thanks for that information! It lets me see BLDC motors in an entirely different light.

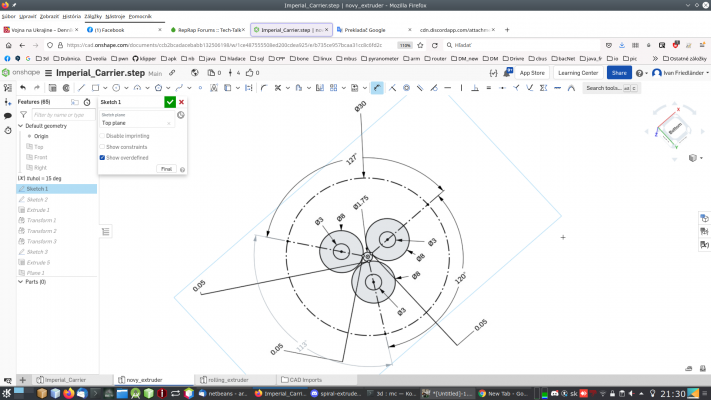

Anyway, here's the final version of the Schneckenstruder. The bearing carrier is PLA, 100% concentric infill and 0.05mm layer height. At this point I don't see the need for having a CNC version machined out of aluminum, but they do look pretty (and weigh more, and cost ALOT more).

The big difference is that the beaings are Imperial units (5/16" OD x 1/8" ID), with extended inner races. Still ABEC-5. Using smaller bearings lets me increase the clearance between the bearings, while the knife edge bites even deeper, so that manufacturing tolerances are much looser. No fine tuning of the shoulder screws, and the knife edge diameter is not as critical because it bites deeper. The extended races means that the belleville washers under the bearings are no longer necessary, and the shoulder screws are all identical. The three belleville washers are also stock Imperial sizes, and also need no trimming. I just basically grind the knife edge on the bearing flange, and screw the assembly together.

With standard PLA, the filament breaks at about 5kg measured with a force gage. I expected the tiny little NEMA 11 motor to stall, but no, the filament broke first. The stepper is running at its rated current, 0.5 amps, and gets slightly warm. Maxxing out at about 300 RPM, it's pushing about 720 cubic millimeters per minute (0.72 cc per minute). Using a BLDC motor could probably increase that by a factor of at least 10, but I guess the trade-off here is speed versus resolution. I've successfully printed the carrier at 5 micron layer height, which would be impossible with a "standard" extruder, but it took over 17 hours.

Some photos and the STL for the carrier are attached.

Edited 1 time(s). Last edit at 04/12/2022 05:25PM by rq3.

|

Re: Maybe the World's Lightest Extruder April 13, 2022 02:59PM |

Registered: 11 years ago Posts: 5,780 |

|

Re: Maybe the World's Lightest Extruder April 13, 2022 05:21PM |

Registered: 4 years ago Posts: 285 |

Quote

the_digital_dentist

PLA? Really?

Yes, really. If you're going to hold very close tolerances, and apply post machining like tapping threads, I have found that PLA is the most rigid and "metal-like" plastic for prototypes. Temperature wise it's not great, nor is long term dimensional stability, but it's rigidity beats the "rubberyness" of everything else, hands down.

|

Re: Maybe the World's Lightest Extruder May 16, 2022 07:14PM |

Registered: 4 years ago Posts: 285 |

Quote

dekutree64

Fabulous! But I still think the posts should be machined as part of the carrier with m3 screws into the top of them to retain the bearings, to eliminate the cost and almost all the weight of the shoulder screws.

Unfortunately I still haven't come up with a machining strategy to make it with my current tools and skills, so I'll probably just stick with the NEMA14 and 3D printed carrier and leave the outrunner version as a theoretical design. Especially since I wouldn't be able to use it anyway since my printer needs a reverse bowden tube. But for printers where the spool is above the extruder, it should be possible to reach below 30 grams with a 2204 outrunner.

Final version, 31.9 grams, Imperial bearings and hardware, 7075 aluminum carrier. No bearing clearance tuning required, or any other "trimming" of hardware, other than grinding the flanged knife edge which takes minutes. With magnesium carrier, ceramic bearings, and proprietary piezo motor, total weight is under 8 grams, and will cost an arm and a leg. I'm done. The NEMA 17 version is permanently mounted on my delta, and still works perfectly after almost a year.

Edited 2 time(s). Last edit at 05/16/2022 07:27PM by rq3.

|

Re: Maybe the World's Lightest Extruder May 18, 2022 06:15PM |

Registered: 3 years ago Posts: 92 |

|

Re: Maybe the World's Lightest Extruder May 18, 2022 08:59PM |

Registered: 4 years ago Posts: 285 |

Quote

dekutree64

Congratulations on a job well done

How about a new BOM with sources for the extended race bearings and such?

Here you go, with the latest STL and STEP files for the CNC'd carrier. I have used Hubs.com for CNC machining from STEP files, and they have been spot on, reasonably priced, and very good at shipping and delivery dates. I have specified 7075 aluminum, with fine machining for my parts. Magnesium is also available if you really want to save a gram or two, but not easy to order.

The carrier files have all of the holes undersized, so that they can be bored for different motor shaft diameters, or diffferent screw sizes, metric or imperial. So final drilling and tapping is up to you.

I use form taps for thread strength, whether metric or Imperial, but standard gun taps would work just as well.

Edited 1 time(s). Last edit at 05/18/2022 09:09PM by rq3.

|

Re: Maybe the World's Lightest Extruder July 04, 2022 11:39AM |

Registered: 1 year ago Posts: 5 |

Great job, this is exactly what I need. I'm working on my version of a BLDC extruder and I'm currently troubleshooting a problem with the accuracy of my rollers. I'd like to ask you if you could post a close-up photo of the sharpened bearing here, and pics or a video of how you sharpened it would be cool too.

Thanks.

Here is my project:

3d Model

BLDC Klipper firmware

Thanks.

Here is my project:

3d Model

BLDC Klipper firmware

|

Re: Maybe the World's Lightest Extruder July 04, 2022 06:34PM |

Registered: 4 years ago Posts: 285 |

Quote

arsi

Great job, this is exactly what I need. I'm working on my version of a BLDC extruder and I'm currently troubleshooting a problem with the accuracy of my rollers. I'd like to ask you if you could post a close-up photo of the sharpened bearing here, and pics or a video of how you sharpened it would be cool too.

Thanks.

Here is my project:

3d Model

BLDC Klipper firmware

Sure. The photos show the knife edge grinding attachment on my 70 year old Unimat lathe. I got a pack of 25 diamond wheels, with arbors and even a little screwdriver, from Amazon for $10. The standard aluminum oxide Dremel discs work too, but they are brittle, expensive, thick, and wear out quickly. Also attached is the FreeCAD file for the cleaned up Imperial version. The bearing cant direction has been reversed, and all of the holes are undersized so that they can be bored/threaded as you like for various screws and motor shaft diameters.

The Metric photo shows the original version where the clearance tolerances were tight, so the knife edge is "upside down". It worked fine that way, but...

The Imperial photo shows (poorly) the current unit on my delta effector. The Imperial version uses identical screws, needs no clearance "tuning", only three belleville washers, and uses common extended inner race bearings so there are no clearance issues.

Folks attempting to duplicate this need to keep in mind that there can be only one mathematical point of intersection between the plane of the tilted knife edge and the center of the filament. Having an extended drive roller, grooved, knife edged, or otherwise as several You Tuber's seem to be doing, gains you nothing but weight and added space.

Edited 1 time(s). Last edit at 07/04/2022 06:42PM by rq3.

|

Re: Maybe the World's Lightest Extruder July 30, 2022 03:38PM |

Registered: 1 year ago Posts: 5 |

I still have a bit of sanding to do, but the building of my version is progressing successfully.

I built a homemade grinder from old stock. Grinding goes at a speed of approx. 0.1mm per hour, but the main thing is that it goes.

Grinder 3D Model

And I slightly adjusted the geometry of the rollers to make more room for the knife.

3D Model

I built a homemade grinder from old stock. Grinding goes at a speed of approx. 0.1mm per hour, but the main thing is that it goes.

Grinder 3D Model

And I slightly adjusted the geometry of the rollers to make more room for the knife.

3D Model

|

Re: Maybe the World's Lightest Extruder August 02, 2022 03:30PM |

Registered: 4 years ago Posts: 285 |

@arsi, very nice! It's also possible to grind a CHISEL edge into the flanges of two bearings, rather than an equal angle KNIFE edge into just one. However, the grinding is easier since you only grind one side, with one bearing mounted chisel up, and the other down. This keeps extrusion and retraction equal.

Either method seems to work equally well, and I've done a few prints with 5 micron (0.005mm) layer heights, which I've never been able to do with any other extruder.

Edited 1 time(s). Last edit at 08/02/2022 03:30PM by rq3.

Either method seems to work equally well, and I've done a few prints with 5 micron (0.005mm) layer heights, which I've never been able to do with any other extruder.

Edited 1 time(s). Last edit at 08/02/2022 03:30PM by rq3.

|

Re: Maybe the World's Lightest Extruder August 02, 2022 04:38PM |

Admin Registered: 16 years ago Posts: 13,886 |

... hmmm ... if you have the possibility to get hands on a marking laser - was experimenting with laser-engraving screw heads to get more "grip" or friction on the surface ... meant for filament transfer - but could be helpful here too ... here the related post:

[reprap.org]

And here the video, engraving one of the srew-heads (was something different for "give-aways") - [www.youtube.com]

This could be done with the surface of a ball bearing too ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

[reprap.org]

And here the video, engraving one of the srew-heads (was something different for "give-aways") - [www.youtube.com]

This could be done with the surface of a ball bearing too ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Maybe the World's Lightest Extruder August 02, 2022 05:01PM |

Registered: 4 years ago Posts: 285 |

Quote

VDX

... hmmm ... if you have the possibility to get hands on a marking laser - was experimenting with laser-engraving screw heads to get more "grip" or friction on the surface ... meant for filament transfer - but could be helpful here too ... here the related post:

[reprap.org]

And here the video, engraving one of the srew-heads (was something different for "give-aways") - [www.youtube.com]

This could be done with the surface of a ball bearing too ...

If you go back to the beginning on this thread and my other related threads...been there, done that. Tried grit, threads, smooth, rough, rubberized. Only a sharp knife edge gives consistent extrusion and retraction.

This design has been on my delta for over a year, and is the only extruder I use. It works on all filaments, even flexibles, and I've done prints with 5 micron layer heights.

Grinding the knife edge on the standard flanged bearing takes about 5 minutes, and I have yet to replace one, which surprises me after running dozens of spools through it. The video is old, the photo shows the current configuration. For scale, that's a 20mm cooling fan.

[www.youtube.com]

Edited 1 time(s). Last edit at 08/02/2022 05:08PM by rq3.

|

Re: Maybe the World's Lightest Extruder August 02, 2022 05:35PM |

Admin Registered: 16 years ago Posts: 13,886 |

... so thumbs up from me!

If you're seraching powerfull micro-motors -- there are two main companies, building some - Faulhaber and Maxxon ... was developing assembling tools, stages and ideas for the smallest motors of them around 15 to 20 years ago

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

If you're seraching powerfull micro-motors -- there are two main companies, building some - Faulhaber and Maxxon ... was developing assembling tools, stages and ideas for the smallest motors of them around 15 to 20 years ago

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Maybe the World's Lightest Extruder August 03, 2022 02:29PM |

Registered: 4 years ago Posts: 285 |

Quote

VDX

... so thumbs up from me!

If you're seraching powerfull micro-motors -- there are two main companies, building some - Faulhaber and Maxxon ... was developing assembling tools, stages and ideas for the smallest motors of them around 15 to 20 years ago

The extruder I'm using these days uses a NEMA17 pancake stepper 11mm thick. It weighs 70 grams. I've also used a NEMA11 pancake stepper 9mm thick, which needs full rated current, and gets a little warm. Not out of spec warm, but it's struggling. It weighs 28 grams.

The attached photo is of a piezo drive motor that juuuust barely works. It weighs 4 grams.

|

Re: Maybe the World's Lightest Extruder August 03, 2022 02:51PM |

Admin Registered: 16 years ago Posts: 13,886 |

... what's the stall-force of your piezo motor?

The radial weren't so strong - have some linear (pushing an Al2O3-rod) with 8N stall force, but less for "sound" operation -- have them in reserve, when in need for an AFM

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

The radial weren't so strong - have some linear (pushing an Al2O3-rod) with 8N stall force, but less for "sound" operation -- have them in reserve, when in need for an AFM

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Maybe the World's Lightest Extruder August 03, 2022 06:18PM |

Registered: 7 years ago Posts: 363 |

How exactly are you grinding a knife edge on such small bearings? I'd like to recreate one of these but I have a few limitations. I don't have a means to precisely drill a motor shaft hollow and I am unsure how I'm suppose to grind a double-bevel on a bearing flange (I should mention that I don't have access to a lathe and that may be the key to success).

|

Re: Maybe the World's Lightest Extruder August 03, 2022 06:28PM |

Registered: 4 years ago Posts: 285 |

Quote

VDX

... what's the stall-force of your piezo motor?

The radial weren't so strong - have some linear (pushing an Al2O3-rod) with 8N stall force, but less for "sound" operation -- have them in reserve, when in need for an AFM

The NEMA11 pancake stepper is about 10mNm, and works at rated current. The piezo motor is about 2 mNm, and is on the hairy edge, but will spin at 900 RPM, with a resolution of 960,000 steps per revolution. It requires it's own driver board, which accepts standard stepper inputs (speed and direction). The driver board runs from 5VDC, but translates that to the 50VDC+ required by the piezo motor.

Yes, the piezo motor is similar to a caterpillar running around the edge of a turntable. It has a rated life of over 100 million revolutions.

|

Re: Maybe the World's Lightest Extruder August 03, 2022 06:42PM |

Registered: 4 years ago Posts: 285 |

Quote

obelisk79

How exactly are you grinding a knife edge on such small bearings? I'd like to recreate one of these but I have a few limitations. I don't have a means to precisely drill a motor shaft hollow and I am unsure how I'm suppose to grind a double-bevel on a bearing flange (I should mention that I don't have access to a lathe and that may be the key to success).

There are photos in this thread, and other related threads, on how folks do this manually, or with a drill press. In the 1700's, the first marine chronometer was built by a man with a saw and some files.

|

Re: Maybe the World's Lightest Extruder August 11, 2022 05:44AM |

Registered: 6 years ago Posts: 39 |

@rq3

I really love this extruder concept ! : it is a real disruptive innovation.

I have also used this concept of thread without thread (with an inclined bearing) on a measurement microscope crossed table. it is just to move precisely the axis when you turn it and you can fast pull the axis if you want it because the bearing glides on the axis . It is simple and works very well.

With your knife bearing you simply avoid the gliding effect on the filament that is not wanted in the case of an extruder.

I think I will try to make one on my side with my inventory parts for my M1 machine in the next monthes.

Edited 1 time(s). Last edit at 08/11/2022 05:45AM by Alvon3DprinTor.

ADG AKA GA3D_tech ------ [www.instagram.com]------ [www.reprap.org] ------ [ga3d.tech]

I really love this extruder concept ! : it is a real disruptive innovation.

I have also used this concept of thread without thread (with an inclined bearing) on a measurement microscope crossed table. it is just to move precisely the axis when you turn it and you can fast pull the axis if you want it because the bearing glides on the axis . It is simple and works very well.

With your knife bearing you simply avoid the gliding effect on the filament that is not wanted in the case of an extruder.

I think I will try to make one on my side with my inventory parts for my M1 machine in the next monthes.

Edited 1 time(s). Last edit at 08/11/2022 05:45AM by Alvon3DprinTor.

ADG AKA GA3D_tech ------ [www.instagram.com]------ [www.reprap.org] ------ [ga3d.tech]

|

Re: Maybe the World's Lightest Extruder August 20, 2022 06:29AM |

Registered: 6 years ago Posts: 39 |

Hi everybody,

I just wanted to show you the quick protoype that I did this week :

it is a first quick and dirty test. I did it with only One Bearing, and a half-cutted PTFE-tube as counterpart.

You can find more details in this youtube shorts : Youtube Shorts - Rolling Thread Extruder

what do you think about it ?

to get an usable extruder I think I still need to secure the pressure on the counterpart with a spring or springlike things, but I think it could do the job at the end.

I'll keep you informed when I'll be further in my tests.

ADG AKA GA3D_tech ------ [www.instagram.com]------ [www.reprap.org] ------ [ga3d.tech]

I just wanted to show you the quick protoype that I did this week :

it is a first quick and dirty test. I did it with only One Bearing, and a half-cutted PTFE-tube as counterpart.

You can find more details in this youtube shorts : Youtube Shorts - Rolling Thread Extruder

what do you think about it ?

to get an usable extruder I think I still need to secure the pressure on the counterpart with a spring or springlike things, but I think it could do the job at the end.

I'll keep you informed when I'll be further in my tests.

ADG AKA GA3D_tech ------ [www.instagram.com]------ [www.reprap.org] ------ [ga3d.tech]

|

Re: Maybe the World's Lightest Extruder August 20, 2022 05:34PM |

Registered: 4 years ago Posts: 285 |

@Alvon3DprinTor, really nice! Two things I noticed when developing this:

1) The knife edge had to be symmetric, or the extrude and retract would be different.

2) The molten filament in the nozzle prevented torsional rotation of the filament, even for flexible TPU. It will be interesting to see if this is still true with only one roller and a rotating Teflon guide.

1) The knife edge had to be symmetric, or the extrude and retract would be different.

2) The molten filament in the nozzle prevented torsional rotation of the filament, even for flexible TPU. It will be interesting to see if this is still true with only one roller and a rotating Teflon guide.

|

Re: Maybe the World's Lightest Extruder September 04, 2022 02:48PM |

Registered: 6 years ago Posts: 39 |

Hi rq3,

thank you for your advice.

unfortunately I've not yet something new to show, I'm doing too many things at the same time (this is a sickness in my case)

1) for the symmetry of the knife, I also had this fear, but it seem to be ok til now there is less grip in reverse mode in my case, but enough to pull out the filament, and more pressure in forward direction.

2) for the rotation of the filament, indeed simply the curvature of the filament entering in the extruder really blocs the rotation

ADG AKA GA3D_tech ------ [www.instagram.com]------ [www.reprap.org] ------ [ga3d.tech]

thank you for your advice.

unfortunately I've not yet something new to show, I'm doing too many things at the same time (this is a sickness in my case)

1) for the symmetry of the knife, I also had this fear, but it seem to be ok til now there is less grip in reverse mode in my case, but enough to pull out the filament, and more pressure in forward direction.

2) for the rotation of the filament, indeed simply the curvature of the filament entering in the extruder really blocs the rotation

ADG AKA GA3D_tech ------ [www.instagram.com]------ [www.reprap.org] ------ [ga3d.tech]

|

Re: Maybe the World's Lightest Extruder September 18, 2022 09:54AM |

Registered: 1 year ago Posts: 5 |

I have tried different knife shapes and the best solution for me is to thin the bearing flange to 0.2-0.3mm and perpendicularly ground to the required diameterQuote

1) The knife edge had to be symmetric, or the extrude and retract would be different.

The force required for rotation has not changed...

But the main problem, which appears with all knife shapes, I have not yet managed to eliminate. The pressure on the filament from the hotend, causes a change in the thread pitch at different speeds of extrusion and therefore the number of steps per millimeter. According to this video, I'm not alone [youtu.be]

Edited 1 time(s). Last edit at 09/18/2022 10:13AM by arsi.

Sorry, only registered users may post in this forum.