Assargadon's self-introduction.

Posted by Assargadon

|

Assargadon's self-introduction. January 02, 2008 01:43PM |

Registered: 16 years ago Posts: 58 |

I observe the RepRap site for a long period of time. It was only the very exiting idea, when I found it first time. The idea was greate but, as far as nothing was made at those time, I doubted it will reach something. I was pessimistic and there are nothing I can help a project with...so I practically forget this project.

So glad I make a mistake.

Since that time I take my degree, I worked some time in IT and now I'm mooving in financial sphere (really unexpected for me, heh). And one day I saw the information about the reprap...somewhere, I don't remember now. It was inspiring chock for me, really.

So I should describe my plans now.

So glad I make a mistake.

Since that time I take my degree, I worked some time in IT and now I'm mooving in financial sphere (really unexpected for me, heh). And one day I saw the information about the reprap...somewhere, I don't remember now. It was inspiring chock for me, really.

So I should describe my plans now.

|

Re: Assargadon's self-introduction. January 02, 2008 01:54PM |

Registered: 16 years ago Posts: 58 |

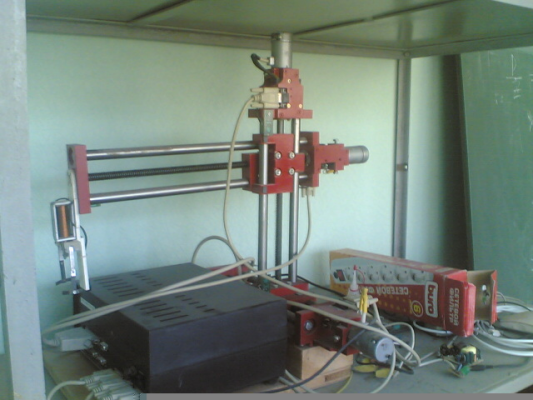

I have a possibility of buying this ancient soviete-union-times 3-axis positioning device: [[http://richart-consalt.ru/robot.jpg]]. It should cost me about $40-$50, and it's fairly cheap, isn't it? I know it working (geeks in university used it for some reason half a year before), but problem is no one know the control protocol (this geeks got some informetion trought revers-engeenering...) and I even don't know if motors of this robot is steppers or not (I hope they do).

|

Re: Assargadon's self-introduction. January 02, 2008 02:13PM |

Registered: 16 years ago Posts: 58 |

The big black box you can see at the photo (see the link above) is the control device. I think, easysest way is abandon this device at all, and provide the motors with reprap electronics.

So as far as I got this soviet-time-system, I should order the electronic kit from Zach (rrrf.org). I don't check it, but I'm sure it's not a problem to find the electronical components - we have a big electronics market every week-end.

So my first milestone is to force this positioning system to move itself by my orders.

I will have a really big problem if motors of this system is not steppers. Maybe it will be possible for me to use Zach's NEMA 23 motor (http://store.rrrf.org/product_info.php?products_id=59)...but it will be a really big problem. I have no manufacturing skills at all and I just cannot imagine how it can be accomplished. Maybe I should find someone to perform it for me.

One of the targets I want to reach with this project - to gain some manufacturing/electronics skills.

So as far as I got this soviet-time-system, I should order the electronic kit from Zach (rrrf.org). I don't check it, but I'm sure it's not a problem to find the electronical components - we have a big electronics market every week-end.

So my first milestone is to force this positioning system to move itself by my orders.

I will have a really big problem if motors of this system is not steppers. Maybe it will be possible for me to use Zach's NEMA 23 motor (http://store.rrrf.org/product_info.php?products_id=59)...but it will be a really big problem. I have no manufacturing skills at all and I just cannot imagine how it can be accomplished. Maybe I should find someone to perform it for me.

One of the targets I want to reach with this project - to gain some manufacturing/electronics skills.

|

Re: Assargadon's self-introduction. January 02, 2008 02:20PM |

Registered: 16 years ago Posts: 58 |

When my positioning system will be functional, I should order the extrudedr toolhead kit from [www.bitsfrombytes.com] (sorry, Zach, and thank for the link), assemle it and force to work.

It's my second milestone - both the positioning and extruder ready, assembled, provided with control electronics and working.

The last step will be an attaching the extruder to positioning device. It's a really big problem for me now - I just don't know how I can perform thee. Maybe I find some usefull idea till that time...or mayube I just attach it with some sort of good glue, heh.

It's my second milestone - both the positioning and extruder ready, assembled, provided with control electronics and working.

The last step will be an attaching the extruder to positioning device. It's a really big problem for me now - I just don't know how I can perform thee. Maybe I find some usefull idea till that time...or mayube I just attach it with some sort of good glue, heh.

|

Re: Assargadon's self-introduction. January 02, 2008 02:26PM |

Registered: 16 years ago Posts: 58 |

|

Re: Assargadon's self-introduction. January 03, 2008 01:54AM |

Admin Registered: 17 years ago Posts: 1,791 |

The server hosting the picture:

[richart-consalt.ru]

seems to be down. I assume you are describing a x-y-z 3-axis machine, rather than something like an human arm or tripod. How big is it? Would it also be useful as a CNC router?

My first step would be to contact the manufacturer of the machine to get the documentation and software.

Hopefully you will be able to use the existing motors. You should be able to figure out what kind of motors they are either by googling the information printed on the motor or by examing the wires going in to it with the aid of an ohmmeter.

How are the motors mounted onto the machine? If it is 4 bolts at the corners of a square, measure the distance between the bolts. If they are 47.1 mm you can use a NEMA 23 motor without fabricating an adaptor plate. If they are not 47.1 mm you may want to buy steppers that fit your machine or fabricate an adaptor plate out of acrylic or aluminum.

"47.1 mm" via:

[www.kelinginc.net]

Also look at how the shaft of the motor couples to the the shaft of the machine. You'll want to get the same kind of shaft or use a shaft adapter. (For light use, a bit of silicone/rubber tubing may work.

Regarding how you can help the RepRap project, I would suggest you familiarize yourself with the software as a first step.

Eventually, we'll want Russian-language documentation of the project. Right now, we're still in development, and everything keeps changing, so it is too early to maintain other-language documentation.

If you end up building a Darwin-type RepRap, you may want to write down who your supppliers are. (mcmaster.com doesn't ship to *.ru (or anywhere else outside the US.)

[richart-consalt.ru]

seems to be down. I assume you are describing a x-y-z 3-axis machine, rather than something like an human arm or tripod. How big is it? Would it also be useful as a CNC router?

My first step would be to contact the manufacturer of the machine to get the documentation and software.

Hopefully you will be able to use the existing motors. You should be able to figure out what kind of motors they are either by googling the information printed on the motor or by examing the wires going in to it with the aid of an ohmmeter.

How are the motors mounted onto the machine? If it is 4 bolts at the corners of a square, measure the distance between the bolts. If they are 47.1 mm you can use a NEMA 23 motor without fabricating an adaptor plate. If they are not 47.1 mm you may want to buy steppers that fit your machine or fabricate an adaptor plate out of acrylic or aluminum.

"47.1 mm" via:

[www.kelinginc.net]

Also look at how the shaft of the motor couples to the the shaft of the machine. You'll want to get the same kind of shaft or use a shaft adapter. (For light use, a bit of silicone/rubber tubing may work.

Regarding how you can help the RepRap project, I would suggest you familiarize yourself with the software as a first step.

Eventually, we'll want Russian-language documentation of the project. Right now, we're still in development, and everything keeps changing, so it is too early to maintain other-language documentation.

If you end up building a Darwin-type RepRap, you may want to write down who your supppliers are. (mcmaster.com doesn't ship to *.ru (or anywhere else outside the US.)

|

Re: Assargadon's self-introduction. January 03, 2008 05:31PM |

Admin Registered: 16 years ago Posts: 13,884 |

Hi Assargadon and Sebastien,

... here is the image of the robot:

It seems to ba a fully usable concept, but the motor-type isn't so clear - could be old-styled 3-phase-steppers, as they are longer and taller, then normal steppers ...

When the motors arent't conventional steppers, then you have to bring to work the driver -- if they are, and you cant't run the driver, then it would be best to use the reprap-electronics or Zachs arduinos ...

Viktor

... here is the image of the robot:

It seems to ba a fully usable concept, but the motor-type isn't so clear - could be old-styled 3-phase-steppers, as they are longer and taller, then normal steppers ...

When the motors arent't conventional steppers, then you have to bring to work the driver -- if they are, and you cant't run the driver, then it would be best to use the reprap-electronics or Zachs arduinos ...

Viktor

|

Re: Assargadon's self-introduction. January 04, 2008 05:28PM |

Registered: 16 years ago Posts: 58 |

Thanks for so quick answer - I'm really inspired by it.

SebastienBailard Wrote:

-------------------------------------------------------

> How big is it?

Working area is cube with 25-30 santimeters side.

>Would it also be useful as a CNC router?

Yes, I think it strong enought for it. I going to use it like subtractive-manufacturing CNC miller...just after I build RepRap of some kind using this as RepStrap.

> My first step would be to contact the manufacturer

> of the machine to get the documentation and software.

Yup...problem is, as I told before, this robot was made in time of soviet union...so it's ABSOLUTELY impossible to find ANY documentation about it.

> You should be able to figure out what

> kind of motors they are either by googling the

> information printed on the motor

I'm really doubt it will be possible to find something THIS way...becouse, as I told before, this robot was maked in soviet union time...so, motors was made at those time, too...in russia.

> or by examing the wires going in to it with the aid of an ohmmeter.

Yes, it's something I should to do - but I'm not sure I know the way waht I should measure and how I should interpret the results. I understand eit will be quite impossible to tell me such information just here - but I have a very usefull and unique skill - I skilled in READING So I need something to read to get general information about what I should searching for. I already start the process using wikipedia

So I need something to read to get general information about what I should searching for. I already start the process using wikipedia

> Regarding how you can help the RepRap project, I would suggest you familiarize

> yourself with the software as a first step.

What you called "familiarize"?

I install thee, it works...crashing sometimes.

I install the SVN client and download the source code (don't yet trying to compile it).

> Right now, we're still in development, and everything keeps changing,

I admit it

> so it is too early to maintain other-language documentation.

Yes. I mean some other help like inventing slices filling alhorithm, for example, or writing code for chips (i have a little expirience in low-level programming).

VDX Wrote:

-------------------------------------------------------

> could be old-styled 3-phase-steppers, as they are longer

> and taller, then normal steppers ...

Yes, and it will be awful.

> then you have to bring to work the driver

Hmm...i thinking about writing my one (i don't know how far reverse-engeeniring, I told before, reaches). I afraid that, despite the fact my driver WILL work, I'll be forced to make a LOT of extra job to make the raprap software working with my driver.

Maybe changing the drives and electronics completely will be easier...but I'm not sure.

SebastienBailard Wrote:

-------------------------------------------------------

> How big is it?

Working area is cube with 25-30 santimeters side.

>Would it also be useful as a CNC router?

Yes, I think it strong enought for it. I going to use it like subtractive-manufacturing CNC miller...just after I build RepRap of some kind using this as RepStrap.

> My first step would be to contact the manufacturer

> of the machine to get the documentation and software.

Yup...problem is, as I told before, this robot was made in time of soviet union...so it's ABSOLUTELY impossible to find ANY documentation about it.

> You should be able to figure out what

> kind of motors they are either by googling the

> information printed on the motor

I'm really doubt it will be possible to find something THIS way...becouse, as I told before, this robot was maked in soviet union time...so, motors was made at those time, too...in russia.

> or by examing the wires going in to it with the aid of an ohmmeter.

Yes, it's something I should to do - but I'm not sure I know the way waht I should measure and how I should interpret the results. I understand eit will be quite impossible to tell me such information just here - but I have a very usefull and unique skill - I skilled in READING

So I need something to read to get general information about what I should searching for. I already start the process using wikipedia

So I need something to read to get general information about what I should searching for. I already start the process using wikipedia

> Regarding how you can help the RepRap project, I would suggest you familiarize

> yourself with the software as a first step.

What you called "familiarize"?

I install thee, it works...crashing sometimes.

I install the SVN client and download the source code (don't yet trying to compile it).

> Right now, we're still in development, and everything keeps changing,

I admit it

> so it is too early to maintain other-language documentation.

Yes. I mean some other help like inventing slices filling alhorithm, for example, or writing code for chips (i have a little expirience in low-level programming).

VDX Wrote:

-------------------------------------------------------

> could be old-styled 3-phase-steppers, as they are longer

> and taller, then normal steppers ...

Yes, and it will be awful.

> then you have to bring to work the driver

Hmm...i thinking about writing my one (i don't know how far reverse-engeeniring, I told before, reaches). I afraid that, despite the fact my driver WILL work, I'll be forced to make a LOT of extra job to make the raprap software working with my driver.

Maybe changing the drives and electronics completely will be easier...but I'm not sure.

|

Re: Assargadon's self-introduction. January 04, 2008 05:45PM |

Admin Registered: 16 years ago Posts: 13,884 |

Hi Assargadon,

... try to open a motor, then you can test, if it's a common stepper and how much phases it has.

- 'normal' bipolar steppers should have 4, 6 or 8 wires - 3-phased have 3, 4 or 6 (sometimes you have some more wires for a tacho or coarse angular sensor, but separated from the motor-lines)

- when opened, you should have a permanent-magnetized rotor toothed like a gear

- the inner stator is toothed too, but in two separated rings displaced by half a teeth (then you can count the teeth for calculating steps-per-turn)

Best you open a motor an post some images, so it would be easier to check ...

Viktor

... try to open a motor, then you can test, if it's a common stepper and how much phases it has.

- 'normal' bipolar steppers should have 4, 6 or 8 wires - 3-phased have 3, 4 or 6 (sometimes you have some more wires for a tacho or coarse angular sensor, but separated from the motor-lines)

- when opened, you should have a permanent-magnetized rotor toothed like a gear

- the inner stator is toothed too, but in two separated rings displaced by half a teeth (then you can count the teeth for calculating steps-per-turn)

Best you open a motor an post some images, so it would be easier to check ...

Viktor

|

Re: Assargadon's self-introduction. January 05, 2008 04:53AM |

Admin Registered: 17 years ago Posts: 1,791 |

|

Re: Assargadon's self-introduction. January 31, 2008 11:17AM |

Registered: 16 years ago Posts: 58 |

|

Re: Assargadon's self-introduction. February 07, 2008 04:30AM |

Admin Registered: 17 years ago Posts: 1,791 |

This is why I suggested not disassembling the motors;

[yarchive.net]

"...

This is a serious misnomer. It should read: DO NOT DISASSEMBLE

without reading the manual. The stator must not be removed from the

20-pole magnet without at the same time pushing in an iron plug of the

same diameter. The magnet will demagnetize itself instantly if the

magnetic return path (the stator or "keeper") is broken even for a

nanosecond. This continuity cannot be over emphasized. All 20 poles

must be in close proximity to a continuous magnetic return path at all

times. Most Dyno Hubs have been disassembled by unwitting mechanics

and their magnets are "flat" producing negligible power ever after.

..."

The rest of

[yarchive.net]

is worth reading, if you are bored or like bikes.

[yarchive.net]

"...

This is a serious misnomer. It should read: DO NOT DISASSEMBLE

without reading the manual. The stator must not be removed from the

20-pole magnet without at the same time pushing in an iron plug of the

same diameter. The magnet will demagnetize itself instantly if the

magnetic return path (the stator or "keeper") is broken even for a

nanosecond. This continuity cannot be over emphasized. All 20 poles

must be in close proximity to a continuous magnetic return path at all

times. Most Dyno Hubs have been disassembled by unwitting mechanics

and their magnets are "flat" producing negligible power ever after.

..."

The rest of

[yarchive.net]

is worth reading, if you are bored or like bikes.

|

Re: Assargadon's self-introduction. November 03, 2008 02:54AM |

Registered: 15 years ago Posts: 73 |

I saw the picture, and that machine would be useless as a router or milling. It is not rigid enough. It could perhaps mill small parts very close to the near end of travel.

A stepper motor will not have an encoder to tell it location. Look to see if there is an encoder somewhere. I see 3 white cables that look like RS232 cables (sort of). I suspect those are encoders. If they are, that would mean the motors are DC motors. Probably low voltage.

You might try putting 5volts on the motor see if it turns. It might need more voltage. If it is a stepper motor it will lock up when power is applied, be more difficult to turn than it is without power. If it is a DC motor, it'll turn when power is applied.

I'm in the process of making a RepRap which will use DC motors rather than steppers. When it is complete you'll be able to use those electronics, probably.

Tony

A stepper motor will not have an encoder to tell it location. Look to see if there is an encoder somewhere. I see 3 white cables that look like RS232 cables (sort of). I suspect those are encoders. If they are, that would mean the motors are DC motors. Probably low voltage.

You might try putting 5volts on the motor see if it turns. It might need more voltage. If it is a stepper motor it will lock up when power is applied, be more difficult to turn than it is without power. If it is a DC motor, it'll turn when power is applied.

I'm in the process of making a RepRap which will use DC motors rather than steppers. When it is complete you'll be able to use those electronics, probably.

Tony

Sorry, only registered users may post in this forum.