Mechanical Pencil Tip

Posted by degroof

|

Mechanical Pencil Tip March 23, 2008 12:49PM |

Registered: 16 years ago Posts: 447 |

I was experimenting yesterday and came up with this:

It's a mechanical pencil tip in an acorn nut. I drilled a hole a bit narrower than the widest part of the pencil tip. The pencil tip is from a 0.5mm Scripto P200. Tightening the nut on the barrel wedges the pencil tip into the hole. As you can see from the photo, it actually managed to extrude some plastic.

Advantages: cheap, easy to make, very little rebound.

Disadvantages: cools quickly, requires a lot of force to extrude.

Interesting but probably not practical for HDPE.

It's a mechanical pencil tip in an acorn nut. I drilled a hole a bit narrower than the widest part of the pencil tip. The pencil tip is from a 0.5mm Scripto P200. Tightening the nut on the barrel wedges the pencil tip into the hole. As you can see from the photo, it actually managed to extrude some plastic.

Advantages: cheap, easy to make, very little rebound.

Disadvantages: cools quickly, requires a lot of force to extrude.

Interesting but probably not practical for HDPE.

|

Re: Mechanical Pencil Tip March 23, 2008 02:00PM |

Admin Registered: 17 years ago Posts: 1,915 |

|

Re: Mechanical Pencil Tip March 23, 2008 02:48PM |

Registered: 16 years ago Posts: 447 |

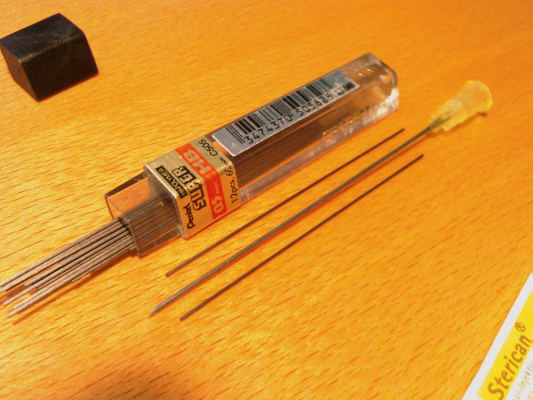

Here's a closeup of the extrusion, along with a 0.5mm pencil lead.

|

Re: Mechanical Pencil Tip March 23, 2008 03:30PM |

Admin Registered: 17 years ago Posts: 1,915 |

|

Re: Mechanical Pencil Tip March 23, 2008 03:42PM |

Registered: 16 years ago Posts: 447 |

|

Re: Mechanical Pencil Tip March 23, 2008 04:25PM |

Admin Registered: 17 years ago Posts: 1,915 |

That clamp thing doesn't work for much of anything aside from PCL.

You can see a different approach that can handle much higher extruder barrel pressures there...

[3dreplicators.com]

and here...

[3dreplicators.com]

You can see a different approach that can handle much higher extruder barrel pressures there...

[3dreplicators.com]

and here...

[3dreplicators.com]

|

Re: Mechanical Pencil Tip March 25, 2008 03:11PM |

Registered: 16 years ago Posts: 447 |

|

Re: Mechanical Pencil Tip March 26, 2008 08:22PM |

Registered: 16 years ago Posts: 447 |

|

Re: Mechanical Pencil Tip April 12, 2008 04:57PM |

Registered: 16 years ago Posts: 46 |

|

Re: Mechanical Pencil Tip April 13, 2008 05:45PM |

Registered: 16 years ago Posts: 56 |

In order to reduce some of the stresses you could grind down the very tip to at least half. The friction on that long of a small nozzle is extreme. I suggest grinding because you would be less likely to pinch the barrel if you cut it. Another thing you can do is use a 0.3 mm pencil tip...if you ever get a the new barrel worked out.

|

Re: Mechanical Pencil Tip April 13, 2008 05:59PM |

Registered: 16 years ago Posts: 370 |

ronanwarrior Wrote:

-------------------------------------------------------

> In order to reduce some of the stresses you could

> grind down the very tip to at least half. The

> friction on that long of a small nozzle is

> extreme. I suggest grinding because you would be

> less likely to pinch the barrel if you cut it.

> Another thing you can do is use a 0.3 mm pencil

> tip...if you ever get a the new barrel worked out.

It will be interesting to see what effect this modification had on the amount of die swell. IIRC Nophead's trials had significantly more swell for similar nozzle diameters, and the main difference I see here is the length of the extrusion channel.

-------------------------------------------------------

> In order to reduce some of the stresses you could

> grind down the very tip to at least half. The

> friction on that long of a small nozzle is

> extreme. I suggest grinding because you would be

> less likely to pinch the barrel if you cut it.

> Another thing you can do is use a 0.3 mm pencil

> tip...if you ever get a the new barrel worked out.

It will be interesting to see what effect this modification had on the amount of die swell. IIRC Nophead's trials had significantly more swell for similar nozzle diameters, and the main difference I see here is the length of the extrusion channel.

|

Re: Mechanical Pencil Tip April 13, 2008 07:19PM |

Registered: 16 years ago Posts: 235 |

|

Re: Mechanical Pencil Tip April 14, 2008 11:32AM |

Registered: 16 years ago Posts: 293 |

I had a similar idea. The suitability of parts of these pencils struck me, like many others probably.

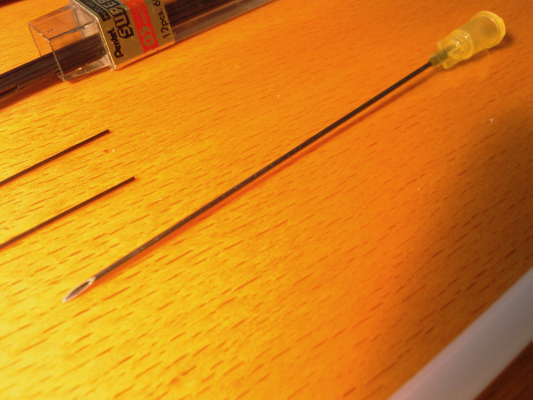

I don't know if anyone thought of this, but I could extrude plastic from such a pen just by applying a voltage to the graphite. I was mostly investigating how I could reduce the dependence on nichrome wire. These graphite (pencil) rods are very straight and become red-hot when you apply power to them. Since this is another heater material, I'd like to know if this allows for measuring the heat by measuring the coefficient of resistance of the material to determine its temperature. This way the heater and the temperature measurement are the same. (I'm sure someone already tried this with nichrome?)

A similar diameter hollow tube is a syringe needle. You can isolate that and put pencil rods around that and apply power to that. This makes very close contact over a length. Such a (long) needle may have too much resistance to extrude plastics through, but that may not be so for metals or fluids with less viscosity.

Sorry for going a bit off-topic!

I don't know if anyone thought of this, but I could extrude plastic from such a pen just by applying a voltage to the graphite. I was mostly investigating how I could reduce the dependence on nichrome wire. These graphite (pencil) rods are very straight and become red-hot when you apply power to them. Since this is another heater material, I'd like to know if this allows for measuring the heat by measuring the coefficient of resistance of the material to determine its temperature. This way the heater and the temperature measurement are the same. (I'm sure someone already tried this with nichrome?)

A similar diameter hollow tube is a syringe needle. You can isolate that and put pencil rods around that and apply power to that. This makes very close contact over a length. Such a (long) needle may have too much resistance to extrude plastics through, but that may not be so for metals or fluids with less viscosity.

Sorry for going a bit off-topic!

|

Re: Mechanical Pencil Tip April 14, 2008 12:37PM |

Registered: 16 years ago Posts: 447 |

I like the graphite idea. I remember, as a kid, making an arc lamp from a pencil.

Syringe needles might be interesting. The one you've got there looks like it's about the same diameter as the pencil leads.

I remember seeing a syringe made entirely from stainless steel recently. I think it was a marinade injector for meat.

Syringe needles might be interesting. The one you've got there looks like it's about the same diameter as the pencil leads.

I remember seeing a syringe made entirely from stainless steel recently. I think it was a marinade injector for meat.

|

Re: Mechanical Pencil Tip April 14, 2008 02:35PM |

Admin Registered: 17 years ago Posts: 1,915 |

|

Re: Mechanical Pencil Tip April 14, 2008 02:37PM |

Registered: 16 years ago Posts: 293 |

Sorry, only registered users may post in this forum.