Nozzle's hole shape...

Posted by MyMaker

|

Nozzle's hole shape... January 12, 2012 06:02AM |

Registered: 12 years ago Posts: 3 |

Hi,

I wonder if changing the shape of the nozzle's hole could help to reduce the visible step between two layers without need to reduce the height of the layers (I know that some of you are printing at 0.02mm by layers but it is too tricky to reach for a newby).

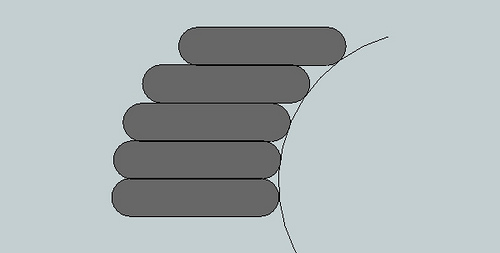

The aim is to change the section of the extruded plastic from :

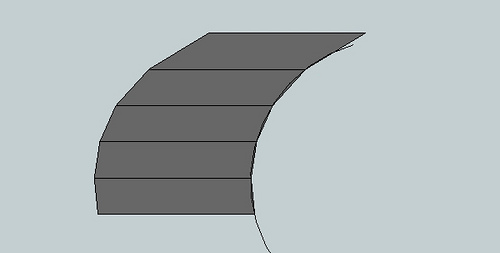

TO

To control the angle of the layer, it could be possible to use a square hole nozzle (or some shape with edges, triangle for exemple) which rotate around the hotend axis.

I just do some experimentation with a mastic gun (so don't be affraid by the extrusion quality) :

First with the round nozzle (top extrusion):

Then with the square nozzle :

This pictures are to be well understood more than a reliable experimentation.

Guillaume

Edited 3 time(s). Last edit at 01/12/2012 01:33PM by MyMaker.

blog.mymaker.fr

I wonder if changing the shape of the nozzle's hole could help to reduce the visible step between two layers without need to reduce the height of the layers (I know that some of you are printing at 0.02mm by layers but it is too tricky to reach for a newby).

The aim is to change the section of the extruded plastic from :

TO

To control the angle of the layer, it could be possible to use a square hole nozzle (or some shape with edges, triangle for exemple) which rotate around the hotend axis.

I just do some experimentation with a mastic gun (so don't be affraid by the extrusion quality) :

First with the round nozzle (top extrusion):

Then with the square nozzle :

This pictures are to be well understood more than a reliable experimentation.

Guillaume

Edited 3 time(s). Last edit at 01/12/2012 01:33PM by MyMaker.

blog.mymaker.fr

|

Re: Nozzle's hole shape... January 12, 2012 06:48AM |

Registered: 13 years ago Posts: 226 |

Hi Guillaume

It's an interesting idea to use a different shaped nozzle hole. Presuming your sketches are looking at the model from the side I can see how it could improve the look of layers on vertical walls, but I think you will still get "steps" between layers when there is overhang or underhang.

Regarding moving the nozzle around the hotend axis I would imaging that introducing any mechanisms to the actual hot-end could lead to leaks. I'd be interested in seeing your designs on this.

Cheers,

Gary

------------------------------------------

garyhodgson.com/reprap | reprap.development-tracker.info | thingtracker.net

It's an interesting idea to use a different shaped nozzle hole. Presuming your sketches are looking at the model from the side I can see how it could improve the look of layers on vertical walls, but I think you will still get "steps" between layers when there is overhang or underhang.

Regarding moving the nozzle around the hotend axis I would imaging that introducing any mechanisms to the actual hot-end could lead to leaks. I'd be interested in seeing your designs on this.

Cheers,

Gary

------------------------------------------

garyhodgson.com/reprap | reprap.development-tracker.info | thingtracker.net

|

Re: Nozzle's hole shape... January 12, 2012 07:53AM |

Admin Registered: 17 years ago Posts: 7,879 |

Interesting. If the filament came out square you wouldn't need to compress it to get good contact with the layer below. If fact if you did you would get bulging sides anyway. So you would be able to have the layer width equal to the layer height, giving better horizontal resolution. Also the cross section of the hole is bigger so the plastic would flow more easily.

This all assumes the plastic will come out square from a square hole. While this may be true for a paste it may not be for molten plastic. Die swell might make it rounded anyway.

[www.hydraraptor.blogspot.com]

This all assumes the plastic will come out square from a square hole. While this may be true for a paste it may not be for molten plastic. Die swell might make it rounded anyway.

[www.hydraraptor.blogspot.com]

|

Re: Nozzle's hole shape... January 12, 2012 10:07AM |

Registered: 12 years ago Posts: 3 |

Quote

nophead

> This all assumes the plastic will come out square

> from a square hole. While this may be true for a

> paste it may not be for molten plastic. Die swell

> might make it rounded anyway.

In fact, even with the mastic, to extrude a square you have to use a kind of 4 branches star like that .

We have to take into account the release of stress due to extrusion. But IMHO, in the same conditions, paste and molten plastic should have the same behaviour.

blog.mymaker.fr

|

Re: Nozzle's hole shape... February 18, 2012 02:19AM |

Registered: 12 years ago Posts: 229 |

|

Re: Nozzle's hole shape... February 19, 2012 04:32PM |

Admin Registered: 16 years ago Posts: 13,888 |

aplavins Wrote:

-------------------------------------------------------

> Great idea! How would one make a 0.5mm star shaped

> hole?

... make a thin walled hole with 1mm and hammer or squeese it to a square and further to a star shape ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

-------------------------------------------------------

> Great idea! How would one make a 0.5mm star shaped

> hole?

... make a thin walled hole with 1mm and hammer or squeese it to a square and further to a star shape ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Nozzle's hole shape... February 19, 2012 04:45PM |

Registered: 12 years ago Posts: 229 |

|

Re: Nozzle's hole shape... February 21, 2012 10:47AM |

Registered: 13 years ago Posts: 581 |

Sorry, only registered users may post in this forum.