|

[solved] Second layer too thin February 05, 2012 10:50AM |

Registered: 12 years ago Posts: 36 |

I've been getting fairly nice prints out of my Prusa - until the nozzle jammed. I cleaned that out, but it has not been the same since [edit: seems like it was just a temporal coincidence]. I'm using Wolfgang's hotend with a .5mm nozzle, printing ABS onto heated PET. +-1°C during the whole print with PID control @240°C, .3 layer height.

The first layer goes down perfectly - it sticks throughout the whole print without creating a ridge. However, once the (faster) second layer starts, it seems like the filament is not hot enough or there is simply not enough extruded. It takes ~15 seconds of printing to normalize, and after that, everything prints nicely.

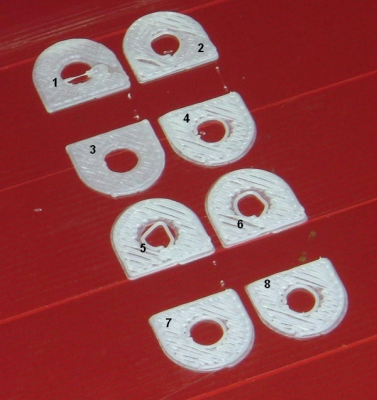

These were stopped after the critical second layer, they were printed counter-clockwise, using a "known-good" profile.

Note how it is too thin at first, but then prints perfectly (top left).

I don't think it is temperature (250°C don't fix it) or too little material extruded, since a) the extruder is calibrated and b) all other layers just work.

I can mitigate the issue by waiting a minute or so after the first layer and then prime the extruder again, but that's more of a hack i have to insert into every .gcode SF generates and doesn't completely cure it.

I'm also positive that this is not related to an un-level bed. I've had larger parts where the second layer infill would start a one point, and then later coming back to that point, with the initial line being too slim and the second one perfectly sticking.

Has anyone experienced something similar?

Thanks,

Tom

Edited 3 time(s). Last edit at 03/17/2012 05:35PM by imitation.

The first layer goes down perfectly - it sticks throughout the whole print without creating a ridge. However, once the (faster) second layer starts, it seems like the filament is not hot enough or there is simply not enough extruded. It takes ~15 seconds of printing to normalize, and after that, everything prints nicely.

These were stopped after the critical second layer, they were printed counter-clockwise, using a "known-good" profile.

Note how it is too thin at first, but then prints perfectly (top left).

I don't think it is temperature (250°C don't fix it) or too little material extruded, since a) the extruder is calibrated and b) all other layers just work.

I can mitigate the issue by waiting a minute or so after the first layer and then prime the extruder again, but that's more of a hack i have to insert into every .gcode SF generates and doesn't completely cure it.

I'm also positive that this is not related to an un-level bed. I've had larger parts where the second layer infill would start a one point, and then later coming back to that point, with the initial line being too slim and the second one perfectly sticking.

Has anyone experienced something similar?

Thanks,

Tom

Edited 3 time(s). Last edit at 03/17/2012 05:35PM by imitation.

|

Re: Second layer too thin February 07, 2012 03:07AM |

Registered: 12 years ago Posts: 179 |

|

Re: Second layer too thin February 12, 2012 04:47PM |

Registered: 12 years ago Posts: 36 |

|

Re: Second layer too thin February 12, 2012 06:02PM |

Admin Registered: 17 years ago Posts: 7,879 |

I have this problem with Wolfgang's nozzles. They have two states. When they are new you can extrude at full speed. After a random time that can be days or weeks they switch to another state where you can only extrude slowly. Cleaning them out does not restore them. Wolfgang blames the plastic but I am sure that it is OK. I suspect the PTFE liner must change in some way but I have never managed to take one apart without breaking it.

If you lower you build speed to the same as the first layer I am sure it will work.

[www.hydraraptor.blogspot.com]

If you lower you build speed to the same as the first layer I am sure it will work.

[www.hydraraptor.blogspot.com]

|

Re: Second layer too thin February 13, 2012 03:06AM |

Registered: 14 years ago Posts: 7,505 |

Ich have the same effect with some ABS. I tryed to clean the Nozzle, change the PTFE-liner, nothing helps.. I change the Spool of ABS and the Effect is gone. ???

Sometimes i print 5-7 Spools... full speed... and suddenly the effect is there. I clean the Nozzle, put the Spool away, an everything is OK again. What happens ?

What is it ? The Brass ? The PTFE i change... The Peek ? Or the ABS ?

Edited 1 time(s). Last edit at 02/13/2012 03:17AM by Stoffel15.

Mfg

Wolfgang

Erfahrungen kann man leider schlecht weiter geben, die muss man selber machen.

Sometimes i print 5-7 Spools... full speed... and suddenly the effect is there. I clean the Nozzle, put the Spool away, an everything is OK again. What happens ?

What is it ? The Brass ? The PTFE i change... The Peek ? Or the ABS ?

Edited 1 time(s). Last edit at 02/13/2012 03:17AM by Stoffel15.

Mfg

Wolfgang

| Aller Anfang war schwer - Wolfstrap | Reprap-fab.org |  |

Erfahrungen kann man leider schlecht weiter geben, die muss man selber machen.

|

Re: Second layer too thin February 13, 2012 04:41AM |

Registered: 12 years ago Posts: 36 |

So i did two more things this morning - i switched to a piece of my previous Filament, which i had printed about two kg of. That didn't make any difference at all.

I then tried to go slower, down from 75 (was working fine) to 60, to 30 and finally to 15mm/s. That made a bit of a difference, but mainly concerning how much of the second layer looked bad. With the mini-octopus as my reference print, now only the perimeter peeled off afterwards instead of 70% of the layer.

When i push down a bit on the extruder or even on the x-ends, the layer prints fine. I have the anti-backlash springs and nuts fitted in the x-ends and have no lash there.

It feels like there is something contracting during the first layer and then expanding again during the second. I have no idea what that could be, since both the hotend and the heated bed stay on the same temperature during those layers.

I then tried to go slower, down from 75 (was working fine) to 60, to 30 and finally to 15mm/s. That made a bit of a difference, but mainly concerning how much of the second layer looked bad. With the mini-octopus as my reference print, now only the perimeter peeled off afterwards instead of 70% of the layer.

When i push down a bit on the extruder or even on the x-ends, the layer prints fine. I have the anti-backlash springs and nuts fitted in the x-ends and have no lash there.

It feels like there is something contracting during the first layer and then expanding again during the second. I have no idea what that could be, since both the hotend and the heated bed stay on the same temperature during those layers.

|

Re: Second layer too thin February 13, 2012 05:09AM |

Admin Registered: 17 years ago Posts: 7,879 |

My last one stopped working at the weekend. It was a 0.4mm nozzle and I ran it at 36mm/s for months. I changed from the white ABS for reprapsource to green from New Image Plastics that I have had for years because I got bored with only making white things for the last year. I last used it on HydraRaptor with a 0.3mm nozzle and had no problems.

I ran it at 240C as it likes lower temperatures and made a couple of objects. They came out fine but it sagged a lot when bridging gaps, so I tried again at 220C. Big mistake! It stripped at the hobbed bolt. I went back to the white filament and flushed it all through so it comes out white. It now will only do the first layer outlines and strips as soon as it starts the first layer infill, which is only about 20mm/s.

My thoughts are that the higher pressure caused by the lower temperature has flipped the nozzle into the sate where it will only extrude slowly. I have three 0.35mm nozzle that went to this state after a few days or a couple of weeks. Soaking them in acetone for weeks and flushing out all the ABS so I can see all the way through does not restore them. I can only run at 20mm/s with one of them now.

The only explanation I can think of is that the pressure causes a gap to form between the bottom of the PTFE liner and the brass. It is hard to prove though as I haven't been able to take one apart. What else could it be though? It can't be the plastic as the same reel was running fine until I tried the green. The green was working fine until I lowered the temperature a little. It wasn't that low as I used to extrude the first layer at 190C on HydraRaptor when I was using it on rafts.

I have other PEEK hot ends with solid PTFE liners instead of tubing and run the same reprapsource plastic through them for 2 years without this problem.

[www.hydraraptor.blogspot.com]

I ran it at 240C as it likes lower temperatures and made a couple of objects. They came out fine but it sagged a lot when bridging gaps, so I tried again at 220C. Big mistake! It stripped at the hobbed bolt. I went back to the white filament and flushed it all through so it comes out white. It now will only do the first layer outlines and strips as soon as it starts the first layer infill, which is only about 20mm/s.

My thoughts are that the higher pressure caused by the lower temperature has flipped the nozzle into the sate where it will only extrude slowly. I have three 0.35mm nozzle that went to this state after a few days or a couple of weeks. Soaking them in acetone for weeks and flushing out all the ABS so I can see all the way through does not restore them. I can only run at 20mm/s with one of them now.

The only explanation I can think of is that the pressure causes a gap to form between the bottom of the PTFE liner and the brass. It is hard to prove though as I haven't been able to take one apart. What else could it be though? It can't be the plastic as the same reel was running fine until I tried the green. The green was working fine until I lowered the temperature a little. It wasn't that low as I used to extrude the first layer at 190C on HydraRaptor when I was using it on rafts.

I have other PEEK hot ends with solid PTFE liners instead of tubing and run the same reprapsource plastic through them for 2 years without this problem.

[www.hydraraptor.blogspot.com]

|

Re: Second layer too thin February 13, 2012 05:29AM |

Admin Registered: 16 years ago Posts: 13,886 |

... can you check, if after cleaning with acetone there is some coating on the inside of the nozzle near the tip or in the range of the heater element?

I heard some talk that overheating ABS or changing material will result in residues not solvable with acetone.

If so, then you'll receive different thermal properties of the nozzle ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

I heard some talk that overheating ABS or changing material will result in residues not solvable with acetone.

If so, then you'll receive different thermal properties of the nozzle ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Second layer too thin February 13, 2012 05:46AM |

Registered: 14 years ago Posts: 3,742 |

The problems were switching between PLA and ABS.

nophead only uses ABS.

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

nophead only uses ABS.

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

|

Re: Second layer too thin February 13, 2012 05:58AM |

Registered: 14 years ago Posts: 7,505 |

i have open it... but there is nothing in between the Ptfe and the Peek. That was the first i thought.. that isnt it. (you must heat them up, befor open)

And the Liner i have cange... the only may be the Brass ? That somthing happens with the Metal (oxidation ?)

The only i can try is to make them from ALU and look if it happens again.

But i think it comes from the ABS ... the bad ABS smells like Oil when it is warm.

I dont change anything at the barrels since one Year, and suddenly they make Problems ? What happens here ?

I print now since 2 Years ABS .. only Material from Orbi-Tech. But every Spool is diffrend.. and i print hundreds of them. I know that Reprap-Source get his Material from Orbitech too. I got some from Ultimaschine ... its a diffrend like Night and Day.

Mfg

Wolfgang

Erfahrungen kann man leider schlecht weiter geben, die muss man selber machen.

And the Liner i have cange... the only may be the Brass ? That somthing happens with the Metal (oxidation ?)

The only i can try is to make them from ALU and look if it happens again.

But i think it comes from the ABS ... the bad ABS smells like Oil when it is warm.

I dont change anything at the barrels since one Year, and suddenly they make Problems ? What happens here ?

I print now since 2 Years ABS .. only Material from Orbi-Tech. But every Spool is diffrend.. and i print hundreds of them. I know that Reprap-Source get his Material from Orbitech too. I got some from Ultimaschine ... its a diffrend like Night and Day.

Mfg

Wolfgang

| Aller Anfang war schwer - Wolfstrap | Reprap-fab.org |  |

Erfahrungen kann man leider schlecht weiter geben, die muss man selber machen.

|

Re: Second layer too thin February 13, 2012 06:33AM |

Admin Registered: 16 years ago Posts: 13,886 |

... with temperatures over 200°C you can hit the critical ranges for some plastic-additives, so they crack and/or change chemistry.

It's not uncommon, that when overheating plastics, they resemble to acids and start reacting with metals ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

It's not uncommon, that when overheating plastics, they resemble to acids and start reacting with metals ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Second layer too thin February 13, 2012 07:28AM |

Admin Registered: 17 years ago Posts: 7,879 |

I have had nozzle apertures get smaller diameter over time due to oxidized plastic glazing them. That is a slow process though and you can tell by the fact the filament diameter reduces and the plastic comes out more oval and curls, see. This is a sudden effect. The nozzle will build many objects at full speed than suddenly it flips to only working at a lower speed. It doesn't coincide with a new reel of plastic and I can use up the reel with a different nozzle.

Also when I cleaned one out with acetone I didn't get any burnt material and I scraped the inside of the end with a 3mm drill and cleaned out the aperture with some fine wire. I can't see any obstruction if I look down it while shining a light in the up the nozzle.

Edited 1 time(s). Last edit at 02/13/2012 08:53AM by nophead.

[www.hydraraptor.blogspot.com]

Also when I cleaned one out with acetone I didn't get any burnt material and I scraped the inside of the end with a 3mm drill and cleaned out the aperture with some fine wire. I can't see any obstruction if I look down it while shining a light in the up the nozzle.

Edited 1 time(s). Last edit at 02/13/2012 08:53AM by nophead.

[www.hydraraptor.blogspot.com]

|

Re: Second layer too thin February 16, 2012 10:48AM |

Registered: 14 years ago Posts: 7,505 |

"Also when I cleaned one out with acetone I didn't get any burnt material and I scraped the inside of the end with a 3mm drill and cleaned out the aperture with some fine wire. I can't see any obstruction if I look down it while shining a light in the up the nozzle."

And you dont see anything inside ?...

strange, the inner of the Nozzel is 3,5h7 ... so you must see the ABS inside at every wall 0,25mm ??????

at every wall 0,25mm ??????

Mfg

Wolfgang

Erfahrungen kann man leider schlecht weiter geben, die muss man selber machen.

And you dont see anything inside ?...

strange, the inner of the Nozzel is 3,5h7 ... so you must see the ABS inside

at every wall 0,25mm ??????

at every wall 0,25mm ??????Mfg

Wolfgang

| Aller Anfang war schwer - Wolfstrap | Reprap-fab.org |  |

Erfahrungen kann man leider schlecht weiter geben, die muss man selber machen.

|

Re: Second layer too thin February 16, 2012 11:40AM |

Registered: 12 years ago Posts: 36 |

Wolfgang, if you want to keep on bashing nophead, i suggest you do so in a separate thread.

As far as my problem goes, i still haven't figured out what causes it. For now, i can print a second layer that is good enough by waiting five minutes (at full temp) after the first layer and then repriming the nozzle.

It feels a lot like it is the hotend causing the trouble. Are you sure that the bore is 3.5mm? For me, a 3.2mm drill bit fit fairly well, and i didn't want to alter the nozzle by going down with a bigger one.

As far as my problem goes, i still haven't figured out what causes it. For now, i can print a second layer that is good enough by waiting five minutes (at full temp) after the first layer and then repriming the nozzle.

It feels a lot like it is the hotend causing the trouble. Are you sure that the bore is 3.5mm? For me, a 3.2mm drill bit fit fairly well, and i didn't want to alter the nozzle by going down with a bigger one.

|

Re: Second layer too thin February 16, 2012 12:07PM |

Admin Registered: 17 years ago Posts: 7,879 |

@imitation,

I don't think Wolgang is having a go at me. Remember he is not a native English speaker.

@Wolfgang,

There was no ABS left because it had been in acetone on and off for a week with random agitation and raking with a drill, etc.. I have two more in MEK at the moment (nasty stuff!)

The inside is smooth all the way to the end is it not? Its the inside of the PTFE liner.

Are you saying the inside of the brass is tapped M3.5?

[www.hydraraptor.blogspot.com]

I don't think Wolgang is having a go at me. Remember he is not a native English speaker.

@Wolfgang,

There was no ABS left because it had been in acetone on and off for a week with random agitation and raking with a drill, etc.. I have two more in MEK at the moment (nasty stuff!)

The inside is smooth all the way to the end is it not? Its the inside of the PTFE liner.

Are you saying the inside of the brass is tapped M3.5?

[www.hydraraptor.blogspot.com]

|

Re: Second layer too thin February 16, 2012 12:21PM |

Registered: 12 years ago Posts: 36 |

nophead Wrote:

> Are you saying the inside of the brass is tapped

> M3.5?

3.5h7 refers to the standard tolerance you get with a drill bit - meaning the bore will either be spot-on or a tiny bit too large. The two threads in Wolfgang's hotend are M6 for the heater block and - i think - M10 for the PEEK.

3.5mm sounds a bit large for 3mm filament - that, in combination with some aging effect, could explain some of the behavior we're seeing.

> Are you saying the inside of the brass is tapped

> M3.5?

3.5h7 refers to the standard tolerance you get with a drill bit - meaning the bore will either be spot-on or a tiny bit too large. The two threads in Wolfgang's hotend are M6 for the heater block and - i think - M10 for the PEEK.

3.5mm sounds a bit large for 3mm filament - that, in combination with some aging effect, could explain some of the behavior we're seeing.

|

Re: Second layer too thin February 17, 2012 03:37AM |

Registered: 14 years ago Posts: 7,505 |

It is not only drilled... i cant translate...

I use this to make the hole better.

And 3mm is to small, did not work. You need to much force to get the filament into.

Mfg

Wolfgang

Erfahrungen kann man leider schlecht weiter geben, die muss man selber machen.

I use this to make the hole better.

And 3mm is to small, did not work. You need to much force to get the filament into.

Mfg

Wolfgang

| Aller Anfang war schwer - Wolfstrap | Reprap-fab.org |  |

Erfahrungen kann man leider schlecht weiter geben, die muss man selber machen.

|

Re: Second layer too thin February 17, 2012 03:39AM |

Registered: 14 years ago Posts: 3,742 |

He used a reamer...

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

|

Re: Second layer too thin February 17, 2012 03:57AM |

Registered: 14 years ago Posts: 7,505 |

there are people, they use the Tip since more then a year with PLA. Without any aging. This effekt is only with some ABS. Not with all.

Mfg

Wolfgang

Erfahrungen kann man leider schlecht weiter geben, die muss man selber machen.

Mfg

Wolfgang

| Aller Anfang war schwer - Wolfstrap | Reprap-fab.org |  |

Erfahrungen kann man leider schlecht weiter geben, die muss man selber machen.

|

Re: Second layer too thin February 17, 2012 06:07AM |

Admin Registered: 17 years ago Posts: 7,879 |

I didn't use the 3mm drill to drill out the solid ABS. I used it as a rake to remove the part dissolved ABS sludge and then put it back in the acetone for more dissolving, until it was all gone. It takes many days otherwise.

I put a part used ABS spool on yesterday and it would not go past the first layer with 0.35mm nozzle @ only 20mm/s. I changed to a brand new spool of the same plastic and it worked. The only difference was the new spool was 2.99mm and the old 2.96mm. There is nothing obviously wrong with the old spool, I had already used most of it on another machine with a 0.4 or 0.5mm nozzle.

Maybe the force to extrude is simply too high and it it right on the limit of grip for ABS. If the plastic is a little softer it strips. The odd thing is this nozzle used to be able to do 36mm/s but now only 20mm/s and only with some spools of plastic.

I generally find smaller diameter filament is harder to push because it has to be fed faster and there is more backflow, but 2.96 is hardly small. It is when it is 2.84mm I normally start to get problems in extruders with a 3.3mm bore.

Edited 1 time(s). Last edit at 02/17/2012 06:10AM by nophead.

[www.hydraraptor.blogspot.com]

I put a part used ABS spool on yesterday and it would not go past the first layer with 0.35mm nozzle @ only 20mm/s. I changed to a brand new spool of the same plastic and it worked. The only difference was the new spool was 2.99mm and the old 2.96mm. There is nothing obviously wrong with the old spool, I had already used most of it on another machine with a 0.4 or 0.5mm nozzle.

Maybe the force to extrude is simply too high and it it right on the limit of grip for ABS. If the plastic is a little softer it strips. The odd thing is this nozzle used to be able to do 36mm/s but now only 20mm/s and only with some spools of plastic.

I generally find smaller diameter filament is harder to push because it has to be fed faster and there is more backflow, but 2.96 is hardly small. It is when it is 2.84mm I normally start to get problems in extruders with a 3.3mm bore.

Edited 1 time(s). Last edit at 02/17/2012 06:10AM by nophead.

[www.hydraraptor.blogspot.com]

|

Re: Second layer too thin February 17, 2012 08:04AM |

Registered: 14 years ago Posts: 7,505 |

But i see something at the Picture

1 is to far away from the Table (dont stick)

3 is ok

2 is down left to near at the table

4,5,6,7,8 is to near at the Table, this close the Hole of the Nozzle. The screw runs "into" the Filament. The screw after that is durty. It cant transport the Filament as it must.

Sorry for my bad english...

Mfg

Wolfgang

Erfahrungen kann man leider schlecht weiter geben, die muss man selber machen.

1 is to far away from the Table (dont stick)

3 is ok

2 is down left to near at the table

4,5,6,7,8 is to near at the Table, this close the Hole of the Nozzle. The screw runs "into" the Filament. The screw after that is durty. It cant transport the Filament as it must.

Sorry for my bad english...

Mfg

Wolfgang

| Aller Anfang war schwer - Wolfstrap | Reprap-fab.org |  |

Erfahrungen kann man leider schlecht weiter geben, die muss man selber machen.

|

Re: Second layer too thin February 17, 2012 08:11AM |

Registered: 14 years ago Posts: 3,742 |

I think what Wolfgang (Stoffel15) is trying to say is that your table is not level.

Check your distance from the hot end in the four corners and the middle.

They should all have the tip of the hot end exactly the same distance from the bed.

If left/right are different it could be the bed or the X-axis.

If front/back are different then it must be the bed.

Edited 1 time(s). Last edit at 02/17/2012 09:12AM by rhmorrison.

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

Check your distance from the hot end in the four corners and the middle.

They should all have the tip of the hot end exactly the same distance from the bed.

If left/right are different it could be the bed or the X-axis.

If front/back are different then it must be the bed.

Edited 1 time(s). Last edit at 02/17/2012 09:12AM by rhmorrison.

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

|

Re: Second layer too thin February 17, 2012 08:27AM |

Registered: 14 years ago Posts: 7,505 |

Yes, thank you Bob.

Mfg

Wolfgang

Erfahrungen kann man leider schlecht weiter geben, die muss man selber machen.

Mfg

Wolfgang

| Aller Anfang war schwer - Wolfstrap | Reprap-fab.org |  |

Erfahrungen kann man leider schlecht weiter geben, die muss man selber machen.

|

Re: Second layer too thin February 17, 2012 08:35AM |

Registered: 12 years ago Posts: 36 |

Like i said, i am absolutely certain that the bed is level. I use a piece of paper to check the distance. If it was unlevel, there wouldn't be that much of a difference from 5 -> 3. The pieces were printed (first to last) 7, 5, 8, 6, 4, 2, 3, 1. While the first couple parts came out too thin, you can see it improving a lot from 2 -> 3 ->1. The blob on 1 is where i stopped the print.

I can also confirm that the hobbed bolt is perfectly clean, i barely ever have to clean it out. It produces enough grip to lift the printer off the floor.

I can also confirm that the hobbed bolt is perfectly clean, i barely ever have to clean it out. It produces enough grip to lift the printer off the floor.

|

Re: Second layer too thin February 17, 2012 09:32AM |

Admin Registered: 17 years ago Posts: 7,879 |

Do you wait for the nozzle and bed supports to expand before starting? I wait a couple of minutes after the bed and extruder are up to temperature, otherwise I get variable layer height during the first layers.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: Second layer too thin February 17, 2012 10:00AM |

Registered: 14 years ago Posts: 7,505 |

Your first layer is to thin... it must look like the part number 3 (now) at the picture.

If you goes so near to the Table you close the Hole, then you get dirt in the Screw... maybe it goes off after a wile printing. Thats why the last parts are a little better.

Clean the Table with some Acetone, then it glues better.

Mfg

Wolfgang

Erfahrungen kann man leider schlecht weiter geben, die muss man selber machen.

If you goes so near to the Table you close the Hole, then you get dirt in the Screw... maybe it goes off after a wile printing. Thats why the last parts are a little better.

Clean the Table with some Acetone, then it glues better.

Mfg

Wolfgang

| Aller Anfang war schwer - Wolfstrap | Reprap-fab.org |  |

Erfahrungen kann man leider schlecht weiter geben, die muss man selber machen.

|

Re: Second layer too thin February 18, 2012 12:45AM |

Registered: 12 years ago Posts: 229 |

It seems like you are printing too quickly, although the host software may say the hotend temp is correct, the temperature in the centre of the molten plastic may be much cooler. resistors over 6 ohms have trouble keeping up unless you insulate heavily. (and remove any fans blowing on the hotend)

Try slowing your feed and flow rates to 15mm/s for the entire build and see what happens.

If that works, you can insulate the hotend and use the power of the heater more efficiently and get faster speeds.

FYI: the skeinforge default is 30mm/s for feed and flow rates. I set mine to 12mm/s with a 0.4 layer height and worked all the bugs out. Now I'm printing at 25mm/s at 0.3 layer height with insulation around the lower half of the hotend. The heater runs at about a 50% duty cycle so I could go faster. My only limitation for speed now is the rigidity of the frame.

Try slowing your feed and flow rates to 15mm/s for the entire build and see what happens.

If that works, you can insulate the hotend and use the power of the heater more efficiently and get faster speeds.

FYI: the skeinforge default is 30mm/s for feed and flow rates. I set mine to 12mm/s with a 0.4 layer height and worked all the bugs out. Now I'm printing at 25mm/s at 0.3 layer height with insulation around the lower half of the hotend. The heater runs at about a 50% duty cycle so I could go faster. My only limitation for speed now is the rigidity of the frame.

|

Re: Second layer too thin February 22, 2012 11:45AM |

Registered: 12 years ago Posts: 36 |

Thanks for everyone's input so far. I have another hotend incoming, until then i'll try all suggestions posted here. I'll report back if i make any progress.

@aplavins: Wolfgang's hotend use a 6.8Ohm resistor, but my PID regulation rarely sets the output to more than 90 (of 127) while printing. I have the heater block insulated with no fan blowing at it. I have successfully used these hotends up to 120mm/s, so i know temperature drop is not that much of an issue. Also, setting the temp to 250°C doesn't help; going slower mitigated the issue, but not much. Having to slow down to 15mm/s or even 25mm/s makes rapid prototyping a lot less rapid - for me, it would lose a lot of its appeal.

@nophead: I tried waiting 1, 5 and 10 minutes at print-ready temperatures before starting the print. No difference.

@Wolfgang: With the first couple of prints, i think everyone had that happen at some point - so did i. However, if i now set my endstop any higher, the first layer is too thin as well, so i think i got the z-height about right. I've watched my hobbed bolt during the first layers and couldn't make out any stripping.

@aplavins: Wolfgang's hotend use a 6.8Ohm resistor, but my PID regulation rarely sets the output to more than 90 (of 127) while printing. I have the heater block insulated with no fan blowing at it. I have successfully used these hotends up to 120mm/s, so i know temperature drop is not that much of an issue. Also, setting the temp to 250°C doesn't help; going slower mitigated the issue, but not much. Having to slow down to 15mm/s or even 25mm/s makes rapid prototyping a lot less rapid - for me, it would lose a lot of its appeal.

@nophead: I tried waiting 1, 5 and 10 minutes at print-ready temperatures before starting the print. No difference.

@Wolfgang: With the first couple of prints, i think everyone had that happen at some point - so did i. However, if i now set my endstop any higher, the first layer is too thin as well, so i think i got the z-height about right. I've watched my hobbed bolt during the first layers and couldn't make out any stripping.

|

Re: Second layer too thin March 17, 2012 05:33PM |

Registered: 12 years ago Posts: 36 |

Hi everyone,

my Budaschnozzle v1.1 0.5mm arrived a couple days ago, today i found some time to try it out. As advertised, it performs incredibly well on higher speeds, it is very easy to push filament through, but in turn, it oozes like an ice cream cone on a hot summer's day and takes twice as long to heat up as Wolfgang's hotend. It also makes no difference in the issue i'm seeing, so it is definitely not the hotend failing in any way. Sorry if questioned your craftsmanship, Wolfgang . Prints as slow as 5mm/s still show the same artifacts.

. Prints as slow as 5mm/s still show the same artifacts.

So i concluded the only other part that could be faulty was the cartesian bot - hard for me to believe, so i pulled out my dial gauge and measured away. Interestingly, i measured about 50µm of backlash in the z-axis, even though i have the anti-backlash springs and nuts installed. But the lash couldn't be the issue, since i have my bot "touch down" to Z0 right before the actual print starts.

But here is a far more interesting measurement - the center of the bed. Since i don't have a sheet of glass or aluminum on top of the Prusa heater, any warpage of the bed will directly influence the layer height. This is what i found:

It affects the second layer the most, since i have SF and Slic3r set to drop the bed temp to 100°C after the first layer. But even when keeping the bed temperature constant, i assume it is most visible on the second layer because the upper layers have some material that sticks up, most likely hex infill curling up, to hold on to - but the first layer always sticks flat to the bed.

So i guess i'll have to get another glass sheet made - i was trying to avoid glass since i already broke a sheet on my second printer. Aluminum is too hard to come by as a +- 50µ flat sheet, and i don't want to wait for a 6 or 8mm thick piece to warm up.

I'll mark this thread as [solved] since i'm sure i've found the underlying problem. If anyone is interested in Youtube video of this wicked behavior, let me know and i'll upload one.

Thanks again for everyone's input and have a nice weekend!

-Tom

my Budaschnozzle v1.1 0.5mm arrived a couple days ago, today i found some time to try it out. As advertised, it performs incredibly well on higher speeds, it is very easy to push filament through, but in turn, it oozes like an ice cream cone on a hot summer's day and takes twice as long to heat up as Wolfgang's hotend. It also makes no difference in the issue i'm seeing, so it is definitely not the hotend failing in any way. Sorry if questioned your craftsmanship, Wolfgang

. Prints as slow as 5mm/s still show the same artifacts.

. Prints as slow as 5mm/s still show the same artifacts. So i concluded the only other part that could be faulty was the cartesian bot - hard for me to believe, so i pulled out my dial gauge and measured away. Interestingly, i measured about 50µm of backlash in the z-axis, even though i have the anti-backlash springs and nuts installed. But the lash couldn't be the issue, since i have my bot "touch down" to Z0 right before the actual print starts.

But here is a far more interesting measurement - the center of the bed. Since i don't have a sheet of glass or aluminum on top of the Prusa heater, any warpage of the bed will directly influence the layer height. This is what i found:

- As soon as the HBP gets powered, it rises (i have the copper traces, which expand, on top) by as much as 200µ within two seconds

- Within ten seconds, it expands to a total of 300µ (that's .3mm!)

- While heating to the 120°C target, it un-warps due to the more evenly distributed heat throughout the HBP, and therefore shrinks back by ~50µ

- When the power gets turned off, it shrinks another 200µ within two seconds and a total of 300µ within ten seconds

- Rinse and repeat as the firmware does its bang-bang regulation on the bed temperature

- In total, the bed swings up and down .35mm during a full heating cycle

It affects the second layer the most, since i have SF and Slic3r set to drop the bed temp to 100°C after the first layer. But even when keeping the bed temperature constant, i assume it is most visible on the second layer because the upper layers have some material that sticks up, most likely hex infill curling up, to hold on to - but the first layer always sticks flat to the bed.

So i guess i'll have to get another glass sheet made - i was trying to avoid glass since i already broke a sheet on my second printer. Aluminum is too hard to come by as a +- 50µ flat sheet, and i don't want to wait for a 6 or 8mm thick piece to warm up.

I'll mark this thread as [solved] since i'm sure i've found the underlying problem. If anyone is interested in Youtube video of this wicked behavior, let me know and i'll upload one.

Thanks again for everyone's input and have a nice weekend!

-Tom

Sorry, only registered users may post in this forum.