Pressure Block for Wade's Extruder

Posted by MichaelT

|

Pressure Block for Wade's Extruder December 06, 2010 08:43AM |

Registered: 13 years ago Posts: 13 |

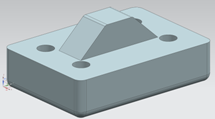

When I was part of a Mendel build we decided to use Wade's extruder. We printed all parts but found that we needed something to pressure the filament into the hobbed bolt. As far as I remember it didn't say how to do this, so we decided to make our own pressure block. It can be seen on the picture.

So far it has worked as it should. Here is the STL file PressureblockforWadesExtruder.stl

Or you can look at the forum on NordicRepRap.com

-Michael

Or you can look at the forum on NordicRepRap.com

-Michael

|

Re: Pressure Block for Wade's Extruder December 06, 2010 09:35AM |

Registered: 14 years ago Posts: 3,742 |

Wades' Idler Block:

You have a BAD STL file for the idler!

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

... for the idler

* 1 X 608 bearing (Skateboard bearing);

* 1 X M8X20 piece of smooth bar, threaded bar or a bolt;

* 4 X M4X45 bolts; - hex head will work best (they won't turn), and longer than 45 mm will be easier to assemble if you can find them.

* 4 X M4 nuts;

* 4 X M4 washers;

* 4 X Springs - 1 mm diameter wire, wound to an OD of 10 mm, with 4 active coils. For a given filament drive force, you'll need about twice the spring force - ie, if you want 100 N of filament drive, your springs need to push with about 50 N each. NOTE: some users have theirs extruders working without this springs, but springs are recommended.

* 16 M4 washers; - optional; 4 washers on each M4X45 idler bolt between the main block and the idler block will limit the idler travel and make reloading filament easier.

You have a BAD STL file for the idler!

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

|

Re: Pressure Block for Wade's Extruder December 09, 2010 11:02AM |

Registered: 13 years ago Posts: 13 |

|

Re: Pressure Block for Wade's Extruder December 09, 2010 11:36AM |

Registered: 14 years ago Posts: 3,742 |

Quote

MichaelT

We printed all parts but found that we needed something to pressure the filament into the hobbed bolt. As far as I remember it didn't say how to do this, so we decided to make our own pressure block.

Oh, I see now... THAT is your modified pressure block.

It will NOT WORK like that!

If you look at the picture in my previous message you see that the Wade pressure block has two holes.

You cut a very short piece of 8 mm steel rod (the width of the pressure block) and then place a 608 bearing onto the rod and snap it into place.

You tighten your bolts for good grip (without deforming the filament).

Without a bearing you won't be able to move the filament, or you will have it too loose to do any good.

You MUST use a 608 bearing (at least for the Wade pressure block)!

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

|

Re: Pressure Block for Wade's Extruder December 13, 2010 06:31AM |

Registered: 13 years ago Posts: 13 |

|

Re: Pressure Block for Wade's Extruder December 15, 2010 01:46PM |

Registered: 13 years ago Posts: 601 |

I think he meant that the standard pressure block will not work without a ball bearing.

Your modified block will work, but it won't be a long term solution. The more you tighten the bolts (in order for the teeth to get better purchase in the filament), the more friction you are going to have. The extra friction, especially static friction, might offset any benefit of having the teeth bite in more. The hobbed bolt is just going to grind away the filament and you'll have to disassemble to clean the plastic out of the teeth.

Even when you adjust the bolts to get the pressure just right, the filament will still wear a groove into that protrusion on your block, eventually.

a ball bearing won't wear in this situation, and minimizes friction, which is why it's in the standard block. your modified block might be good to have in a backup parts kit, though, just in case the standard one breaks. However, I think the problems with it are going to make it hard to get very high quality prints.

Your modified block will work, but it won't be a long term solution. The more you tighten the bolts (in order for the teeth to get better purchase in the filament), the more friction you are going to have. The extra friction, especially static friction, might offset any benefit of having the teeth bite in more. The hobbed bolt is just going to grind away the filament and you'll have to disassemble to clean the plastic out of the teeth.

Even when you adjust the bolts to get the pressure just right, the filament will still wear a groove into that protrusion on your block, eventually.

a ball bearing won't wear in this situation, and minimizes friction, which is why it's in the standard block. your modified block might be good to have in a backup parts kit, though, just in case the standard one breaks. However, I think the problems with it are going to make it hard to get very high quality prints.

|

Re: Pressure Block for Wade's Extruder December 15, 2010 03:29PM |

Admin Registered: 17 years ago Posts: 7,879 |

It would probably work quite well printed in HDPE. With the original screw drive extruder I used an HDPE filament guide to press the filament into the thread. People (Charles Pax IIRC) have also used Delrin to apply pressure and reported good results. ABS is soft and will wear quickly as it not very slippery. PLA is harder but even less slippery.

The 608 bearing is a better solution because it will have the lowest friction and never wear out. Another of those self replication versus reliability quandaries.

[www.hydraraptor.blogspot.com]

The 608 bearing is a better solution because it will have the lowest friction and never wear out. Another of those self replication versus reliability quandaries.

[www.hydraraptor.blogspot.com]

|

Re: Pressure Block for Wade's Extruder December 19, 2010 03:24PM |

Registered: 13 years ago Posts: 13 |

Sorry, only registered users may post in this forum.