What temparature should I expect where inside my extruder hotend?

Posted by Flackster

|

What temparature should I expect where inside my extruder hotend? September 16, 2011 10:17AM |

Registered: 13 years ago Posts: 104 |

I've been having trouble with my extruder/hot end occasionally jamming. I believe this is because the temperature inside my PTFE barrier is too high, the PLA undergoes 'glass transition' and expands causing it to jam.

So, I thought I'd try to measure the temperature inside my hot end using a thermocouple thermometer.

My understanding is that PLA undergoes 'glass transition' at about 60deg C. So, I assume I want my hot end temperature inside the PTFE part to be less than that. That sounds quite hard to achieve since I'm heated the nozzle to 180-200 deg C just a couple of centimetres away. Have I misunderstood what temperatures should occur where?

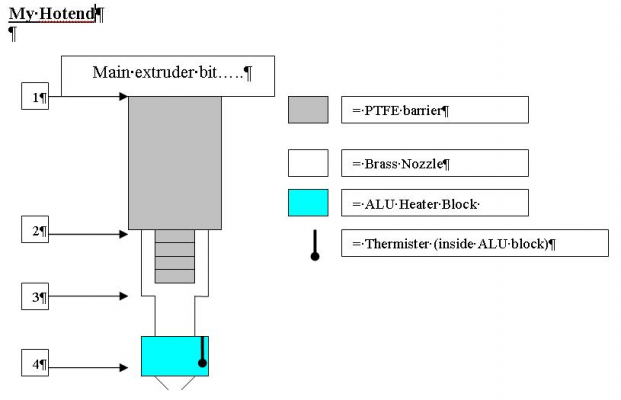

What I'd be interested to know is what sort of temperature people have in your hotends. In particular, where the PLA filament will be surrounded by PTFE. See attached diagram - What sorts of temperature should I expect where?

Assuming that my temperature is too high - Any suggests about the best way to cool it. Heat sink (made from some material I can easily get hold of)? Small fan? (How small?)

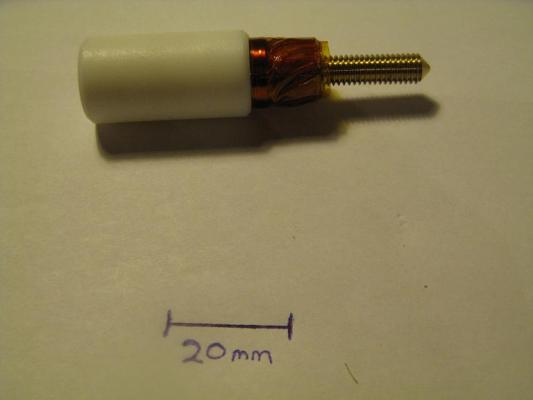

My hot end looks like this:

All help very much appreciated

Thanks

Pete

(In case it matters, I've a Mendel with Gen6 electronics running RepSnapper)

So, I thought I'd try to measure the temperature inside my hot end using a thermocouple thermometer.

My understanding is that PLA undergoes 'glass transition' at about 60deg C. So, I assume I want my hot end temperature inside the PTFE part to be less than that. That sounds quite hard to achieve since I'm heated the nozzle to 180-200 deg C just a couple of centimetres away. Have I misunderstood what temperatures should occur where?

What I'd be interested to know is what sort of temperature people have in your hotends. In particular, where the PLA filament will be surrounded by PTFE. See attached diagram - What sorts of temperature should I expect where?

Assuming that my temperature is too high - Any suggests about the best way to cool it. Heat sink (made from some material I can easily get hold of)? Small fan? (How small?)

My hot end looks like this:

All help very much appreciated

Thanks

Pete

(In case it matters, I've a Mendel with Gen6 electronics running RepSnapper)

|

Re: What temparature should I expect where inside my extruder hotend? September 16, 2011 04:37PM |

Registered: 15 years ago Posts: 332 |

|

Re: What temparature should I expect where inside my extruder hotend? September 16, 2011 08:44PM |

Registered: 13 years ago Posts: 301 |

|

Re: What temparature should I expect where inside my extruder hotend? September 17, 2011 11:13AM |

Registered: 13 years ago Posts: 1,780 |

You have to major problems with your hot end design. First, the heater is too close to the PTFE when it should be on the other end as near to the tip of the amall nozzle opening as possible. This is why your PTFE is getting too hot. The second is that the brass nozzle would tend to pop out of the PTFE once it's hot as PTFE softens and the nozzle loosens as PTFE expands more than brass. This is why Adrian's design include a PEEK block to keep that from happening and current designs now use PTFE lined PEEK instead of PTFE insulator.

Having corrected those problems, you might still find it necessary to provide additional cooling to the thermal insulation using forced air or heat sink in order to use PLA.

Edited 1 time(s). Last edit at 09/17/2011 11:15AM by brnrd.

Having corrected those problems, you might still find it necessary to provide additional cooling to the thermal insulation using forced air or heat sink in order to use PLA.

Edited 1 time(s). Last edit at 09/17/2011 11:15AM by brnrd.

Sorry, only registered users may post in this forum.