Double Extruder Idea - (Not a dual extruder)

Posted by enuro12

|

Double Extruder Idea - (Not a dual extruder) May 23, 2012 08:59PM |

Registered: 11 years ago Posts: 16 |

Not to be confused with a dual extruder!

I've been researching 'reusing' and diy 'filament' methods. What i've seen amounts to poor quality at best and a whole lot more effort that i care to put into it.

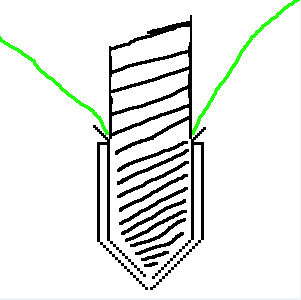

I've thought up the double extruder. It would require the addition of a servo or maybe parking the head when not in use. The stepper becomes a constant drive screw/auger. Filament or chunks of plastic are fed directly into the screw and get melted as they enter the head. As the filament melts and is extruded from the primary extruder it enters the secondary extruder head. If the tip is blocked (via a servo or parking the head) the fillament just travels around the secondary cavity and back into the extruder screw.

The cavity between the primary and secondary would need to be wide enough that it could fill and flow relitivly easy rather than trying to push out the head.

Basicly you're combining the filament extruder with a regular extruder so instead of trying to get a nice piece of filament to work with, you can toss in small plastic chunks from your shredder and out comes the product.

I've been researching 'reusing' and diy 'filament' methods. What i've seen amounts to poor quality at best and a whole lot more effort that i care to put into it.

I've thought up the double extruder. It would require the addition of a servo or maybe parking the head when not in use. The stepper becomes a constant drive screw/auger. Filament or chunks of plastic are fed directly into the screw and get melted as they enter the head. As the filament melts and is extruded from the primary extruder it enters the secondary extruder head. If the tip is blocked (via a servo or parking the head) the fillament just travels around the secondary cavity and back into the extruder screw.

The cavity between the primary and secondary would need to be wide enough that it could fill and flow relitivly easy rather than trying to push out the head.

Basicly you're combining the filament extruder with a regular extruder so instead of trying to get a nice piece of filament to work with, you can toss in small plastic chunks from your shredder and out comes the product.

|

Re: Double Extruder Idea - (Not a dual extruder) June 15, 2012 01:40AM |

That is a good idea to turning pellets into filament, since it adds a method to consistently control filament output from the valve. The ability to make filament from pellets was discussed as something needed. And that idea adds consistency to filament output.

If the push is pressure plate or even heavy weight on a piston like valve in a hopper, then the push to move fluid out would be at some rate based on pressure.

If back pressure is put on the output, after traveling though a copper tube that cools filament, then the maximum speed of output is controlled, that would create back pressure. Just like the filament is pushed into a printer valve, it could be restrained from leaving the pellet to filament machine valve except at one speed, and any excess pressure would be forced out into a tube going to store the plastic for next cooking of waste plastic to filaments.

That solves many problems of different pressure levels when turning pellets to filaments, and consistent pressure adds to a consistent output. With the back pressure, and from a vacuum heated cooking area, the plastic output filament would have very few air bubbles and be of consistent quality of thickness.

Any output pressure more then speed required is released by second exit from mechanism.

And output would also have back pressure if it feeds through a mechanism limiting its output speed.

One exit from valve leaves to cooling tube then into speed setting device for back pressure, that limits output of filament.

The other exit from valve goes to some area for storage to be used again in next batch it is not speed regulated so all excess pressure is vented through that tube.

Robert Eastwood

If the push is pressure plate or even heavy weight on a piston like valve in a hopper, then the push to move fluid out would be at some rate based on pressure.

If back pressure is put on the output, after traveling though a copper tube that cools filament, then the maximum speed of output is controlled, that would create back pressure. Just like the filament is pushed into a printer valve, it could be restrained from leaving the pellet to filament machine valve except at one speed, and any excess pressure would be forced out into a tube going to store the plastic for next cooking of waste plastic to filaments.

That solves many problems of different pressure levels when turning pellets to filaments, and consistent pressure adds to a consistent output. With the back pressure, and from a vacuum heated cooking area, the plastic output filament would have very few air bubbles and be of consistent quality of thickness.

Any output pressure more then speed required is released by second exit from mechanism.

And output would also have back pressure if it feeds through a mechanism limiting its output speed.

One exit from valve leaves to cooling tube then into speed setting device for back pressure, that limits output of filament.

The other exit from valve goes to some area for storage to be used again in next batch it is not speed regulated so all excess pressure is vented through that tube.

Robert Eastwood

|

Re: Double Extruder Idea - (Not a dual extruder) July 03, 2012 04:05AM |

Registered: 11 years ago Posts: 1 |

Sorry, only registered users may post in this forum.