Muxtruder - WIP open source plastic extruder

Posted by mux

|

Muxtruder - WIP open source plastic extruder September 26, 2013 03:43AM |

Registered: 13 years ago Posts: 4 |

Let me preface this with: this is a working design, but it is absolutely too early to release as proper open hardware right now. Electronics don't work right yet, the printed parts are totally unoptimized and the nozzle design is primitive. This topic is meant to get input on this project's viability and find people that are interested to help development.

Alright, with that out of the way: I have been building a plastic extruder, mostly out of necessity. For my internship I had to devise a way to print with a plastic that was only available as granulate. Even though there have been some very high profile extruder projects out there (Lyman, Filabot, Filastruder, ExtrusionBot), none of them were available in a form that wouldn't require a whole bunch of work - or available at all. Many of them - most famously Lyman - claim low part cost, but only when you order the parts in thousands quantities. And because I'm an electronics guy I also took some offense from the meh electronics design on most of them.

So, instead of bitching about it I just designed something that is:

- Actually cheap to build in low quantities

- Simple to build and assemble using tools available to most of us (i.e. no milled, extruded, lathed parts)

- don't require you to do your own sourcing for absolutely everything, i.e. no proper BOM attached.

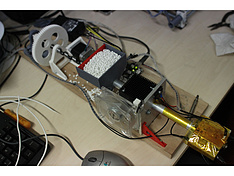

So this is my first iteration:

full image

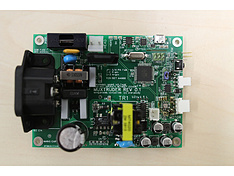

I've also designed a custom electronics board for it. It is essentially a sanguinololu with all the unnecessary parts ripped out and a 90-240VAC/16W power supply added. There is also galvanically isolated USB on there. Here it is:

full image

Because it's a sanguinololu, the board doesn't need any custom firmware or host software. All you need is something like Repetier and the extruder will present itself as if it were a reprap 3D printer with just a nozzle. Only an extruder motor and heater. As you can see on the first picture, I am not actually using the custom electronics right now. That is because there are some bugs, most notably with the power supply not performing quite as it should (it seems to have trouble with >160VAC) and the stepper driver having the wrong footprint (derp). I will respin the board this week.

I've also attached a vestigial part of the manual. I hesitated to release it in incomplete form, but I am really pressed for time this week and I also really wanted the project to be out in the open and commented on.

My question to you is:

- Is this project a viable open source plastic extruder, i.e. is it worth my time and the time of future contributors to develop this into a fully functional, high quality machine? I invested about a man-month into development so far. I expect at least a man-year of development, testing and refinement until this could be acceptable quality for e.g. Kickstarter or general open source usage

- Is the project interesting enough, or will it be forgotten in the masses of other efforts people are doing in this field? Is there enough innovation to warrant attention?

If the answer to both of those questions is no, then I'll just continue development until the projects is good enough for myself, and then stop. There is way too much work in this that doesn't benefit myself, but needs to be done to make this project of acceptable quality for the masses.

If the answer is yes, a godawful amount of mostly testing and review needs to be done and I would like to ask the community to take a leap of faith and try it out. The end goal is to make a complete package that could easily be sold in kit form, just like reprap kits, and assembled without finding out that you actually need other stuff as well, or dicking around in Arduino for a week until you get the config settings right. One seller making the electronics, the next selling aluminum parts and screws, the last one selling the printed parts. Assemble it and it works.

Manual: Muxtruder manual (INCOMPLETE)

Edited 1 time(s). Last edit at 09/26/2013 04:07AM by mux.

[ssj3gohan.tweakblogs.net]

Alright, with that out of the way: I have been building a plastic extruder, mostly out of necessity. For my internship I had to devise a way to print with a plastic that was only available as granulate. Even though there have been some very high profile extruder projects out there (Lyman, Filabot, Filastruder, ExtrusionBot), none of them were available in a form that wouldn't require a whole bunch of work - or available at all. Many of them - most famously Lyman - claim low part cost, but only when you order the parts in thousands quantities. And because I'm an electronics guy I also took some offense from the meh electronics design on most of them.

So, instead of bitching about it I just designed something that is:

- Actually cheap to build in low quantities

- Simple to build and assemble using tools available to most of us (i.e. no milled, extruded, lathed parts)

- don't require you to do your own sourcing for absolutely everything, i.e. no proper BOM attached.

So this is my first iteration:

full image

I've also designed a custom electronics board for it. It is essentially a sanguinololu with all the unnecessary parts ripped out and a 90-240VAC/16W power supply added. There is also galvanically isolated USB on there. Here it is:

full image

Because it's a sanguinololu, the board doesn't need any custom firmware or host software. All you need is something like Repetier and the extruder will present itself as if it were a reprap 3D printer with just a nozzle. Only an extruder motor and heater. As you can see on the first picture, I am not actually using the custom electronics right now. That is because there are some bugs, most notably with the power supply not performing quite as it should (it seems to have trouble with >160VAC) and the stepper driver having the wrong footprint (derp). I will respin the board this week.

I've also attached a vestigial part of the manual. I hesitated to release it in incomplete form, but I am really pressed for time this week and I also really wanted the project to be out in the open and commented on.

My question to you is:

- Is this project a viable open source plastic extruder, i.e. is it worth my time and the time of future contributors to develop this into a fully functional, high quality machine? I invested about a man-month into development so far. I expect at least a man-year of development, testing and refinement until this could be acceptable quality for e.g. Kickstarter or general open source usage

- Is the project interesting enough, or will it be forgotten in the masses of other efforts people are doing in this field? Is there enough innovation to warrant attention?

If the answer to both of those questions is no, then I'll just continue development until the projects is good enough for myself, and then stop. There is way too much work in this that doesn't benefit myself, but needs to be done to make this project of acceptable quality for the masses.

If the answer is yes, a godawful amount of mostly testing and review needs to be done and I would like to ask the community to take a leap of faith and try it out. The end goal is to make a complete package that could easily be sold in kit form, just like reprap kits, and assembled without finding out that you actually need other stuff as well, or dicking around in Arduino for a week until you get the config settings right. One seller making the electronics, the next selling aluminum parts and screws, the last one selling the printed parts. Assemble it and it works.

Manual: Muxtruder manual (INCOMPLETE)

Edited 1 time(s). Last edit at 09/26/2013 04:07AM by mux.

[ssj3gohan.tweakblogs.net]

|

Re: Muxtruder - WIP open source plastic extruder September 26, 2013 04:42PM |

Registered: 11 years ago Posts: 210 |

|

Re: Muxtruder - WIP open source plastic extruder September 26, 2013 04:50PM |

Registered: 13 years ago Posts: 406 |

I think its a positive thing to have more development on turning granules into filament, so some constructive comments....

why use a stepper and driver, why not a DC motor with gearbox, I think its important to have a consistant diameter of fillament, so the motor speed must be consistant, the screw must be a good fit to the barrel at working temp,

the take up spool must also be tuned not to pull to much or to little. ( usualy after a cooling bath)

been a long time since I was involved with extruders... hope this helps.

Random Precision

why use a stepper and driver, why not a DC motor with gearbox, I think its important to have a consistant diameter of fillament, so the motor speed must be consistant, the screw must be a good fit to the barrel at working temp,

the take up spool must also be tuned not to pull to much or to little. ( usualy after a cooling bath)

been a long time since I was involved with extruders... hope this helps.

Random Precision

|

Re: Muxtruder - WIP open source plastic extruder September 26, 2013 04:53PM |

Registered: 11 years ago Posts: 210 |

|

Re: Muxtruder - WIP open source plastic extruder September 26, 2013 06:28PM |

Registered: 13 years ago Posts: 406 |

He's using a stepper because steppers have open loop speed control built in

Not sure what you mean, but a 12v wiper motor (scrap yard) running from a PC power supply?.

I recently bought a pwm dc motor driver, 6amp, up tp 30v, speed pot and reverse switch readt built for £7, so good I bought another for stock.

maybe I misunderstand.

P.S proper screws had variable pitch to inrease pressure towards exit.

Edit, OK so speed read the manual, see a wiper motor being used.

Edited 2 time(s). Last edit at 09/26/2013 06:38PM by johnrpm.

Random Precision

Not sure what you mean, but a 12v wiper motor (scrap yard) running from a PC power supply?.

I recently bought a pwm dc motor driver, 6amp, up tp 30v, speed pot and reverse switch readt built for £7, so good I bought another for stock.

maybe I misunderstand.

P.S proper screws had variable pitch to inrease pressure towards exit.

Edit, OK so speed read the manual, see a wiper motor being used.

Edited 2 time(s). Last edit at 09/26/2013 06:38PM by johnrpm.

Random Precision

|

Re: Muxtruder - WIP open source plastic extruder September 26, 2013 06:33PM |

Registered: 11 years ago Posts: 210 |

He (mix) is using using a stepper motor in his design because it is capable of constant velocity without needing closed loop control.

A DC motor is not capable of this.

The downside to this is the need for external gearing, and the fact that even with reasonably sized gears, it is difficult to generate the necessary torque from a NEMA 17 stepper if you have the auger even halfway in the melt zone, which is desired for better mixing of colorant and masterbatch.

I do not know how to make it any simpler.

A DC motor is not capable of this.

The downside to this is the need for external gearing, and the fact that even with reasonably sized gears, it is difficult to generate the necessary torque from a NEMA 17 stepper if you have the auger even halfway in the melt zone, which is desired for better mixing of colorant and masterbatch.

I do not know how to make it any simpler.

|

Re: Muxtruder - WIP open source plastic extruder September 27, 2013 04:03AM |

Registered: 13 years ago Posts: 4 |

> 65C is not above the Tg of ABS.

Good point, I think I meant PLA. I learnt that the hard way by putting a PLA printed part in front of my car heating.

> why use a stepper and driver, why not a DC motor

> with gearbox, I think its important to have a

> consistant diameter of fillament, so the motor

> speed must be consistant, the screw must be a good

> fit to the barrel at working temp,

> the take up spool must also be tuned not to pull

> to much or to little. ( usualy after a cooling

> bath)

Stepper and driver: exactly to get a consistent extrusion speed, but also to keep everything compatible with reprap host software. I want this to be able to be used in tandem with a 3D printer like a 3rd or 4th extrusion head. This thing can be programmed into g-code for a print, and just extrude filament on demand. Haven't had success with this aspect yet, but the consistency is there to do it in the near future.

I haven't had any trouble with fit, but spooling is still a problem. Mostly because I have only been doing (dyed) nylon, and that stuff is super-brittle. Doesn't like bending at all.

> you definitely need several N-m of torque - hard to do that on printed gears and steppers.

I haven't found this to be true *at all*. I'm amazed at the amount of torque people are throwing at these machines. This runs at 12V @ 400mA with a 10:75 reduction and it can do 400mm/min on nylon-6, which is the most viscous material ever. With PLA it will probably do ridiculous speeds if I weren't limited by step rate.

The auger right now is about 3cm into the ~5cm melt zone. I have not tried adding colorant, but I get good dehydration and filament solidity this way (nylon is extremely hygroscopic).

[ssj3gohan.tweakblogs.net]

Good point, I think I meant PLA. I learnt that the hard way by putting a PLA printed part in front of my car heating.

> why use a stepper and driver, why not a DC motor

> with gearbox, I think its important to have a

> consistant diameter of fillament, so the motor

> speed must be consistant, the screw must be a good

> fit to the barrel at working temp,

> the take up spool must also be tuned not to pull

> to much or to little. ( usualy after a cooling

> bath)

Stepper and driver: exactly to get a consistent extrusion speed, but also to keep everything compatible with reprap host software. I want this to be able to be used in tandem with a 3D printer like a 3rd or 4th extrusion head. This thing can be programmed into g-code for a print, and just extrude filament on demand. Haven't had success with this aspect yet, but the consistency is there to do it in the near future.

I haven't had any trouble with fit, but spooling is still a problem. Mostly because I have only been doing (dyed) nylon, and that stuff is super-brittle. Doesn't like bending at all.

> you definitely need several N-m of torque - hard to do that on printed gears and steppers.

I haven't found this to be true *at all*. I'm amazed at the amount of torque people are throwing at these machines. This runs at 12V @ 400mA with a 10:75 reduction and it can do 400mm/min on nylon-6, which is the most viscous material ever. With PLA it will probably do ridiculous speeds if I weren't limited by step rate.

The auger right now is about 3cm into the ~5cm melt zone. I have not tried adding colorant, but I get good dehydration and filament solidity this way (nylon is extremely hygroscopic).

[ssj3gohan.tweakblogs.net]

|

Re: Muxtruder - WIP open source plastic extruder October 09, 2013 08:16PM |

Registered: 11 years ago Posts: 58 |

For whatever it's worth, I think this is an interesting twist - it's the first of the extruder projects I've seen that I would build. The others seem. . . clunky. This looks like a much more elegant and well-thought-through solution. And your manual is worth reading even just for the details about the other projects, even before getting to the description of your design. . .

|

Re: Muxtruder - WIP open source plastic extruder October 11, 2013 05:06AM |

Registered: 10 years ago Posts: 1,381 |

|

Re: Muxtruder - WIP open source plastic extruder October 28, 2013 03:39PM |

Registered: 13 years ago Posts: 4 |

Hey, just a quick update to let everybody know what's up with the project

This project is part of some work I did on my internship in the last 3 months. That's finished now, I've clocked in quite a few hours on the muxtruder and although I've succesfully used it, there are definitely still a slew of problems to fix before this is ready for prime time. Also, the electronic redesign is still not finished. I have to work on university work before I can continue with that.

I have also been getting tons and tons of feedback and related ideas on how to make this design work a lot better. A big part of this was a visit to Europe's largest plastics trade fair last week (K2013 in Düsseldorf). I've seen some real industrial filament extruders there (small ones with *less* performance than muxtruder easily retail for €100.000, go figure) that gave me a lot to think about the way these things should be designed. I'm definitely doing a complete mechanical redesign besides investing time into the electronics.

[ssj3gohan.tweakblogs.net]

This project is part of some work I did on my internship in the last 3 months. That's finished now, I've clocked in quite a few hours on the muxtruder and although I've succesfully used it, there are definitely still a slew of problems to fix before this is ready for prime time. Also, the electronic redesign is still not finished. I have to work on university work before I can continue with that.

I have also been getting tons and tons of feedback and related ideas on how to make this design work a lot better. A big part of this was a visit to Europe's largest plastics trade fair last week (K2013 in Düsseldorf). I've seen some real industrial filament extruders there (small ones with *less* performance than muxtruder easily retail for €100.000, go figure) that gave me a lot to think about the way these things should be designed. I'm definitely doing a complete mechanical redesign besides investing time into the electronics.

[ssj3gohan.tweakblogs.net]

|

Re: Muxtruder - WIP open source plastic extruder October 29, 2013 08:10AM |

Registered: 10 years ago Posts: 1,381 |

Sorry, only registered users may post in this forum.