Low cost 3D printing filament extruder for recycled plastics

Posted by Xabbax

|

Low cost 3D printing filament extruder for recycled plastics May 03, 2013 04:34AM |

Registered: 11 years ago Posts: 173 |

Low cost filament extruder made from 10 mm ID stainless steel tube, silver soldered inside an ordinary plumber 15 mm copper tube (melt zone) Auger is a 10 mm wood drill bit with the end cut off 5-10 mm in the melt zone. 1 mm hole in a brass endstop at the end of the copper pipe. Aluminium block with a 15 mm hole to fit around the copper pipe. Fixed to the outside of the aluminium two 220 volt 200 degree PTC heaters( I tried 12 volt 230 degrees but the temperature was to high) Insulated with glass fibre cloth. The ptc heaters are available on aliexpress for $1 each)

System driven with a car windscreen motor at the low speed (I have a 2 speed motor - salvaged from scrap yard)

I use the white plastic that is in the inside of the doors of scrap refrigerators. Cut it up with a circular saw and extrude that to a filament of 1.75 mm

I use this filament in my Delta printer on a daily basis.

The trick to have a nice filament is to let the filament run over a copper pipe that is suspended in front of the extruder and let natures G force take over. I fix a weight(clothes-peg) at the end of the filament as it comes out of the hole untill it reaches the floor and then move the end of the filament to the outside of a circle approximately 1 meter away.From then on the G force will take over and produce a nice circular movement of the filament to roll it on the floor .

The slightest air movement or other external force that you apply to the extruded filament will result in a kink in the filament - no fans required.

No fancy electronics involved.

Material cost to should be less than $100

This extruder was only tested with the white refrigerator plastic ( I think it is ABS because it will desolve in acetone ) - no ABS pellets or any other plastic tested.

Edited 1 time(s). Last edit at 05/03/2013 04:44AM by Xabbax.

System driven with a car windscreen motor at the low speed (I have a 2 speed motor - salvaged from scrap yard)

I use the white plastic that is in the inside of the doors of scrap refrigerators. Cut it up with a circular saw and extrude that to a filament of 1.75 mm

I use this filament in my Delta printer on a daily basis.

The trick to have a nice filament is to let the filament run over a copper pipe that is suspended in front of the extruder and let natures G force take over. I fix a weight(clothes-peg) at the end of the filament as it comes out of the hole untill it reaches the floor and then move the end of the filament to the outside of a circle approximately 1 meter away.From then on the G force will take over and produce a nice circular movement of the filament to roll it on the floor .

The slightest air movement or other external force that you apply to the extruded filament will result in a kink in the filament - no fans required.

No fancy electronics involved.

Material cost to should be less than $100

This extruder was only tested with the white refrigerator plastic ( I think it is ABS because it will desolve in acetone ) - no ABS pellets or any other plastic tested.

Edited 1 time(s). Last edit at 05/03/2013 04:44AM by Xabbax.

Attachments:

open | download - DSC00847.JPG (119 KB)

open | download - DSC00848.JPG (109.6 KB)

open | download - DSC00850.JPG (108.5 KB)

open | download - DSC00852.JPG (111.3 KB)

open | download - DSC00932.JPG (83.8 KB)

open | download - DSC00933.JPG (104.8 KB)

open | download - DSC00934.JPG (98.1 KB)

open | download - DSC00958.JPG (78.8 KB)

open | download - DSC00965.JPG (106.4 KB)

open | download - DSC00843.JPG (55.5 KB)

open | download - DSC00847.JPG (119 KB)

open | download - DSC00848.JPG (109.6 KB)

open | download - DSC00850.JPG (108.5 KB)

open | download - DSC00852.JPG (111.3 KB)

open | download - DSC00932.JPG (83.8 KB)

open | download - DSC00933.JPG (104.8 KB)

open | download - DSC00934.JPG (98.1 KB)

open | download - DSC00958.JPG (78.8 KB)

open | download - DSC00965.JPG (106.4 KB)

open | download - DSC00843.JPG (55.5 KB)

|

Re: Low cost 3D printing filament extruder for recycled plastics May 03, 2013 05:59AM |

Admin Registered: 11 years ago Posts: 3,096 |

I would not dare to try this indoors, the chemicals you can create by melting unknown plastics can give you all kinds of poisonous reactions. Even though it is a nice thought to do something like this.

Did you ever see this one?

[youtu.be]

It's a machine that also uses recycled plastics to create a chair that is printed in one line

Crazy!

Did you ever see this one?

[youtu.be]

It's a machine that also uses recycled plastics to create a chair that is printed in one line

Crazy!

|

Re: Low cost 3D printing filament extruder for recycled plastics May 03, 2013 07:14AM |

Registered: 13 years ago Posts: 226 |

Nice work Xabbax,

It looks like you changed the design between pics DSC00847 and DSC00850, by adding a flange to stop the heat travelling back along the extruder pipe, is that right?

Do you have temperature control at all? EDIT - now I reread your post I see you used fixed temperature heaters.

Cheers,

Gary

Edited 1 time(s). Last edit at 05/03/2013 07:15AM by garyhodgson.

------------------------------------------

garyhodgson.com/reprap | reprap.development-tracker.info | thingtracker.net

It looks like you changed the design between pics DSC00847 and DSC00850, by adding a flange to stop the heat travelling back along the extruder pipe, is that right?

Cheers,

Gary

Edited 1 time(s). Last edit at 05/03/2013 07:15AM by garyhodgson.

------------------------------------------

garyhodgson.com/reprap | reprap.development-tracker.info | thingtracker.net

|

Re: Low cost 3D printing filament extruder for recycled plastics May 03, 2013 07:22AM |

Registered: 11 years ago Posts: 173 |

|

Re: Low cost 3D printing filament extruder for recycled plastics May 03, 2013 07:27AM |

Admin Registered: 11 years ago Posts: 3,096 |

|

Re: Low cost 3D printing filament extruder for recycled plastics May 03, 2013 07:34AM |

Registered: 11 years ago Posts: 173 |

garyhodgson Wrote:

-------------------------------------------------------

> Nice work Xabbax,

>

Thank you

> It looks like you changed the design between pics

> DSC00847 and DSC00850, by adding a flange to stop

> the heat travelling back along the extruder pipe,

> is that right?

DCS00847 is a new one and similar to the one in DSC00850 but with 270 degree heaters that I want to use to test PET extrusion - when I have the time!

The flange is to limit the heat travelling backwards. I had a fan on it but the fan cooled the system to much so I removed it.

The PTC heaters are self limiting to their design temperature. Available at the source on aliexpress temperatures 80, 100, 120, 135,150,180,200,230and 270 degrees C in 220 volt and 230 degrees c in 12 volt

I am in the process of building the heatbed for my Delta with the 100 degrees C heaters

>

> Do you have temperature control at all? EDIT - now

> I reread your post I see you used fixed

> temperature heaters.

>

>

> Cheers,

> Gary

-------------------------------------------------------

> Nice work Xabbax,

>

Thank you

> It looks like you changed the design between pics

> DSC00847 and DSC00850, by adding a flange to stop

> the heat travelling back along the extruder pipe,

> is that right?

DCS00847 is a new one and similar to the one in DSC00850 but with 270 degree heaters that I want to use to test PET extrusion - when I have the time!

The flange is to limit the heat travelling backwards. I had a fan on it but the fan cooled the system to much so I removed it.

The PTC heaters are self limiting to their design temperature. Available at the source on aliexpress temperatures 80, 100, 120, 135,150,180,200,230and 270 degrees C in 220 volt and 230 degrees c in 12 volt

I am in the process of building the heatbed for my Delta with the 100 degrees C heaters

>

> Do you have temperature control at all? EDIT - now

> I reread your post I see you used fixed

> temperature heaters.

>

>

> Cheers,

> Gary

|

Re: Low cost 3D printing filament extruder for recycled plastics May 03, 2013 07:44AM |

Registered: 11 years ago Posts: 173 |

Ohmarinus Wrote:

-------------------------------------------------------

> You got an awesome project going on there anyway.

>

The recycled plastic was available so I did that was natural instead of buying very expensive plastic( even imported from China it is expensive)

> You might be able to create a machine that can

> recycle ABS filament into a new 3mm string. Is

> that even possible?..

I will try it in future but have to buy a 25 kg bag of plastic to test it - the suppliers promised a 1 or 2 kg if they have a spill somewhere but I am still waiting for that to happen. I think a 3mm extrusion is possible , yes.

-------------------------------------------------------

> You got an awesome project going on there anyway.

>

The recycled plastic was available so I did that was natural instead of buying very expensive plastic( even imported from China it is expensive)

> You might be able to create a machine that can

> recycle ABS filament into a new 3mm string. Is

> that even possible?..

I will try it in future but have to buy a 25 kg bag of plastic to test it - the suppliers promised a 1 or 2 kg if they have a spill somewhere but I am still waiting for that to happen. I think a 3mm extrusion is possible , yes.

|

Re: Low cost 3D printing filament extruder for recycled plastics May 03, 2013 02:17PM |

Registered: 12 years ago Posts: 177 |

|

Re: Low cost 3D printing filament extruder for recycled plastics May 03, 2013 03:39PM |

Registered: 11 years ago Posts: 173 |

SanjayM Wrote:

-------------------------------------------------------

> How did you grind your fridge bits into

> processable pellets/bits.

>

Cut it up in long managable strips with garden shears and then used the circular saw to cut it by moving the plastic strips back and forth over the blade shaving away 3-5 mm of plastic at a time- see the attached image of the circular saw and the modification to it.

The size of the pellets are dependent on the speed that you feed the plastic through the blade but much the same as typical wood sawdust.

> Really nice work by the way.

Thank You!

-------------------------------------------------------

> How did you grind your fridge bits into

> processable pellets/bits.

>

Cut it up in long managable strips with garden shears and then used the circular saw to cut it by moving the plastic strips back and forth over the blade shaving away 3-5 mm of plastic at a time- see the attached image of the circular saw and the modification to it.

The size of the pellets are dependent on the speed that you feed the plastic through the blade but much the same as typical wood sawdust.

> Really nice work by the way.

Thank You!

|

Re: Low cost 3D printing filament extruder for recycled plastics July 16, 2013 05:01AM |

Registered: 11 years ago Posts: 173 |

Ohmarinus Wrote:

-------------------------------------------------------

> You got an awesome project going on there anyway.

>

> You might be able to create a machine that can

> recycle ABS filament into a new 3mm string. Is

> that even possible?..

I received a bag of Tairilac ABS plastic from my local agent. Extruding very well with the maschine - a hole size of 1mm getting filament of 1.7 mm with the 200 degree PTC heaters attached. See the attached image.

-------------------------------------------------------

> You got an awesome project going on there anyway.

>

> You might be able to create a machine that can

> recycle ABS filament into a new 3mm string. Is

> that even possible?..

I received a bag of Tairilac ABS plastic from my local agent. Extruding very well with the maschine - a hole size of 1mm getting filament of 1.7 mm with the 200 degree PTC heaters attached. See the attached image.

|

Re: Low cost 3D printing filament extruder for recycled plastics July 16, 2013 06:02AM |

Registered: 10 years ago Posts: 9 |

Wow great work! Do you think it would be a simple matter of scaling everything up by the correct amount to get a 3mm filament extruder, including the heaters? also I'm not sure if I understand how you can get a 1.7mm extrusion from a 1mm hole as per your last post, is that right?

thanks!

thanks!

|

Re: Low cost 3D printing filament extruder for recycled plastics July 16, 2013 06:40AM |

Registered: 11 years ago Posts: 173 |

isotone Wrote:

-------------------------------------------------------

> Wow great work! Do you think it would be a simple

> matter of scaling everything up by the correct

> amount to get a 3mm filament extruder, including

> the heaters? also I'm not sure if I understand how

> you can get a 1.7mm extrusion from a 1mm hole as

> per your last post, is that right?

I think you can scale it up. To get the right diameter filament play around with the size of the hole.

I tried a .95 mm hole but the filament size was to small. From memory I think 1.55 mm filament.

Yes I do get a 1.7 mm filament from a 1mm hole - the molten plastic swells out as it exits the hole.

I will experiment with the hole size to see if I can get a 3mm filament.

-------------------------------------------------------

> Wow great work! Do you think it would be a simple

> matter of scaling everything up by the correct

> amount to get a 3mm filament extruder, including

> the heaters? also I'm not sure if I understand how

> you can get a 1.7mm extrusion from a 1mm hole as

> per your last post, is that right?

I think you can scale it up. To get the right diameter filament play around with the size of the hole.

I tried a .95 mm hole but the filament size was to small. From memory I think 1.55 mm filament.

Yes I do get a 1.7 mm filament from a 1mm hole - the molten plastic swells out as it exits the hole.

I will experiment with the hole size to see if I can get a 3mm filament.

|

Re: Low cost 3D printing filament extruder for recycled plastics July 16, 2013 02:39PM |

Registered: 11 years ago Posts: 173 |

isotone Wrote:

-------------------------------------------------------

> Wow great work! Do you think it would be a simple

> matter of scaling everything up by the correct

> amount to get a 3mm filament extruder, including

> the heaters?

I tested my current setup with a 2.5 mm hole and the filament that came out was 3.1 mm

I guess one could try a 2.4 mm hole ( I do not have a .4 mm drillbit could not do a test here)

-------------------------------------------------------

> Wow great work! Do you think it would be a simple

> matter of scaling everything up by the correct

> amount to get a 3mm filament extruder, including

> the heaters?

I tested my current setup with a 2.5 mm hole and the filament that came out was 3.1 mm

I guess one could try a 2.4 mm hole ( I do not have a .4 mm drillbit could not do a test here)

|

Re: Low cost 3D printing filament extruder for recycled plastics July 17, 2013 04:24AM |

Registered: 10 years ago Posts: 9 |

|

Re: Low cost 3D printing filament extruder for recycled plastics July 17, 2013 08:40AM |

Registered: 11 years ago Posts: 173 |

|

Re: Low cost 3D printing filament extruder for recycled plastics July 17, 2013 10:33AM |

Admin Registered: 11 years ago Posts: 3,096 |

Awesome man, you made your own filament machine!!!

You know, it is possible to buy just the granules so you get a clean supply and you can make your own filament

I know that normal extrusion processes have the freshly-extruded strings run into a bath of water to immediately cool them down, but thats not an option for filament that you want to print with because you don't want any vapor/fluids in contact with your freshly made filament.

Now that you have produced your own filament, do you think in the long run it will be cost-effective? Do you think this will make it cheaper to print?

It's mostly very rewarding to recycle your own filament. I have a big box with bags with all failed prints and am just waiting until a filament-recycler comes out.

You know, it is possible to buy just the granules so you get a clean supply and you can make your own filament

I know that normal extrusion processes have the freshly-extruded strings run into a bath of water to immediately cool them down, but thats not an option for filament that you want to print with because you don't want any vapor/fluids in contact with your freshly made filament.

Now that you have produced your own filament, do you think in the long run it will be cost-effective? Do you think this will make it cheaper to print?

It's mostly very rewarding to recycle your own filament. I have a big box with bags with all failed prints and am just waiting until a filament-recycler comes out.

|

Re: Low cost 3D printing filament extruder for recycled plastics July 17, 2013 12:09PM |

Registered: 11 years ago Posts: 210 |

Ohmarinus Wrote:

-------------------------------------------------------

>

> It's mostly very rewarding to recycle your own

> filament. I have a big box with bags with all

> failed prints and am just waiting until a

> filament-recycler comes out.

Such a beast already exists, you just need Marcus Thymark's shredder and one of these:

[www.kickstarter.com]

They're taking waitlist orders.

-------------------------------------------------------

>

> It's mostly very rewarding to recycle your own

> filament. I have a big box with bags with all

> failed prints and am just waiting until a

> filament-recycler comes out.

Such a beast already exists, you just need Marcus Thymark's shredder and one of these:

[www.kickstarter.com]

They're taking waitlist orders.

|

Re: Low cost 3D printing filament extruder for recycled plastics July 24, 2013 07:28AM |

Registered: 10 years ago Posts: 7 |

Hi all,

I think a vertical design is better as you can use gravity to increase the flow rate. However the speed is of importance.

The speed should be in the range of 36 - 48" per minute like the extrusion bot. Any ideas on how to achieve that without dropping filament accuracy?

What is the speed that you get on this machine? How accurate is the filament from this machine?

I think a vertical design is better as you can use gravity to increase the flow rate. However the speed is of importance.

The speed should be in the range of 36 - 48" per minute like the extrusion bot. Any ideas on how to achieve that without dropping filament accuracy?

What is the speed that you get on this machine? How accurate is the filament from this machine?

|

Re: Low cost 3D printing filament extruder for recycled plastics July 24, 2013 05:47PM |

Registered: 11 years ago Posts: 210 |

I get about 18"/minute, +/-0.05mm with ABS. Keep in mind there are a number of variables, guaranteeing a speed is not realistic. MFI, nozzle temp, COF, etc.

Gravity will not measurably impact flowrate. It would contribute around 0.1% of the total force.

Why is 36-48"/minute necessary? The Filastruder makes filament faster than my three Solidoodles can use it...

Gravity will not measurably impact flowrate. It would contribute around 0.1% of the total force.

Why is 36-48"/minute necessary? The Filastruder makes filament faster than my three Solidoodles can use it...

|

Re: Low cost 3D printing filament extruder for recycled plastics July 25, 2013 04:35AM |

Registered: 11 years ago Posts: 173 |

coolplastic Wrote:

-------------------------------------------------------

> Hi all,

> I think a vertical design is better as you can use

> gravity to increase the flow rate. However the

> speed is of importance.

>

> The speed should be in the range of 36 - 48" per

> minute like the extrusion bot. Any ideas on how to

> achieve that without dropping filament accuracy?

You can change the motor but the idea is to keep the cost down - wiper motors are available everywhere

>

> What is the speed that you get on this machine?

35 meters per hour

> How accurate is the filament from this machine?

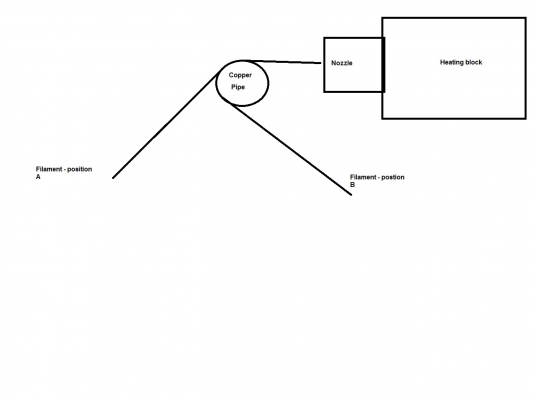

As soon as an outside force acts on the filament there will be a distortion in the filament size ( for example air movement) and as the filament moves over the copper pipe in front of the nozzle you will get a smaller diameter filament when the filament is in position A, in the image attached, than when the filament is in postion B. There will be less friction on the pipe when the filament is in position A

A rotating pipe(tube) in front of the nozzle may improve this.

Edited 1 time(s). Last edit at 07/25/2013 04:59AM by Xabbax.

-------------------------------------------------------

> Hi all,

> I think a vertical design is better as you can use

> gravity to increase the flow rate. However the

> speed is of importance.

>

> The speed should be in the range of 36 - 48" per

> minute like the extrusion bot. Any ideas on how to

> achieve that without dropping filament accuracy?

You can change the motor but the idea is to keep the cost down - wiper motors are available everywhere

>

> What is the speed that you get on this machine?

35 meters per hour

> How accurate is the filament from this machine?

As soon as an outside force acts on the filament there will be a distortion in the filament size ( for example air movement) and as the filament moves over the copper pipe in front of the nozzle you will get a smaller diameter filament when the filament is in position A, in the image attached, than when the filament is in postion B. There will be less friction on the pipe when the filament is in position A

A rotating pipe(tube) in front of the nozzle may improve this.

Edited 1 time(s). Last edit at 07/25/2013 04:59AM by Xabbax.

|

Re: Low cost 3D printing filament extruder for recycled plastics July 25, 2013 01:09PM |

Registered: 12 years ago Posts: 132 |

The rotating pipe could work if it rotates under its own power. Asking the filament to do any mechanical work like turning a roller or pressing a switch easily turns to disaster.at the nozzle. Also run a fan or blower on the filament as close to the nozzle as possible without cooling the nozzle itself. The quicker you can get the filament to harden, the more stable it will be.

|

Re: Low cost 3D printing filament extruder for recycled plastics July 25, 2013 01:39PM |

Registered: 10 years ago Posts: 7 |

I understand that if you want to make a reel or two the speed would be good enough but I read somewhere that you need 333 meters of 1.75 filament the to make 1kg so at 35 meters will approximately take ten hours.

For larger runs keeping the wiper motor or even the motor used in the picture looks doubtful because of heat buildup...

I know we want to keep the cost low but I think speed for making a kg of filament should be around an hour to an hour and a half max.

Just increasing the extrusion speed is not a viable solution if you want to maintain filament accuracy at +-0.1.

I think the extrusion bot uses a small constriction before pushing the plastic into the melt chamber. That constriction acts like a gear pump which is used to maintain extrusion quality in bigger machines. Giving feedback to the motor to adjust speed depending on internal pressures is way too much work for a thing as simple as this.

For larger runs keeping the wiper motor or even the motor used in the picture looks doubtful because of heat buildup...

I know we want to keep the cost low but I think speed for making a kg of filament should be around an hour to an hour and a half max.

Just increasing the extrusion speed is not a viable solution if you want to maintain filament accuracy at +-0.1.

I think the extrusion bot uses a small constriction before pushing the plastic into the melt chamber. That constriction acts like a gear pump which is used to maintain extrusion quality in bigger machines. Giving feedback to the motor to adjust speed depending on internal pressures is way too much work for a thing as simple as this.

|

Re: Low cost 3D printing filament extruder for recycled plastics July 25, 2013 10:14PM |

Registered: 11 years ago Posts: 210 |

coolplastic Wrote:

-------------------------------------------------------

> I think the extrusion bot uses a small

> constriction before pushing the plastic into the

> melt chamber. That constriction acts like a gear

> pump which is used to maintain extrusion quality

> in bigger machines. Giving feedback to the motor

> to adjust speed depending on internal pressures is

> way too much work for a thing as simple as this.

What gives you that idea?

-------------------------------------------------------

> I think the extrusion bot uses a small

> constriction before pushing the plastic into the

> melt chamber. That constriction acts like a gear

> pump which is used to maintain extrusion quality

> in bigger machines. Giving feedback to the motor

> to adjust speed depending on internal pressures is

> way too much work for a thing as simple as this.

What gives you that idea?

|

Re: Low cost 3D printing filament extruder for recycled plastics July 26, 2013 12:13AM |

Registered: 10 years ago Posts: 7 |

|

Re: Low cost 3D printing filament extruder for recycled plastics August 01, 2013 11:00AM |

Registered: 10 years ago Posts: 7 |

|

Re: Low cost 3D printing filament extruder for recycled plastics August 01, 2013 05:10PM |

Registered: 10 years ago Posts: 219 |

|

Re: Low cost 3D printing filament extruder for recycled plastics August 04, 2013 03:21AM |

Registered: 10 years ago Posts: 7 |

|

Re: Low cost 3D printing filament extruder for recycled plastics August 05, 2013 02:39AM |

Registered: 11 years ago Posts: 173 |

coolplastic Wrote:

-------------------------------------------------------

> Has anyone tried multiple string extruder. Like

> instead of putting one hole on 1.75mm put more

> than one.

Yes I did - with two holes horizontally seperated about 8 mm. Extruding OK but the problem is the coiling of the filament on the floor. Getting a bit messy after a while.

-------------------------------------------------------

> Has anyone tried multiple string extruder. Like

> instead of putting one hole on 1.75mm put more

> than one.

Yes I did - with two holes horizontally seperated about 8 mm. Extruding OK but the problem is the coiling of the filament on the floor. Getting a bit messy after a while.

|

Re: Low cost 3D printing filament extruder for recycled plastics September 28, 2013 02:54AM |

Registered: 10 years ago Posts: 4 |

|

Re: Low cost 3D printing filament extruder for recycled plastics September 28, 2013 05:03AM |

Registered: 13 years ago Posts: 38 |

Sorry, only registered users may post in this forum.