Low cost 3D printing filament extruder for recycled plastics

Posted by Xabbax

|

Re: Low cost 3D printing filament extruder for recycled plastics November 01, 2013 01:14PM |

Registered: 10 years ago Posts: 153 |

|

Re: Low cost 3D printing filament extruder for recycled plastics November 07, 2013 08:58PM |

Registered: 10 years ago Posts: 113 |

|

Re: Low cost 3D printing filament extruder for recycled plastics November 15, 2013 10:38PM |

Registered: 10 years ago Posts: 113 |

|

Re: Low cost 3D printing filament extruder for recycled plastics November 18, 2013 12:55PM |

Registered: 11 years ago Posts: 173 |

|

Re: Low cost 3D printing filament extruder for recycled plastics December 05, 2013 07:00AM |

Registered: 10 years ago Posts: 1 |

Hallo!

I find your extruder great, it works good and has no fancy or expensive parts!!! But there is still something, where I could use a bit help...: I write from Germany (I am greek), you know, a country well known for metal forming and machining... And because of the german mentality, I could never start building an extruder like yours, because I miss all the measurements! I would really be thankfull, if you could take the time to fill in a measurements list, because you know it yourself, reproducible results come from similar setups... How long is your steel tube, and how long the copper tube? What is the OD and ID of the 2 tubes?How wide is the overlapping between the steel and the copper tube? How long is your oger (23cm?), and what is the distance between the ogers tip, and the inner surface of the nozzles end? How wide and long is your feed-window, and at what distance from the tubes end does it beginn? Did you measure the temperature of the copper tube before starting the extrusion, so to say, when the copper tube is stillt empty, and the copper tube temperature when extruding, so to say when it is full? You write, that the oger gos 5-10mm in the hearing zone/copper tube: Do you mean the part of the copper tube overlappig with the steel tube, or does the oger exceeds the steel tube for about 5-10mm? Below I have a list, which you could use, so that everybody can see at a glance, what the matter is. I fill in already some gaps, whenever I thought that I have extracted the corresponding information from your postings. At last, please excuse my english, I have very little exercise. You will surely find a lot of mistakes!!! I would find it great, if everyone in the world could reproduce your extruder, no matter where he/she lives. Myself, I am a biochemist, but now unemployed, so I cannot buy an extruder, I have to build one on my own...

Steel tube length:

OD:

ID: 10mm

Copper tube length:

OD:

ID:

mm of overlapping between steel and copper tube:

Oger length:

Oger diameter: 10mm

Feed-window length:

Feed-window width:

Window distance from steel tube end:

(Oger) mm of exceeding the steel tubes end:

Distance between the ogers tip and the nozzles inner surface:

Copper tube temperature at the end of warming up:

Copper tube temperature during extruding:

I find your extruder great, it works good and has no fancy or expensive parts!!! But there is still something, where I could use a bit help...: I write from Germany (I am greek), you know, a country well known for metal forming and machining... And because of the german mentality, I could never start building an extruder like yours, because I miss all the measurements! I would really be thankfull, if you could take the time to fill in a measurements list, because you know it yourself, reproducible results come from similar setups... How long is your steel tube, and how long the copper tube? What is the OD and ID of the 2 tubes?How wide is the overlapping between the steel and the copper tube? How long is your oger (23cm?), and what is the distance between the ogers tip, and the inner surface of the nozzles end? How wide and long is your feed-window, and at what distance from the tubes end does it beginn? Did you measure the temperature of the copper tube before starting the extrusion, so to say, when the copper tube is stillt empty, and the copper tube temperature when extruding, so to say when it is full? You write, that the oger gos 5-10mm in the hearing zone/copper tube: Do you mean the part of the copper tube overlappig with the steel tube, or does the oger exceeds the steel tube for about 5-10mm? Below I have a list, which you could use, so that everybody can see at a glance, what the matter is. I fill in already some gaps, whenever I thought that I have extracted the corresponding information from your postings. At last, please excuse my english, I have very little exercise. You will surely find a lot of mistakes!!! I would find it great, if everyone in the world could reproduce your extruder, no matter where he/she lives. Myself, I am a biochemist, but now unemployed, so I cannot buy an extruder, I have to build one on my own...

Steel tube length:

OD:

ID: 10mm

Copper tube length:

OD:

ID:

mm of overlapping between steel and copper tube:

Oger length:

Oger diameter: 10mm

Feed-window length:

Feed-window width:

Window distance from steel tube end:

(Oger) mm of exceeding the steel tubes end:

Distance between the ogers tip and the nozzles inner surface:

Copper tube temperature at the end of warming up:

Copper tube temperature during extruding:

|

Re: Low cost 3D printing filament extruder for recycled plastics December 14, 2013 02:24AM |

Registered: 11 years ago Posts: 173 |

Steel tube length:200 mm (seamless stainless steel pipe)Quote

hiliagusta

OD:12.7 mm

ID: 10mm

Copper tube length: 80 mm - ordinary plumbers pipe

OD: 15 mm

ID: 13 mm

mm of overlapping between steel and copper tube: 10 mm

Oger length: 300 mm - cut to size that will fit your setup

Oger diameter: 10mm

Feed-window length: 25 mm

Feed-window width: 7.5 mm

Window distance from steel tube end: 50 mm

(Oger) mm of exceeding the steel tubes end: 0 mm

Distance between the ogers tip and the nozzles inner surface: 80-10 = 70 mm

Copper tube temperature at the end of warming up: not measured

Copper tube temperature during extruding: not measured

Aluminium heater block : 55 x 45 x 20 mm

Aluminium heatsink 65 OD ( I used a salvaged part from a motor found in an old tape recorder)

When you extrude for the first time feed the plastic into the heat chamber up to the nozzle and switch off the motor - wait for 15 - 30 minutes and then proceed.

Use a piece of wire through the nozzle to gauge the front of the plastic.

When you extrude and get a ripple effect on the filament your temperature is to low.

make sure that you allow enough time for the plastic to melt before you start the motor for extrusion. I lost a pipe and boke an auger bit when did not wait long enough and the motor distorted the stainless pipe at the feed window. I then made the feed window smaller to the current dimensions listed above.

Edited 1 time(s). Last edit at 12/14/2013 02:29AM by Xabbax.

|

Re: Low cost 3D printing filament extruder for recycled plastics March 03, 2014 02:16PM |

Registered: 10 years ago Posts: 153 |

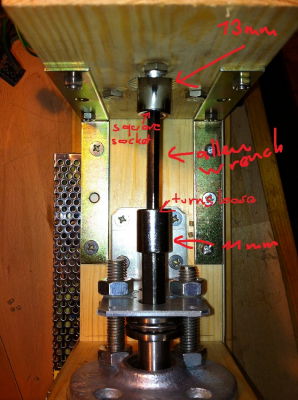

My extruder is now roughly built. Some minor stuff needs to be tweaked. For example the coupling from the motor to the auger bit. I tried several methods and the last I came about was by using two nuts joined with an allen wrench.

See picture below. This describes it best.

It worked for some test runs but unfortunately my PWM motor controller died. So now the motor runs without controller. Full speed. What happened now is that the allen wrench went "nuts". The square inside the socket/nut quirled (?) and now the "allen wrench-coupling" turns loose.

Any suggestions ?

I have some more massive nuts (11mm for the auger + 13 mm for the motor) with a 13mm square socket. I could get a 13mm square solid steel rod.

I would be glad about any ideas !!!

See picture below. This describes it best.

It worked for some test runs but unfortunately my PWM motor controller died. So now the motor runs without controller. Full speed. What happened now is that the allen wrench went "nuts". The square inside the socket/nut quirled (?) and now the "allen wrench-coupling" turns loose.

Any suggestions ?

I have some more massive nuts (11mm for the auger + 13 mm for the motor) with a 13mm square socket. I could get a 13mm square solid steel rod.

I would be glad about any ideas !!!

|

Re: Low cost 3D printing filament extruder for recycled plastics March 03, 2014 10:27PM |

Registered: 10 years ago Posts: 239 |

|

Re: Low cost 3D printing filament extruder for recycled plastics March 03, 2014 11:05PM |

Registered: 11 years ago Posts: 89 |

|

Re: Low cost 3D printing filament extruder for recycled plastics March 11, 2014 02:21PM |

Registered: 10 years ago Posts: 153 |

Thanks for the pictures Xabbax !

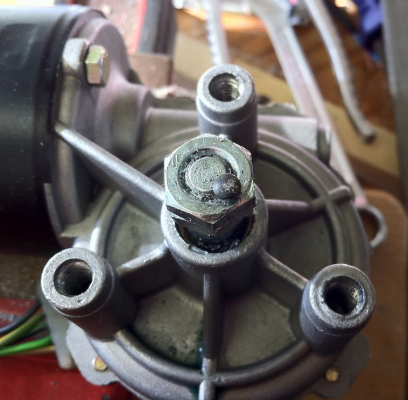

But I wonder what parts you used in picture F and G.

And how did you fasten the nut on the motor shaft.

Is this a square nut that connects the axis to the nut (from picture E) ??

I put a hex-nut onto the motorshaft and drilled a hole between the thread of the nut and shaft and put a 2mm steal bolt into it so that it doesn't loosen while driving the auger bit.

First I used Loctite but this was not strong enough to keep up with the motor power.

Edited 1 time(s). Last edit at 03/11/2014 02:24PM by ianmcmill.

But I wonder what parts you used in picture F and G.

And how did you fasten the nut on the motor shaft.

Is this a square nut that connects the axis to the nut (from picture E) ??

I put a hex-nut onto the motorshaft and drilled a hole between the thread of the nut and shaft and put a 2mm steal bolt into it so that it doesn't loosen while driving the auger bit.

First I used Loctite but this was not strong enough to keep up with the motor power.

Edited 1 time(s). Last edit at 03/11/2014 02:24PM by ianmcmill.

|

Re: Low cost 3D printing filament extruder for recycled plastics March 12, 2014 03:22AM |

Registered: 11 years ago Posts: 173 |

Quote

ianmcmill

Thanks for the pictures Xabbax !

But I wonder what parts you used in picture F and G.

And how did you fasten the nut on the motor shaft.

Is this a square nut that connects the axis to the nut (from picture E) ??

I put a hex-nut onto the motorshaft and drilled a hole between the thread of the nut and shaft and put a 2mm steal bolt into it so that it doesn't loosen while driving the auger bit.

[attachment 28421 bolt.jpg]

First I used Loctite but this was not strong enough to keep up with the motor power.

Very good idea of you to fix the nuts to the motor shaft !!

I used a grinder to make a square nut from the hex nuts on the motor shaft to fit into the back of the socket.

The parts in picture F and G are steel tubes. The idea is not to have any force from the auger bit transfered to the motor shaft. I used a steel tube to keep the outer ring of the bearing a certain distance from the bracket where the motor is mounted. The socket can rotate freely inside the steel tube. The outer tube keeps the inner tube and the washer in position. I had to flare the outer tube to fit over the bearing You can use a plastic tube for the outside. I used what was available in my workshop at the time.

You only learn when you change your mind.

[www.deltaprinter.co.za]

|

Re: Low cost 3D printing filament extruder for recycled plastics March 15, 2014 09:12AM |

Registered: 10 years ago Posts: 153 |

Thanks for the clarification.

I am now satisfied with my coupling and trying to get filament extruded. I have got some PC/ABS blend pellets with a processing temperature of 260-280 °C. Once the auger transports the pellets to the heater, the temperature drops from 280°C to 250°C and heats up again slowly.

The problem is that the fan is not enough to cool the filament quickly enough. Therefore the filalement ravels and sticks to the aluminium tube and although sliding into the fan (bad).

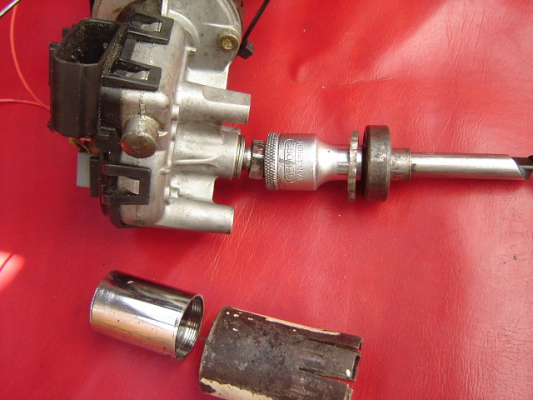

Here is a picture of the nozzle-part. From your experience, do you have any suggestion on how to improve this setup ?

Edited 1 time(s). Last edit at 03/15/2014 09:14AM by ianmcmill.

I am now satisfied with my coupling and trying to get filament extruded. I have got some PC/ABS blend pellets with a processing temperature of 260-280 °C. Once the auger transports the pellets to the heater, the temperature drops from 280°C to 250°C and heats up again slowly.

The problem is that the fan is not enough to cool the filament quickly enough. Therefore the filalement ravels and sticks to the aluminium tube and although sliding into the fan (bad).

Here is a picture of the nozzle-part. From your experience, do you have any suggestion on how to improve this setup ?

Edited 1 time(s). Last edit at 03/15/2014 09:14AM by ianmcmill.

|

Re: Low cost 3D printing filament extruder for recycled plastics March 15, 2014 03:42PM |

Registered: 10 years ago Posts: 153 |

I just found your Masterbatch guide. Wonderful !!

That filament looks awesome! This will serve me as a model !

I made some pictures of the filament and recorded an extrusion.

This is my extruder in action. The cracking sound of the pellets is nasty...

[www.youtube.com]

This is the result of around 30 minutes extruding.

Extrusion temp. around 270-280°C

Extrusion temp. around 270-280°C

Here you can see that the pellets are hollowed. May this cause those bubbles and ravels ?

Oh and I did not dry the pellets in the oven before.

And some questions:

1) What is your extrusion speed ? I am getting around 3m/min. That is 118"/min (for 2mm filament)

2) How fast is your motor running ? As it is a wiper motor, it has Speed 1 / 2 and "3" if you (or at least me) connect the speed 1 pin to ground and speed 2 to voltage in of the the motor.

3) Your nozzle diameter ? But I think I can recall you said something about 1mm.

Edited 4 time(s). Last edit at 03/16/2014 05:56AM by ianmcmill.

That filament looks awesome! This will serve me as a model !

I made some pictures of the filament and recorded an extrusion.

This is my extruder in action. The cracking sound of the pellets is nasty...

[www.youtube.com]

This is the result of around 30 minutes extruding.

Extrusion temp. around 270-280°C

Extrusion temp. around 270-280°C

Here you can see that the pellets are hollowed. May this cause those bubbles and ravels ?

Oh and I did not dry the pellets in the oven before.

And some questions:

1) What is your extrusion speed ? I am getting around 3m/min. That is 118"/min (for 2mm filament)

2) How fast is your motor running ? As it is a wiper motor, it has Speed 1 / 2 and "3" if you (or at least me) connect the speed 1 pin to ground and speed 2 to voltage in of the the motor.

3) Your nozzle diameter ? But I think I can recall you said something about 1mm.

Edited 4 time(s). Last edit at 03/16/2014 05:56AM by ianmcmill.

|

Re: Low cost 3D printing filament extruder for recycled plastics March 16, 2014 12:38PM |

Registered: 11 years ago Posts: 173 |

Quote

ianmcmill

I just found your Masterbatch guide. Wonderful !!

I made some pictures of the filament and recorded an extrusion.

This is my extruder in action. The cracking sound of the pellets is nasty...

[www.youtube.com]

[attachment 28686 IMG_0820_web.jpg] This is the result of around 30 minutes extruding.

[attachment 28683 IMG_0825_web.jpg] Extrusion temp. around 270-280°C

[attachment 28684 IMG_0827_web.jpg] Extrusion temp. around 270-280°C

[attachment 28685 IMG_0830_web.jpg] Here you can see that the pellets are hollowed. May this cause those bubbles and ravels ?

Oh and I did not dry the pellets in the oven before.

And some questions:

1) What is your extrusion speed ? I am getting around 3m/min. That is 118"/min (for 2mm filament)

2) How fast is your motor running ? As it is a wiper motor, it has Speed 1 / 2 and "3" if you (or at least me) connect the speed 1 pin to ground and speed 2 to voltage in of the the motor.

3) Your nozzle diameter ? But I think I can recall you said something about 1mm.

You have a nice machine there!!! and I like your laser engraver!!

Temperature is to high - try anything from 190 to 210 for ABS then you will not have bubbles in the filament. At the moment you are boiling the plastic with temperatures higher than 260 C.

The hollow pellets should not be a problem and drying the pellets not needed under normal conditions.

My motor speed is about the same as yours.

My nozzle diameter is 1 mm for a 1.65 mm filament

You only learn when you change your mind.

[www.deltaprinter.co.za]

|

Re: Low cost 3D printing filament extruder for recycled plastics March 16, 2014 01:55PM |

Registered: 10 years ago Posts: 153 |

Thanks. Getting the laser to work was alot of fun.

Oh I forgot to mention that I am not using pure ABS but a PC/ABS compound. It combines the high temperature rating of PC with the lower one from ABS.

The datasheet says "Processing (melt) temperature = 240-270°C" (Link to the datasheet)

Also when extruding the temperature decreases continuously by circa 0.1-0.2 °C per second and the heater can't keep up. (200 Watt heater). After 30 minutes I stopped the extrusion and the temperature was down to 270°C from 305°C.

I did choose 305°C as a starting temperature because I thought an extra buffer might help the PID/Heater to counteract the temperature decline.

Edited 2 time(s). Last edit at 03/16/2014 05:37PM by ianmcmill.

Oh I forgot to mention that I am not using pure ABS but a PC/ABS compound. It combines the high temperature rating of PC with the lower one from ABS.

The datasheet says "Processing (melt) temperature = 240-270°C" (Link to the datasheet)

Also when extruding the temperature decreases continuously by circa 0.1-0.2 °C per second and the heater can't keep up. (200 Watt heater). After 30 minutes I stopped the extrusion and the temperature was down to 270°C from 305°C.

I did choose 305°C as a starting temperature because I thought an extra buffer might help the PID/Heater to counteract the temperature decline.

Edited 2 time(s). Last edit at 03/16/2014 05:37PM by ianmcmill.

|

Re: Low cost 3D printing filament extruder for recycled plastics March 23, 2014 05:57PM |

Registered: 10 years ago Posts: 153 |

Quote

ianmcmill

Thanks. Getting the laser to work was alot of fun.

Oh I forgot to mention that I am not using pure ABS but a PC/ABS compound. It combines the high temperature rating of PC with the lower one from ABS.

The datasheet says "Processing (melt) temperature = 240-270°C" (Link to the datasheet)

Also when extruding the temperature decreases continuously by circa 0.1-0.2 °C per second and the heater can't keep up. (200 Watt heater). After 30 minutes I stopped the extrusion and the temperature was down to 270°C from 305°C.

I did choose 305°C as a starting temperature because I thought an extra buffer might help the PID/Heater to counteract the temperature decline.

Okay I got it now to the right diameter (1.70mm) without bubbles and raffles. G-force really much helps in adjusting the diameter. The shorter the distance to the floor, the thicker the filament. A fan helps increase the diameter by roughly 0.1mm.

Now to the fun part. Untangle the filament and get on a spool.

There is this filawinder ob the filastruder page. But as with your simplistic low cost but fast extruder do you have another great idea in your backhand ?

|

Re: Low cost 3D printing filament extruder for recycled plastics March 27, 2014 11:21AM |

Registered: 10 years ago Posts: 2 |

|

Re: Low cost 3D printing filament extruder for recycled plastics April 10, 2014 05:17AM |

Registered: 10 years ago Posts: 153 |

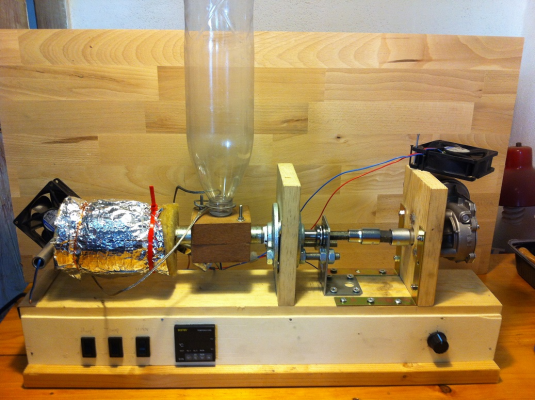

Hi again ! I have finished my build.

Runs perfect and the filament comes out smooth and shiny.

Thanks Xabbax for the tips !

Runs perfect and the filament comes out smooth and shiny.

Thanks Xabbax for the tips !

|

Re: Low cost 3D printing filament extruder for recycled plastics May 25, 2014 12:13AM |

Registered: 9 years ago Posts: 5 |

Hi,

I'm trying to do a filament extruder and I get this;

too many bubbles in it, temperature were 190C, do you have any suggestion?

what's the dimension between the nozzle and the auger?

Thanks

I'm trying to do a filament extruder and I get this;

too many bubbles in it, temperature were 190C, do you have any suggestion?

what's the dimension between the nozzle and the auger?

Thanks

|

Re: Low cost 3D printing filament extruder for recycled plastics May 25, 2014 01:23AM |

Registered: 10 years ago Posts: 1,381 |

A few ideas:

1. Black plastic can be difficult to work with due to fillers.

2. Moisture causes bubbles, dry your regrind. What kind of plastic are you extruding?

3. Inconsistent extrusion rate causes thick to thin cross sections. Are you pulling the extrudate? The distance between the screw and nozzle if large could be acting as a spring and pulsing.

4. Screw binding, or friction, if your auger is rubbing the inside of the barrel you could get inconsistent extrudate diameter.

5. Nozzle occlusion, if there is a particle floating in front of the nozzle inside the barrel it will have an effect on the diameter.

6. Drive train, if the gears are jerking you'll get inconsistent extrusion.

7. Melt fracture: when the polymer exits too fast from an extruder, the surface starts to exhibits undulations or irregularities, the distortions can become so severe that they cause the extrudate to break.

You should post a pic of your rig and provide more details.

Edited 2 time(s). Last edit at 05/26/2014 01:57PM by A2.

1. Black plastic can be difficult to work with due to fillers.

2. Moisture causes bubbles, dry your regrind. What kind of plastic are you extruding?

3. Inconsistent extrusion rate causes thick to thin cross sections. Are you pulling the extrudate? The distance between the screw and nozzle if large could be acting as a spring and pulsing.

4. Screw binding, or friction, if your auger is rubbing the inside of the barrel you could get inconsistent extrudate diameter.

5. Nozzle occlusion, if there is a particle floating in front of the nozzle inside the barrel it will have an effect on the diameter.

6. Drive train, if the gears are jerking you'll get inconsistent extrusion.

7. Melt fracture: when the polymer exits too fast from an extruder, the surface starts to exhibits undulations or irregularities, the distortions can become so severe that they cause the extrudate to break.

You should post a pic of your rig and provide more details.

Edited 2 time(s). Last edit at 05/26/2014 01:57PM by A2.

|

Re: Low cost 3D printing filament extruder for recycled plastics May 26, 2014 06:22AM |

Registered: 11 years ago Posts: 173 |

Quote

Dougwar

Hi,

I'm trying to do a filament extruder and I get this;

too many bubbles in it, temperature were 190C, do you have any suggestion?

what's the dimension between the nozzle and the auger?

Thanks

I think the temperature may be a bit high hence the bubbles.

Distance between the augers tip and the nozzles inner surface: 80-10 = 70 mm

You only learn when you change your mind.

[www.deltaprinter.co.za]

|

Re: Low cost 3D printing filament extruder for recycled plastics May 26, 2014 07:32PM |

Registered: 9 years ago Posts: 5 |

|

Re: Low cost 3D printing filament extruder for recycled plastics July 05, 2014 09:39AM |

Registered: 10 years ago Posts: 118 |

|

Re: Low cost 3D printing filament extruder for recycled plastics July 09, 2014 02:11PM |

Registered: 9 years ago Posts: 7 |

Sorry, only registered users may post in this forum.