Bits from bytes v 3.0

Posted by Batist

|

Bits from bytes v 3.0 April 18, 2009 09:27PM |

Registered: 15 years ago Posts: 32 |

Hi guys,

although the manual for the extruder assembly seems to be missing it 's pretty straightforward to put it together viewing the total assembly.

However, the nozzle doesn't seem to touch the platform when I put it at maximum height... any thoughts? Did I mis-mount something?

[www.coded.be]

although the manual for the extruder assembly seems to be missing it 's pretty straightforward to put it together viewing the total assembly.

However, the nozzle doesn't seem to touch the platform when I put it at maximum height... any thoughts? Did I mis-mount something?

[www.coded.be]

|

Re: Bits from bytes v 3.0 April 18, 2009 10:14PM |

Registered: 16 years ago Posts: 235 |

It would be bad if you rammed the platform into the nozzle so I'd guess its not supposed to touch, just come quite close. How much space is there between the bottom of the nozzle and the platform at maximum height?

PS Pics would help, if you did do something wrong it would be easier to see.

PS Pics would help, if you did do something wrong it would be easier to see.

|

Re: Bits from bytes v 3.0 April 19, 2009 04:59AM |

Registered: 15 years ago Posts: 32 |

Ok, I solved the problem by taking away one bolt, but I suppos this isn't the way...?

I took some pictures to make things clear:

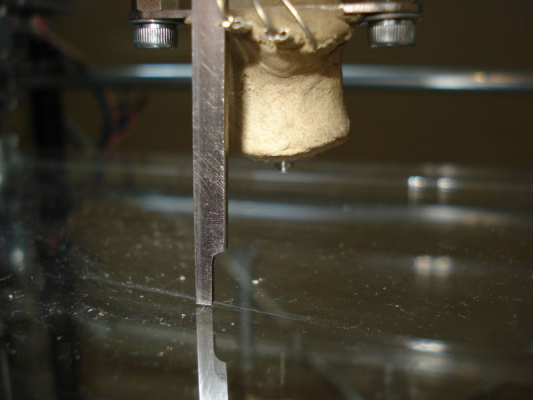

First my nozzle was pretty far from the plate:

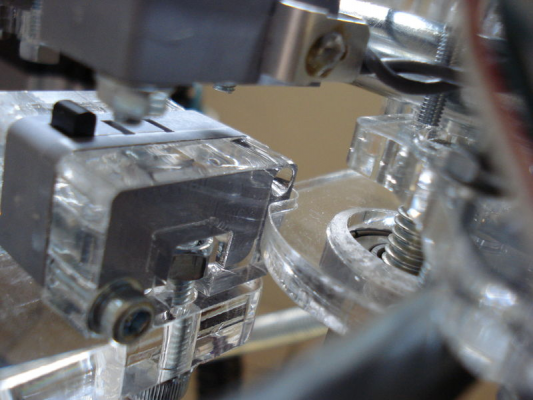

This is due to a bolt that can't pass a corner block:

However, if you simply remove this bolt, it neatly fits:

Now I think the height of the nozzle is pretty good:

So that seems to be solved...

But, how about connecting the extruder (electronically...), I can't seem to find any documentation on assembling it..? (it's always version 2.*...)

[www.coded.be]

I took some pictures to make things clear:

First my nozzle was pretty far from the plate:

This is due to a bolt that can't pass a corner block:

However, if you simply remove this bolt, it neatly fits:

Now I think the height of the nozzle is pretty good:

So that seems to be solved...

But, how about connecting the extruder (electronically...), I can't seem to find any documentation on assembling it..? (it's always version 2.*...)

[www.coded.be]

|

Re: Bits from bytes v 3.0 April 19, 2009 02:11PM |

Registered: 16 years ago Posts: 270 |

Coming very very soon finished extruder manual, yes the bolt needs to be removed I'll amend the manual for this as well, this is due to replacing the MDF print platten with Acrylic as ABS prints better on Acrylic, but this is thinner (and then the problem with the bolt) i didn't catch this until recently as I tested with the acrylic on the MDF as it was a quicker fit  . I also lowered the switch which didn't help sorry!

. I also lowered the switch which didn't help sorry!

It was also a late desission to go with the acrylic as it was more expensive but it is much easier to print onto so hopefully the small problem is compensated by the better product

I also note from the pictures the nuts under the bearings are loose this could give erratic Z movement.

Ian

[www.bitsfrombytes.com]

. I also lowered the switch which didn't help sorry!

. I also lowered the switch which didn't help sorry!It was also a late desission to go with the acrylic as it was more expensive but it is much easier to print onto so hopefully the small problem is compensated by the better product

I also note from the pictures the nuts under the bearings are loose this could give erratic Z movement.

Ian

[www.bitsfrombytes.com]

|

Re: Bits from bytes v 3.0 May 22, 2009 12:42PM |

Registered: 14 years ago Posts: 8 |

I understand a revised PTFE heater barrel is on its way, however here is a quick and very tough solution. You make it by hammering 12mm PTFE down a brass tube of 12mm internal diameter, then turning each end to 10mm. the trick is that the brass tube not only braces the PTFE from rupturing, it also stops it being pushed out of the heter under pressure as it shoud be cut to push against the perspex base plate above.

I am also using six ceramic M3 washers to insulate the heater (tryangle) plate from the metal pillars. the heat saved is significant.

I am also using six ceramic M3 washers to insulate the heater (tryangle) plate from the metal pillars. the heat saved is significant.

Sorry, only registered users may post in this forum.