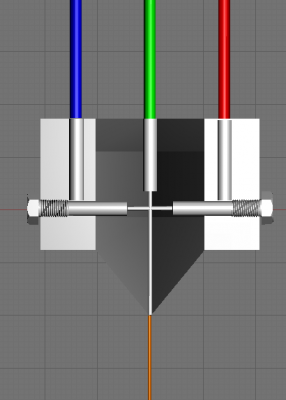

color extruder concept

Posted by goaran

|

color extruder concept May 23, 2010 03:42PM |

Registered: 14 years ago Posts: 176 |

Hi there...

i was thinking a bit about color printing and came up with this concept...

it is a heated nozzle with several inputs ( red green blue, black and white) but for experimenting i will do just two colors first..

Each color is driven by a stepper, mechanics like in other extruders, nothing special..

the nozzle will milled from aluminium with a high-temperature-resistor as heater..

this it how it will look like or something..

the advantage of one multi-color extruder instead of an extruder for each color will be first, that for changing the color the extruder does not have to stop/start extruding and there is no repositioning...

another nice thing in this concept is, that it is able to mix colors... there will be rainbows coming out of the nozzle (and unicorns maybe too)

the pipes will habe a small diameter( maybee one mm) at the place they join, so no turbulences will come in and mix the colors...

what do you think of the concept??

any ideas what to improve before i start millig...

have phun...

my projects: [www.robotik.dyyyh.de] ...

i was thinking a bit about color printing and came up with this concept...

it is a heated nozzle with several inputs ( red green blue, black and white) but for experimenting i will do just two colors first..

Each color is driven by a stepper, mechanics like in other extruders, nothing special..

the nozzle will milled from aluminium with a high-temperature-resistor as heater..

this it how it will look like or something..

the advantage of one multi-color extruder instead of an extruder for each color will be first, that for changing the color the extruder does not have to stop/start extruding and there is no repositioning...

another nice thing in this concept is, that it is able to mix colors... there will be rainbows coming out of the nozzle (and unicorns maybe too)

the pipes will habe a small diameter( maybee one mm) at the place they join, so no turbulences will come in and mix the colors...

what do you think of the concept??

any ideas what to improve before i start millig...

have phun...

my projects: [www.robotik.dyyyh.de] ...

|

Re: color extruder concept May 23, 2010 05:27PM |

Registered: 15 years ago Posts: 332 |

The long thin tubes are going to give you a fair bit of friction, especially if you're turning at right angles. I've been toying with the idea of drilling three 3.5mm holes through a block of metal so they meet at a tetrahedral point, then having a very short thin hole to the nozzle. The shorter you can make the meeting point->nozzle distance, the less purging you're going to have to do to make sure what colour you're printing, and you might get more reliable colours if it's totally symmetrical (in the picture, you might well find that green dribbles more because of the smaller amount of friction) If you can, try and avoid too many joins in your design, you'd have to be careful that the molten plastic didn't seep along the threads, pla especially will get through anything.

I assume you're planning on using bowden extruders? There might be issues with the springiness, if a non-printing plastic's force is too great, it'll dribble, too little and the printing colour will be pushed into the wrong colour hole.

I assume you're planning on using bowden extruders? There might be issues with the springiness, if a non-printing plastic's force is too great, it'll dribble, too little and the printing colour will be pushed into the wrong colour hole.

|

Re: color extruder concept May 24, 2010 10:09AM |

Registered: 14 years ago Posts: 278 |

I agree with James.. looking at the diagram, I think you'll have problems with pressure control pushing the wrong color into the other chambers instead of thru the exit nozzle.

I wonder.. how hard would it be to inject dye into a white filament at the extrusion exit? Rather than use different color plastics, use a single plastic base, and 'ink jet' it on the way out..?

I wonder.. how hard would it be to inject dye into a white filament at the extrusion exit? Rather than use different color plastics, use a single plastic base, and 'ink jet' it on the way out..?

|

Re: color extruder concept May 24, 2010 04:02PM |

Registered: 16 years ago Posts: 536 |

|

Re: color extruder concept May 25, 2010 03:53AM |

Registered: 14 years ago Posts: 176 |

Thanks for the replies..

i will change the design an bit, so that there arent so many edges to cause friction, and then i'll just try it.. Dont know what pump i will use jet, maybee kind of the thread-extruder thing... with the weight i will habe no problem cause (my reprap is realy havy, but later you might have to use bowden extruders for this..

my projects: [www.robotik.dyyyh.de] ...

i will change the design an bit, so that there arent so many edges to cause friction, and then i'll just try it.. Dont know what pump i will use jet, maybee kind of the thread-extruder thing... with the weight i will habe no problem cause (my reprap is realy havy, but later you might have to use bowden extruders for this..

my projects: [www.robotik.dyyyh.de] ...

|

Re: color extruder concept May 27, 2010 05:20PM |

Registered: 14 years ago Posts: 278 |

Another thing, not directly related... your diagram shows inputs of "red", "green" and "blue", implying that it will do color addition.

Unfortunately, I don't think the dyes and pigments in plastic will mix the same way as mixing different color light as you typically do for computer monitor display -- in this regard, I suspect its closer to printing technology, say, a CYMK basis. Except, you'll probably also need to add White, since you won't be printing into a 'white' medium like you typically do with printers and inks.

However, the technique you outline would probably be good enough for a limited range of colors, where you can achieve a few brilliant and saturated colors (using 100% of one colored plastic), as well as a range of 'muddy' colors where you mix two of the plastics together. Before you invest too much time into making the extruder, it might be useful to actually mash together a few plastic samples together on a stove to see if the 'muddy' colors you would get would give you the effect and variations you'd want for the amount of effort it might take to get a working multi-plastic print head.

I think more bang for the buck may be achievable with a white or clear basis, where dye is injected or you use a RepAirBrush toolhead to paint the plastic after it has cooled...

Unfortunately, I don't think the dyes and pigments in plastic will mix the same way as mixing different color light as you typically do for computer monitor display -- in this regard, I suspect its closer to printing technology, say, a CYMK basis. Except, you'll probably also need to add White, since you won't be printing into a 'white' medium like you typically do with printers and inks.

However, the technique you outline would probably be good enough for a limited range of colors, where you can achieve a few brilliant and saturated colors (using 100% of one colored plastic), as well as a range of 'muddy' colors where you mix two of the plastics together. Before you invest too much time into making the extruder, it might be useful to actually mash together a few plastic samples together on a stove to see if the 'muddy' colors you would get would give you the effect and variations you'd want for the amount of effort it might take to get a working multi-plastic print head.

I think more bang for the buck may be achievable with a white or clear basis, where dye is injected or you use a RepAirBrush toolhead to paint the plastic after it has cooled...

|

Re: color extruder concept October 21, 2010 05:10PM |

unfortunately i can't log into these forums for a while. My beautiful PC is down and out until next month or so when i can get some fried connections on the motherboard fixed (my SATA ports all died. fortunately it's just a problem on the board itself, not the bridge or anything. good for a 1200$ board)

anyway, i can't log in because this PC runs vista which doesn't have the invisible character in my name. alt + 0160

SKIP HERE FOR IDEA YOU CARE ABOUT---------------------------------------------------------------------------------------------------------------------------------------------------

but anyway, following your concept, i've long been considering instead having a 6 head array.

3x2, and one of the rows of 3 is shifted horizontally by the radius of the heads... or something.

anyway, 6 extruder heads that form a paralellogram with angles 60, 60, 120, and 120. this way you could simply feed 6 different filaments in to get multicolor, or multi material, or whatever, and if you don't want multi anything, you can simply put 6 identical filaments in, and recieve a 6x print speed.

here's the first idea i had for heating the material:

the heater part would be made of brass naturally, and i suppose require milling, but it would be somewhat similar to cartoon brass knuckles, wherein the circles around the heater barrels are all connected, so they can be heated together.

but then i realized if you wanted to use say mostly colored PLA but a little bit of clear ABS, you'd need a drastic temperature difference, so now i'm moving towards 6 individual brass cylinders held together with some sort of adhesive that's also a terrible conductor of heat, so as to insulate.

You could then run nichrome around all of them, which would make heating relatively to set up.

anyway, all of this could easily be set up to be controlled on a single board, although running power to heat 6 barrels through one board may be a bad plan.

well there's my idea.

anyway, i can't log in because this PC runs vista which doesn't have the invisible character in my name. alt + 0160

SKIP HERE FOR IDEA YOU CARE ABOUT---------------------------------------------------------------------------------------------------------------------------------------------------

but anyway, following your concept, i've long been considering instead having a 6 head array.

3x2, and one of the rows of 3 is shifted horizontally by the radius of the heads... or something.

anyway, 6 extruder heads that form a paralellogram with angles 60, 60, 120, and 120. this way you could simply feed 6 different filaments in to get multicolor, or multi material, or whatever, and if you don't want multi anything, you can simply put 6 identical filaments in, and recieve a 6x print speed.

here's the first idea i had for heating the material:

the heater part would be made of brass naturally, and i suppose require milling, but it would be somewhat similar to cartoon brass knuckles, wherein the circles around the heater barrels are all connected, so they can be heated together.

but then i realized if you wanted to use say mostly colored PLA but a little bit of clear ABS, you'd need a drastic temperature difference, so now i'm moving towards 6 individual brass cylinders held together with some sort of adhesive that's also a terrible conductor of heat, so as to insulate.

You could then run nichrome around all of them, which would make heating relatively to set up.

anyway, all of this could easily be set up to be controlled on a single board, although running power to heat 6 barrels through one board may be a bad plan.

well there's my idea.

Sorry, only registered users may post in this forum.