Filament Reducer

Posted by mikefazz

|

Filament Reducer February 02, 2015 04:16AM |

Registered: 15 years ago Posts: 37 |

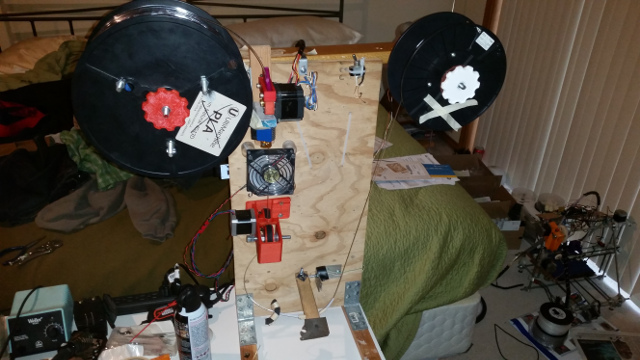

So I have a few spools of 3mm filament from before I got with the times and switched over to 1.75. I want to eventually make my own filament so have been playing around with adding various components to reduce the filament diameter. I finally have something that works decently and I was able to make if from various stuff I had left from other projects.

[www.youtube.com]

So the main components visible in the video:

- 3mm spool with cardboard fingers to keep it from unspooling too fast

- Homemade extruder... most any type would work

- Filament Puller, I made this using the rubber from some old printer feeding mechanism (custom design)

- Extruded lever switch to control the spooling motor (custom design)

- Loop of tubing to hold some tension

- Spooling motor with really noisy/sloppy gearbox

So anyone who has looked into this probably knows about the filaspooler:

[www.filastruder.com]

Which is a nice way to go but if you're like me and want to do it the hard way then this option works too.

I control the device with a RUMBA running a special version of Marlin (bioprinter) which allows multiple 'extruders' to run simultaneously at different speeds. My extruder output is bigger than 1.75 I control the output diameter by running the 'puller' at different speeds. This is a nice way to go because once set the diameter stays fairly consistent with a variance maybe 0.1mm. The puller also keeps the filament from getting pulled out of the extruder too fast during extruding.

I ordered a proper gearmotor to make it quieter and may eventually add a spreader to more evenly load the spool.

Other than noise the main issue is the autospooling is pretty touchy it would be nice to add a little delay so the motor isn't turning on and off so much.

If there is enough interest I can publish all the info with more detail.

[www.youtube.com]

So the main components visible in the video:

- 3mm spool with cardboard fingers to keep it from unspooling too fast

- Homemade extruder... most any type would work

- Filament Puller, I made this using the rubber from some old printer feeding mechanism (custom design)

- Extruded lever switch to control the spooling motor (custom design)

- Loop of tubing to hold some tension

- Spooling motor with really noisy/sloppy gearbox

So anyone who has looked into this probably knows about the filaspooler:

[www.filastruder.com]

Which is a nice way to go but if you're like me and want to do it the hard way then this option works too.

I control the device with a RUMBA running a special version of Marlin (bioprinter) which allows multiple 'extruders' to run simultaneously at different speeds. My extruder output is bigger than 1.75 I control the output diameter by running the 'puller' at different speeds. This is a nice way to go because once set the diameter stays fairly consistent with a variance maybe 0.1mm. The puller also keeps the filament from getting pulled out of the extruder too fast during extruding.

I ordered a proper gearmotor to make it quieter and may eventually add a spreader to more evenly load the spool.

Other than noise the main issue is the autospooling is pretty touchy it would be nice to add a little delay so the motor isn't turning on and off so much.

If there is enough interest I can publish all the info with more detail.

|

Re: Filament Reducer February 08, 2015 04:05AM |

Registered: 10 years ago Posts: 478 |

Wow!

I hardly could believe my eyes what I saw :-)

I mean, congratulations, your... contraption works.

Noisy but it works.

My obvious question is: why don't you swap your 3mm with 1.75mm with somebody.

I'm sure somebody would be interested in this swap.

On the other hand, hm....I was thinking if there is anything I can learn from your project and put it in my perlettes filament extruder.

I mean, a two stage filament extruder.

First stage is to change the filament granules into a filament (with rather big thickness)

Second stage, reduce the diameter by re-extruding it to a desired width.

This, based on the assumption that variations in the input diameter will lead to variations to the output length and not output diameter.

Coming back to your design: what's with the "Master" lock on the bottom of the design?

It even has a key in it :-)

Have you used it as a weight tensioner or...something else?

I hardly could believe my eyes what I saw :-)

I mean, congratulations, your... contraption works.

Noisy but it works.

My obvious question is: why don't you swap your 3mm with 1.75mm with somebody.

I'm sure somebody would be interested in this swap.

On the other hand, hm....I was thinking if there is anything I can learn from your project and put it in my perlettes filament extruder.

I mean, a two stage filament extruder.

First stage is to change the filament granules into a filament (with rather big thickness)

Second stage, reduce the diameter by re-extruding it to a desired width.

This, based on the assumption that variations in the input diameter will lead to variations to the output length and not output diameter.

Coming back to your design: what's with the "Master" lock on the bottom of the design?

It even has a key in it :-)

Have you used it as a weight tensioner or...something else?

|

Re: Filament Reducer February 16, 2015 10:33PM |

Registered: 15 years ago Posts: 37 |

Hi Alexella,

Yes it works... for the most part. I still get issues with the extruder skipping which means a pause and break in the extruded filament and another takeup spool needed. Probably going a bit too fast...

. I could try swapping filament around but I found this interesting and educational... also I will have most the parts ready if I ever get a filastruder.

A couple new things:

- I am using a Potentiometer (as a voltage divider) at the bottom instead of the switch. From some initial testing this works really well in that it slows the spool take up and then speeds back up as the lever moves up and down.

- I got the gear motor and it is silent in comparison... just working on mounting it

As to the lock yes it is just a counterweight... it was lying nearby

perlettes filament extruder?

Mike

Yes it works... for the most part. I still get issues with the extruder skipping which means a pause and break in the extruded filament and another takeup spool needed. Probably going a bit too fast...

. I could try swapping filament around but I found this interesting and educational... also I will have most the parts ready if I ever get a filastruder.

A couple new things:

- I am using a Potentiometer (as a voltage divider) at the bottom instead of the switch. From some initial testing this works really well in that it slows the spool take up and then speeds back up as the lever moves up and down.

- I got the gear motor and it is silent in comparison... just working on mounting it

As to the lock yes it is just a counterweight... it was lying nearby

perlettes filament extruder?

Mike

|

Re: Filament Reducer March 26, 2015 05:08PM |

Registered: 10 years ago Posts: 478 |

"perlettes filament extruder."... I don't know how to name them.

Plastic grains I mean, the standard ones.

Yes, indeed, I agree with you: the educational part rulez.

Anyone would have been able to do a swap but... a filament reducer, that's far more interesting.

I don't have enough time these days so my filament extruder was put on a pause.

And I returned to my filament supplier which...gives it to me for a good price.

As in your case, making my own filament was/ is more likely a challenge then a necessity.

keep on havin' fun

Alex

Plastic grains I mean, the standard ones.

Yes, indeed, I agree with you: the educational part rulez.

Anyone would have been able to do a swap but... a filament reducer, that's far more interesting.

I don't have enough time these days so my filament extruder was put on a pause.

And I returned to my filament supplier which...gives it to me for a good price.

As in your case, making my own filament was/ is more likely a challenge then a necessity.

keep on havin' fun

Alex

|

Re: Filament Reducer March 31, 2015 10:00PM |

Registered: 15 years ago Posts: 37 |

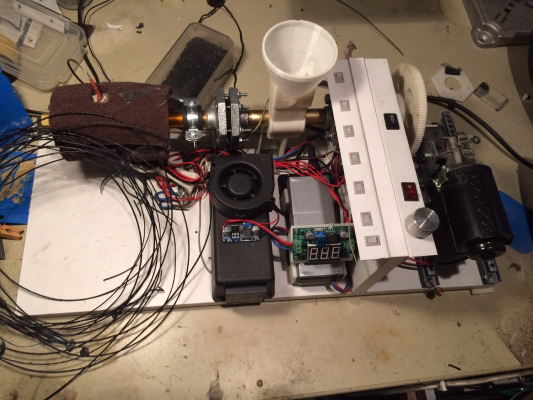

Here is my updated system,

[www.youtube.com]

Improvements:

- E3D Hot end

- Potentiometer and LM317 voltage regulator to control spooling

- Gear Motor

I have been able to reduce ABS, PLA, and PC. I couldn't get nylon (taulmen 618) to work it doesn't seem to like to be pulled, either the temp is too high and it drops out of the hot end or the temp is too low and it doesn't stretch.

PC worked at much lower temperatures than expected I have run it at 200 and 220 with a feedrate of 75 and 125 respectively.

I have also been printing with the filament I make, jams seem to happen more often then professional plastic but I went through lots of plastic during the development of my system.

Some [minor] issues still:

- Spooling isn't spread evenly, if I have enough distance from the 'spooling regulator' this seems to take care of itself for the most part

- Consistency: the filament diameter stays pretty consistent tolerance +-0.1mm but running my fingers along the filament I can tell its not perfect. I extrude undersize ~1.65 to be safe

In general I am happy with the results, it's a good platform for when I eventually try making my own filament from pellets or recycled prints.

Mike

[www.youtube.com]

Improvements:

- E3D Hot end

- Potentiometer and LM317 voltage regulator to control spooling

- Gear Motor

I have been able to reduce ABS, PLA, and PC. I couldn't get nylon (taulmen 618) to work it doesn't seem to like to be pulled, either the temp is too high and it drops out of the hot end or the temp is too low and it doesn't stretch.

PC worked at much lower temperatures than expected I have run it at 200 and 220 with a feedrate of 75 and 125 respectively.

I have also been printing with the filament I make, jams seem to happen more often then professional plastic but I went through lots of plastic during the development of my system.

Some [minor] issues still:

- Spooling isn't spread evenly, if I have enough distance from the 'spooling regulator' this seems to take care of itself for the most part

- Consistency: the filament diameter stays pretty consistent tolerance +-0.1mm but running my fingers along the filament I can tell its not perfect. I extrude undersize ~1.65 to be safe

In general I am happy with the results, it's a good platform for when I eventually try making my own filament from pellets or recycled prints.

Mike

|

Re: Filament Reducer April 15, 2015 04:03PM |

Registered: 10 years ago Posts: 478 |

First of all, I like your bedroom :-)

Second, I put my filament extruder on a pause..

I works but.. the output looks like a crappy shit from a tired small mouse.

It's brittle and with lot's of bubbles.

In my next attempt, I will try first to dry the ABS.

Also, I have to make the automated spool system, otherwise it's no fun.

Or, the best plan, is to completelly replycate the Lyman v5.

For this, I need around 200EUR or more but, with that amount of money, I can buy around 16kg of filament and ... this amount is enough for a year atleast.

Still, in my next idle time, I will make more progress on my filament extruder...

Second, I put my filament extruder on a pause..

I works but.. the output looks like a crappy shit from a tired small mouse.

It's brittle and with lot's of bubbles.

In my next attempt, I will try first to dry the ABS.

Also, I have to make the automated spool system, otherwise it's no fun.

Or, the best plan, is to completelly replycate the Lyman v5.

For this, I need around 200EUR or more but, with that amount of money, I can buy around 16kg of filament and ... this amount is enough for a year atleast.

Still, in my next idle time, I will make more progress on my filament extruder...

|

Re: Filament Reducer April 16, 2015 06:56AM |

Registered: 10 years ago Posts: 550 |

|

Re: Filament Reducer April 16, 2015 02:41PM |

Registered: 10 years ago Posts: 478 |

I have no ideea if temp was to high.

what you see in the picture is the only filament I've made.

Just wanderind if the motor will be powerfull enough to extrude, no further tests.

Temperature probably around 220C...

On my next attempt, I'll do it more sistematically, writing down parameters and retuning after each attempt.

I will start first by drying out the ABS

what you see in the picture is the only filament I've made.

Just wanderind if the motor will be powerfull enough to extrude, no further tests.

Temperature probably around 220C...

On my next attempt, I'll do it more sistematically, writing down parameters and retuning after each attempt.

I will start first by drying out the ABS

|

Re: Filament Reducer September 27, 2015 06:20AM |

Registered: 9 years ago Posts: 92 |

Try again at 180 degree Celsius to get better surfaces.

Vary around this temperature +/- 10 degree to find best match to your kind of ABS.

CTC 3D Drucker, fabrikator II mini, ultimaker-diy,

Modifizierter Prusa I3 Boxed.

Baubericht im Blog: [blog.gafu.de]

Vary around this temperature +/- 10 degree to find best match to your kind of ABS.

CTC 3D Drucker, fabrikator II mini, ultimaker-diy,

Modifizierter Prusa I3 Boxed.

Baubericht im Blog: [blog.gafu.de]

|

Re: Filament Reducer October 13, 2015 02:36PM |

Registered: 10 years ago Posts: 478 |

well... thanks for the advice but, I think I'll leave this as heritage for the next filament extruder.

Eventually I decided that it takes far to much space and time (compared to my filament requirements) so I intend to close this project.

I found a cheap source and.. I'll stick with it.

However, I noticed also at my printer that my quality of prints (and popping noise) dramatically decreased after I reduced the ABS printing temperature...

Eventually I decided that it takes far to much space and time (compared to my filament requirements) so I intend to close this project.

I found a cheap source and.. I'll stick with it.

However, I noticed also at my printer that my quality of prints (and popping noise) dramatically decreased after I reduced the ABS printing temperature...

|

Re: Filament Reducer October 14, 2015 05:34AM |

Registered: 10 years ago Posts: 550 |

|

Re: Filament Reducer October 20, 2015 01:49PM |

Registered: 10 years ago Posts: 478 |

yes but.. moisture should explode around 100C.

The fact that I'm hearing popping at 235C but no more popping at 210C (for example), makes me thing that maybe I'm extruding at a temperature that's higher than required.

Otherwise, allthough I know what you mean through filament moisture, I have... no reasonable way to dry it. I'm just relying that my room is dry enough (no humidity sources and computer runs all the time)

The fact that I'm hearing popping at 235C but no more popping at 210C (for example), makes me thing that maybe I'm extruding at a temperature that's higher than required.

Otherwise, allthough I know what you mean through filament moisture, I have... no reasonable way to dry it. I'm just relying that my room is dry enough (no humidity sources and computer runs all the time)

Sorry, only registered users may post in this forum.