New extruder concept

Posted by goaran

|

New extruder concept June 17, 2010 02:25PM |

Registered: 14 years ago Posts: 176 |

Hi there,..

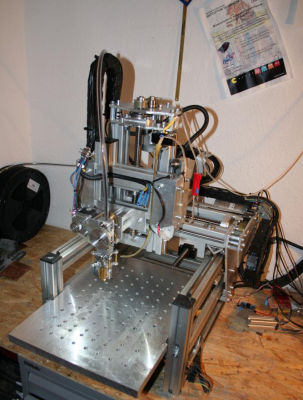

at the time i'm updating my cnc mill to reprap and i thougt a bit about the extruder.

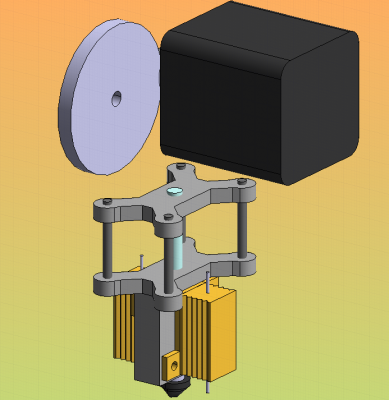

i came up with this concept then..

the drive works kind of like in wades extruder, but for heating i use dale high-power resisors.

i allready tried if the work fot the needed temperatures and it seems to be no problem:

the heat barrier will be a glas-tube which i found in the basement and the connection between the upper and lower part will be with 4 screws which have some heatisolation in between.

why? cause it looks better than those taped extruders and hopfully it will live longer. the extruderhead can't pop out because its really fixed.

what do you think about it?

my projects: [www.robotik.dyyyh.de] ...

at the time i'm updating my cnc mill to reprap and i thougt a bit about the extruder.

i came up with this concept then..

the drive works kind of like in wades extruder, but for heating i use dale high-power resisors.

i allready tried if the work fot the needed temperatures and it seems to be no problem:

the heat barrier will be a glas-tube which i found in the basement and the connection between the upper and lower part will be with 4 screws which have some heatisolation in between.

why? cause it looks better than those taped extruders and hopfully it will live longer. the extruderhead can't pop out because its really fixed.

what do you think about it?

my projects: [www.robotik.dyyyh.de] ...

|

Re: New extruder concept June 17, 2010 02:50PM |

Registered: 16 years ago Posts: 106 |

I would think the main constraint with this design would be fitting it to a Mendel. However, for a CNC conversion that is a non-issue.

I'm currently using resistors as heaters. In my opinion they are far easier to replace and use as heater elements vs nichrome and seem to work just as well. I'm using a very well heatsinked single 5W 5.8ohm resistors, and it is still working after 20+ hours of usage. The dual setup you have may be overkill, depending on the amount of loss your extruder has.

----

[www.binaryconstruct.com]

I'm currently using resistors as heaters. In my opinion they are far easier to replace and use as heater elements vs nichrome and seem to work just as well. I'm using a very well heatsinked single 5W 5.8ohm resistors, and it is still working after 20+ hours of usage. The dual setup you have may be overkill, depending on the amount of loss your extruder has.

----

[www.binaryconstruct.com]

|

Re: New extruder concept June 17, 2010 04:15PM |

Registered: 15 years ago Posts: 199 |

|

Re: New extruder concept June 17, 2010 05:09PM |

Registered: 16 years ago Posts: 536 |

|

Re: New extruder concept June 18, 2010 05:10AM |

Registered: 14 years ago Posts: 176 |

Thanks for the fast replies.

I have a cnc reprap, so with the size there will be no problem, maybee its possible to adjust the design a bit for use in mendel as well.

The fins of the resistors are bad, i know, (but they look really nice maybee ill put some insulating material around there.

maybee ill put some insulating material around there.

Another idea would be milling out the place for the resisotrs from a bigger aluminum part in the middel and mounting them the other way round. then the colling-fins are in contact with the block and no heat is wasted. i ll put up a desin for that later..

my projects: [www.robotik.dyyyh.de] ...

I have a cnc reprap, so with the size there will be no problem, maybee its possible to adjust the design a bit for use in mendel as well.

The fins of the resistors are bad, i know, (but they look really nice

maybee ill put some insulating material around there.

maybee ill put some insulating material around there. Another idea would be milling out the place for the resisotrs from a bigger aluminum part in the middel and mounting them the other way round. then the colling-fins are in contact with the block and no heat is wasted. i ll put up a desin for that later..

my projects: [www.robotik.dyyyh.de] ...

|

Re: New extruder concept June 18, 2010 06:37AM |

Admin Registered: 17 years ago Posts: 7,879 |

I am not sure you can call this a new concept, I have used those resistors before and Makergear have tried a glass insulator [www.makergear.com].

In my experience those resistors make a reliable heater, but not very efficient due to the large surface area, which is an awkward shape to insulate. There is also considerable mass, making it slow to warm up. [hydraraptor.blogspot.com]

I have moved on to using vitreous enamel resistors wrapped in AL foil and jammed into a hole through an AL block.

[hydraraptor.blogspot.com]

That works a lot better and is easier to make. I have since moved on to a smaller resistor giving less surface area and mass: [hydraraptor.blogspot.com].

With an integrated heater and nozzle I get good warm up times. It doesn't heat too fast for the thermistor to keep up so I don't need PID control. It also heats slowly enough for the plastic to melt, so once up to temp it is ready to go with no risk of jamming.

The integrated design has a very small melt zone, which gives a good start / stop response.

I haven't tried glass, but I see a couple of potential snags. It isn't a good insulator, compared to say PTFE, so it needs to be quite thin. It would have to be well supported otherwise a collision with the bed or an object might break it. If my extruder was glass I would certainly have broken it many times!

Molten PLA sticks to hot glass very well [hydraraptor.blogspot.com], so it might be difficult to push through a glass tube, i.e. lots of viscous drag.

[www.hydraraptor.blogspot.com]

In my experience those resistors make a reliable heater, but not very efficient due to the large surface area, which is an awkward shape to insulate. There is also considerable mass, making it slow to warm up. [hydraraptor.blogspot.com]

I have moved on to using vitreous enamel resistors wrapped in AL foil and jammed into a hole through an AL block.

[hydraraptor.blogspot.com]

That works a lot better and is easier to make. I have since moved on to a smaller resistor giving less surface area and mass: [hydraraptor.blogspot.com].

With an integrated heater and nozzle I get good warm up times. It doesn't heat too fast for the thermistor to keep up so I don't need PID control. It also heats slowly enough for the plastic to melt, so once up to temp it is ready to go with no risk of jamming.

The integrated design has a very small melt zone, which gives a good start / stop response.

I haven't tried glass, but I see a couple of potential snags. It isn't a good insulator, compared to say PTFE, so it needs to be quite thin. It would have to be well supported otherwise a collision with the bed or an object might break it. If my extruder was glass I would certainly have broken it many times!

Molten PLA sticks to hot glass very well [hydraraptor.blogspot.com], so it might be difficult to push through a glass tube, i.e. lots of viscous drag.

[www.hydraraptor.blogspot.com]

|

Re: New extruder concept June 18, 2010 06:59AM |

Admin Registered: 16 years ago Posts: 13,884 |

... look here (in the atached image) for some other useful types ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: New extruder concept June 18, 2010 08:45AM |

Registered: 14 years ago Posts: 176 |

@nophead

ok, i didnt know someone did this befor. so im gonna read a bit about the experiences before i start building it.

if the glass really breaks it is possible to replace it withe the default PTFE without changing the concept.

how important is it to keep the meltzone small? in the default desing the brassy tube is also about 25mm long and brass conducts heat not that bad.

your design with the pluged in resistor is nice too, maybe that will be a better way to manage it without having a too big surface for heat radiation.

for the pla, didnt try that jet, but the abs does not stick on the glass-tube.

maybee ill also not stick the tube directly to the aluminium block, but put a little piece of PTFE in between as sealing ring, so that the mounting of the tube is softer and it doesnt break that easy. im gonna think about that...

@viktor

i bougt a pack of big resistors at Pollin for one bug, maybee some of them would work too.. dont have any datasheet for max temperatur of those but ill test that..

(if somebody is intrested in some of those i could send you some for free (exept shippingcosts from germany)

my projects: [www.robotik.dyyyh.de] ...

ok, i didnt know someone did this befor. so im gonna read a bit about the experiences before i start building it.

if the glass really breaks it is possible to replace it withe the default PTFE without changing the concept.

how important is it to keep the meltzone small? in the default desing the brassy tube is also about 25mm long and brass conducts heat not that bad.

your design with the pluged in resistor is nice too, maybe that will be a better way to manage it without having a too big surface for heat radiation.

for the pla, didnt try that jet, but the abs does not stick on the glass-tube.

maybee ill also not stick the tube directly to the aluminium block, but put a little piece of PTFE in between as sealing ring, so that the mounting of the tube is softer and it doesnt break that easy. im gonna think about that...

@viktor

i bougt a pack of big resistors at Pollin for one bug, maybee some of them would work too.. dont have any datasheet for max temperatur of those but ill test that..

(if somebody is intrested in some of those i could send you some for free (exept shippingcosts from germany)

my projects: [www.robotik.dyyyh.de] ...

|

Re: New extruder concept June 18, 2010 10:01AM |

Admin Registered: 17 years ago Posts: 7,879 |

Quote

how important is it to keep the meltzone small?

Well it certainly works with a long melt zone as all the current designs are like that. The Plumbstruder I have on my Mendel works well and is totally reliable, but the extruder I have on HydraRaptor gives better quality prints. It is hard to do a direct comparison because it has a smaller nozzle, but it starts and stops more cleanly. Having said that, I think commercial machine have quite a big melt zone.

[www.hydraraptor.blogspot.com]

|

Re: New extruder concept June 18, 2010 10:41AM |

Registered: 14 years ago Posts: 176 |

Ok thanks, ill think about how to keep it short - maybee 10mm should be fine

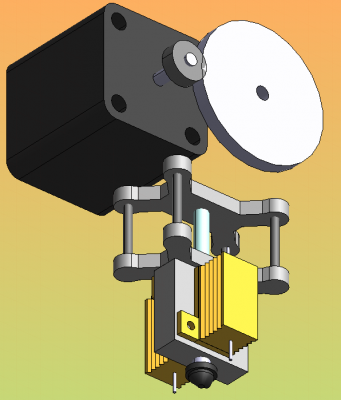

ok, first i added the gears... i did the rpm speed reduktion in two steps what results in smaller gears and makes it samller.

the gear ratio is now about 1:16 think that is fine.... and the skein is pushed twice which allows lower preasure and therfore less deformation i hope...

if somebody is intrested in here are the design files for heekscad:

[robotik.dyyyh.de]

Edited 2 time(s). Last edit at 06/18/2010 02:33PM by goaran.

my projects: [www.robotik.dyyyh.de] ...

ok, first i added the gears... i did the rpm speed reduktion in two steps what results in smaller gears and makes it samller.

the gear ratio is now about 1:16 think that is fine.... and the skein is pushed twice which allows lower preasure and therfore less deformation i hope...

if somebody is intrested in here are the design files for heekscad:

[robotik.dyyyh.de]

Edited 2 time(s). Last edit at 06/18/2010 02:33PM by goaran.

my projects: [www.robotik.dyyyh.de] ...

|

Re: New extruder concept June 19, 2010 05:40PM |

Registered: 14 years ago Posts: 573 |

For printed parts you may want bigger instead of smaller gears. To make them easier to print.

I´m really curious about the performance of such an extruder.

The hot part is pretty big and I guess that the supports above it may get soft after 4-30h of printing.

I can´t see all the path of the filament.

How do you pull out the filament for cleaning or changing the color or if it gets stuck?

How do pressure-bearing and filament-driver look like?

-------------------------------------------

* homeprototype free 3d design repository

* Blog

* Google+

I´m really curious about the performance of such an extruder.

The hot part is pretty big and I guess that the supports above it may get soft after 4-30h of printing.

I can´t see all the path of the filament.

How do you pull out the filament for cleaning or changing the color or if it gets stuck?

How do pressure-bearing and filament-driver look like?

-------------------------------------------

* homeprototype free 3d design repository

* Blog

* Google+

|

Re: New extruder concept September 04, 2010 06:55AM |

Registered: 14 years ago Posts: 176 |

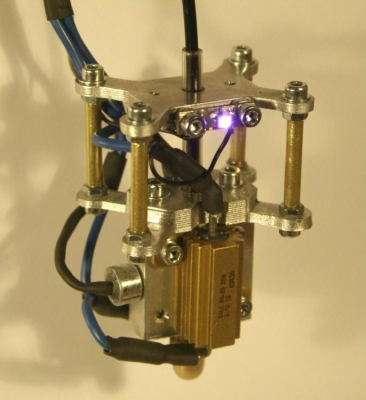

i started building the extruder tonight. the thermal part is finished, next i will mill the the gear-block.

my projects: [www.robotik.dyyyh.de] ...

my projects: [www.robotik.dyyyh.de] ...

|

Re: New extruder concept September 04, 2010 09:36AM |

Registered: 14 years ago Posts: 689 |

|

Re: New extruder concept September 08, 2010 08:34AM |

Registered: 13 years ago Posts: 482 |

|

Re: New extruder concept October 31, 2010 05:45PM |

Registered: 14 years ago Posts: 248 |

|

Re: New extruder concept December 29, 2010 03:03PM |

Registered: 14 years ago Posts: 176 |

|

Re: New extruder concept December 30, 2010 01:09AM |

Admin Registered: 15 years ago Posts: 1,470 |

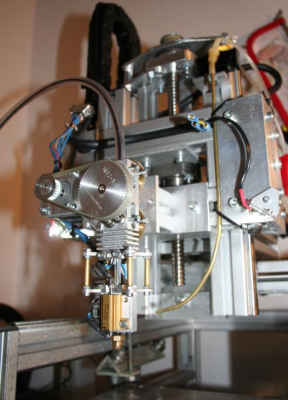

That is one sexy extruder! I love the almost steam punk look to it.

|

Help improve the RepRap wiki!

Just click "Edit" in the top-right corner of the page and start typing. Anyone can edit the wiki! |

Sorry, only registered users may post in this forum.