Infill/hatching technique

Posted by james19181

|

Infill/hatching technique March 28, 2011 08:40AM |

Registered: 13 years ago Posts: 1 |

|

Re: Infill/hatching technique March 28, 2011 02:46PM |

Registered: 13 years ago Posts: 49 |

|

Re: Infill/hatching technique March 31, 2011 09:23AM |

Admin Registered: 13 years ago Posts: 41 |

|

Re: Infill/hatching technique March 31, 2011 02:21PM |

Registered: 16 years ago Posts: 438 |

It sounds like you're trying to ask if you can "turn on" the extruder and never turn it off until the print is done. The short answer is no.

There does appear to be some benefit to making the entire object from a single strand, but for several reasons we don't even try to do that. The main one is simplicity though. If you're doing a complex object with several "islands" as it grows, you'd have to do some really complex crap to make sure the print head didn't run into the already built piece. Almost certainly have to be able to tip the extruder on it's side, for instance. There is some software/algorythms written to do that, there was a guy who was doing wire extrusion fabrication and wrote something that would convert any object into a toolpath for a single piece of wire. Don't remember where I saw that though, and it was his master's thesis or something so who knows how useable it really was.

If OTOH, you're simply concerned about the problems that many people have had with "blobs" where the Z-movement takes place, and think that doing the Z movement gradually throughout the layer would solve that no problem. In which case you may have a point, but you'd run into similar problems with islands, and there are better solutions. The "correct" solution is of course to tune retract so it works perfectly, which solves blobs when moving from island to island as well. You can also change something (I forget what) to make it so the Z movement happens on the inside of the object where nobody can see it anyway.

As for filling in a 3D model, there's differing opinions. Forrest doesn't fill his models at all, prefering the quick print speed and lack of warping possible when printing just the shell. For most people, squares and hexagons have both been done. Playing with the infill settings in skeinforge and viewing the results in (for instance) repsnapper might be very educational.

Nobody that I know of is in the habit of printing solid objects. Plastic is so strong that there's really no point. And it greatly increases warping stresses, you'd probably have to have a heated chamber to get it to work well. Most people use several sold shells, a few solid layers on the top and bottom, and the infill in between all that is sparse to one degree or another.

--

I'm building it with Baling Wire

There does appear to be some benefit to making the entire object from a single strand, but for several reasons we don't even try to do that. The main one is simplicity though. If you're doing a complex object with several "islands" as it grows, you'd have to do some really complex crap to make sure the print head didn't run into the already built piece. Almost certainly have to be able to tip the extruder on it's side, for instance. There is some software/algorythms written to do that, there was a guy who was doing wire extrusion fabrication and wrote something that would convert any object into a toolpath for a single piece of wire. Don't remember where I saw that though, and it was his master's thesis or something so who knows how useable it really was.

If OTOH, you're simply concerned about the problems that many people have had with "blobs" where the Z-movement takes place, and think that doing the Z movement gradually throughout the layer would solve that no problem. In which case you may have a point, but you'd run into similar problems with islands, and there are better solutions. The "correct" solution is of course to tune retract so it works perfectly, which solves blobs when moving from island to island as well. You can also change something (I forget what) to make it so the Z movement happens on the inside of the object where nobody can see it anyway.

As for filling in a 3D model, there's differing opinions. Forrest doesn't fill his models at all, prefering the quick print speed and lack of warping possible when printing just the shell. For most people, squares and hexagons have both been done. Playing with the infill settings in skeinforge and viewing the results in (for instance) repsnapper might be very educational.

Nobody that I know of is in the habit of printing solid objects. Plastic is so strong that there's really no point. And it greatly increases warping stresses, you'd probably have to have a heated chamber to get it to work well. Most people use several sold shells, a few solid layers on the top and bottom, and the infill in between all that is sparse to one degree or another.

--

I'm building it with Baling Wire

|

Re: Infill/hatching technique April 01, 2011 10:59PM |

Registered: 14 years ago Posts: 172 |

rhysjones Wrote:

-------------------------------------------------------

> I can't speak for skeinforge, but the host

> software *should* do this just by setting the

> number of shells to a ridiculously high value.

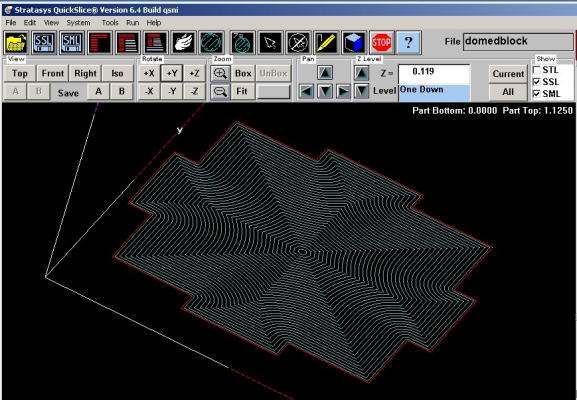

I believe this is what rhysjones is describing: It's not a spiral, as each road is a closed loop, but the effect is essentially the same.

I think a more interesting infill is the one described in this paper: [www.google.com]

Coincidentally, the first reference noted in that paper is a mathematics journal article by some 'A. Bowyer' chap...

[haveblue.org]

-------------------------------------------------------

> I can't speak for skeinforge, but the host

> software *should* do this just by setting the

> number of shells to a ridiculously high value.

I believe this is what rhysjones is describing: It's not a spiral, as each road is a closed loop, but the effect is essentially the same.

I think a more interesting infill is the one described in this paper: [www.google.com]

Coincidentally, the first reference noted in that paper is a mathematics journal article by some 'A. Bowyer' chap...

[haveblue.org]

|

Re: Infill/hatching technique April 10, 2011 04:30AM |

Registered: 13 years ago Posts: 1,797 |

[forums.reprap.org] has a way to remove z height change blobs from the outside shells

there is some merit to spiraling up and having z axis be continuously increasing. the reprap hardware is not capable of doing this with precision as of today, as there are backlash issues in many reprap designs on z axis, as well as issues with speed of the slowest axis (z axis).

I tried the spiral method on my rapman to remove defects from the outside shell and thought it would increase precision. my biggest issue was when z axis needed to go back down and up rapidly as the inside layers need to be filled as well. I had many head crashes, many software lockups of rapman, and also very slow rates of increase as your total speed is based on your slowest moving axis. z max speed is around 3-10mm/s where x and y speed is around 40-200mm/s. a lot of the speed issues are from the weight on the z axis, and in my case the fact that i had a Darwin design with 4 pulleys and 4 screws on z axis.

the speed would be limited by the steps to process the z axis which are in the thousands per mm. the arduino is not currently capable of doing this with default firmware and the calculations needed to process incoming data. you may want to try the 'teacup' firmware. also you may want to use a different type of z axis.

the benefits from spiraling are more even outer shell walls, and no strings on objects and no blobs and an optical illusion to the eyes that there are no layers, as we will not see diagonal lines as layers, but process the image from up to down and side to side.

the most fascinating experiment someone can do is print an object vertically at a 45 deg angle, then clean the part up, lay it down on its sides, and ask someone how it was printed. they will not see any layering, unless you point it out to them!

there is some merit to spiraling up and having z axis be continuously increasing. the reprap hardware is not capable of doing this with precision as of today, as there are backlash issues in many reprap designs on z axis, as well as issues with speed of the slowest axis (z axis).

I tried the spiral method on my rapman to remove defects from the outside shell and thought it would increase precision. my biggest issue was when z axis needed to go back down and up rapidly as the inside layers need to be filled as well. I had many head crashes, many software lockups of rapman, and also very slow rates of increase as your total speed is based on your slowest moving axis. z max speed is around 3-10mm/s where x and y speed is around 40-200mm/s. a lot of the speed issues are from the weight on the z axis, and in my case the fact that i had a Darwin design with 4 pulleys and 4 screws on z axis.

the speed would be limited by the steps to process the z axis which are in the thousands per mm. the arduino is not currently capable of doing this with default firmware and the calculations needed to process incoming data. you may want to try the 'teacup' firmware. also you may want to use a different type of z axis.

the benefits from spiraling are more even outer shell walls, and no strings on objects and no blobs and an optical illusion to the eyes that there are no layers, as we will not see diagonal lines as layers, but process the image from up to down and side to side.

the most fascinating experiment someone can do is print an object vertically at a 45 deg angle, then clean the part up, lay it down on its sides, and ask someone how it was printed. they will not see any layering, unless you point it out to them!

|

Re: Infill/hatching technique April 04, 2013 06:56AM |

Registered: 11 years ago Posts: 74 |

Sorry, only registered users may post in this forum.