The 0.8mm filament experiment

Posted by o_lampe

|

The 0.8mm filament experiment March 27, 2018 12:22PM |

Registered: 8 years ago Posts: 5,232 |

Hi everyone,

as we know, the step from 3mm to 1.75mm filament changed 3DP a lot. I always thought, it could get even better with thinner filament. Mostly reducing extruder weight is the goal in this experiment.

I started to make my own 0.8mm filament, simply by extruding 1.75 filament through a 0.6mm nozzle, while the printhead made continuous circles.

Why 0.8mm? It fits nicely in 1mm ID PTFE tube and I could easily modify a 0.4mm nozzle with a brass tube of 2x0.5mm.

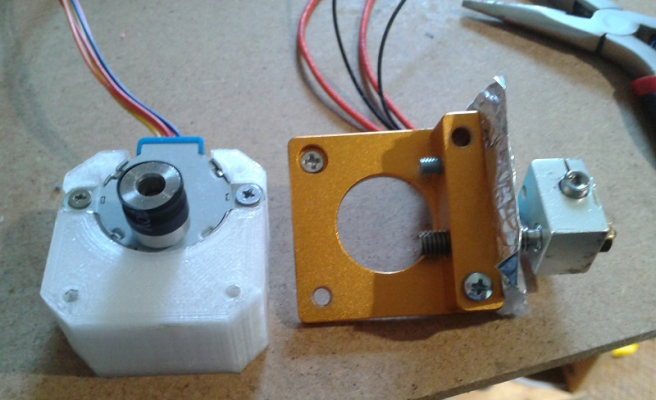

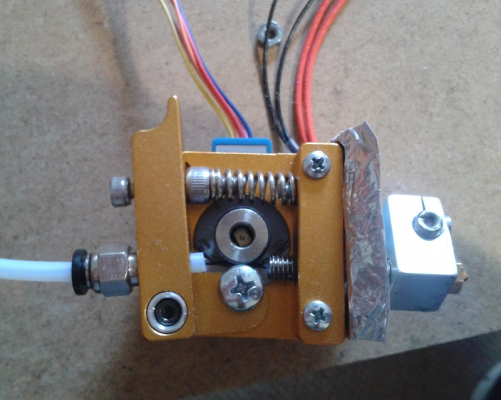

So I took a MK8 direct drive extruder, pushed the 1mm ID PTFE tube into the standard 2mm ID PTFE tube of the heatbrake.

The drive gear had way too much pressure and almost bit through the filament, so I took a smaller drive gear and added two layers of shrinktube. I also had to replace the grooved idler gear with a flat one.

A NEMA17 1.7A motor had no problem at all to extrude at 15mm/s. The cross section is 5.4 times smaller, so I guess the required torque can be 5.4 times smaller, too? I ordered a NEMA17 20mm pancake ( weight 140 gram ) with 13Ncm holding torque. ( a bit different to the pancake E3d uses for their Titan extruder. )

It will surely do the job, but I'm tempted to try an even smaller stepper, like the 14HR05-05A ( weight 50 gram ) with 7Ncm. Maybe add a 3:1 gear, like a tiny Titan. It would then be ~100gram lighter.

I already tried to extrude with a modified 28BYJ stepper, but it was a little bit too weak at 500mA.

I'll post a video of filament making later. Here it is

Edited 3 time(s). Last edit at 03/27/2018 12:46PM by o_lampe.

as we know, the step from 3mm to 1.75mm filament changed 3DP a lot. I always thought, it could get even better with thinner filament. Mostly reducing extruder weight is the goal in this experiment.

I started to make my own 0.8mm filament, simply by extruding 1.75 filament through a 0.6mm nozzle, while the printhead made continuous circles.

Why 0.8mm? It fits nicely in 1mm ID PTFE tube and I could easily modify a 0.4mm nozzle with a brass tube of 2x0.5mm.

So I took a MK8 direct drive extruder, pushed the 1mm ID PTFE tube into the standard 2mm ID PTFE tube of the heatbrake.

The drive gear had way too much pressure and almost bit through the filament, so I took a smaller drive gear and added two layers of shrinktube. I also had to replace the grooved idler gear with a flat one.

A NEMA17 1.7A motor had no problem at all to extrude at 15mm/s. The cross section is 5.4 times smaller, so I guess the required torque can be 5.4 times smaller, too? I ordered a NEMA17 20mm pancake ( weight 140 gram ) with 13Ncm holding torque. ( a bit different to the pancake E3d uses for their Titan extruder. )

It will surely do the job, but I'm tempted to try an even smaller stepper, like the 14HR05-05A ( weight 50 gram ) with 7Ncm. Maybe add a 3:1 gear, like a tiny Titan. It would then be ~100gram lighter.

I already tried to extrude with a modified 28BYJ stepper, but it was a little bit too weak at 500mA.

I'll post a video of filament making later. Here it is

Edited 3 time(s). Last edit at 03/27/2018 12:46PM by o_lampe.

|

Re: The 0.8mm filament experiment April 04, 2018 02:08AM |

Registered: 8 years ago Posts: 5,232 |

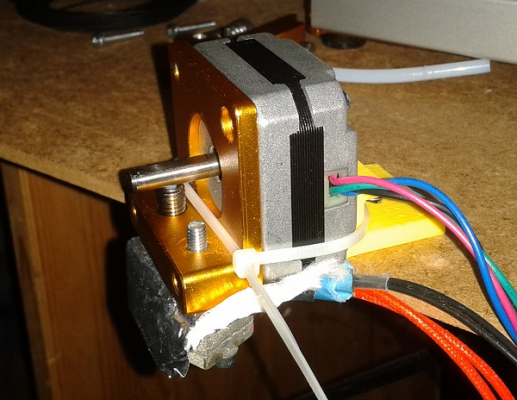

The short body NEMA17 arrived and I tested it, extruding in free air.

I tried to slice an XYZcalibration cube with 0.8mm filament setting, but Slic3r came up with an error message. So I had to cheat by using 5.4 times more e-steps.

It worked quite well at first, but after a few minutes the shrink tube on the drive gear ripped apart and the filament got chewed by the sharp teeth of the drive gear again. I have to make my own drive gear, maybe start with a brass pinion gear with less sharp teeth and grind a small hob into.

Is anyone here, able to produce decent drive gears ( and an M6 nozzle with 1mm melting chamber diameter, too) ? Please PM me

I tried to slice an XYZcalibration cube with 0.8mm filament setting, but Slic3r came up with an error message. So I had to cheat by using 5.4 times more e-steps.

It worked quite well at first, but after a few minutes the shrink tube on the drive gear ripped apart and the filament got chewed by the sharp teeth of the drive gear again. I have to make my own drive gear, maybe start with a brass pinion gear with less sharp teeth and grind a small hob into.

Is anyone here, able to produce decent drive gears ( and an M6 nozzle with 1mm melting chamber diameter, too) ? Please PM me

|

Re: The 0.8mm filament experiment April 05, 2018 03:51AM |

Registered: 8 years ago Posts: 5,232 |

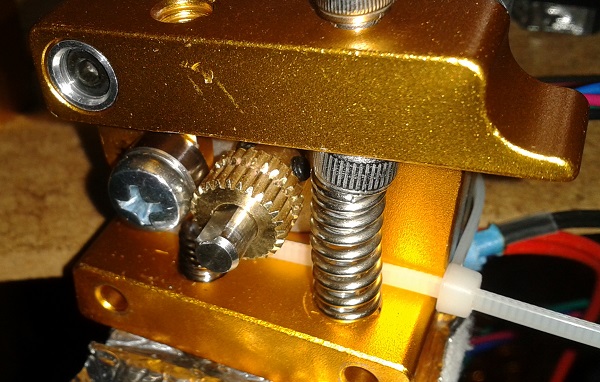

I took a Dremel cutter wheel and cut a groove in the brass drive wheel while it was spinning.

Now I have the right amount of bite without the teeth chewing through the filament.

Now it's time to mount it in my Prusa i3 and actually print something.

It's still too big to fit on a Delta effector, but one step at a time . I could reduce motor current to 600mA at 200% printspeed ( 1000mA max. ), before it skipped steps. I'm sure the 14HR05-05 stepper ( 50gram ) with 11Ncm will do fine with a little gearing or smaller drive gear.

Now I have the right amount of bite without the teeth chewing through the filament.

Now it's time to mount it in my Prusa i3 and actually print something.

It's still too big to fit on a Delta effector, but one step at a time . I could reduce motor current to 600mA at 200% printspeed ( 1000mA max. ), before it skipped steps. I'm sure the 14HR05-05 stepper ( 50gram ) with 11Ncm will do fine with a little gearing or smaller drive gear.

|

Re: The 0.8mm filament experiment May 18, 2018 05:31PM |

Registered: 8 years ago Posts: 338 |

Olampe, I just saw this. Very interesting! I look forward to your experiments. My only concern is the increased risk of filament breakage with the reduced diameter.. maybe this is good case for a belt-extruder instead of hobbled teeth?

Edited 1 time(s). Last edit at 05/18/2018 05:33PM by Qdeathstar.

Edited 1 time(s). Last edit at 05/18/2018 05:33PM by Qdeathstar.

|

Re: The 0.8mm filament experiment May 19, 2018 02:19AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: The 0.8mm filament experiment May 19, 2018 06:29AM |

Admin Registered: 13 years ago Posts: 6,998 |

|

Re: The 0.8mm filament experiment May 20, 2018 02:49AM |

Registered: 8 years ago Posts: 5,232 |

Quote

Dust

just what we need, another standard....

Is that the same comment you made, when 1.75mm filament replaced 3mm?

We are all searching for the ultimate leightweigth extruder motor, but we either struggle with closed loop dc-motor drivers or with highly geared pancake steppers.

Because we use 1.75mm filament.

0.8mm dia is probably not the best choice, because the drive gear chews it like nothing. But the PTFE tube I could get, was either 2mm ID or 1mmID.

Edited 1 time(s). Last edit at 05/20/2018 02:59AM by o_lampe.

|

Re: The 0.8mm filament experiment May 20, 2018 04:38AM |

Registered: 9 years ago Posts: 978 |

|

Re: The 0.8mm filament experiment May 20, 2018 10:08AM |

Admin Registered: 13 years ago Posts: 6,998 |

Quote

o_lampe

Is that the same comment you made, when 1.75mm filament replaced 3mm?

This never happened. Plenty of 3mm machines still out there. Working just as well as the 1.75 machines. Eg Ultimaker

Quote

frankvdh

Better too many standards than one wrong standard.

How is this relevant, are you trying to imply that 3 mm or 1.75 are wrong?

Edited 2 time(s). Last edit at 05/20/2018 10:12AM by Dust.

|

Re: The 0.8mm filament experiment May 20, 2018 02:59PM |

Registered: 9 years ago Posts: 978 |

Quote

Dust

Quote

o_lampe

Is that the same comment you made, when 1.75mm filament replaced 3mm?

This never happened. Plenty of 3mm machines still out there. Working just as well as the 1.75 machines. Eg Ultimaker

Quote

frankvdh

Better too many standards than one wrong standard.

How is this relevant, are you trying to imply that 3 mm or 1.75 are wrong?

Yes... if experiments show that 0.8mm is right in some circumstances.

|

Re: The 0.8mm filament experiment May 30, 2018 10:42PM |

Registered: 8 years ago Posts: 338 |

Quote

o_lampe

Yes, the filament drive is the weak point right now. ( Or too strong, to be exact )

How would a belt-extruder look like?

[www.thingiverse.com]

|

Re: The 0.8mm filament experiment May 31, 2018 02:51AM |

Registered: 8 years ago Posts: 5,232 |

Sorry, only registered users may post in this forum.