Extruder jam

Posted by mathijs.kossen

|

Extruder jam June 14, 2011 02:28AM |

Registered: 13 years ago Posts: 14 |

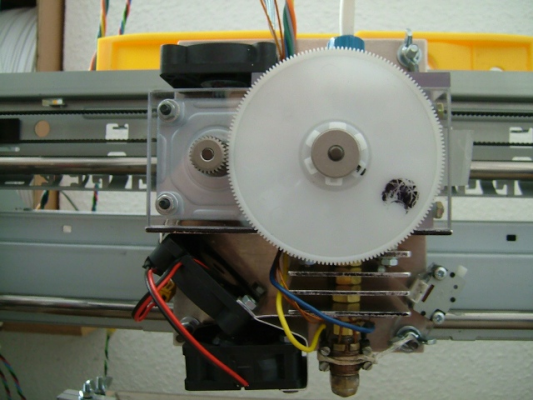

Hello, for some time i'm struggling with my extruder. I'm building a shapercube, with a pre-made extruder. (see link below). The problem is, as i've read more about on all fora, that it gets jammed. My shapercube uses a Wade's geared extruder

I try to extrude ABS at a temperature of 240C, but it neither works at 250C. I ordered a new extruder, which i only use for extrusion of ABS. SO i don't use multiple materials on one extruder.

The grip of my whobbed bolt seems fine. I can not pull it through by hand (even not with force) and when I put my stepper motor in reverse it drives the filament out without any problems. I added a picture of my filament, once it got jammed and is driven out. Can anything be derived of the shape of this?

Wades geared extruder

[reprap.org]

Extruder

[www.reprapsource.com]

I try to extrude ABS at a temperature of 240C, but it neither works at 250C. I ordered a new extruder, which i only use for extrusion of ABS. SO i don't use multiple materials on one extruder.

The grip of my whobbed bolt seems fine. I can not pull it through by hand (even not with force) and when I put my stepper motor in reverse it drives the filament out without any problems. I added a picture of my filament, once it got jammed and is driven out. Can anything be derived of the shape of this?

Wades geared extruder

[reprap.org]

Extruder

[www.reprapsource.com]

|

Re: Extruder jam June 14, 2011 03:11AM |

Admin Registered: 16 years ago Posts: 13,886 |

... best measure the real temperature with a thermometer - the thermistor can be wrong by some ten degrees ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Extruder jam June 14, 2011 04:48PM |

Registered: 16 years ago Posts: 824 |

What is your hot end? I recently saw a jamming problem where the channel of the hot end was 3mm, and was causing jamming after about a minute of extruding. It turned out to be expansion of the filament (PLA in that case). Drilling out the tube to 3.5 mm was suggested, but I don't know the results of that effort.

|

Re: Extruder jam June 14, 2011 09:54PM |

Registered: 12 years ago Posts: 27 |

jcabrer Wrote:

-------------------------------------------------------

> What is your hot end? I recently saw a jamming

> problem where the channel of the hot end was 3mm,

> and was causing jamming after about a minute of

> extruding. It turned out to be expansion of the

> filament (PLA in that case). Drilling out the

> tube to 3.5 mm was suggested, but I don't know the

> results of that effort.

Ehi, i have exactly the same problem! i drilled the channel with a 3mm drill bit and the pla is always jamming. I will try with the 3.5 solution, as soon as i find the cobalt drill bit. I really hope this is the solution.. it's days that i'm stuck with this problem..

-------------------------------------------------------

> What is your hot end? I recently saw a jamming

> problem where the channel of the hot end was 3mm,

> and was causing jamming after about a minute of

> extruding. It turned out to be expansion of the

> filament (PLA in that case). Drilling out the

> tube to 3.5 mm was suggested, but I don't know the

> results of that effort.

Ehi, i have exactly the same problem! i drilled the channel with a 3mm drill bit and the pla is always jamming. I will try with the 3.5 solution, as soon as i find the cobalt drill bit. I really hope this is the solution.. it's days that i'm stuck with this problem..

|

Re: Extruder jam June 19, 2011 08:13AM |

Registered: 13 years ago Posts: 1,352 |

Imo it might be also an issue with the porosity of the surface walls. I dont know if i recall correctly, but the drill bit will make the walls at approx 300 and if you stick some sandpaper on a toothpick and the toolpick in your bore-machine, it will sand the walls to maybe 80 (not like sandpaper granulation scale, actually inverse: smaller = finer) and this should impact alot on the frictions to the walls. Without the toolpick if the sandingpaper is strong enough by itself, make a cylinder out of it and fix it in the chuck and try spinning it around. Dunno about plastic on metal frictions, but about metal on metal this method works neat. Might worth investigating, just an ideea. Maybe its not entirelly about the hole diameter, maybe the surface quality of the hole walls have an impact too, at some extent.

|

Re: Extruder jam July 05, 2011 07:54AM |

Registered: 13 years ago Posts: 228 |

|

Re: Extruder jam October 28, 2011 04:09AM |

Registered: 12 years ago Posts: 29 |

The same problem here.

I made extruder my self - it is simillar to V9 m**p** extruder and extrudes ABS for weeks withouth any problems.

Then I switchet to green PLA and it jamed, so I made anther extruder - clean one and it jamed again - I tried ewery possible temperatures - from 190 to 230°C. I can print let say 0,5cm of something small - after that james it self.

I also tried to switch back to ABS and withouth any problem ABS works.

Any sugjestions.

Best regards.

Bogdan

I made extruder my self - it is simillar to V9 m**p** extruder and extrudes ABS for weeks withouth any problems.

Then I switchet to green PLA and it jamed, so I made anther extruder - clean one and it jamed again - I tried ewery possible temperatures - from 190 to 230°C. I can print let say 0,5cm of something small - after that james it self.

I also tried to switch back to ABS and withouth any problem ABS works.

Any sugjestions.

Best regards.

Bogdan

|

Re: Extruder jam October 28, 2011 08:39AM |

Registered: 15 years ago Posts: 537 |

Hello,

PLA expanding in the hot-end will cause many hot-ends to jam. The trick is to keep the filament cool as long as possible until it needs to be heated. If the PLA is not kept cool enough, it will expand and jam.

The resolution is usually to have a hot-end with either a heat-sink or some sort of ventilation system that keeps the filament cool for as long as possible. At this time, the Arcol.hu, Budaschnozzle, and J-Head are equipped to do so.

Disclaimer: I make the J-Head nozzles and hot-ends.

Regards,

Brian

PLA expanding in the hot-end will cause many hot-ends to jam. The trick is to keep the filament cool as long as possible until it needs to be heated. If the PLA is not kept cool enough, it will expand and jam.

The resolution is usually to have a hot-end with either a heat-sink or some sort of ventilation system that keeps the filament cool for as long as possible. At this time, the Arcol.hu, Budaschnozzle, and J-Head are equipped to do so.

Disclaimer: I make the J-Head nozzles and hot-ends.

Regards,

Brian

|

Re: Extruder jam January 15, 2012 12:15AM |

Registered: 12 years ago Posts: 3 |

|

Re: Extruder jam January 18, 2012 10:10AM |

Registered: 12 years ago Posts: 88 |

Do you need to treat the entire length or just the first bit? Does the oil cause any problems with layer adhesion or leave any buildup on the hotend?

I will put in a vote for Brian's J-Head hot ends. I have one and it has been working great with PLA without needing to treat the filament before using. It hasn't needed any adjusting and worked right away on installation. I haven't tried it with ABS yet as I don't have the heated bed hooked up.

I will put in a vote for Brian's J-Head hot ends. I have one and it has been working great with PLA without needing to treat the filament before using. It hasn't needed any adjusting and worked right away on installation. I haven't tried it with ABS yet as I don't have the heated bed hooked up.

|

Re: Extruder jam January 18, 2012 05:19PM |

Registered: 12 years ago Posts: 3 |

I treat the entire length of filament but not sure if it is necessary. Adhesion is the same as without oil - only tried extrusion on heated glass (tiles). The oil seems to stay in the extruder mostly seeking the colder parts of the assembly.

I have an all metal extruder (stainless steel heat barrier) - when disassembling the extruder there is no buildup only liquid oil in the cold and semi hot parts and on the inside surface.

Motor oil works well in the high temperature environment and the is no fumes (Haven't tried other types of oil).

To start width I used plenty of oil but now I just use a small amount to wet the filament - I think it works by lowering the friction between filament and metal surface in the cold and semi hot parts of extruder. The force needed to push the filament is much lower with oil.

I am in the process of building a new hot end extruder (all metal) - maybe it will work without the oil, as it will have smaller hot zone and better head conductivity in hot part.

I have an all metal extruder (stainless steel heat barrier) - when disassembling the extruder there is no buildup only liquid oil in the cold and semi hot parts and on the inside surface.

Motor oil works well in the high temperature environment and the is no fumes (Haven't tried other types of oil).

To start width I used plenty of oil but now I just use a small amount to wet the filament - I think it works by lowering the friction between filament and metal surface in the cold and semi hot parts of extruder. The force needed to push the filament is much lower with oil.

I am in the process of building a new hot end extruder (all metal) - maybe it will work without the oil, as it will have smaller hot zone and better head conductivity in hot part.

|

Re: Extruder jam January 20, 2012 02:52PM |

Registered: 12 years ago Posts: 162 |

I also had jamming problem with the first version of my stainless steel extruder :

At this time I only used PLA.

I shorten the distance between the hot end and cold end and now it works perfectly :

At this time I only used PLA.

I shorten the distance between the hot end and cold end and now it works perfectly :

|

Re: Extruder jam February 18, 2012 02:04AM |

Registered: 12 years ago Posts: 229 |

Drill the heater barrel out to 3.5mm and use a reamer to smooth the walls. Drill bits create jagged walled holes. don't drill out the insulator though, keep it at just over 3mm (1/8" is ~3.18mm). A toothpick / small drill bit with sandpaper may work if you can't afford the reamer ($25).

Some buffing compound on a tissue wrapped around a toothpick could improve it still but for me the reamer is sufficient.

Some buffing compound on a tissue wrapped around a toothpick could improve it still but for me the reamer is sufficient.

Sorry, only registered users may post in this forum.

.

.