Home

>

Library - projects, parts, arts, docs, and policy

>

Let's design something! (I've got an idea ...)

>

Topic

Good examples?

Posted by DaveR

|

Good examples? June 10, 2008 05:18PM |

Registered: 15 years ago Posts: 186 |

Hi all.

I've been lurking for a bit, and RepRap sounds like a really interesting project. However, before I jump in with both feet, I'd like to ask for some opinions/advice.

Currently, the stated primary focus of the RepRap project is to reproduce itself. This is a great goal and very cool. However, if this is achieved, it will initially be a parasite. Preying on the time, money and effort of supporters, it will quickly reproduce itself until it has consumed every available host, evolving as it goes.

To assist with the WAF (Wife Acceptance Factor), and to shift towards a symbiotic relationship, does anyone have any good examples or ideas of things it can currently make?

To get the ball rolling, would these be actual practical objects for the current Darwin 1.0?

Customised Key Fobs?

Cases for mobile phones/iPods?

Custom stencils (with holes to draw/paint through)

Custom stamps (to make impressions on biscuits/cookies, for example)

Examples that seem practical so far:

The water filter (nice idea!)

The Fiesta/ipod clip (good use!)

I suppose I'm asking for practical ideas for a Darwin 1.0?

I've been lurking for a bit, and RepRap sounds like a really interesting project. However, before I jump in with both feet, I'd like to ask for some opinions/advice.

Currently, the stated primary focus of the RepRap project is to reproduce itself. This is a great goal and very cool. However, if this is achieved, it will initially be a parasite. Preying on the time, money and effort of supporters, it will quickly reproduce itself until it has consumed every available host, evolving as it goes.

To assist with the WAF (Wife Acceptance Factor), and to shift towards a symbiotic relationship, does anyone have any good examples or ideas of things it can currently make?

To get the ball rolling, would these be actual practical objects for the current Darwin 1.0?

Customised Key Fobs?

Cases for mobile phones/iPods?

Custom stencils (with holes to draw/paint through)

Custom stamps (to make impressions on biscuits/cookies, for example)

Examples that seem practical so far:

The water filter (nice idea!)

The Fiesta/ipod clip (good use!)

I suppose I'm asking for practical ideas for a Darwin 1.0?

|

Re: Good examples? June 10, 2008 11:03PM |

Registered: 15 years ago Posts: 7 |

Unfortunately, most of the items the machine is now capable of making: plastic shot glass, flyswatter, coat hook, kids flip flops, are also available at the 99 cent store with little effort.

The term parasite is overstated, but please note that many of the hobby activities of the male hobbiest, are about making better tools of some kind. And hoping to leverage that tool to do something otherwise unatainable. Notice all the articles in magazines like home machinist, on how to make a gadget for a lathe etc.

This stuff is more like doing something magical rather than useful, IMHO. It will keep you off the streets, and keep you and the family in tune with recent technology, and keep you creative if that says anything.

I have a homemade CNC dremel made several years ago and have used it for architectural models, but the machine never made any actual income. It just helps some feel a little younger and in touch with what is new.

The term parasite is overstated, but please note that many of the hobby activities of the male hobbiest, are about making better tools of some kind. And hoping to leverage that tool to do something otherwise unatainable. Notice all the articles in magazines like home machinist, on how to make a gadget for a lathe etc.

This stuff is more like doing something magical rather than useful, IMHO. It will keep you off the streets, and keep you and the family in tune with recent technology, and keep you creative if that says anything.

I have a homemade CNC dremel made several years ago and have used it for architectural models, but the machine never made any actual income. It just helps some feel a little younger and in touch with what is new.

|

Re: Good examples? June 11, 2008 02:18AM |

Registered: 15 years ago Posts: 186 |

Sorry, on re-reading the post sounds a little harsh.I wrote the 'paraste' with a little smile - maybe I should have added a few smileys :-).

I'm personally really interested in building one. I have a degree in Mechanical Engineering and 14 years experience in software development, so I understand the fun and learning experience, plus it sounds like a really good idea - I really understand where it's coming from. I've been thinking about building a home cnc-miller since my final year project (a simulator for g-code, it drew the tool path on the screen)

I think, that what I'm asking - is are there ideas/examples that a 'lay' person would be impressed with? You're quite correct, a coat hook, etc can be picked up for a few dollars. However, a customised keyring (idea stolen from fab@home) could be difficult/impossible to obtain in other ways.

I'm personally really interested in building one. I have a degree in Mechanical Engineering and 14 years experience in software development, so I understand the fun and learning experience, plus it sounds like a really good idea - I really understand where it's coming from. I've been thinking about building a home cnc-miller since my final year project (a simulator for g-code, it drew the tool path on the screen)

I think, that what I'm asking - is are there ideas/examples that a 'lay' person would be impressed with? You're quite correct, a coat hook, etc can be picked up for a few dollars. However, a customised keyring (idea stolen from fab@home) could be difficult/impossible to obtain in other ways.

|

Anonymous User

Re: Good examples? June 11, 2008 09:27AM |

I have an idea, but I don't know if it's feasible, since my reprap isn't finished yet  I've done woodcuts for printing, but it's quite time consuming. I'm hoping to be able to make those easier by printing an extrusion of a pattern with some backing. Rubber stamps can be expensive ($5-$20/each) so I think if I can get it to work it would appeal to scrapbookers.

I've done woodcuts for printing, but it's quite time consuming. I'm hoping to be able to make those easier by printing an extrusion of a pattern with some backing. Rubber stamps can be expensive ($5-$20/each) so I think if I can get it to work it would appeal to scrapbookers.

- Gary

I've done woodcuts for printing, but it's quite time consuming. I'm hoping to be able to make those easier by printing an extrusion of a pattern with some backing. Rubber stamps can be expensive ($5-$20/each) so I think if I can get it to work it would appeal to scrapbookers.

I've done woodcuts for printing, but it's quite time consuming. I'm hoping to be able to make those easier by printing an extrusion of a pattern with some backing. Rubber stamps can be expensive ($5-$20/each) so I think if I can get it to work it would appeal to scrapbookers.- Gary

|

Re: Good examples? June 11, 2008 10:25AM |

Registered: 16 years ago Posts: 447 |

gmsieling Wrote:

-------------------------------------------------------

> I'm hoping to be able to make those

> easier by printing an extrusion of a pattern with

> some backing. Rubber stamps can be expensive

> ($5-$20/each) so I think if I can get it to work

> it would appeal to scrapbookers.

Yeah, I can see these being relatively easy to make. I guess the material would need to be fairly flexible. Maybe something like silicone sealant would do.

-------------------------------------------------------

> I'm hoping to be able to make those

> easier by printing an extrusion of a pattern with

> some backing. Rubber stamps can be expensive

> ($5-$20/each) so I think if I can get it to work

> it would appeal to scrapbookers.

Yeah, I can see these being relatively easy to make. I guess the material would need to be fairly flexible. Maybe something like silicone sealant would do.

|

Re: Good examples? June 11, 2008 05:47PM |

Registered: 15 years ago Posts: 7 |

|

Re: Good examples? June 11, 2008 07:02PM |

Registered: 16 years ago Posts: 370 |

WonderWheeler Wrote:

-------------------------------------------------------

> Unfortunately, most of the items the machine is

> now capable of making: plastic shot glass,

> flyswatter, coat hook, kids flip flops, are also

> available at the 99 cent store with little

> effort.

I disagree - most of the objects it can make are in that complexity class, not necessarily those types of objects. The items the machine can make are nearly infinite in variety, and the whole point is that you can design your own to meet your unique needs, as long as the object you design is within the technical specs of your printer. If someone out there is making five million copies of your object a month, it will probably still be cheaper to buy it from them, especially at first.

-------------------------------------------------------

> Unfortunately, most of the items the machine is

> now capable of making: plastic shot glass,

> flyswatter, coat hook, kids flip flops, are also

> available at the 99 cent store with little

> effort.

I disagree - most of the objects it can make are in that complexity class, not necessarily those types of objects. The items the machine can make are nearly infinite in variety, and the whole point is that you can design your own to meet your unique needs, as long as the object you design is within the technical specs of your printer. If someone out there is making five million copies of your object a month, it will probably still be cheaper to buy it from them, especially at first.

|

Re: Good examples? June 11, 2008 11:01PM |

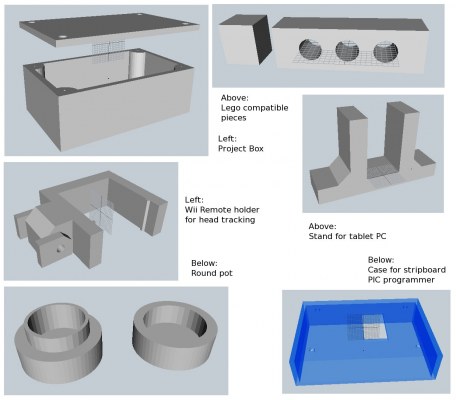

Registered: 15 years ago Posts: 38 |

|

Re: Good examples? June 12, 2008 04:02PM |

Registered: 15 years ago Posts: 186 |

That's what I'm talking about - some good concrete examples.

A reprap could print pretty much anything, but it's a bit like a blank sheet of paper - what do you draw first? Is it going to be any good?

(according to tradition, the shotglass) :-)

A customised keyring is simple, easy to design, and should be a good candidate for reprap to print (flat, tolerances not an issue) - also not a critical problem if it fails.

A rubber stamp also sounds pretty printable - you could print a 'mould' and fill it with silicone and print a backing plate/handle - or possibly printing the stamp directly from plastic.

I've also found out that the community is 'younger' than I expected - I assumed that people had RepRaps for a while. I didn't realise that most of the significant steps (self replication, etc) have only occured this year. Well done chaps!

I'm even keener to build one now - I'm on my third HTPC, and probably need a different outlet for my fiddling:-)

Edited 1 time(s). Last edit at 06/12/2008 04:04PM by DaveR.

A reprap could print pretty much anything, but it's a bit like a blank sheet of paper - what do you draw first? Is it going to be any good?

(according to tradition, the shotglass) :-)

A customised keyring is simple, easy to design, and should be a good candidate for reprap to print (flat, tolerances not an issue) - also not a critical problem if it fails.

A rubber stamp also sounds pretty printable - you could print a 'mould' and fill it with silicone and print a backing plate/handle - or possibly printing the stamp directly from plastic.

I've also found out that the community is 'younger' than I expected - I assumed that people had RepRaps for a while. I didn't realise that most of the significant steps (self replication, etc) have only occured this year. Well done chaps!

I'm even keener to build one now - I'm on my third HTPC, and probably need a different outlet for my fiddling:-)

Edited 1 time(s). Last edit at 06/12/2008 04:04PM by DaveR.

|

Re: Good examples? June 12, 2008 04:39PM |

Admin Registered: 17 years ago Posts: 1,791 |

|

Anonymous User

Re: Good examples? June 12, 2008 04:45PM |

|

Re: Good examples? June 12, 2008 05:03PM |

Admin Registered: 16 years ago Posts: 13,884 |

|

Re: Good examples? June 12, 2008 05:11PM |

Admin Registered: 17 years ago Posts: 7,879 |

Place it face down on a hot plate?

Dip it in MEK solvent? (a tip I got from Ian Adkins)

Edited 1 time(s). Last edit at 06/13/2008 01:00PM by nophead.

[www.hydraraptor.blogspot.com]

Dip it in MEK solvent? (a tip I got from Ian Adkins)

Edited 1 time(s). Last edit at 06/13/2008 01:00PM by nophead.

[www.hydraraptor.blogspot.com]

|

Re: Good examples? June 14, 2008 07:35AM |

Registered: 16 years ago Posts: 161 |

How about...

Novelty "glasses"

from other threads,

Chess or other game pieces

customized/personalized toys such as blocks or push cars

replacements for broken plastic bits

But I agree that for me this is a chance to stay cutting edge/learn new stuff and to make a better tool to make a better tool with.

Novelty "glasses"

from other threads,

Chess or other game pieces

customized/personalized toys such as blocks or push cars

replacements for broken plastic bits

But I agree that for me this is a chance to stay cutting edge/learn new stuff and to make a better tool to make a better tool with.

|

Re: Good examples? June 15, 2008 11:17AM |

Registered: 16 years ago Posts: 161 |

|

Re: Good examples? June 15, 2008 03:04PM |

Registered: 15 years ago Posts: 186 |

|

Re: Good examples? June 17, 2008 07:47PM |

Registered: 15 years ago Posts: 40 |

DaveR Wrote:

-------------------------------------------------------

> Anyone played Portal?

>

> [www.instructables.com]

> yped-Weighted-delCompaniondel-Stor/

> :-)

Loved it.

Loved it so much I went and stuck these .stl's in my SLS Machine.

Aluminum/Nylon 11 by 50/50 weight mix, Companion Cube!

Need to sort out this blistering effect I get from Al mixes

-------------------------------------------------------

> Anyone played Portal?

>

> [www.instructables.com]

> yped-Weighted-delCompaniondel-Stor/

> :-)

Loved it.

Loved it so much I went and stuck these .stl's in my SLS Machine.

Aluminum/Nylon 11 by 50/50 weight mix, Companion Cube!

Need to sort out this blistering effect I get from Al mixes

|

Re: Good examples? June 18, 2008 12:27PM |

Registered: 15 years ago Posts: 186 |

|

Re: Good examples? July 06, 2008 04:39AM |

Registered: 16 years ago Posts: 293 |

Hi DaveR! It seems very good to have you on board given your skills. I also like the practical evaluation you make of the usefulness and the fact that you intend to continue with it. This kind of makes RepRap succeed a VERY important test.

I have built a RepRap but had some problems after my first print, but it was such a good learning experience for me (I have hardly a technical education played with electronics and mechanics all my life). This is really a step upwards in the things I will be able to make. This simply was enough reason for me to start building it. The really nice plus is that during my build the RepRap evolved to become much better and seeing the progress of others was really exciting. I had expected that commercial quality would be decades away, I think it's years at most + RepRap could have features beyond what a commercial machine could ever have since the design is completely open and the users are very different and make and share their 'genetic drift'

By the way: kits are back in stock!

Tim Attwood: Like the KeyFob, I'm going to print it! It's nice to carry a tangible example around to be able to show when you explain you have a 3D printer... it's still abstract for many people. But then again, it's still magic to me as well...

Regards,

Erik de Bruijn

[Ultimaker.com] - [blog.erikdebruijn.nl]

I have built a RepRap but had some problems after my first print, but it was such a good learning experience for me (I have hardly a technical education played with electronics and mechanics all my life). This is really a step upwards in the things I will be able to make. This simply was enough reason for me to start building it. The really nice plus is that during my build the RepRap evolved to become much better and seeing the progress of others was really exciting. I had expected that commercial quality would be decades away, I think it's years at most + RepRap could have features beyond what a commercial machine could ever have since the design is completely open and the users are very different and make and share their 'genetic drift'

By the way: kits are back in stock!

Tim Attwood: Like the KeyFob, I'm going to print it! It's nice to carry a tangible example around to be able to show when you explain you have a 3D printer... it's still abstract for many people. But then again, it's still magic to me as well...

Regards,

Erik de Bruijn

[Ultimaker.com] - [blog.erikdebruijn.nl]

|

Re: Good examples? July 06, 2008 04:36PM |

I think as long as we retain the focus of making RepRap able to create itself we'll stay on the path of making a machine that can do some fairly general construction.

I think a lot of the first models may appear in schools so example 3d solids various kinds of sparsing eg. honeycomb will all be very useful in education.

In real life I can imagine, when the library is big enough, I might go to it for the little clips and catches that I cant be bothered to search the shops for. The little catches that hold up shelves in fitted kitchens. All this stuff you can get cheaper as long as you don't count the journey to the shop and the favt that you have to buy tem when you only want one. I think there are all sorts of little gauges and clips that one cannot buy.

I can imagine there might be a lot of inserts to go in things like CD cases to allow you to pack button batteries or leggo men or whatever tidily.

I think novelty items that are so niche that no manufacturer would bother and Items that need to be customized would have their place.

I think a lot of the first models may appear in schools so example 3d solids various kinds of sparsing eg. honeycomb will all be very useful in education.

In real life I can imagine, when the library is big enough, I might go to it for the little clips and catches that I cant be bothered to search the shops for. The little catches that hold up shelves in fitted kitchens. All this stuff you can get cheaper as long as you don't count the journey to the shop and the favt that you have to buy tem when you only want one. I think there are all sorts of little gauges and clips that one cannot buy.

I can imagine there might be a lot of inserts to go in things like CD cases to allow you to pack button batteries or leggo men or whatever tidily.

I think novelty items that are so niche that no manufacturer would bother and Items that need to be customized would have their place.

|

Re: Good examples? September 14, 2008 08:14PM |

so much good stuff that can be done, for a little kid you could make custom legos and k'nex (which is alot safer than how i use'd to make custom knex parts as a kid {involving me burning myself ALOT and making one heck of a mess})

OTHER THINGS

replacement desk handle

book ends

a magnet key holder (for hiding keys under your car)

(another kid thing)- a casket/tombstone for a small dead pet (fish, mouse, ect) {creepy i know, but some little kids do have a pet grave yard}

a custom computer mouse (canabalise the electronics from another mouse i did a test with tape and a box)

replacement computer keys

custom game controllers (if your carefull you can dismantel an design your own game controlers but that is a risky venture and i wouldnt advise it ) honestly this works with most electronics

and many otherthings that i would point out if my shift hadent ended 10 minutes ago

OTHER THINGS

replacement desk handle

book ends

a magnet key holder (for hiding keys under your car)

(another kid thing)- a casket/tombstone for a small dead pet (fish, mouse, ect) {creepy i know, but some little kids do have a pet grave yard}

a custom computer mouse (canabalise the electronics from another mouse i did a test with tape and a box)

replacement computer keys

custom game controllers (if your carefull you can dismantel an design your own game controlers but that is a risky venture and i wouldnt advise it ) honestly this works with most electronics

and many otherthings that i would point out if my shift hadent ended 10 minutes ago

|

Re: Good examples? March 01, 2009 12:49PM |

Registered: 15 years ago Posts: 21 |

>Loved it so much I went and stuck these .stl's in my SLS Machine.

>Aluminum/Nylon 11 by 50/50 weight mix, Companion Cube!

>Need to sort out this blistering effect I get from Al mixes

How does this mix work? Doesn't Nylon decompose thermally

long before Aluminium even melts at 660.32 °C, 1220.58 °F ?

(Apparently not?) Also: What kind of SLS-machine you used,

and how much it costs?

Cheers,

Antti

>Aluminum/Nylon 11 by 50/50 weight mix, Companion Cube!

>Need to sort out this blistering effect I get from Al mixes

How does this mix work? Doesn't Nylon decompose thermally

long before Aluminium even melts at 660.32 °C, 1220.58 °F ?

(Apparently not?) Also: What kind of SLS-machine you used,

and how much it costs?

Cheers,

Antti

|

Re: Good examples? March 02, 2009 11:36PM |

Registered: 15 years ago Posts: 40 |

Kartturi Wrote:

-------------------------------------------------------

> How does this mix work? Doesn't Nylon decompose

> thermally

> long before Aluminium even melts at 660.32 °C,

> 1220.58 °F ?

>

> (Apparently not?) Also: What kind of SLS-machine

> you used,

> and how much it costs?

>

> Cheers,

>

> Antti

Hi Antti,

The Aluminium does nothing but give the material a metallic aesthetic. You are correct, the Aluminium does not melt at all, it just gets encased in the melted and fused nylon around it. A few of our customers have also reported it has much better heat conductivity.

It can actually be brought up to quite a good polish if you have the time and patience to do so. It looks a bit like the brushed aluminium that is on everything these days.

The SLS Machines we use are 3D Systems (formerly DTM) Sinterstation 2500+. They're certainly not cheap, but we acquired a second hand one last year for about US$100,000.

Unfortunately I don't have many pictures of it finished, but I have a few random photo's.

-------------------------------------------------------

> How does this mix work? Doesn't Nylon decompose

> thermally

> long before Aluminium even melts at 660.32 °C,

> 1220.58 °F ?

>

> (Apparently not?) Also: What kind of SLS-machine

> you used,

> and how much it costs?

>

> Cheers,

>

> Antti

Hi Antti,

The Aluminium does nothing but give the material a metallic aesthetic. You are correct, the Aluminium does not melt at all, it just gets encased in the melted and fused nylon around it. A few of our customers have also reported it has much better heat conductivity.

It can actually be brought up to quite a good polish if you have the time and patience to do so. It looks a bit like the brushed aluminium that is on everything these days.

The SLS Machines we use are 3D Systems (formerly DTM) Sinterstation 2500+. They're certainly not cheap, but we acquired a second hand one last year for about US$100,000.

Unfortunately I don't have many pictures of it finished, but I have a few random photo's.

|

Re: Good examples? March 14, 2009 04:59AM |

Registered: 15 years ago Posts: 2 |

I make my own icecream, and I'd love to be able to "print" a mold for it with my own initials and a dragon transferred to the final product

And ofcourse it would have been nice to have had a reprap back when my signet broke and I had to order a new one.. New one just broke the other day, and I still don't have a reprap.. Those signets are expensive..

But could the plastic even survive the close encounter with hot, liquid wax?

And ofcourse it would have been nice to have had a reprap back when my signet broke and I had to order a new one.. New one just broke the other day, and I still don't have a reprap.. Those signets are expensive..

But could the plastic even survive the close encounter with hot, liquid wax?

|

Re: Good examples? March 14, 2009 05:17AM |

Registered: 15 years ago Posts: 96 |

scandragon Wrote:

-------------------------------------------------------

> I make my own icecream, and I'd love to be able to

> "print" a mold for it with my own initials and a

> dragon transferred to the final product

>

> And ofcourse it would have been nice to have had a

> reprap back when my signet broke and I had to

> order a new one.. New one just broke the other

> day, and I still don't have a reprap.. Those

> signets are expensive..

> But could the plastic even survive the close

> encounter with hot, liquid wax?

There are 2 things you have to take care of:

1. When you try to cool down some kinds of plastic under the 0C point, they will become as brittle as glass. Tupperware for example has warnings on their products warning them not to put in the fridge.

2. Same goes for hot wax. If the temperature is too high, then the plastic will warp too much or become soft and not usable.

You can do it, but you need to find the right kind of plastic for the right kind of job.

-------------------------------------------------------

> I make my own icecream, and I'd love to be able to

> "print" a mold for it with my own initials and a

> dragon transferred to the final product

>

> And ofcourse it would have been nice to have had a

> reprap back when my signet broke and I had to

> order a new one.. New one just broke the other

> day, and I still don't have a reprap.. Those

> signets are expensive..

> But could the plastic even survive the close

> encounter with hot, liquid wax?

There are 2 things you have to take care of:

1. When you try to cool down some kinds of plastic under the 0C point, they will become as brittle as glass. Tupperware for example has warnings on their products warning them not to put in the fridge.

2. Same goes for hot wax. If the temperature is too high, then the plastic will warp too much or become soft and not usable.

You can do it, but you need to find the right kind of plastic for the right kind of job.

|

Re: Good examples? March 14, 2009 05:33AM |

Registered: 15 years ago Posts: 2 |

|

Re: Good examples? March 14, 2009 07:13AM |

Registered: 15 years ago Posts: 186 |

ABS has a melting temp of >200C, so it should be fine with hot wax (>60C), chocolate, foodstuff temp - just not hot sugar! ABS is also licenced for food use, so it shouldn't give off nasty chemicals. I haven't put it below 0C yet (I'll go and put a chunk of filament in the freezer now and report back in a few hours.)

DaveR

DaveR

|

Re: Good examples? March 14, 2009 07:51AM |

Admin Registered: 17 years ago Posts: 7,879 |

Actually ABS melts at 105C. It goes soft around 90C. I think it is OK to about -20C.

Edited 1 time(s). Last edit at 03/14/2009 07:53AM by nophead.

[www.hydraraptor.blogspot.com]

Edited 1 time(s). Last edit at 03/14/2009 07:53AM by nophead.

[www.hydraraptor.blogspot.com]

|

Re: Good examples? March 14, 2009 02:38PM |

Registered: 15 years ago Posts: 186 |

|

Re: Good examples? March 14, 2009 03:00PM |

Registered: 15 years ago Posts: 96 |

Sorry, only registered users may post in this forum.