Home

>

Library - projects, parts, arts, docs, and policy

>

Let's design something! (I've got an idea ...)

>

Topic

Drive Belt/Chain

Posted by aka47

|

Drive Belt/Chain August 20, 2008 06:06AM |

Registered: 16 years ago Posts: 900 |

Sourcing compatible and cost effective drive belt can be challenging.

Cost alone is a not insignificant fraction of Adrian's projected build budget.

6mm Servo Chain (aka 04B1 roller chain) in steel is more cost effective but still not something we can churn out from a working Darwin.

Some design effort put into printable drive belt/chain would be good.

I have been looking at 6mm chain and have been asking the question can we print this in plastic instead of steel.

Current feedback suggests that it may be at the extreem of our current capabilities. But is it ????

Or is there a better alternative that we can print out and progress further along towards the goal of having a completely printout able replicator ????

aka47

Necessity hopefully becomes the absentee parent of successfully invented children.

Cost alone is a not insignificant fraction of Adrian's projected build budget.

6mm Servo Chain (aka 04B1 roller chain) in steel is more cost effective but still not something we can churn out from a working Darwin.

Some design effort put into printable drive belt/chain would be good.

I have been looking at 6mm chain and have been asking the question can we print this in plastic instead of steel.

Current feedback suggests that it may be at the extreem of our current capabilities. But is it ????

Or is there a better alternative that we can print out and progress further along towards the goal of having a completely printout able replicator ????

aka47

Necessity hopefully becomes the absentee parent of successfully invented children.

|

Re: Drive Belt/Chain August 20, 2008 06:33AM |

Admin Registered: 16 years ago Posts: 13,888 |

|

Re: Drive Belt/Chain August 20, 2008 06:52AM |

Registered: 16 years ago Posts: 900 |

More questions

which plastics would give best wear/flexibility for a printed drive belt and would the weld be strong enough to resist the shear forces.

I guess this would be directly;y affected by the minimum bending radius you subjected the finished belt to ....

I am thinking here of the piles of retread tyre littering the sides of UK motorways.

aka47

Necessity hopefully becomes the absentee parent of successfully invented children.

which plastics would give best wear/flexibility for a printed drive belt and would the weld be strong enough to resist the shear forces.

I guess this would be directly;y affected by the minimum bending radius you subjected the finished belt to ....

I am thinking here of the piles of retread tyre littering the sides of UK motorways.

aka47

Necessity hopefully becomes the absentee parent of successfully invented children.

|

Re: Drive Belt/Chain August 20, 2008 01:37PM |

Registered: 17 years ago Posts: 370 |

I think for printability's sake we may end up having a throwback to the old Zaphod days, where iirc there was a central drive gear that turned all four (three back then?) corner posts. I think that trying to print belts will be gimmicky at best - they're generally made from materials much more flexible than any of the plastics we've been trying, I think. And chains require relatively high tolerances to connect/roll together... I don't really see that happening on a Darwin.

|

Re: Drive Belt/Chain August 20, 2008 03:47PM |

Registered: 16 years ago Posts: 900 |

I think that that is why timing belts etc have the steel wires in them.

It sort of fixes the too flexible plastic thing.

The most interesting sort of belt/chain I have seen (but was stupidly expensive) had three wires with plastic bars molded onto it at pitch spaced intervals. and was used with a duplex sprocket. Quite clever really.

The wire provided the strength and the bars provided traction. without a whole actual belt.

I think they did it in a two wire version too.

Vik and Toby are currently doing some wonderful experimentation with ball chain which looks very promising. Particularly as it is cheap and available.

All very interesting and great for now but long term we really need is something we can reprap.

Lateral thinking time......

Not sure I have found anything yet though, best offer so far is Viktors above.

aka47

Necessity hopefully becomes the absentee parent of successfully invented children.

It sort of fixes the too flexible plastic thing.

The most interesting sort of belt/chain I have seen (but was stupidly expensive) had three wires with plastic bars molded onto it at pitch spaced intervals. and was used with a duplex sprocket. Quite clever really.

The wire provided the strength and the bars provided traction. without a whole actual belt.

I think they did it in a two wire version too.

Vik and Toby are currently doing some wonderful experimentation with ball chain which looks very promising. Particularly as it is cheap and available.

All very interesting and great for now but long term we really need is something we can reprap.

Lateral thinking time......

Not sure I have found anything yet though, best offer so far is Viktors above.

aka47

Necessity hopefully becomes the absentee parent of successfully invented children.

|

Re: Drive Belt/Chain August 22, 2008 08:28AM |

Registered: 15 years ago Posts: 100 |

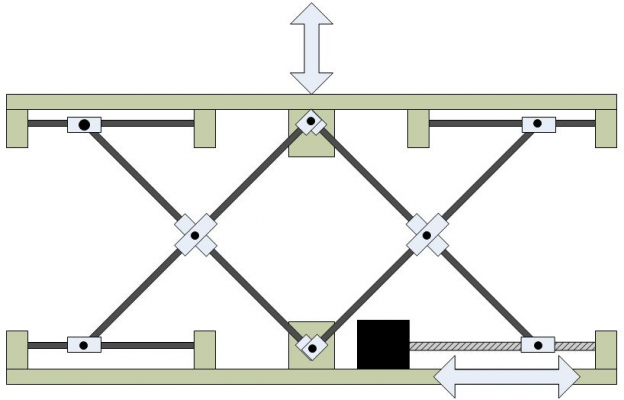

I think it has come up a few times before but a scissor jack or variant on one could be easier to RepRap. Using steel rod it might not take all that much plastic to make.

By building two of the above and placing them so they cross at the non sliding joint a single motor could drive the whole arrangement removing the need to synchronization belts etc.

The main problem seems to be non-linearity: one turn near the top does not move the platform the same distance as near the bottom. This leads to three problems, more complex maths, resolution and accuracy.

More Maths: The maths for this isn't very complex, just trig functions.

Resolution: If the amount the screw needs turning to raise the platform 0.1mm is near to or smaller than the motors resolution. This seems very unlikely though as the movement at the screw thread is scaled to 180/360 steps per mm. As long as the linkage provides less than a 10/1 advantage we should be fine.

Accuracy: Owing to the varying movement from a fixed rotation of the screw the starting position is important. If the controller thinks it is at a different height than it really is the wrong number of steps will be sent causing squashing or elongation. An end stop can help with this, but it is also important not to loose any steps. The extremes are the most non-linear and so this could be mitigated by only using the middle of the platforms range.

A closed loop system that measures the platform height directly would be ideal, for accuracy and simpler maths. If the travel is relatively short a cheap digital caliper could be hacked to act as the position sensor.

By building two of the above and placing them so they cross at the non sliding joint a single motor could drive the whole arrangement removing the need to synchronization belts etc.

The main problem seems to be non-linearity: one turn near the top does not move the platform the same distance as near the bottom. This leads to three problems, more complex maths, resolution and accuracy.

More Maths: The maths for this isn't very complex, just trig functions.

Resolution: If the amount the screw needs turning to raise the platform 0.1mm is near to or smaller than the motors resolution. This seems very unlikely though as the movement at the screw thread is scaled to 180/360 steps per mm. As long as the linkage provides less than a 10/1 advantage we should be fine.

Accuracy: Owing to the varying movement from a fixed rotation of the screw the starting position is important. If the controller thinks it is at a different height than it really is the wrong number of steps will be sent causing squashing or elongation. An end stop can help with this, but it is also important not to loose any steps. The extremes are the most non-linear and so this could be mitigated by only using the middle of the platforms range.

A closed loop system that measures the platform height directly would be ideal, for accuracy and simpler maths. If the travel is relatively short a cheap digital caliper could be hacked to act as the position sensor.

|

Re: Drive Belt/Chain August 22, 2008 10:10AM |

Registered: 15 years ago Posts: 199 |

As I suggested here: [forums.reprap.org] it seems feasible to me to print out links of ladder chain that can snap together.

aka47 Wrote:

-------------------------------------------------------

> 6mm Servo Chain (aka 04B1 roller chain) in steel

> is more cost effective but still not something we

> can churn out from a working Darwin.

>

> Some design effort put into printable drive

> belt/chain would be good.

aka47 Wrote:

-------------------------------------------------------

> 6mm Servo Chain (aka 04B1 roller chain) in steel

> is more cost effective but still not something we

> can churn out from a working Darwin.

>

> Some design effort put into printable drive

> belt/chain would be good.

|

Re: Drive Belt/Chain August 22, 2008 10:21AM |

Registered: 16 years ago Posts: 900 |

Nonlinearity

Can be fixed through a look up table if you have the resolution and memory space to store it. This is the usual fix for processing challenged microcontrolers but can (and would in this case) be a large table even if you do it half size, interpolate (half the difference) and put up with the error.

Ladder chain ???

How does this differ from Bush/Roller chain and have you allowed for polygon effect when you suggest that it could be printed large enough to fit our capabilities. Usual minimum sprocket size is 19 teeth to minimize polygon effect.

A piccy/drawing of your thoughts would be great.

Cheers

aka47

Necessity hopefully becomes the absentee parent of successfully invented children.

Can be fixed through a look up table if you have the resolution and memory space to store it. This is the usual fix for processing challenged microcontrolers but can (and would in this case) be a large table even if you do it half size, interpolate (half the difference) and put up with the error.

Ladder chain ???

How does this differ from Bush/Roller chain and have you allowed for polygon effect when you suggest that it could be printed large enough to fit our capabilities. Usual minimum sprocket size is 19 teeth to minimize polygon effect.

A piccy/drawing of your thoughts would be great.

Cheers

aka47

Necessity hopefully becomes the absentee parent of successfully invented children.

|

Re: Drive Belt/Chain August 22, 2008 12:26PM |

Registered: 15 years ago Posts: 199 |

Ladder chain uses only one kind of link, sort of like a roller chain "half link". The side plates are offset so the narrow end of one link fits between the side plates of the adjoining link. The wide end has a simple bar across it and the narrow end hooks over the bar of the adjoining link. The bars fit between teeth on the sprockets.

I think an octagonal (or even square) square bar would work. so there would be no overhangs greater then 45

I think an octagonal (or even square) square bar would work. so there would be no overhangs greater then 45

|

Re: Drive Belt/Chain August 22, 2008 06:26PM |

Registered: 16 years ago Posts: 900 |

Minor problem

Clearence between the Lead Screw and corner bar on an average Darwin is 29mm (Just measured it on the one I am building with a pair of vernier calipers. 29mm is just over an inch (1" = 25.4mm)

Other than that the idea of having an angle cutout in the narrow portion of the chain is good.

I was wondering how to printout an out an extended pin, but your idea doesn't need to, cool.

Your quite right it would be a struggle to printout a perfectly round pin at these sort of diameters, it probably would end up hexagonal ish.

I am currently fitting 21 tooth sprockets to the Z axis Lead Screws and using 6mm pitch Roller chain (Same type as bicycle chain but a bunch smaller). The pitch is the distance between centers of the chain pins. (The sprocket toothing has got to match)

This is giving me a clearance between the sprocket tooth and the corner bar of approx 9mm. (Again measured as I write with a pair of vernier calipers)

I guess this is why I chose 6mm chain and it was cheaper than timing belt as well as being to hand (a very important qualification)

I have got to admit I fancied bicycle chain originally for cost effect and availability but it is dimensionally too big for a Darwin if you want a smooth drive.

Hope this helps

aka47

Necessity hopefully becomes the absentee parent of successfully invented children.

Clearence between the Lead Screw and corner bar on an average Darwin is 29mm (Just measured it on the one I am building with a pair of vernier calipers. 29mm is just over an inch (1" = 25.4mm)

Other than that the idea of having an angle cutout in the narrow portion of the chain is good.

I was wondering how to printout an out an extended pin, but your idea doesn't need to, cool.

Your quite right it would be a struggle to printout a perfectly round pin at these sort of diameters, it probably would end up hexagonal ish.

I am currently fitting 21 tooth sprockets to the Z axis Lead Screws and using 6mm pitch Roller chain (Same type as bicycle chain but a bunch smaller). The pitch is the distance between centers of the chain pins. (The sprocket toothing has got to match)

This is giving me a clearance between the sprocket tooth and the corner bar of approx 9mm. (Again measured as I write with a pair of vernier calipers)

I guess this is why I chose 6mm chain and it was cheaper than timing belt as well as being to hand (a very important qualification)

I have got to admit I fancied bicycle chain originally for cost effect and availability but it is dimensionally too big for a Darwin if you want a smooth drive.

Hope this helps

aka47

Necessity hopefully becomes the absentee parent of successfully invented children.

|

Re: Drive Belt/Chain August 23, 2008 08:30PM |

Registered: 15 years ago Posts: 199 |

|

Re: Drive Belt/Chain August 24, 2008 03:51AM |

Registered: 16 years ago Posts: 900 |

I have only really tried 6mm because it is readily available. I found it existed through looking at modeling suppliers and ways to link up to RC servo's. 6mm Chain appeared to be an option.

Then found I could get it in the UK cheaper than Timing Belt.

7mm does not appear to be a standard size.

These appear to be :-

04B-1 6.000

05B-1 8.000

06B-1 9.525

Beyond 9.5mm I suspect we have had it as an option, in fact the following figures confirm we are pushing our luck.

It may be worth considering 8.00mm

Their sprockets appear to be nominaly OD,

19 Tooth 51.9mm

20 Tooth 54.4mm

21 Tooth 67.0mm

As opposed to the 6mm chain sprockets which are:-

19 Tooth 39.8mm

20 Tooth 40.7mm

21 Tooth 42.6mm

Looking at the figures I think we would actually struggle with 8mm chain unless we reduced the tooth count below the magic 19 teeth (necessary to minimize polygon error, read the Chain Designers guide from the Renolds Chain Manufacturers web site).

The data here is taken from the Challenge (Chain manufacturers) data sheets available as PDF's from their web site.

Cheers

aka47

Necessity hopefully becomes the absentee parent of successfully invented children.

Then found I could get it in the UK cheaper than Timing Belt.

7mm does not appear to be a standard size.

These appear to be :-

04B-1 6.000

05B-1 8.000

06B-1 9.525

Beyond 9.5mm I suspect we have had it as an option, in fact the following figures confirm we are pushing our luck.

It may be worth considering 8.00mm

Their sprockets appear to be nominaly OD,

19 Tooth 51.9mm

20 Tooth 54.4mm

21 Tooth 67.0mm

As opposed to the 6mm chain sprockets which are:-

19 Tooth 39.8mm

20 Tooth 40.7mm

21 Tooth 42.6mm

Looking at the figures I think we would actually struggle with 8mm chain unless we reduced the tooth count below the magic 19 teeth (necessary to minimize polygon error, read the Chain Designers guide from the Renolds Chain Manufacturers web site).

The data here is taken from the Challenge (Chain manufacturers) data sheets available as PDF's from their web site.

Cheers

aka47

Necessity hopefully becomes the absentee parent of successfully invented children.

|

Re: Drive Belt/Chain August 24, 2008 04:44AM |

Admin Registered: 17 years ago Posts: 7,879 |

If all your sprockets are the same size then doesn't the polygon error cancel out?

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: Drive Belt/Chain August 24, 2008 05:35PM |

Registered: 16 years ago Posts: 900 |

It generally relates to the fact that if you use too few teeth, as the chain attempts to describe a circle (round the sprocket) using straight chain links (would form a polygon if you put a closed circle of chain close around the sprocket) that below a certain radius in relation to the chains pitch the ride around the sprocket is bumpy ie the speed of the chain travel increases and decreases on a per link basis as the sprocket engages and disengages the chain. (Not great for accuracy and precision)

In so much as if all the sprockets are larger than the magic size as related to the pitch of the chain then yes your suggestion holds true.

But if any one (or more) of the sprockets it travels round is less than the magic radius then it will manifest the bumpy thing all along the chains length. I would imagine worse if more than one was under size.

Take a gander at:-

[www.renold.com]

Download the Designers guide PDF

Checkout page 8 of 27 (pdf reader pages) "Polygonal Effect"

It explains it all rather better than I can manage here, a couple of bottles of vino down......

Cheers

aka47

Necessity hopefully becomes the absentee parent of successfully invented children.

In so much as if all the sprockets are larger than the magic size as related to the pitch of the chain then yes your suggestion holds true.

But if any one (or more) of the sprockets it travels round is less than the magic radius then it will manifest the bumpy thing all along the chains length. I would imagine worse if more than one was under size.

Take a gander at:-

[www.renold.com]

Download the Designers guide PDF

Checkout page 8 of 27 (pdf reader pages) "Polygonal Effect"

It explains it all rather better than I can manage here, a couple of bottles of vino down......

Cheers

aka47

Necessity hopefully becomes the absentee parent of successfully invented children.

Sorry, only registered users may post in this forum.