Home

>

Library - projects, parts, arts, docs, and policy

>

Let's design something! (I've got an idea ...)

>

Topic

Idea for increasing build volume of delta style printers in z direction

Posted by naxem42

|

Idea for increasing build volume of delta style printers in z direction March 19, 2014 06:31PM |

Registered: 10 years ago Posts: 13 |

Hi, I don't know a whole lot about delta printers, but I was wondering if this would work.

So the idea is that the arms are all horizontal, but the line goes all the way to the hinge that attaches to the hot end mount. It's kind of hurting my brain. If all the motors turn at the same rate, will it still move the whole thing up and down? And if you change their speeds relative to each other correctly will it still move the print head only on the plane without moving the whole mess up and down?

thanks

So the idea is that the arms are all horizontal, but the line goes all the way to the hinge that attaches to the hot end mount. It's kind of hurting my brain. If all the motors turn at the same rate, will it still move the whole thing up and down? And if you change their speeds relative to each other correctly will it still move the print head only on the plane without moving the whole mess up and down?

thanks

|

Re: Idea for increasing build volume of delta style printers in z direction March 21, 2014 12:10AM |

Admin Registered: 13 years ago Posts: 730 |

By "line" do you mean something like a cable or a tendon? And there are three cables, each independently driven by a motor (kind of like in THOR Simpson)? Each cable would then go up one of the three vertical "legs" to a motor on top? Provided something took the slack out of the cables (gravity maybe) I think this could work.

|

Re: Idea for increasing build volume of delta style printers in z direction March 21, 2014 12:33AM |

Registered: 10 years ago Posts: 13 |

Sorry, I meant spectra braided fishing line. And I also like how the motors are placed in this design.

So yeah, just like in the link but with horizontal jointed arms that constrain the hot end mount to only a plane.

So yeah, just like in the link but with horizontal jointed arms that constrain the hot end mount to only a plane.

|

Re: Idea for increasing build volume of delta style printers in z direction March 21, 2014 12:53AM |

Admin Registered: 13 years ago Posts: 730 |

|

Re: Idea for increasing build volume of delta style printers in z direction March 21, 2014 01:39AM |

Registered: 10 years ago Posts: 13 |

Cool

It was just an idea though, maybe someone out there might want to pursue it further because I'm in college and I've already spent a lot of time thinking about another design.

Maybe it can be called Bart Simpson because he has a flat head...

Edited 1 time(s). Last edit at 03/21/2014 01:41AM by naxem42.

It was just an idea though, maybe someone out there might want to pursue it further because I'm in college and I've already spent a lot of time thinking about another design.

Maybe it can be called Bart Simpson because he has a flat head...

Edited 1 time(s). Last edit at 03/21/2014 01:41AM by naxem42.

|

Re: Idea for increasing build volume of delta style printers in z direction March 21, 2014 10:32AM |

Registered: 10 years ago Posts: 979 |

Neat!

A few notes:

*You would need 3 steppers for the XY motion to avoid bad singularities in the middle of the work volume. However, this is over-constrained and would be hard to control without the steppers fighting each other.

*It would probably be easier to keep this XY stage stationary and move the bed up.

*Wally is sort of a 2 armed version of this. One thing I don't like about Wally is the break in radial symmetry.

*GUS arms could be used sideways for this.

ConceptFORGE

Wally, GUS Simpson, LISA Simpson, THOR Simpson, Sextupteron, CoreXZ

A few notes:

*You would need 3 steppers for the XY motion to avoid bad singularities in the middle of the work volume. However, this is over-constrained and would be hard to control without the steppers fighting each other.

*It would probably be easier to keep this XY stage stationary and move the bed up.

*Wally is sort of a 2 armed version of this. One thing I don't like about Wally is the break in radial symmetry.

*GUS arms could be used sideways for this.

ConceptFORGE

Wally, GUS Simpson, LISA Simpson, THOR Simpson, Sextupteron, CoreXZ

|

Re: Idea for increasing build volume of delta style printers in z direction March 21, 2014 01:40PM |

Registered: 10 years ago Posts: 1,381 |

@naxem42:

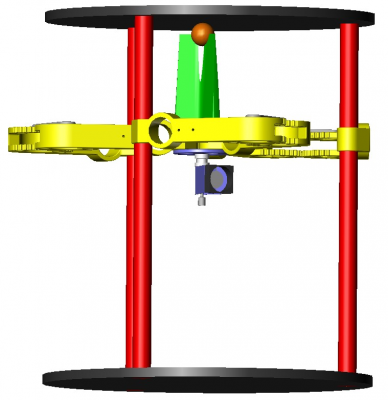

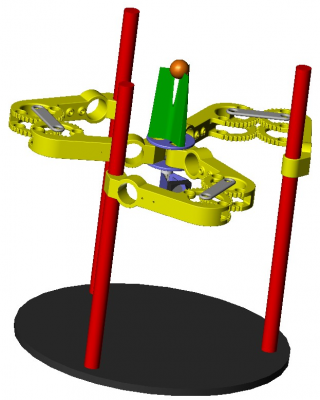

I had a similar idea, It would look pretty cool

It would take 7 steppers to drive it.

Maybe a software mash-up between Wally, and Lisa could make it work.

Enjoy.

Delta Galaxy:

Edited 1 time(s). Last edit at 03/21/2014 01:42PM by A2.

I had a similar idea, It would look pretty cool

It would take 7 steppers to drive it.

Maybe a software mash-up between Wally, and Lisa could make it work.

Enjoy.

Delta Galaxy:

Edited 1 time(s). Last edit at 03/21/2014 01:42PM by A2.

|

Re: Idea for increasing build volume of delta style printers in z direction March 21, 2014 04:57PM |

Registered: 10 years ago Posts: 13 |

|

Re: Idea for increasing build volume of delta style printers in z direction March 21, 2014 05:18PM |

Registered: 10 years ago Posts: 1,381 |

Quote

naxem42

Maybe you can use less steppers if you move the platform like how Nicholas was saying?

I think moving the bed down is best, and moving the hot end is superior to moving the object.

If you use two steppers for the bed then you save one stepper, less you use the bed from Wally

which I think uses one motor for a two motor reduction.

You can also envision with the concept that I posted the arms are on a fixed plane, and the bed moves down.

Quote

nicholas.seward

*You would need 3 steppers for the XY motion to avoid bad singularities in the middle of the work volume.

However, this is over-constrained and would be hard to control without the steppers fighting each other.

Can you help me understand what over-constrained is in this context.

Tks.

Edited 1 time(s). Last edit at 03/21/2014 05:21PM by A2.

|

Re: Idea for increasing build volume of delta style printers in z direction March 22, 2014 01:29PM |

Admin Registered: 13 years ago Posts: 730 |

I know Nicholas is the expert hereQuote

nicholas.seward

*You would need 3 steppers for the XY motion to avoid bad singularities in the middle of the work volume. However, this is over-constrained and would be hard to control without the steppers fighting each other.

but I think that the cable drive on this one makes it kind of a weird beast. In naxem42's original design, the platform is also free to rotate about the Z axis - but it finds a unique minimum. (Maybe this is what Nicholas means by singularities - that the platform is inherently not stiff to disturbances in Z rotation. But if the extruder is in the middle of the platform we don't mind so much about this.)

but I think that the cable drive on this one makes it kind of a weird beast. In naxem42's original design, the platform is also free to rotate about the Z axis - but it finds a unique minimum. (Maybe this is what Nicholas means by singularities - that the platform is inherently not stiff to disturbances in Z rotation. But if the extruder is in the middle of the platform we don't mind so much about this.) What I'm trying to say, what my hunch is, is that naxem42's design with three motors (where line lengths are: L1, L2, L3) and four degrees of freedom (x,y,z, and theta = rotation about z) should actually give you a unique (x,y,z,theta) for each (L1, L2, L3) because gravity (and/or springs if you add them) provides the remaining constraint and brings the system to a minimum solution. Furthermore, a smooth path in (L1, L2, L3) should result in a smooth path in (x,y,z,theta) even in the center of the workspace.

Time permitting I will make a mockup out of Legos or something to test out my hypothesis.

|

Re: Idea for increasing build volume of delta style printers in z direction March 22, 2014 02:25PM |

Registered: 10 years ago Posts: 1,381 |

There will be a lot of up, and down Z axis movement in the arm joints.

How about adding a ridged connection between the arms and the top plate using magnets.

The table would move down for the Z axis.

The magnet would roll like a bearing against a metal plate attached to the top plate.

This would prevent push back (upward movement) from the extrudate, and drooping of the arms.

I think you could also use GUS software without modifying it other than changing the Z axis command.

Edited 2 time(s). Last edit at 03/22/2014 02:30PM by A2.

How about adding a ridged connection between the arms and the top plate using magnets.

The table would move down for the Z axis.

The magnet would roll like a bearing against a metal plate attached to the top plate.

This would prevent push back (upward movement) from the extrudate, and drooping of the arms.

I think you could also use GUS software without modifying it other than changing the Z axis command.

Edited 2 time(s). Last edit at 03/22/2014 02:30PM by A2.

|

Re: Idea for increasing build volume of delta style printers in z direction March 25, 2014 09:23PM |

Registered: 10 years ago Posts: 13 |

Sorry, only registered users may post in this forum.