Home

>

Library - projects, parts, arts, docs, and policy

>

Let's design something! (I've got an idea ...)

>

Topic

Variable diameter nozzle

Posted by ingpconci

|

Variable diameter nozzle December 01, 2015 05:25PM |

Registered: 9 years ago Posts: 9 |

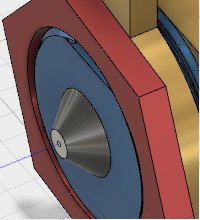

Hi , I would like to design and manufacture a variable diameter nozzle as a open source hardware project.

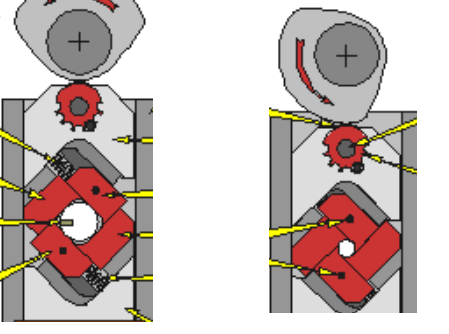

The idea is to replicate the mechanism of the four jaw cork compressor.

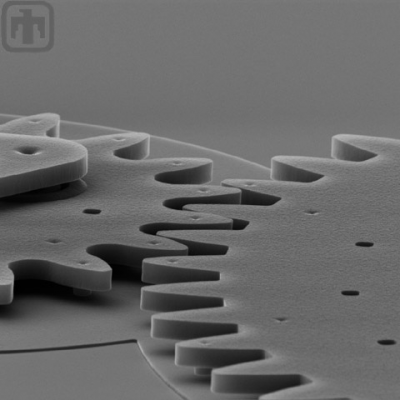

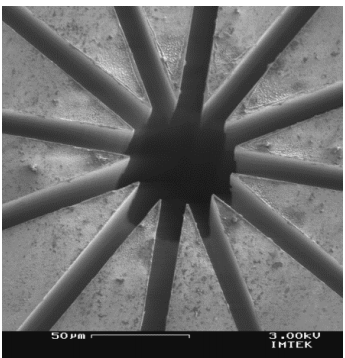

To build the microscopic jaws I use the MEMS technology.

In the pictures you can see what we can realize with this top-down technology:

"Courtesy Sandia National Laboratories, SUMMiT™ Technologies, www.sandia.gov/mstc"

I would like to ask to the community if my idea is interesting.

I'd appreciate suggestion and comments

Kind regards

Paolo

The idea is to replicate the mechanism of the four jaw cork compressor.

To build the microscopic jaws I use the MEMS technology.

In the pictures you can see what we can realize with this top-down technology:

"Courtesy Sandia National Laboratories, SUMMiT™ Technologies, www.sandia.gov/mstc"

I would like to ask to the community if my idea is interesting.

I'd appreciate suggestion and comments

Kind regards

Paolo

|

Re: Variable diameter nozzle December 01, 2015 05:47PM |

Admin Registered: 16 years ago Posts: 13,884 |

... what material for the parts? - the nozzle has to withstand hihg pressure and the (sideways) extruded material can clogg the mechanism ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Variable diameter nozzle December 02, 2015 01:40AM |

Registered: 9 years ago Posts: 9 |

The silicon micromachining technology was used in several devices, ink jet printing and other.

For example in a StartJet molten metal nozzle chip, where the chip operate at 350C.

Ref:

Molten Jet Nozzle

The thermal conductivity is very good and the silicon MEMS technology can benefit form from the batch fabrication in large arrays.

For example in a StartJet molten metal nozzle chip, where the chip operate at 350C.

Ref:

Molten Jet Nozzle

The thermal conductivity is very good and the silicon MEMS technology can benefit form from the batch fabrication in large arrays.

|

Re: Variable diameter nozzle December 02, 2015 04:45AM |

Admin Registered: 16 years ago Posts: 13,884 |

... molten metal is a totally different thing than the different plastics with pretty wide viscosity ranges and probably intermixed microparticles and fillers.

My main concern is clogging/blocking of the slider mechanis through microparticles or burnt plastic residues ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

My main concern is clogging/blocking of the slider mechanis through microparticles or burnt plastic residues ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Variable diameter nozzle December 08, 2015 03:59PM |

Registered: 9 years ago Posts: 9 |

Viktor, I agree, the design of the slider is very challenging.

We need to optimize the geometries of the mechanism, it is not easy because the molten polymer fill easily cavity(like in DVD fabrication or in micromolding)

Very important is the control of the surface in order to obtain a poor wettability of molten polymer.

Paolo

We need to optimize the geometries of the mechanism, it is not easy because the molten polymer fill easily cavity(like in DVD fabrication or in micromolding)

Very important is the control of the surface in order to obtain a poor wettability of molten polymer.

Paolo

|

Re: Variable diameter nozzle December 08, 2015 05:24PM |

Admin Registered: 16 years ago Posts: 13,884 |

... could be, Magnetoshape is interesting for such tasks.

Essentially it's a solid metallic form, that will change size or shape/strain with changing magnetic field around.

I have a sample of a simple block, which will change his length (20mm) up to to 5% in a B-field from 0 to 1.2T.

with a more complex (assembled) form there can be much more complex morphing/shape-changing

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Essentially it's a solid metallic form, that will change size or shape/strain with changing magnetic field around.

I have a sample of a simple block, which will change his length (20mm) up to to 5% in a B-field from 0 to 1.2T.

with a more complex (assembled) form there can be much more complex morphing/shape-changing

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Variable diameter nozzle December 09, 2015 04:25PM |

Registered: 9 years ago Posts: 9 |

|

Re: Variable diameter nozzle December 10, 2015 06:59AM |

Admin Registered: 16 years ago Posts: 13,884 |

... cooling (heatbreaks) or 'remote' operation via sticks/wires á la Bowden ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Variable diameter nozzle December 21, 2015 09:14AM |

Registered: 9 years ago Posts: 9 |

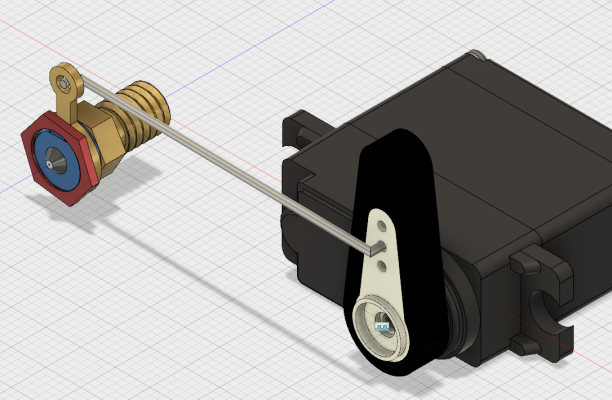

To reduce the thermal effect on the nozzle we can use a connecting rod.

The heat flux for an AISI 304 connecting rod (diameter 1 mm,lenght 40mm, dT=200C) is < 0.1 W.

The heat flux for an AISI 304 connecting rod (diameter 1 mm,lenght 40mm, dT=200C) is < 0.1 W.

|

Re: Variable diameter nozzle January 08, 2016 07:35AM |

Registered: 10 years ago Posts: 14 |

Cool idea.

For closing the nozzle and getting zero ooze that will be a solution.

For changing the nozzle size, the shutter needs to be the last thing the filament will pass. Otherwise the material will end up after the shutter in a "room" the size of the largest diameter of the shutter, and it will do nothing as the material will then expand again(either by back pressure or die swell).

For closing the nozzle and getting zero ooze that will be a solution.

For changing the nozzle size, the shutter needs to be the last thing the filament will pass. Otherwise the material will end up after the shutter in a "room" the size of the largest diameter of the shutter, and it will do nothing as the material will then expand again(either by back pressure or die swell).

|

Re: Variable diameter nozzle January 14, 2016 09:26AM |

Registered: 9 years ago Posts: 9 |

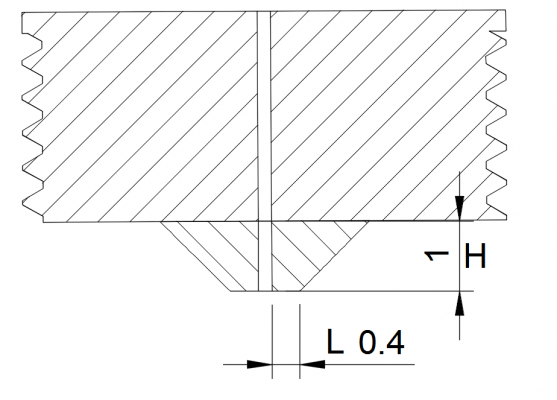

I think an extruded area in the center of the nozzle.

Have you some suggestion about the H and L dimension?

What is the minimum acceptable values for H?

Have you some suggestion about the H and L dimension?

What is the minimum acceptable values for H?

|

Re: Variable diameter nozzle April 23, 2016 03:36PM |

Registered: 8 years ago Posts: 6 |

|

Re: Variable diameter nozzle June 05, 2016 08:58AM |

Registered: 9 years ago Posts: 9 |

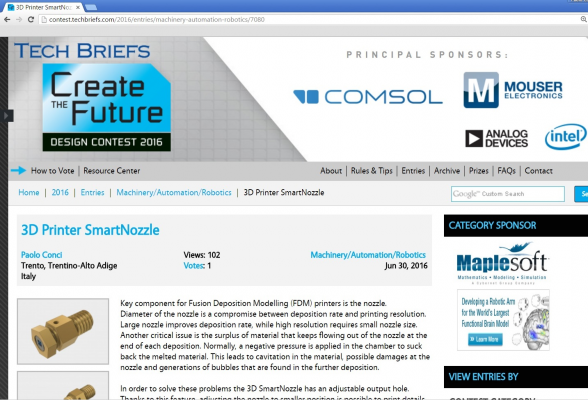

Hi, I can confirm that the developments continue.

There are some issues about the actuators but we are working on developing a dedicated microfabrication process.

In the next month we will apply for a technical competition and we hope to win the first prize in order to start with the microfabrication process.

Paolo

There are some issues about the actuators but we are working on developing a dedicated microfabrication process.

In the next month we will apply for a technical competition and we hope to win the first prize in order to start with the microfabrication process.

Paolo

|

Re: Variable diameter nozzle June 05, 2016 10:37AM |

Admin Registered: 16 years ago Posts: 13,884 |

... good luck!

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Variable diameter nozzle June 06, 2016 02:39AM |

Registered: 10 years ago Posts: 14 |

|

Re: Variable diameter nozzle July 12, 2016 12:47PM |

Registered: 9 years ago Posts: 9 |

We have applied to Create The Future Design Contest 2016

You can vote for it in the contest website

Design Contest 2016

You can vote for it in the contest website

Design Contest 2016

|

Re: Variable diameter nozzle July 13, 2016 02:57AM |

Registered: 10 years ago Posts: 14 |

|

Re: Variable diameter nozzle September 08, 2016 05:31PM |

Registered: 8 years ago Posts: 318 |

Quote

josmaukcc

Nice one. Just remember that FDM is a proprietary name only to be used by Stratasys. (oops I wrote it myself now, hope I don’t get sued)

yeah, its FFF for everyone else, I said FFF in knowledgeable company and immediately they tried to correct me : /

But anyway, this looks awesome, hope one can make it to production. Im currently designing my own printer, and am thinking about having 3 extruders that would be set up as:

1 Main material .3mm nozzle for perimeters

2 Main material .8mm nozzle for infill

3 Support material/ secondary color .3mm

But this variable extruder would be way more elegant

If you need some help, or don't understand what I just said, feel free to send me a PM anytime

Printer: Prusa i3, 2 E3D v6 Hotends, Arduino + RAMPS 1.4 with a Bypassed 5V Regulator, 400w Insignia ATX PSU, Custom Designed Bowden Extruders

|

Re: Variable diameter nozzle March 02, 2017 04:48AM |

Registered: 7 years ago Posts: 42 |

I couldn't help but wonder if a motor driven rotating disc with various nozzle-tip sizes wouldn't suffice for the same solution. Not sure if retraction would keep it clean enough during rotation - but if it was right on the end of the heat block it may stay hot enough to not even worry about it.

|

Re: Variable diameter nozzle March 05, 2017 02:01AM |

Registered: 7 years ago Posts: 42 |

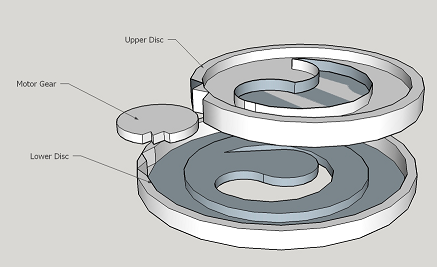

Just a quick picture of a variable nozzle size with two pinch discs.

Edited 1 time(s). Last edit at 03/05/2017 02:02AM by tgit23.

Edited 1 time(s). Last edit at 03/05/2017 02:02AM by tgit23.

|

Re: Variable diameter nozzle June 27, 2022 07:09AM |

Registered: 9 years ago Posts: 7 |

Sorry, only registered users may post in this forum.