Home

>

Library - projects, parts, arts, docs, and policy

>

Let's design something! (I've got an idea ...)

>

Topic

X,Y and Z "endstop" triggering by pushing wire to activate a single lever-based probe (renishaw or otherwise)

Posted by realthor

|

X,Y and Z "endstop" triggering by pushing wire to activate a single lever-based probe (renishaw or otherwise) May 09, 2016 09:56AM |

Registered: 9 years ago Posts: 1,035 |

I couldn't explain better in a few words the crazy idea that stays on my mind for a while.

I was thinking how can I activate a single sensor/microswitch/probe at both ends of each carriage (Xmin, Xmax, Ymin, Ymax, Zmin, Zmax) and how to differentiate (in software) which side triggered.

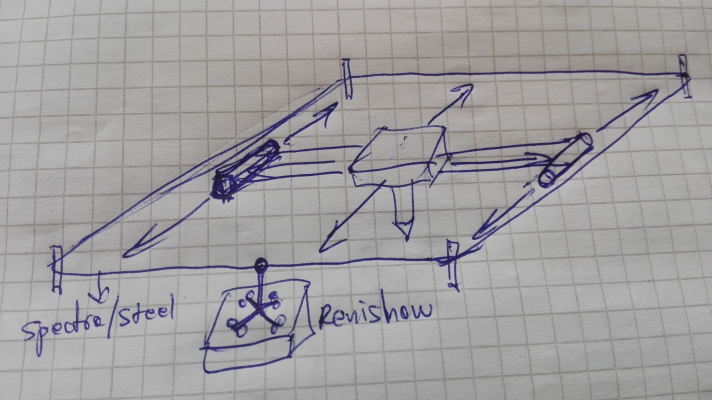

I only have a napkin-sketch so far because I didn't waste too much time on it since I imagine there could be a number of issues with the idea.

Here it is:

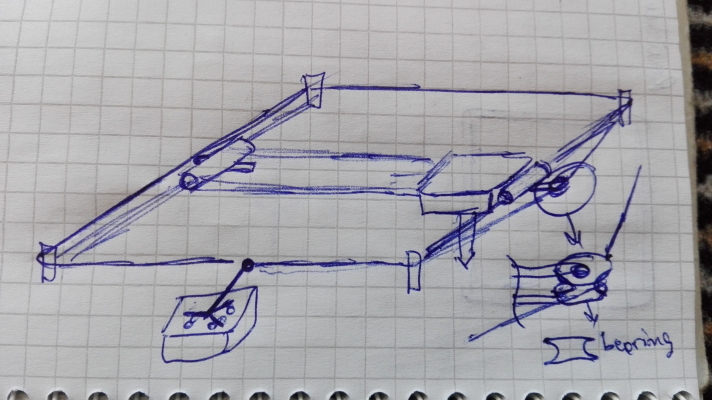

The idea is to have a loop of some wire that is pushed by protrusions designed into the X carriage left and right and on the sides of the Y carriages. When X or Y gets to the wire, that protrusion pushes the wire slightly but enough to activate the probe, which looses contact (due to the lever effect of the probe's stick). It must not be a renishaw-like probe, in fact it can be a simpler scissors probe with both ends of the wire connected to the short ends while the long ends of the "scissors" will move much faster and further away when the short side are pulled so they can click together at a very fast speed.

I will sketch a scissor-like probe too so you have an idea what I am thinking at.

Oh forgot about the software knowing which side triggered. This could be calculated from the known variables of the system like which way the printhead is going towards, etc. Not much detail here from me... maybe someone else has a better idea.

Edited 3 time(s). Last edit at 05/10/2016 02:42AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

I was thinking how can I activate a single sensor/microswitch/probe at both ends of each carriage (Xmin, Xmax, Ymin, Ymax, Zmin, Zmax) and how to differentiate (in software) which side triggered.

I only have a napkin-sketch so far because I didn't waste too much time on it since I imagine there could be a number of issues with the idea.

Here it is:

The idea is to have a loop of some wire that is pushed by protrusions designed into the X carriage left and right and on the sides of the Y carriages. When X or Y gets to the wire, that protrusion pushes the wire slightly but enough to activate the probe, which looses contact (due to the lever effect of the probe's stick). It must not be a renishaw-like probe, in fact it can be a simpler scissors probe with both ends of the wire connected to the short ends while the long ends of the "scissors" will move much faster and further away when the short side are pulled so they can click together at a very fast speed.

I will sketch a scissor-like probe too so you have an idea what I am thinking at.

Oh forgot about the software knowing which side triggered. This could be calculated from the known variables of the system like which way the printhead is going towards, etc. Not much detail here from me... maybe someone else has a better idea.

Edited 3 time(s). Last edit at 05/10/2016 02:42AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Anonymous User

Re: X,Y and Z "endstop" triggering by pushing wire to activate a single lever-based probe (renishaw or otherwise) May 10, 2016 01:50AM |

|

Re: X,Y and Z "endstop" triggering by pushing wire to activate a single lever-based probe (renishaw or otherwise) May 10, 2016 02:43AM |

Registered: 9 years ago Posts: 1,035 |

Quote

MKSA

I have seen similar set up but Instead of the renishaw it was a claymore mine

Haha, let's blast the enemy (X Carriage) for not complying with our wishes (speed, weight, etc)

There are several possible issues with this approach I'll start so maybe that way the discussion can get started:

1) spectra/steel wire ... even if properly tensioned might not react fast enough

2) the force needed to activate the probe's lever is (maybe) different along the wire due to the corners and I think it might be easier to activate it in the centre (like in the second sketch) while it will take a bit more force near thecorners, making pretty difficult the calibration of the triggering point

3) it's kind of hard to determine which "endstop" triggered.

A more sensible approach could be just replacing the X endstops with two wire lengths going along the Y axis and each such segment to have its own microswitch at one end which gets triggered when the X carriage pushes it.

Edited 2 time(s). Last edit at 05/10/2016 06:39AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Anonymous User

Re: X,Y and Z "endstop" triggering by pushing wire to activate a single lever-based probe (renishaw or otherwise) May 10, 2016 05:50AM |

|

Re: X,Y and Z "endstop" triggering by pushing wire to activate a single lever-based probe (renishaw or otherwise) May 10, 2016 06:01AM |

Registered: 9 years ago Posts: 1,035 |

Use a single "sensor/probe" and a wire loop system to be used as a medium to trigger the sensor/probe, with no moving components.

Edited 1 time(s). Last edit at 05/10/2016 06:01AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Edited 1 time(s). Last edit at 05/10/2016 06:01AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Anonymous User

Re: X,Y and Z "endstop" triggering by pushing wire to activate a single lever-based probe (renishaw or otherwise) May 10, 2016 09:52AM |

Quote

realthor

Use a single "sensor/probe" and a wire loop system to be used as a medium to trigger the sensor/probe, with no moving components.

So what are the advantage compared to 2, eventually 4 microswitches ???? (a renishaw is just that, 3 switches, well made and very expensive).

Note that for my Z axis, I indeed modified the microswitch which I do not consider fit for this positioning job (OK for X and Y), to work like the simple circuit opening of the renishaw (berylium leaf spring and gold plated contact) !

Edited 1 time(s). Last edit at 05/10/2016 09:53AM by MKSA.

|

Re: X,Y and Z "endstop" triggering by pushing wire to activate a single lever-based probe (renishaw or otherwise) May 10, 2016 04:53PM |

Registered: 9 years ago Posts: 1,035 |

Quote

MKSA

Quote

realthor

Use a single "sensor/probe" and a wire loop system to be used as a medium to trigger the sensor/probe, with no moving components.

So what are the advantage compared to 2, eventually 4 microswitches ???? (a renishaw is just that, 3 switches, well made and very expensive).

Note that for my Z axis, I indeed modified the microswitch which I do not consider fit for this positioning job (OK for X and Y), to work like the simple circuit opening of the renishaw (berylium leaf spring and gold plated contact) !

Main advantage I see is that you get rid of the X Carriage both left and right endstops (most have only one). No more moving endstops+the attached wires bulking the bundle that gets out from the extruder to the controller board. Wherever on the Y axis should the X carrriage contact the Y carriage thus pushing the wire it triggers the endstop.

Another advantage is that the renishaw-probe (or any other fast-response-lever-based probe) can be mostly 3D printed (not the gold plated expensive stuff though - there are several examples on thingiverse) and in the reprap spirit you get rid of some vitamins. Actually a "2D" renishaw probe is better suited for this job.

The wire loop should replace 4 endstops for the XY stage and provide enough accuracy. Z needs a better sensor though, just like you say, to repeatedly bring the bed at the same distance from nozzle (an IR probe or other precise probe should be used for that).

Edited 1 time(s). Last edit at 05/10/2016 04:54PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Sorry, only registered users may post in this forum.